Toolex 532215 User manual

INSTRUCTION MANUAL

PLEASE READ THESE INSTRUCTIONS CAREFULLY

TO ENSURE THE SAFE AND EFFECTIVE USE OF THIS TOOL.

532215

BANDSAW HORIZONTAL & VERTICAL

150 X 115MM

CONSUMER SERVICE CENTRE

PO BOX 1012

HAMILTON NSW 2303 AUSTRALIA

Made in P.R.C.

Page 2

‐1‐

SAFETY

1.Knowyourbandsaw.Readtheoperator'sManualcarefully.Learntheoperations,

applicationsandlimitations.

2.Userecommendedaccessories.Improperaoclxsoricsmaybeha?ardous.

3.Wearproprapparel.

4.Keepunnecessarypeopleaway.

5.Don'tverreachorstandontool.

6.Avoiddangerousenvironment.Don'tusebandsawindamporwetlocations.

keepworkareawelllighted.

7.Keepworkareaclean.Clutteredandslipperynoorsinviteaccidents.

8.Removeadjustingkeysandwrcnch«sfrombandsawbeforeturningonpower.

9.Avoidaccidentalstarting.Makesureswitchisoflbeforeplugginginpowercord.

10.Don'tforeebandsaw.Itissafetooperateatthecuttingrateforwhichitwas

designed.

11.Bespeciallycarelulwhmusingbandsawsinverticalpositiontokeepfingersand

handsoutofthcpathofblade,bothaboveandbeneaththetable.

12.Neverhandholdthematerialwithsawinhorizontalposition.Alwaysusethe

vise,clampsecurely.

13.Keepbeltguardandwheelcoversinplaceandinworkingorder.

14.Supportlong,heavyworkfromthenoor.

15.Alwaysremembertoswitchoflthcmachinewhentheworkiscompleted.

16.Disconnlcctpowercordbeforeadjusting.servicingandchangingblade.

17.Checkdamagedparts.Damagedpartsmustbcr中组cedorrepaired.

18.Movingpartsshouldkeepinalignment.Alladjustmemsaretobemadewith

powerdisconnected.

19.Useasharpbladeandkeeptoolcleanforbestandsakstperformance.

20·Safetyisacombinationofoperator'scommonsenseand.Alertnessatall

timeswhmthesawisfunctioning.

21.Keepingthebandsawintopconditionisessentialforsafety.

FEATURES

1.Specialdesignedhorizontalandverticalbandsaw.

2.Offersthreespeedsforcuttingmetalplasticorwood.

‐2‐

3.Shutsoflautomaticallywhenmaterialiscut.

4.Withscaleforthemiteringvise.

5.Nonoisewhileoperating.

6.Castcrs(optional)quickandeasymoving

SPECIFICATIONS

1.Capacity :41/2"(l15mm)round

4x6"(100mmx150mm)rectangular

2.Speeds :24-36-61m/min60HZ(20-29-50m/min50HD

3.Motor:I/3HPorI/2HP1700RPM60HZ(1400RPM50HZ)

4.Blades:1/2"X.025"X641/2"(12.5nunx0.64mmx1638mm)

5.Bladevnlals :73/8(187mm)Highstrengthflangcdcastiron..

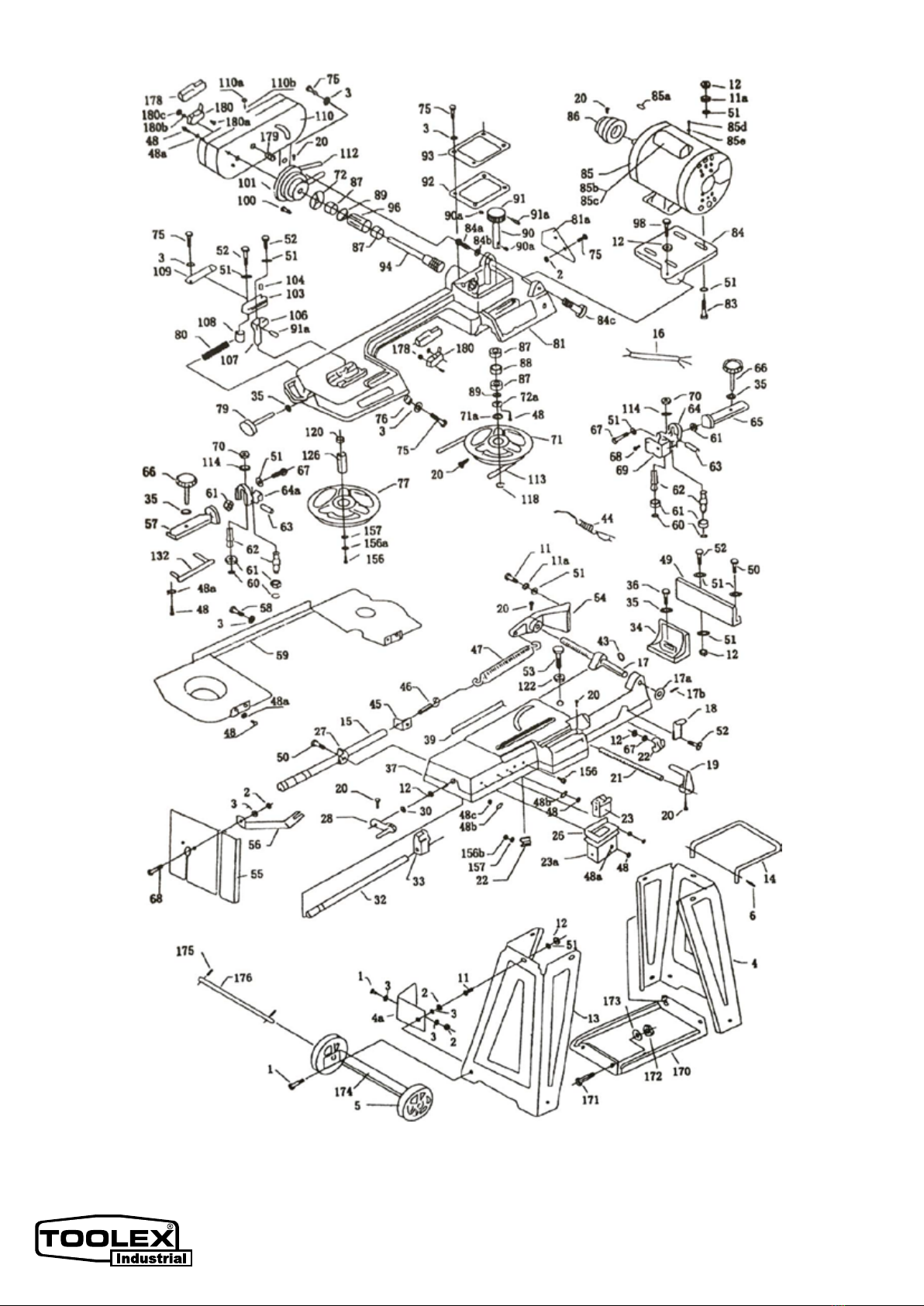

ASSEMBLY

1.AssemblestandlegsonBandSawBase.Assemblydiagram

2.Assemblehandlevicewheel,ti8htcnsctscrew.

BLADEGUIDEBEARINGADJUSTMENT

Thisisthcmostimportantadjustmentonyoursaw.Itisimpossibletoget

satisfactoryworkfromyoursaw«thebladeguidesarenotproperlyadjusted.The

bladeguidebearingsforyourMetalcuttingBandsawareadjustedandpowertested

withseveraltestcutsbeforeleavingthefactorytoinsurepropersetting.Theneed

foradjustmentshouldrarelyoccurwhenthesawisusedproperly.Iftheguidesdo

gctoutofadjustment,itisextremelyimportanttoreadjustimmediately.Ifproper

adjustmentisnotmaintained,thebladewillnotcutstraightandifthesituationis

notcorrected,itwillcausebladedamage.

Becauseguideadjustmentisacriticalfactorintheperformanceofyoursaw,itis

alwaysbesttotryanewbladetoseeifthiswillconectpoorcuttingbefore

beginningtoadjusttheb«arings.Ifabladebecom«sdullononesidesoonerthan

theother,forexample,itwillbegincuttingcrooked.Asimplebladechangeshould

correctthispr«»blem-themorediflicultguideadjustmentwillnot.

Ifanewbladedoesnotcorrecttheproblem,checkthebladeguidesforproper

spacurg.

Thereshouldbe0.001”clearancebetwnthe0.025"thicknessbladeandguide

bearings.Toobtainthisclcaranecadjustasfouows

I.Theinnerguidebearin8isfixedandcannotbeadjusted.

Page 3

‐2‐

3.Shutsoflautomaticallywhenmaterialiscut.

4.Withscaleforthemiteringvise.

5.Nonoisewhileoperating.

6.Castcrs(optional)quickandeasymoving

SPECIFICATIONS

1.Capacity :41/2"(l15mm)round

4x6"(100mmx150mm)rectangular

2.Speeds :24-36-61m/min60HZ(20-29-50m/min50HD

3.Motor:I/3HPorI/2HP1700RPM60HZ(1400RPM50HZ)

4.Blades:1/2"X.025"X641/2"(12.5nunx0.64mmx1638mm)

5.Bladevnlals :73/8(187mm)Highstrengthflangcdcastiron..

ASSEMBLY

1.AssemblestandlegsonBandSawBase.Assemblydiagram

2.Assemblehandlevicewheel,ti8htcnsctscrew.

BLADEGUIDEBEARINGADJUSTMENT

Thisisthcmostimportantadjustmentonyoursaw.Itisimpossibletoget

satisfactoryworkfromyoursaw«thebladeguidesarenotproperlyadjusted.The

bladeguidebearingsforyourMetalcuttingBandsawareadjustedandpowertested

withseveraltestcutsbeforeleavingthefactorytoinsurepropersetting.Theneed

foradjustmentshouldrarelyoccurwhenthesawisusedproperly.Iftheguidesdo

gctoutofadjustment,itisextremelyimportanttoreadjustimmediately.Ifproper

adjustmentisnotmaintained,thebladewillnotcutstraightandifthesituationis

notcorrected,itwillcausebladedamage.

Becauseguideadjustmentisacriticalfactorintheperformanceofyoursaw,itis

alwaysbesttotryanewbladetoseeifthiswillconectpoorcuttingbefore

beginningtoadjusttheb«arings.Ifabladebecom«sdullononesidesoonerthan

theother,forexample,itwillbegincuttingcrooked.Asimplebladechangeshould

correctthispr«»blem-themorediflicultguideadjustmentwillnot.

Ifanewbladedoesnotcorrecttheproblem,checkthebladeguidesforproper

spacurg.

Thereshouldbe0.001”clearancebetwnthe0.025"thicknessbladeandguide

bearings.Toobtainthisclcaranecadjustasfouows

I.Theinnerguidebearin8isfixedandcannotbeadjusted.

Page 4

‐3‐

2.Theouterguidebearingismountedtoaneccentricboltandcanbeadjusted.

3.Mosenthenutwhileholdingtheboltwithawrench.

4.Positiontheeccentricbyturningthebolttothedesiredpositionofclearance.

5.Tightenthenut.

6.Adjustthesecondbladeguidebearinginthcsamemanner.

7.ThebackedgeofthebladeshouldjusttouchthelipoftheBladeGuideBearing.

BLADEGUIDEASSEMBLYADJUSTMENT

TheMetalCuttingBandsawisequippedwithtwoadjustablebladeguide

assemblies.Thisfeaturewillpermityoutoadjustthepositionofthcbladeguidesfor

varipuswidthsofworkpicces.

Toeflectthemostaccuratecutandprolongthelifeoftheblade.Thcblade

guideassembliesshouldbeadjustedtojustclearthepiecetobecut.Thisisdoneas

follows

1.Placethcworkpieceintheviseofbandsawandclamptightly.

2.Adjustcatchbladeguideassemblytothedesiredpositionbylooseningthehand

knobsandpositioningtheguidesasrequired.

3.Tightenthehandknobs.

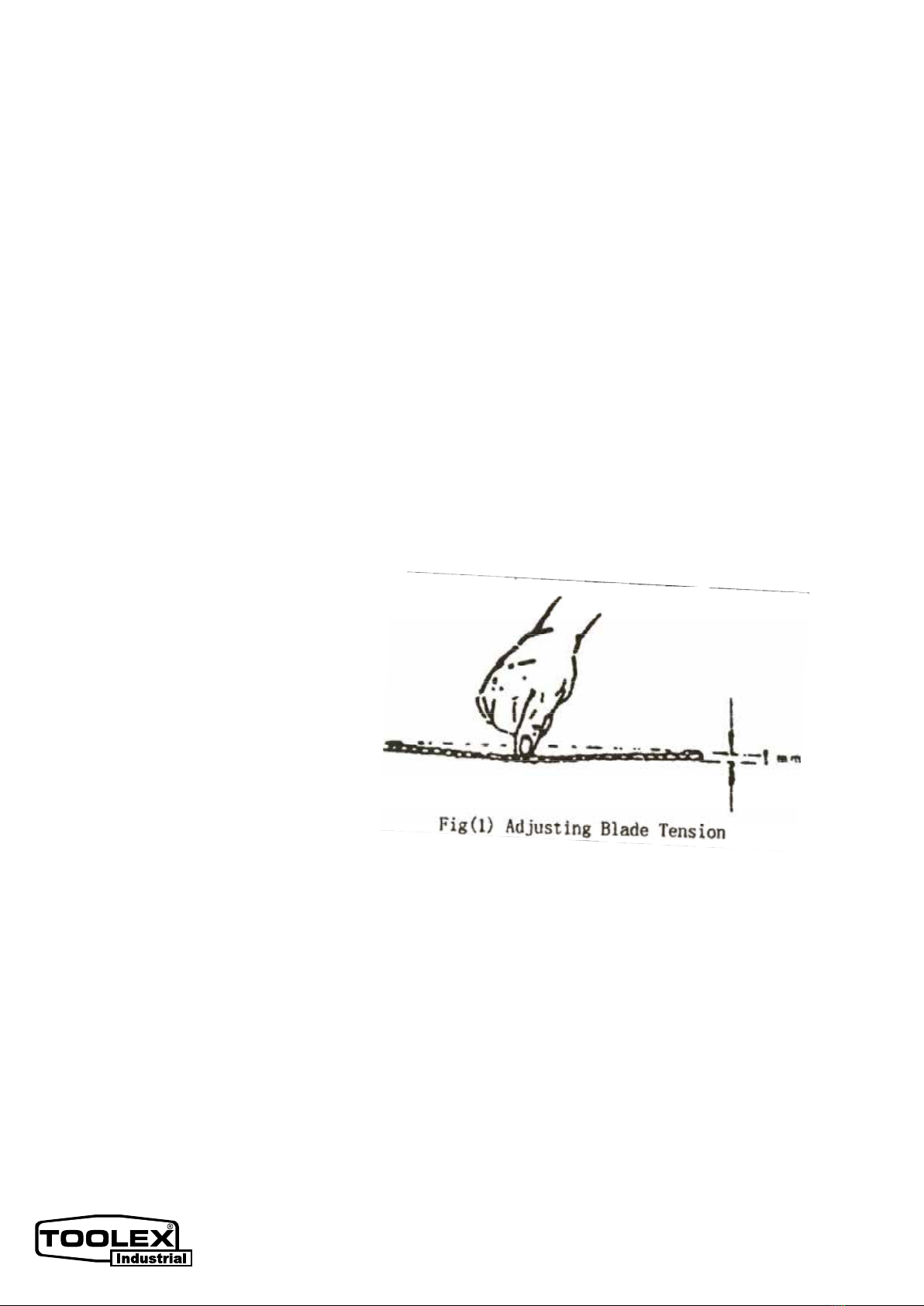

ADJUSTINGBLADETENSION

1.MakesurethemotorisshutofF.

2.Pressthebladelightlywiththe

lefthand,maketherearblade

againstthenangeofbladewheel

andtestthebladetension.

3.Adjustthebladetensionadjus-

tableknobwiththerighthand

untilthebladeobtaintheproper

tension.

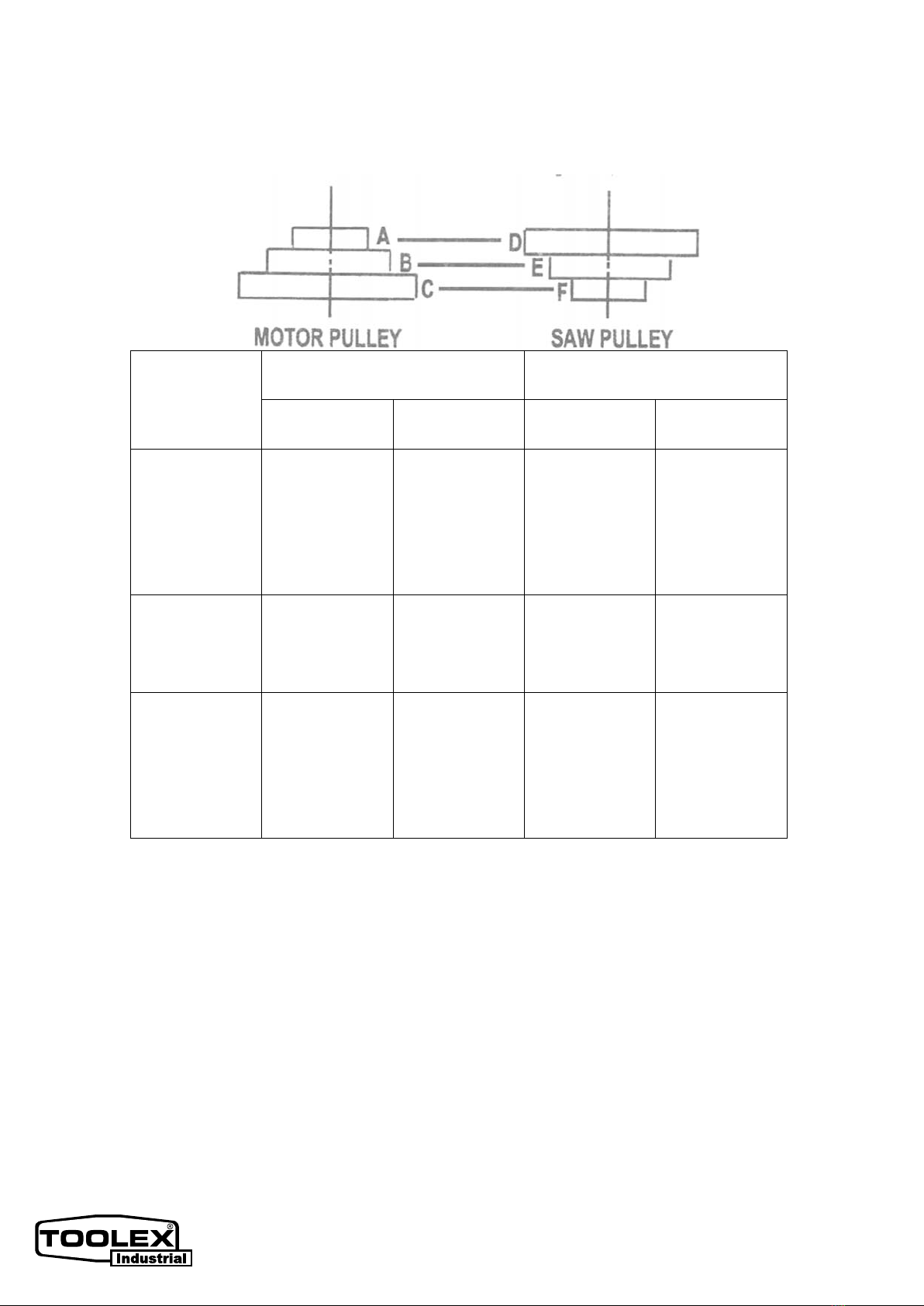

CHANGINGSPEED

WhenusingyourBandSaw,alwayschangethebladespeedtobestsuitthematerial

beingcut.Thematerialcuttingchartisshowninfig(2).

Cutoflpower.Openthepulleyguardcover.Loosentheleadscrew(.98.),youarenow

Page 5

‐4‐

abletochangethepositionofthebelttogainthedesiredspeed.Cheekthebelttension

asins-bcfone.Whenthctensionofbeltiswelladjusted,lockthemotorlırmly.

Closethepulleyguardcover

Fig(2)MaterialCuttingChart

BLADESELECTION

I.Specialnote:1(112 ° xo.025"X64ı/zmin,651/2max)14toothperinchgeneralweblade

isfurnshedwiththemetalcuttingBandSaw.AdditionalbladesinIOand14

toothsizesareavailable.

2.Thechoiceofbladepitchisgovernedbythethicknessoftheworktobecut;the

thinnertheworkpiece,themoreteethadvised.Aminimumof3teethshouldbcin

theworkpieceatalltimesforpropercutting.

3.Ifthcteethofthcbladearesofarapartthattheystraddlethework,severedamage

Material Speed(m/min) BeltGrooveUsed

50Hz 60Hz Motorpuml SawPuïley

Stainless or

Alloy Steel

BearingBronzes

20 24 SmallA LargeD

Mild Steei Hard

brassorBronze

29 36 MediumB MediumE

Soft Brass

Aluminum and

othermaterials

50 61 LargeC SmallF

Page 6

‐5‐

totheworkpieceandtothebladecanresult.

CHANGINGBLADE

Raisesawheadtoverticalposition.Loosenbladetensionadjustableknob

sufficientlytoallowthcsawbladetoslipolTthewheeıs.Instauthcnewbladeas

follows:

I.Placethebladeinbetweeneachof guidebearing.

2.Slipthebladearoundthemotorpulley(bottom)withthelefthandandholdinposition.

3.Holdthebladetautagainstthemotorpulleybypullinsthebladeupwardwiththe

righthandwhichisplacedatthetopoftheblade.

4.Removelefthandfrombottompulleyandplaceitatthetopsideofthebladeto

continuetheapplicationontheupwardpullontheblade.

5.Remove ńghthandfrombladeandadjustthepositionofthetoppulleytopermitleft

handtoslipthebladearoundthepulleyusingthethumb,indexandlittlefingeras

guides.

6.Adjustthebladetensionknobclockwiseuntilitisjustrightenoughsonoblade

slippageoccure.Donottightenexcessively.

7.Place2-3dropsofoilontheblade.

8.Replacethebladeguard.

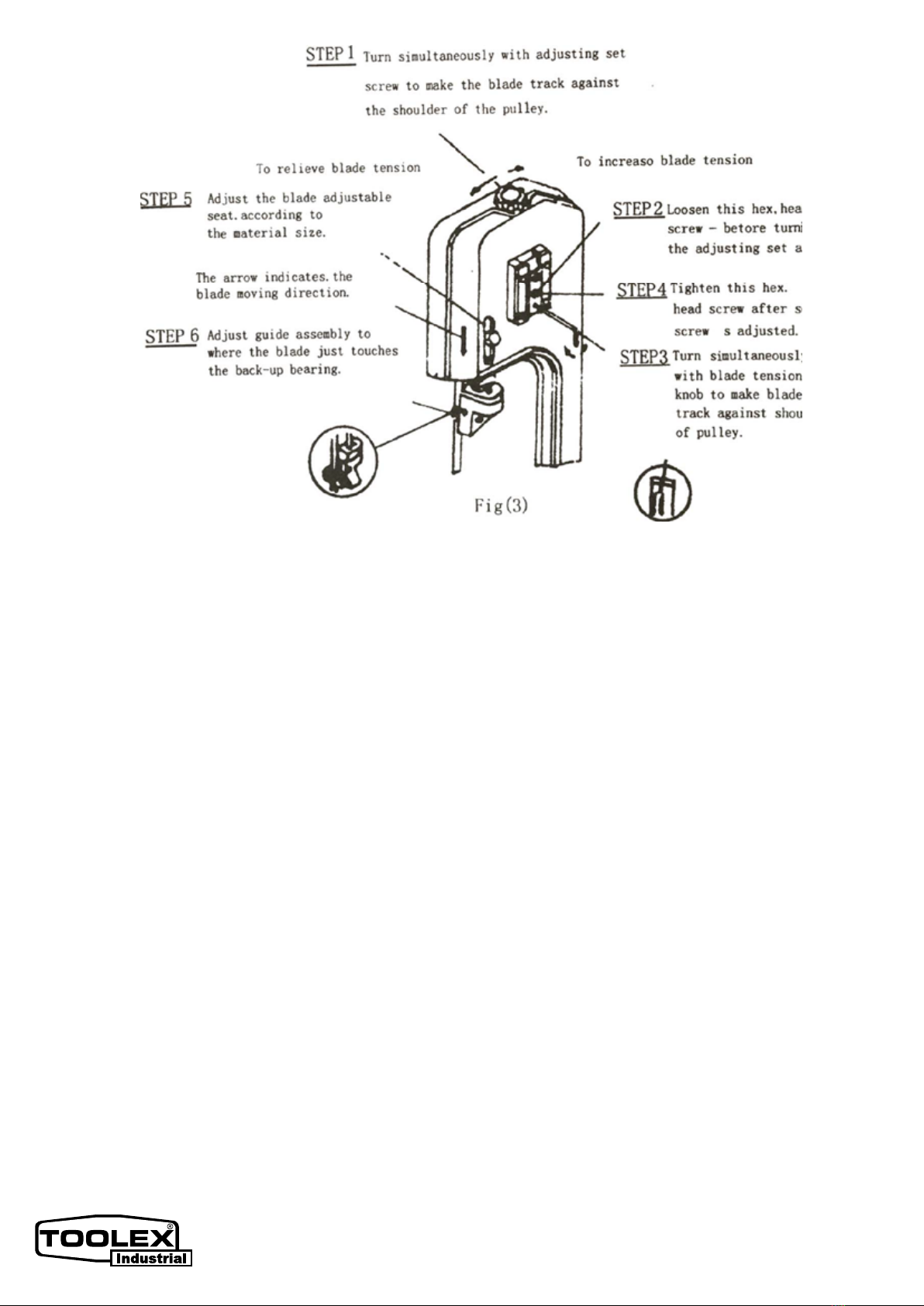

ADJUSTINGTHEBLADETRACKING

Thisadjustmenthasbeencompletedandpower-testedatthefactory.Theneedfor

adjustmentshouldrarelyoccurwhenthesawisusedproperly.Ifthetrackinggoesoutof

adjustmentthebladewillleavethewheelanddamagewillresult.Themethodof

adjustmentislistedbelow.

Page 7

‐6‐

HORIZONTALCU-GOPERATION

Beforeoperating,pleasereadinstructionmanualandexamineeverypartincluding

spd.Bladeselection,guideassembleposition,etc.Operationisasfollows:

WORKSETUP

1.Raisethesawheadtothev«ticalposition.

2.Openthevisetoacceptthcpiecetobecutbyrotatingthewheelatthecndof

thebase(counterclockwise).

3.Placetheworkpieceonthesawbed.Ifthepieceislong,supporttheend.

4.Clamptheworkpiecesecwelyinthevisebyrotatingthehandwheelclockwise.

CUTTING

Closeswitch,lettingtheheaddownslowlyontothework,Donotdropor

force.Iettheweightofthesawheadprovidethecuttingforce.Thesawautomatically

shutsoftatthccndofthecut.

Page 8

‐7‐

Methodofadjustingblade:

A.Lossenthescrew#11.

B.Adjustthebladeadjustableseat#64tomakethebladeverticaltobcd.

c.Placethcsquareonthebedtocheckifthebladeisvertical,ifnot,repeatthe

processAtoc.

D.Tightenthescrew#11.

Fig(4)Adjustingtheblade

LUBRICATION

LubńcatethefollowingcomponentsusingLubńcant,L-HV32

1.Ballbeańng-none.

2.Bladeguidebearing-none.

3.Drivenwheelbearing-none.

4.Viseleadscrew-asneeded.

5.Thcdrivegearsrunintheoilbathandwillbotrequirealubricantchanegemoreoften

thenonceayear.Whenneedingachange,mtputdownthehtadtoaHorizontal

Position,thenloosen4screw(#75)ofthegearboxopenthecover(#93).Placing

apanunderthetightlowercomerofthegearbox,slowlyraisetheheaduntil

thcoilnowsout,Lowerhead.Thenwipeupexcmodandforeignmatterwith

softrags.Thenaddlubricantintotheboxuntilitisfullandnotflowover.Close

thecover,tighten4screws.

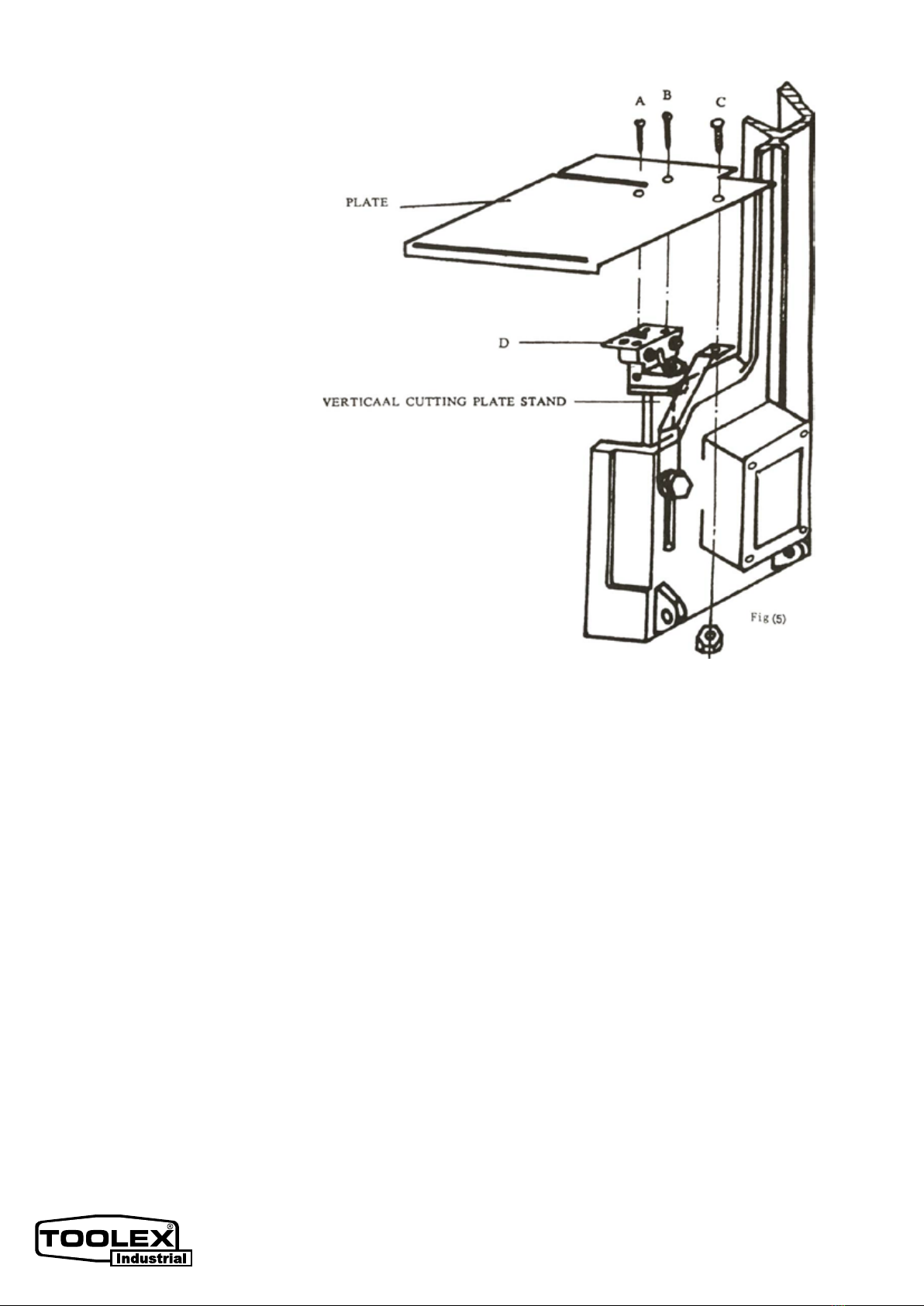

THEVERHCALCUTHNGPLATEASSH

Stepsforassembling

Page 9

‐8‐

1.LoosentheA.B.C.threescrewsfromthebladeguide.Z

Andtakeawaythepart"D"

2. Tolocktheverticalcutting

platestandonthevalve.

3.Toputthephteonthe

guideandvertica\cutting

platestand,thenlocktheA.B.

C.threescrews.

4.Pleaseoperatethevertica\

cutting.

5.Usethemilergaugeinthe

worktablegroovesto

obtainanyanglenpto4S

degreeeitherleftorright.

CAUTION-Theuscofany

otheraccessorisesmaybe

hazardous.

CAUTION-Alwaysusepush

sticksparticulartywhen.

cuttingsmallpieces.

Page 10

‐9‐

Page 11

‐10‐

symptom

PossibleCause(s)

CorrectiveAction

ExcessiveBlade

Breakagc

1.Materiallooseinvise

2.IncorTectspeedor

3.Bladeteethspacingtoo

large

4.Materialtoocoarse

5.Incorrectbladetension

6.Teethincontactwith

materialbeforesaw

started

7.Bladerubsonwheel

Hange

8.Misalignedguide

bearings

9.Crackingatweld

1.Clampworksecurely

2.AdjustspMorfeed

3.Replacewithasmallteeth

spacingblade

4.Useabladeofslowspeed

andsmallteethspacing

5.Adjusttbwherebladejust

doesnotsliponwheel

6.Placebladeincontactwith

workaftermotorisstarted

7.Adjustwhlalignment

8.Adjustguidebearings

9.Weldagain,notetheweld

skill

PrematureBlade

Dulling

I.Teethtoocoarse

2.Toomuchsp

3.Inadequatefeedpress

ure

4Hardspotsorscale

onmaterial

5.Workhardeningof

material

6.Bladetwist

7.Insufficientblade

1.Usefinerteeth

2.Decreasespeed

3.Decreasespringtensionon

sideofsaw

4.Reducespeed,increase

feedpressure

5.Increaseleedpressureby

reducingspringtension

6.R中lacewithanewblade,

andadjustbladetension

7.Tightenbladetension

adjustableknob

UnusualWearor

Sidepackof

Blade

1.BladeguidESWORN

2.Bladeguidebearings

notadjustedproperly

3.Bladeguidebearing

bracketisloose

1.Relace

2.Adjustasperoperators

manual

3.Tighten

Page 12

‐11‐

symptom

PossibleCause(s)

CorrectiveAction

TeethRipping

fromBlade

1.Toothtoocoarsefor

work

2.Tooheavypmure,

tooslowspeed

3.Vibratingworkpiece

4.Gulletsloading

1.usefinertoothblade

2.Decreasepressure,

increasespeed

3.Clampworkpteccsecurely

4.Usecoarsertooth

bladeorbrushtoremovechips

Motornuuling

toobot

1.Bladetensiontoohigh

2.Drivebelttensiontoo

Mgh

3.Gearsneedlubrication

4.Cutisbindingblade

5.Gearsallignedimprop-

erly

1.Reducetensiononblade

2.Reducetensionondrive

belt

3.Checkoiloath

4.Decreasefeedandspeed

5.Adjustgearssothatworm

isincenterofgear

BadCuts

(Cr(x)ked)

1.Feedpressuretoogreat

2.Guidebearingsnot

adjustedproperly

3.Inadequatebladetension

4.Dullblade

5.Speedincorrect

6.Bladeguidesspacedout

toomuch

7.Bladeguideassembly

loose

8.Bladetrucktoofar

awayfromwheelflanges

1.Reducepressuneby

incrcasinBspringtension

onsideofsaw

2.A4justguidebearing,thc

clearancecannotgreater

that.001

3.Increasebladetensior'by

adjustbladetension

4.Replaceblade

5.Adjustspeed

6.-Adjustguidesspace

7.Tishten

8.Retrackbladeaccordingto

operatinginstructions

BadCuts

(Rough)

1.Toomuchspeedorfeed

2.Bladeistoocoarse

3.Bladetensionloose

1.Descreascspeedorfeed

2.ReplacewithHncrblade

3.Adjustbladetension

Bladeis

twisting

1.Cutisbindingblade

2.Toomuchbladetension

1.Decreasefeedpressure

2.Dccrcascbladetension

Page 13

‐12‐

Page 14

‐13‐

Page 15

‐14‐

Page 16

532215

BANDSAW HORIZONTAL & VERTICAL

150 X 115MM

Table of contents

Other Toolex Saw manuals