FlexArm FLEXARM RNR User manual

1/4/2021 REV. 002 2

TABLE OF CONTENTS:

Safe Operation: READ THIS FIRST - - - - - - - - - - - - - - - - - - - -

3

Warranty - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

4

Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

5-7

Counterbalance Adjustments - - - - - - - - - - - - - - - - - - - - - - -

8

Operating Instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - -

9-10

Adjusting Torque Holder Clutch Setting - - - - - - - - - - - - - - -

11

Torque Requirements for Tapping Chart - - - - - - - - - - - - - - -

12

Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

13-14

Drawing: RNR Working Range - - - - - - - - - - - - - - - - - - - - - -

15

Parts and assembly- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

16-18

RNRM Instructions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

19-20

Multi Head Parts and Assembly - - - - - - - - - - - - - - - - - - - - -

21

Semi Tap Lube Instructions - - - - - - - - - - - - - - - - - - - - - - - -

22

Semi Tap Lube Parts and Assembly - - - - - - - - - - - - - - - - - -

23-24

Auto Depth Stop Instructions - - - - - - - - - - - - - - - - - - - - - - -

25

Auto Depth Stop Parts and Assembly - - - - - - - - - - - - - - - - -

26

Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

27-29

1/4/2021 REV. 002 3

SAFE OPERATION: READ THIS FIRST

•Read the entire unit manual before operating the machine.

•Do not remove shipping zip tie strap until instructed in this manual.

•Wear eye protection when operating this machine.

•Do not wear jewelry when operating this machine. Tie hair back when using this machine.

•Do not wear gloves when operating this machine.

•Turn off the air supply before adding oil to the filter / lubricator.

•Turn off the air supply before preforming any maintenance operations.

•Hearing Protection is recommended.

•Removing the tool or weight from the arm will allow the arms to extend rapidly possibly causing

damage or injury.

•Keep hands clear of the motor chuck and tap when the motor is running.

•Keep hands clear of pinch points when operating the machine.

•Do not alter or modify the FlexArm.

•Periodically inspect for damage, loose hardware or anything irregular on the FlexArm.

•Preform regular maintenance according to this manual.

•Do not alter or modify the machine.

•Read the Limited Warranty before performing any maintenance or repairs.

•Flex Machine Tools is not responsible for accident or injury resulting from the misuse of this machine

or for use other than originally designed and intended.

IT IS IMPERATIVE THAT THE TABLE OR MOUNTING SURFACE BE LAGGED TO THE FLOOR AND SECURE BEFORE

INSTALLING THE FLEXARM. Failure to secure the table or mounting surface could result in serious injury to the

operator as well as the FlexArm.

1/4/2021 REV. 002 4

FLEXARM LIMITED WARRANTY

What does a FlexArm Warranty Cover

The repair or replacement of the FlexArm product if it is found to be defective due to faulty materials,

workmanship or function within the guarantee period of 1 year. The warranty is based off normal

usage, or equivalent to a 40-hour work week. Claims within the first 90 days will be handled under a

direct return and replace policy. Freight can be credited up to $500.00 upon a positive warranty claim.

What is not covered by a FlexArm Warranty

FlexArm Inc shall not be liable for costs of repair or replacement of a product incurred as a result of:

•A FlexArm product that has had the serial number altered or removed.

•Cylinders with scratches or marks on the shaft.

•Handling of the product which is not in accordance with the product manual.

•Damage as a result of using the unit over its stated capacities.

•FlexArm products not purchased direct or from an authorized dealer.

•Use of parts and accessories other than those produced or recommended by FlexArm.

•Improper maintenance or lack of maintenance per the manual.

•Damage from external sources such as transit, weather, electrical outages, power surges, or bad

air quality (compressor).

•Repairs or alterations carried out by parties other than FlexArm or its authorized distributors.

•Tap Holders and Helicoil components do not carry a warranty.

In Air Motors: Filters, Springs, Blades/Vanes, O-Rings are not covered.

Warranty Service

Before service can take place, the terms of the limited warranty require that you contact FlexArm with

your model, serial number, and date of purchase. Please keep your purchase receipt in a safe place to

ensure you have this information. The serial number is found on the FlexArm’s side plate.

•An RGA must be obtained from a FlexArm Customer Service Representative.

•All work will be coordinated by FlexArm or its authorized distributors.

•Any replaced defective parts must/will become the property of FlexArm.

Service under this warranty will not extend the period of this warranty. If your FlexArm is not

functioning properly, please call FlexArm at 1-800-837-2503. Most issues can be rectified over the

telephone by our trained Customer Service Department.

1/4/2021 REV. 002 5

INSTALLATION

1. Drill four bolt holes on a flat, smooth table or

work bench in the pattern shown in Figure 1.

2. Make sure the table the arm is being installed on

is secure, and will not tip over if the arm extended

off the side of the table.

3. Fasten the FlexArm base mount to the table and secure it with 3/8” or M10 bolts as shown in Figure 2.

4. Slide the angle mount over the shaft of the base mount as shown in Figure 3.

5. Secure the angle mount by placing the washer on top of the lower bore and tighten the angle bolt

securely into the base mount. If this bolt in not properly tightened and the angle mount is not secure,

the perpendicularity could be offset.

Figure 3

Figure 2

Figure 1

1/4/2021 REV. 002 6

6. Insert the rear pin of the FlexArm into the upper bearing bore of the angle mount as shown in Figure 4.

Use care when inserting the pin into the bearings; the pin may need to be tapped by a rubber mallet

into the bearing as it is a snug fit. If the pin slides through the top

bearing, the washer and flat head screw shown in Figure 4 can be

used to draw the pin completely through the second bearing.

7. Install the unit’s airline into the press-to-release airline fitting.

8. Install a ¼” NPT fitting into the incoming air port on the unit’s filter /

lubricator (see Figure 5). The supply airline should have a minimum

½” I.D. The unit must have a proper air supply (90 – 120 psi and 27-

28 cfm) at the motor to generate the torque required to drive the

maximum tap capacity for this unit.

9. Fill the lubricator bowl approximately ¾ full by removing the black fill

plug on the top of the lubricator and pouring oil into the fill port.

Use only a quality ISO Grade 32 hydraulic or spindle oil. Never use

Marvel Mystery Oil, synthetic air tool oil, or similar products.

10. With the motor running, slowly adjust the lubricator adjustment knob (see Figure 5) so 1-3 drops of oil

are dispensed per minute. The site glass to see the drops is located in the adjustment knob. Clockwise

decreases the flow, counter-clockwise increases it.

NOTE: It may be necessary to open the

adjustment knob considerably before the oil starts

to drip. Once oil starts to drip, slowly close the

adjustment knob to achieve the target drip rate of

1-3 drops per minute.

11. The filter is equipped with an auto drain and will

automatically remove water from the filter bowl.

Figure 4

Figure 5

Figure 5

1/4/2021 REV. 002 7

12. Check the counterbalance of the unit.

a. The unit comes counterbalanced to factory specifications.

b. The counterbalance can be adjusted to meet the operator’s preference.

13. To adjust the counterbalance, refer to the counterbalance adjustment page of this manual.

14. The unit is now ready for use.

1/4/2021 REV. 002 8

COUNTERBALANCE ADJUSTMENT

Both the front and rear arms counterbalance can be adjusted to meet the operator preference.

To adjust the counterbalance, turn the adjuster knob located between the top plates for the front arms, and

the adjuster knob located between the rear plates for the rear arms (see Figure 6).

When adjusting the front cylinder, it will be easier to turn the adjustment knob if the front arms are fully

extended up. When adjusting the rear cylinder, it will be easier to turn the adjustment knob if the rear arms

are pulled down, parallel to the floor.

1. To decrease the counterbalance force applied by

the gas cylinders, turn the knob of the

adjuster knob clockwise.

2. To increase the counterbalance

force applied by the gas

cylinders, turn the knob of the

adjuster knob counter-clockwise.

Figure 6

1/4/2021 REV. 002 9

OPERATING INSTRUCTIONS:

1. Ensure the part to be tapped is secured and sitting flat on

the same flat surface that the tapping arm is mounted.

2. Select the correct tap holder for the tap size required.

Insert the tap into the holder by depressing the locking

ring. Seat the tap square into the tap holder. Release

the locking ring (see Figure 7).

3. Push up the quick-change chuck’s collar to insert the tap holder.

When inserting the tap holder in the quick-change chuck, turn the

holder to align the ears of the holder to the drive slots in the quick-

change chuck. Push up to lock the holder in the chuck (see Figure 8).

4. Select gear 1 or gear 2 by turning the knob on the gearbox. It may be

necessary to wiggle the motor’s chuck back and forth slightly while

turning the knob on the gearbox to switch from one gear to the

other. Ensure the knobs indicator is fully aligned with the gear 1 or

gear 2 marking on the gearbox. If not, the gears are not fully

engaged and damage to the internals of the gearbox may occur.

5. NEVER CHANGE GEARS WHILE THE MOTOR IS RUNNING!

6. Position the tap over the hole to be tapped.

7. When tapping through holes, remember that the tap will protrude through the bottom side of the

work piece. Ensure there is sufficient clearance below the workpiece to allow the tap to extend below

the bottom surface of the part and not hit the work surface.

8. Use a torque style tap holder when tapping blind or bottom holes. The built-in safety clutch on the

torque holders will rachet and stop the tap from turning when the tap reaches the bottom of the hole.

Figure 8

Figure 7

1/4/2021 REV. 002 10

9. Actuate the motor by depressing the throttle lever and gently guide the tap into the hole. Exert only

enough downward pressure to start the tap in the hole. Once started, the tap will pull itself through

the hole.

Do not push or pull on the motor when the tap is engaged in the hole and completing the tapping

process. This will result in poor thread quality, oversized threads, and broken taps.

10. When the hole is tapped (the torque holder rachets for blind holes or the tap extends past the bottom

of through holes) actuate the throttle lever and reverse button at the same time to reverse the

rotation of the motor and remove the tap from the hole.

11. To change tap holders, release the tap holder by pulling up on the quick-change chuck collar and

pulling the tap holder out of the quick-change chuck.

1/4/2021 REV. 002 11

ADJUSTING TORQUE HOLDER CLUTCH SETTING:

The torque holders are factory preset to the standard break torque limits developed for each tap size in mild

steel (approximately 229 BHN or 25 RC). The break torque limit protects the tap when tapping blind or bottom

holes. When the tap reaches the bottom of the hole, resistance will cause the torque holder’s safety clutch to

ratchet and stop the tap from turning, over-torquing and ultimately breaking. When tapping hardened steel

(above 40 RC), stainless steel, or other tough alloys, an increase in the factory torque setting may be required

in order to drive the tap the full depth of the hole. When using the torque adapters to tap soft materials or

plastics, a decrease in the factory torque setting prevents the tap from over-torquing after it reaches the

bottom of the hole (See “Torque Requirements for Tapping” chart on the following page).

There are two locking holes on the outside diameter of the torque holder that the tail of the snap ring aligns

to. These two positions allow the holder to be adjusted one half of a full notch of the adjustable thread ring at

a time. The tail of the snap ring must be inserted in the hole at either position and through a notch of the

thread ring in order to lock the adjusted torque setting. Figure 9 below shows the components related to the

adjustment of the torque holder.

Caution: Never adjust the torque setting more than one (1) notch at a time. Adverse tapping conditions and

broken taps may result!

To adjust the torque setting, first

remove the tap, then remove the

snap ring as shown in figure 10.

Take note of the hole location in

which the tail of the snap ring was

removed. Use the spanner wrench

to turn the torque adjustment ring

either clockwise to increase the torque setting, or counter-clockwise to reduce the torque setting.

After turning the thread ring a full notch, reinsert the tail of the snap ring in the original hole. If a lesser

adjustment is needed, turn the adjusting thread ring half the distance between the thread ring notches. Insert

the snap ring tail in the alternate hole on the outside diameter of the torque holder. This hole will be aligned

with a notch of the adjusting ring.

Figure 9

Figure 10

1/4/2021 REV. 002 12

TORQUE REQUIREMENTS FOR TAPPING:

Tap Size Brass

(in/lbs)

Aluminum and

leaded brass

(in/lbs)

200 BHN

Steel

(in/lbs)

300 BHN

Steel

(in/lbs)

400 BHN

Steel

(in/lbs)

Approx.

Break Torque

(in/lbs)

Torque Holder

Factory Setting

(in/lbs)

#6

4

2

7

9

10

18

15

#8

4.5

2.25

8

10

11

30

17

#10

8.5

4.25

15

19

21

42

31

1/4

16

8

28

36

40

106

70

5/16

24

12

42

54

60

180

100

3/8

37

18.5

65

83

93

240

150

7/16

54

27

94.5

122

135

500

250

1/2

68

34

119

153

170

700

300

9/16

88

44

154

198

220

850

350

5/8

119

59.5

208

268

298

1,000

400

3/4

170

85

298

383

425

1,500

620

7/8

238

119

416

536

595

2,100

880

1

337

168.5

590

758

842

2,700

1,200

1-1/4

554

277

970

1,246

1,385

3,000+

2,100

1-1/2

850

425

1,488

1,912

2,125

3,100

1-3/4

1,411

706

2,471

3,177

3,530

5,500

2

1,904

952

3,332

4,284

4,760

7,000

1/4/2021 REV. 002 13

MAINTENANCE:

•Oiling the Motor:

If the FlexArm has been sitting a while between jobs, it may be necessary to add 4-5 drips of oil directly

into the motor inlet to place oil on the vanes before running. It will take the lubricator a short time to

actually get the oil to the motor when first running the unit. The lubricator must be checked periodically to

ensure that the flow rate of 1-3 drops per minute is maintained.

•Cleaning the FlexArm:

The FlexArm should be periodically cleaned and free of dirt, debris, grinding dust, etc. An airline can be

used to blow the dust and chips away from the arms, arm joints, motor, chuck, etc. Never use oil, WD-40,

or any other lubricant to lubricate the arm joints (arm joints are constructed with self-lubricating bushings

and require no maintenance). Never use harsh cleaners or solvents. Never allow any cleaning agent to

reach the arm joints.

•Periodically check the bolts throughout the unit for tightness:

If the bolts have loosened up, use Loctite 242 (blue) on the threads and reassemble. This should prevent

any further problems.

•Filter / Lubricator:

Check that the filter/lubricator is set for approximately 1-3 drops per minute as indicated in the

INSTALLATION of this manual. Always use 10 wt. hydraulic oil or light spindle oil. (EP-32 hydraulic oil is

recommended). Never use Marvel Mystery Oil or synthetic products. Make sure to clean the filter and

drain excess water from the filter bowl on a regular basis.

•Motors with a quick-change chuck:

Keep both the motor and the chuck free from contamination by cleaning regularly: An airline can be used

to blow dust, dirt, and debris off of the motor and chuck collar. Make sure to clean inner surface of the

chuck as well. If contaminants build up too excessively, it may become necessary to soak the entire chuck

in cleaning solvent or WD-40 type penetrating oil before using the airline. Doing this regularly will

considerably reduce, and may even eliminate, the need to disassemble the quick-change chuck to clean it.

If, however, the chuck has accumulated so much dirt and grime that disassembly is necessary, follow the

procedures given below:

oQuick Change Chuck with Knurled Collar:

Lift the snap ring out of the groove and slide it towards the motor, resting on the chuck body. The

collar can then slide along the chuck body, exposing the compression spring and the two ball

bearings. (CAUTION: The ball bearings are held in place only by the collar; be careful not to lose

these ball bearings!) Clean the exposed area of the chuck body, the spring, and the two ball

1/4/2021 REV. 002 14

bearings and reassemble the chuck. Use the spring to hold one of the ball bearings in place,

position the other ball bearing, and slide the collar back into position (it may be necessary to

depress the ejector in the center of the chuck body to completely slide the collar back into place.)

Replace the snap ring in the groove on the chuck body.

oQuick Change Chuck with Smooth Collar:

Slide the collar upward until it locks into the upper most position. The snap ring is located between

the chuck body and the collar (on the open end where the tap holders inserted). Use an awl or

small slotted screwdriver to locate one of the snap ring ends. Rotate the snap ring end until it is

positioned in one of the two chuck slots. It can now be carefully lifted upward and by using a

circular motion, the ring can be completely removed. The collar can now be removed by depressing

the ejector in the center of the chuck body (CAUTION: The collar may eject rapidly. Be careful not

to damage the collar or lose the ball bearings, spring, or snap ring). Clean the exposed area of the

chuck and reassemble (It may be necessary to depress the ejector in the center of the chuck body

to completely slide the collar back into place). Replace the snap ring in the groove on the chuck

body.

1/4/2021 REV. 002 15

DRAWING: RNR

1/4/2021 REV. 002 16

PARTS AND ASSEMBLY: GEAR BOX

1/4/2021 REV. 002 17

PARTS AND ASSEMBLY

1/4/2021 REV. 002 18

ITEM QTY

PART

NUMBER

DESCRIPTION

1 1 0385M

ELBOW FITTING, 1/2" O.D.

2 1 0391M

FILTER / LUBRICATOR, NO ELBOW

ITEM QTY

PART

NUMBER

DESCRIPTION

1 1 420004

FILTER / LUBE MOUNT BRACKET

2 1 420006

LUBRICATOR HALF

3 1 420012

FILTER HALF

ITEM QTY

PART NUMBER DESCRIPTION

1 1 420002

FILTER ELEMENT (5 MICRON)

2 1 420003

O-RING FOR BOWL

3 1 420005

O-RING FOR MOUNT

4 1 420007

LUBRICATOR BOWL KIT

5 1 420008

LUBRICATOR DOMESIGHT

6 1 420009

LUBRICATOR FILL PLUG

7 1 420013

FILTER BOWL KIT

1/4/2021 REV. 002 19

RNRM: INSTRUCTIONS

1. To use the multi-head option for an RNR, first start by loosening the handle shown in Figure 11. This

will allow the gearbox/motor to freely rotate right or left as shown in Figure 12. Make sure you have a

firm gasp on the motor.

2. Loosen the handle shown in Figure 13 to be able to rotate the multi-head down so that the motor is in

a horizontal orientation parallel to the work surface. Be sure to have a firm grasp on the motor so that

it does not fall unsupported. Failure to support the motor when rotating it to the horizontal

orientation has the potential to cause harm or damage to the arm, motor, gearbox, or operator.

Figure 11

Figure 12

Figure 13

1/4/2021 REV. 002 20

3. Insert the Size 2 alignment plug into the quick-change chuck (Figure14).

4. Move the arm to the vertical surface (perpendicular to the surface the arm is mounted) you are

tapping and secure it to the surface via the magnetic plug. Tighten only the rear handle that fastens

through the front side plates of the arm (Figure 13).Leave the handle on the tapping head (Figure 12)

loose. This will allow the tap to follow the hole in as it taps the hole.

5. Before you pull the magnetic plug away, make sure it is flush with the tapping surface. Once the plug is

removed, make sure the tap is going to easily follow the hole you are tapping.

Figure 14

Table of contents

Other FlexArm Rack & Stand manuals

Popular Rack & Stand manuals by other brands

tikamoon

tikamoon A036 Assembly, Use, Maintenance Manual

Rhino-Rack

Rhino-Rack RWHL instructions

Dock Doctors

Dock Doctors Wall-Mounted Storage Rack Assembly instructions

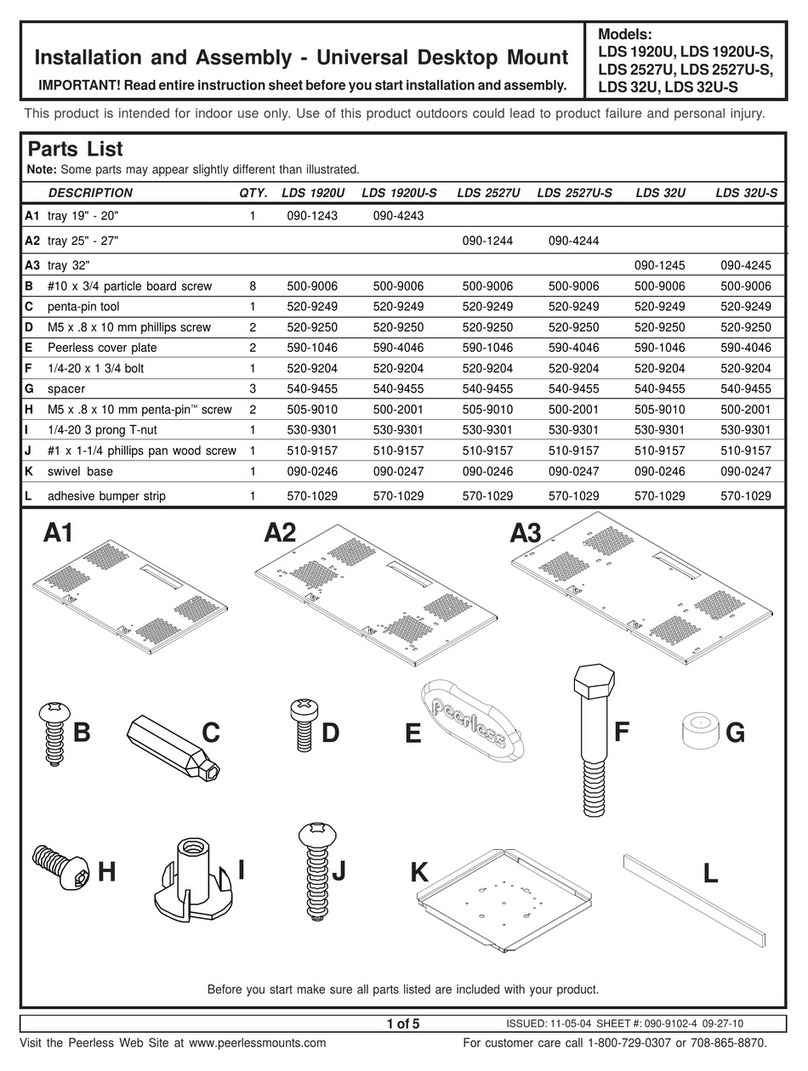

PEERLESS

PEERLESS LDS 1920U Installation and assembly

Festo

Festo VAME-P5-MK Assembly instructions

NEC

NEC Wall Mount PDW S 32-55 P (WMS 32-55 P user manual