Flexco MHCP Technical Document

MHCP Primary Cleaner

Installation, Operation

and Maintenance Manual

www.flexco.com

www.flexco.com

MHCP Primary Cleaner

Purchase Date:______________________________________________________________

Purchased From: ____________________________________________________________

Installation Date: ____________________________________________________________

This information will be helpful for any future inquiries or questions about belt cleaner

replacement parts, specifications or troubleshooting.

3

Table of Contents

Section 1 – Important Information ...........................................................................................................4

1.1 General Introduction ..................................................................................................................................4

1.2 User Benets ................................................................................................................................................4

1.3 Service Option .............................................................................................................................................4

Section 2 – Safety Considerations and Precautions ..................................................................................5

2.1 Stationary Conveyors..................................................................................................................................5

2.2 Operating Conveyors ..................................................................................................................................5

Section 3 – Pre-Installation Checks and Options......................................................................................6

3.1 Checklist .......................................................................................................................................................6

3.2 Cleaner Location Adjustments ..................................................................................................................7

Section 4 – Installation Instructions..........................................................................................................8

Section 5 – Pre-Operation Checklist and Testing....................................................................................12

5.1 Pre-Op Checklist .......................................................................................................................................12

5.2 Test Run the Conveyor .............................................................................................................................12

Section 6 – Maintenance ..........................................................................................................................13

6.1 New Installation Inspection ...........................................................................................................................13

6.2 Routine Visual Inspection........................................................................................................................13

6.3 Routine Physical Inspection.....................................................................................................................13

6.4 Blade Replacement Instructions..............................................................................................................14

6.5 Maintenance Log .......................................................................................................................................16

6.6 Cleaner Maintenance Checklist...............................................................................................................17

Section 7 – Troubleshooting ....................................................................................................................18

Section 8 – Specs and CAD Drawings......................................................................................................19

8.1 Specications and Guidelines.........................................................................................................................19

8.2 CAD Drawings...........................................................................................................................................20

Section 9 – Replacement Parts .................................................................................................................22

9.1 Replacement Parts List..............................................................................................................................22

9.2 Optional Assemblies, Tensioners & Kits.................................................................................................23

Section 10 – Other Flexco Conveyor Products........................................................................................27

4MHCP Primary Cleaner

1.1 General Introduction

Section 1 – Important Information

We at Flexco are very pleased that you have selected a MHCP Primary Cleaner for your conveyor system.

is manual will help you to understand the operation of this product and assist you in making it work up to

its maximum eciency over its lifetime of service.

It is essential for safe and ecient operation that the information and guidelines presented be properly

understood and implemented. is manual will provide safety precautions, installation instructions,

maintenance procedures and troubleshooting tips.

If, however, you have any questions or problems that are not covered, please visit our web site or contact our

Customer Service Department:

Customer Service: +27-11-608-4180

Visit www.exco.com for other Flexco locations and products.

Please read this manual thoroughly and pass it on to any others who will be directly responsible for

installation, operation and maintenance of this cleaner. While we have tried to make the installation and

service tasks as easy and simple as possible, it does however require correct installation and regular

inspections and adjustments to maintain top working condition.

1.2 User Benets

Correct installation and regular maintenance will provide the following benets for your operation:

• Reduced conveyor downtime

• Reduced man-hour labor

• Lower maintenance budget costs

• Increased service life for the belt cleaner and other conveyor components

1.3 Service Option

e MHCP Primary Cleaner is designed to be easily installed and serviced by your on-site personnel.

However, if you would prefer complete turn-key factory service, please contact your local Flexco Field

Representative.

5

Section 2 – Safety Considerations and Precautions

Before installing and operating the MHCP Primary Cleaner, it is important to review and understand the following

safety information.

There are set-up, maintenance and operational activities involving both stationary and operating conveyors. Each

case has a safety protocol.

2.1 Stationary Conveyors

The following activities are performed on stationary conveyors:

• Installation • Blade replacement • Repairs

• Tension adjustments • Cleaning

DANGER

DANGER

WARNING

WARNING

WARNING

!

!

!

!

!

It is imperative that Lockout/Tagout (LOTO)

regulations, be followed before undertaking the

preceding activities. Failure to use LOTO exposes

workers to uncontrolled behavior of the belt cleaner

caused by movement of the conveyor belt. Severe injury

or death can result.

Before working:

• Lockout/Tagout the conveyor power source

• Disengage any takeups

• Clear the conveyor belt or clamp securely in place

Use Personal Protective Equipment (PPE):

• Safety eyewear

• Hardhats

• Safety footwear

Close quarters, springs and heavy components create

a worksite that compromises a worker’s eyes, feet

andskull.

PPE must be worn to control the foreseeable hazards

associated with conveyor belt cleaners. Serious injuries

can be avoided.

2.2 Operating Conveyors

There are two routine tasks that must be performed while the conveyor is running:

• Inspection of the cleaning performance

• Dynamic troubleshooting

Every belt cleaner is an in-running nip hazard. Never

touch or prod an operating cleaner. Cleaner hazards

cause instantaneous amputation and entrapment.

Never adjust anything on an operating cleaner.

Unforseeable belt projections and tears can catch on

cleaners and cause violent movements of the cleaner

structure. Flailing hardware can cause serious injury

ordeath.

Belt cleaners can become projectile hazards. Stay as far

from the cleaner as practical and use safety eyewear and

headgear. Missiles can inflict serious injury.

6MHCP Primary Cleaner

3.1 Checklist

Section 3 – Pre-Installation Checks and Options

• Check that the cleaner size is correct for the beltline width

• Check the belt cleaner carton and make sure all the parts are included

• Review the “Tools Needed” list on the top of the installation instructions

• Check the conveyor site:

- Will the cleaner be installed on a chute

- Are there obstructions that may require cleaner location adjustments

(see 3.2 – Cleaner Location Adjustments)

- Is the install on an open head pulley requiring mounting structure

(see 3.3 – Optional Installation Accessories)

7

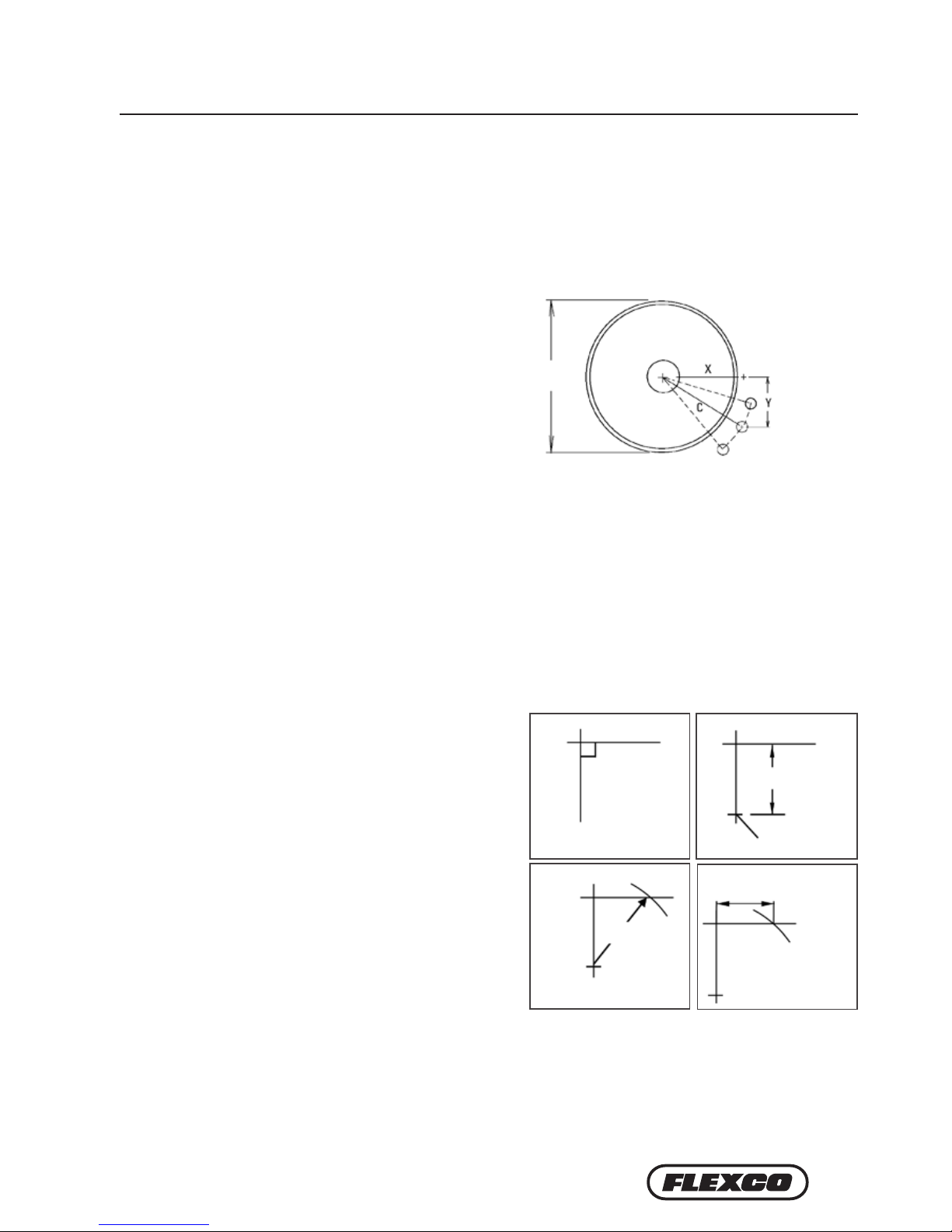

3.2 Cleaner Location Adjustments

Section 3 – Pre-Installation Checks and Options

In certain applications it is necessary to modify the location of the primary cleaner pole due to permanent

obstacles that obstruct the desired location. Relocating the pole location can be done easily and does not hinder the

performance of the cleaner as long as the “C” dimension is maintained.

NOTE: In the following example we will be lowering the pole location in the “Y” direction, but the same method

could also be applied in the “X” direction.

Conveyor situation:

Pulley Diameter: 900mm

X = 450mm

Y = 359mm

C = 575mm

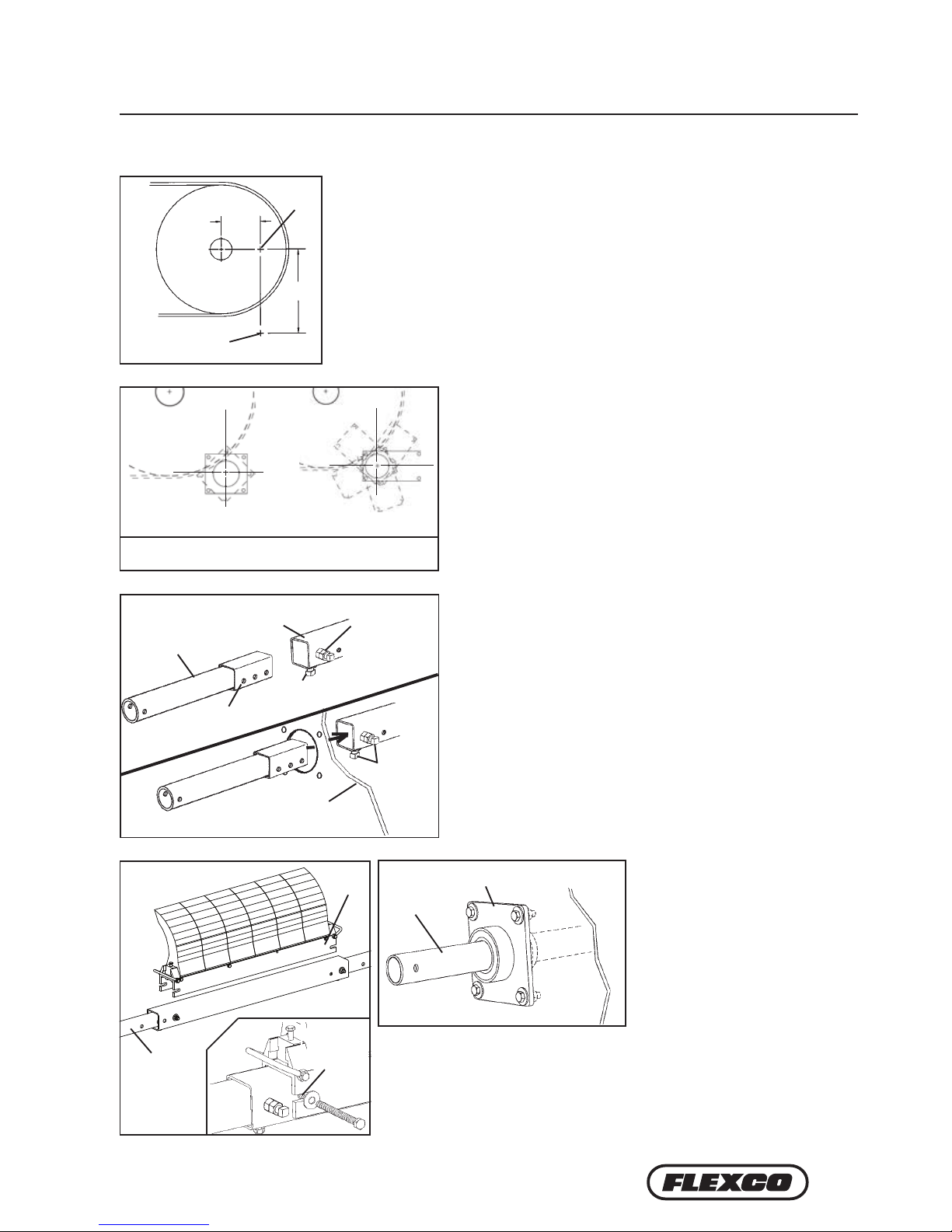

1. Determine the given location dimensions and define the change needed. After laying out the given X & Y

dimensions, determine the distance of the modification required for adequate clearance of the pole and tensioning

system. (In the example we decide to lower the pole 50mm to clear the support structure).

2. Write down known dimensions. We can now determine two of the three required dimension which will allow us

to find the third. We know we cannot alter the “C” dimension, so this will remain the same. Also we are required to

lower the unit in the “Y” dimension 50mm, so we add 50mm to the given “Y” dimension.

X = ? mm

Y =359+50=409mm

C = 575mm

3. Determine final dimension. On a flat vertical surface,

using a level, draw one horizontal line and one vertical

line creating a right triangle (Fig 3a). Measure down from

the intersection the determined “Y” dimension and mark

(Fig 3b). With the tape measure starting at the modified

“Y” mark, swing the tape across the “X” line and mark at

the “C” dimension where it crosses the “X” line (Fig 3c).

Measure from the intersection to the “C” intersection and

this will be your new “X” dimension (Fig. 3d).

X = 403mm

Y = 409mm

C = 575mm

900 mm

Fig. 3a

Fig. 3c

Fig. 3b

Fig. 3d

Y 409 mm

mark

This distance is the new

“X” dimension

403 mm

C 575 mm

8MHCP Primary Cleaner

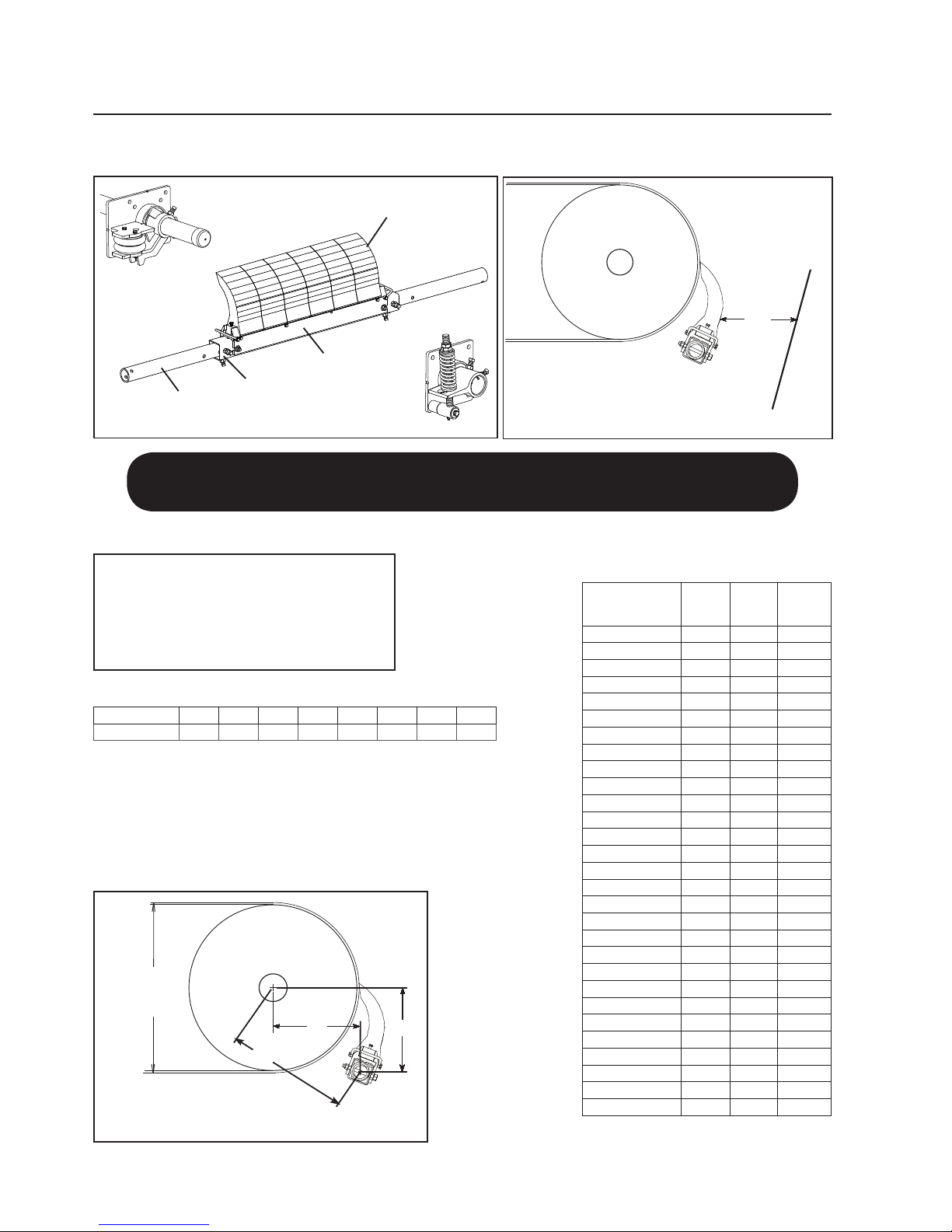

Section 4 – Installation Instructions

Physically lock out and tag the conveyor at the power source

before you begin cleaner installation.

1. Find the X, Y & C specifications. Measure the pulley diameter

(including the belt and the lagging) (Fig. 1).

Pulley Diameter _____mm; X=_____mm; Y=_____mm; C=_____mm.

(Adjustments can be made to the X & Y coordinates to move away

from obstacles as long as the C dimension remains constant.)

CAUTION: Components may be heavy. Use safety-approved lifting procedures.

X & Y Chart for Pole Location

Pulley Diameter

(including belt

and lagging) X Y C

500 254 365 445

525 267 365 451

550 279 365 460

575 292 365 467

600 305 365 476

625 318 365 483

650 330 365 492

675 343 365 502

700 356 365 511

725 368 365 518

750 381 365 527

775 394 365 537

800 406 365 546

825 419 365 556

850 432 365 565

875 445 365 575

900 457 365 584

925 470 365 594

950 483 365 606

975 495 365 616

1000 508 365 625

1025 521 365 635

1050 533 365 648

1075 546 365 657

1100 565 365 673

1125 581 365 686

1150 597 365 699

1175 610 365 711

1200 625 365 724

Blades per Cleaner Size

mm 600 750 900 1050 1200 1350 1500 1800

Blades Required 3 4 5 6 7 8 9 11

4.1 MHCP Primary Cleaner

Tools Needed:

• Tape Measure

• Wrenches or Crescent Wrenches: (2)19mm,

(2) 38mm, (1) 24mm, and (1) 16mm

• C-clamps for AWT only

Fig. 1

X

C

Y

Pole Location Specs

Pulley Diameter

(incl. belt and

lagging)

AWT Air/Water Tensioner

PST Spring Tensioner

Supershear Blades

Blade Cartridge

Centre Pole

Extender Pole

MHCP Parts List

Chute Wall

Recommended spacing from back chute wall

Maximum

lump size

+ 200mm (8")

9

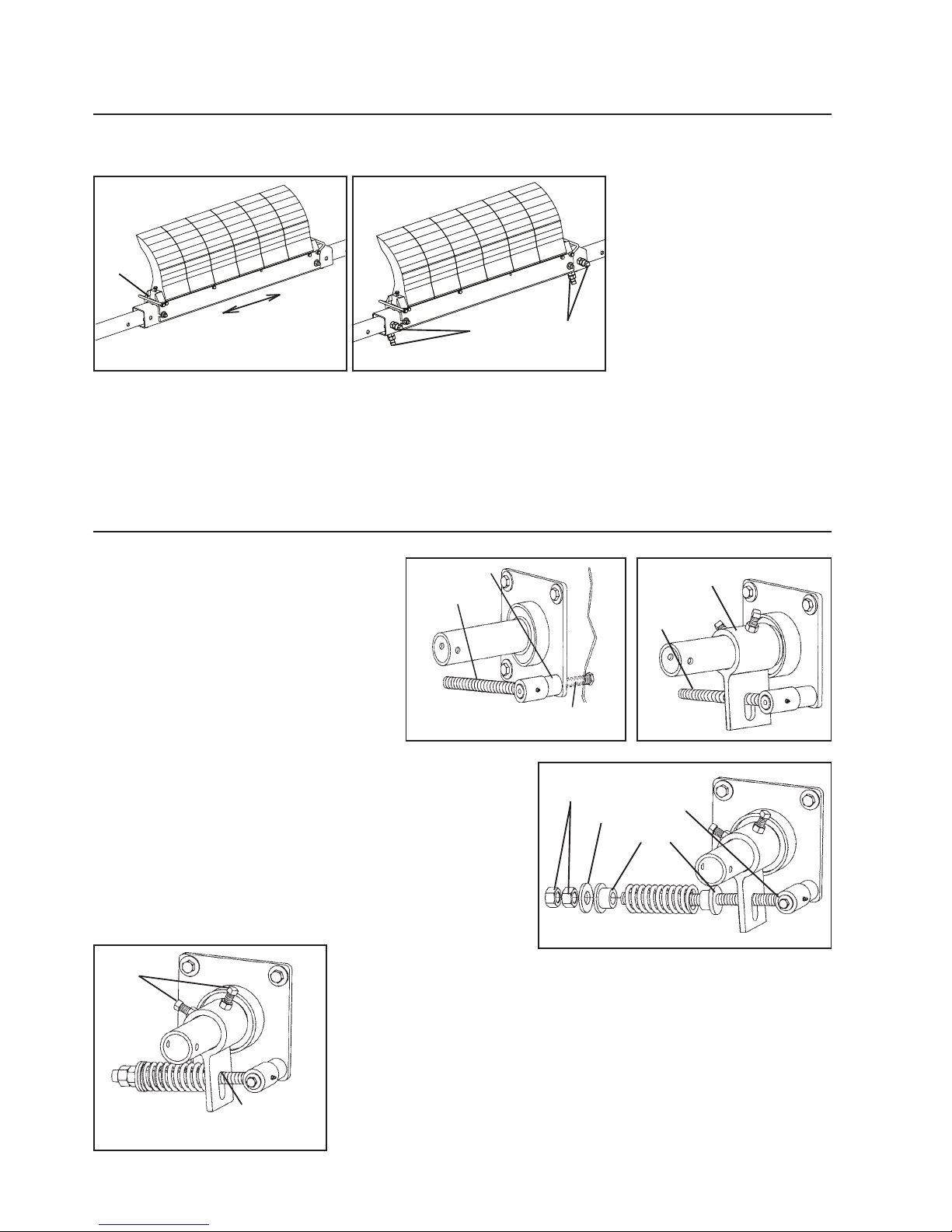

5. Install the mounting bases.

Bolt the mounting bases to the

chute with the bolts provided

(Fig. 5).

6. Install the blade cartridge.

Place the blade cartridge onto

the centre pole. Adjust the

extender poles until the holes

align with the holes in

the centre pole and lock the cartridge into place with the two bolts,

washers and nuts (Fig. 6). NOTE: Be sure at least 150mm of the extender

pole extends out of the mounting base on each side for tensioner

installation. Adjust the extender poles in the centre pole if more or less

length is needed.

Section 4 – Installation Instructions

2. Lay out the dimensions on the chute wall. Measure out the X dimension

horizontally from the centre of the pulley shaft and mark. (NOTE: It may be

easier to put a level on top of the pulley shaft, draw a horizontal line and then

measure down half the diameter of the shaft and make a line from the front of

the shaft. Now subtract half the pulley shaft diameter from the X coordinate

and measure on the line and make a mark.) Then measure down vertically the

Y dimension and mark. This is the correct position for the centre of the cleaner

pole (Fig. 2). Lay out and mark the same dimensions on the other side.

3. Mark and cut the mounting base holes. Using the

mounting base template provided in the instruction packet,

position the large pole hole of the template on the chute with

the hole notches aligned with the layout lines. Trace the pole

hole and mounting holes (Fig. 3). Each base can be mounted

in any position 360° around the pole as long as the pole’s

centre point does not change. Cut the holes on both sides of

the chute.

4. Assemble the extender poles to the centre pole. Insert the

extender poles through the chute holes and into the centre

pole and make sure the locating bolt holes align with the

centre pole holes (holes are offset to the lower half). Position

the centre pole with the welded nuts and locking bolts on

one side facing down and on the adjoining side facing away

from the head pulley (Fig. 4). Leave the locking bolts loose.

4. 1 MHCP Primary Cleaner (cont.)

mark

Y

X

mark

Center large template hole notches on pole center mark,

rotate to desired angle and trace holes

Template for

PST mounting baseTemplate for

AWT/NT mounting base

Blade

Cartridge

6" of pole end

must extend

outside the

mounting base

on each side

Align holes

and install

bolts, washers

and nuts

Extender

Pole

Mounting Plate

(Pst Shown)

Chute wall

(cut away)

Chute wall

(cut away)

Center Pole

Extender Pole

Must be facing

away from

head pulley

Locating bolt

holes

Locking

Bolts

Must align with

extender pole

holes

Must be

facing down

Fig. 2

mark

Y

X

mark

Center large template hole notches on pole center mark,

rotate to desired angle and trace holes

Template for

PST mounting baseTemplate for

AWT/NT mounting base

Blade

Cartridge

6" of pole end

must extend

outside the

mounting base

on each side

Align holes

and install

bolts, washers

and nuts

Extender

Pole

Mounting Plate

(Pst Shown)

Chute wall

(cut away)

Chute wall

(cut away)

Center Pole

Extender Pole

Must be facing

away from

head pulley

Locating bolt

holes

Locking

Bolts

Must align with

extender pole

holes

Must be

facing down

Fig. 3

mark

Y

X

mark

Center large template hole notches on pole center mark,

rotate to desired angle and trace holes

Template for

PST mounting baseTemplate for

AWT/NT mounting base

Blade

Cartridge

6" of pole end

must extend

outside the

mounting base

on each side

Align holes

and install

bolts, washers

and nuts

Extender

Pole

Mounting Plate

(Pst Shown)

Chute wall

(cut away)

Chute wall

(cut away)

Center Pole

Extender Pole

Must be facing

away from

head pulley

Locating bolt

holes

Locking

Bolts

Must align with

extender pole

holes

Must be

facing down

Fig. 4

mark

Y

X

mark

Center large template hole notches on pole center mark,

rotate to desired angle and trace holes

Template for

PST mounting baseTemplate for

AWT/NT mounting base

Blade

Cartridge

6" of pole end

must extend

outside the

mounting base

on each side

Align holes

and install

bolts, washers

and nuts

Extender

Pole

Mounting Plate

(Pst Shown)

Chute wall

(cut away)

Chute wall

(cut away)

Center Pole

Extender Pole

Must be facing

away from

head pulley

Locating bolt

holes

Locking

Bolts

Must align with

extender pole

holes

Must be

facing down

Fig. 5

Fig. 6 Blade

Cartridge

150 mm of pole

end must extend

outside the

mounting base

on each side

Align holes

and install

bolts, washers

and nuts

10 MHCP Primary Cleaner

Section 4 – Installation Instructions

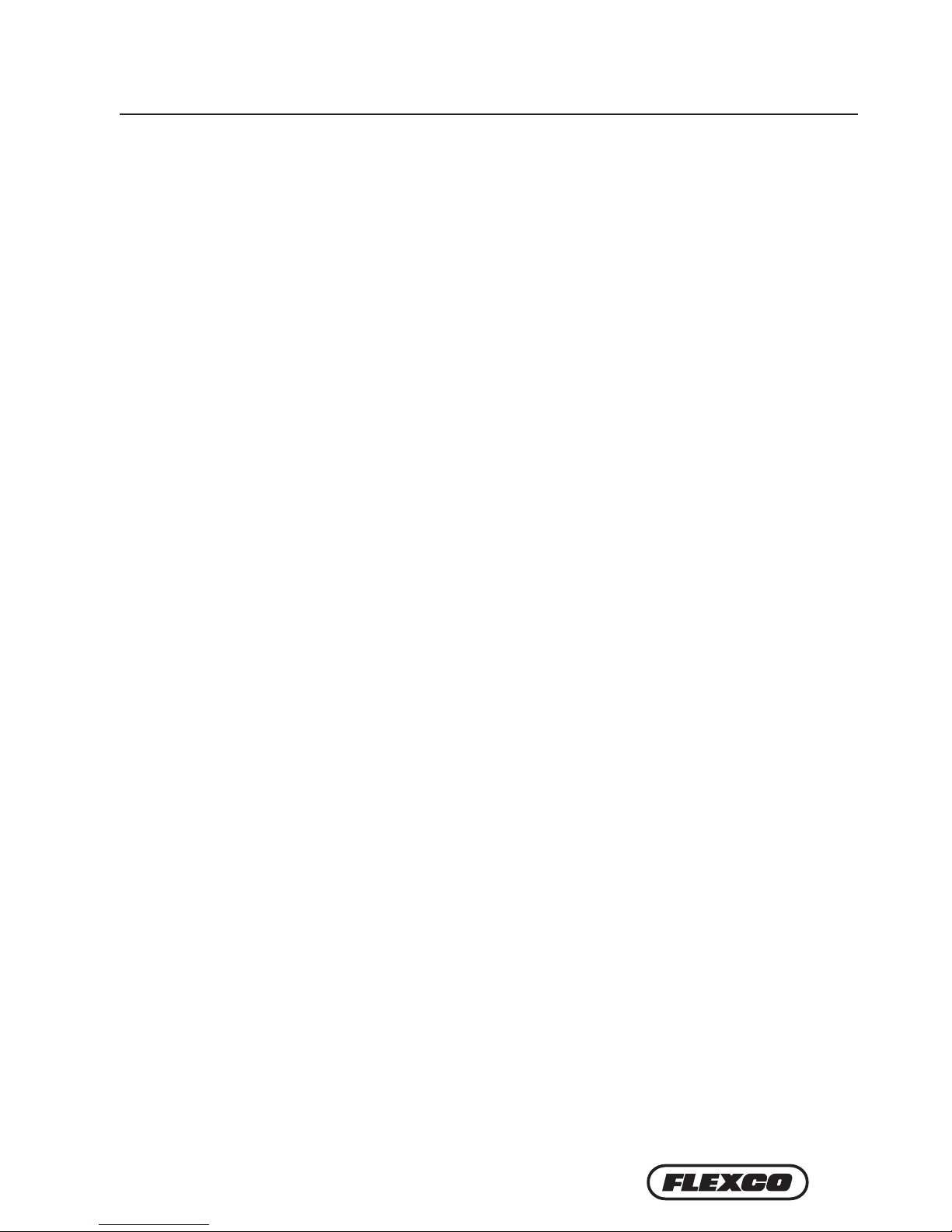

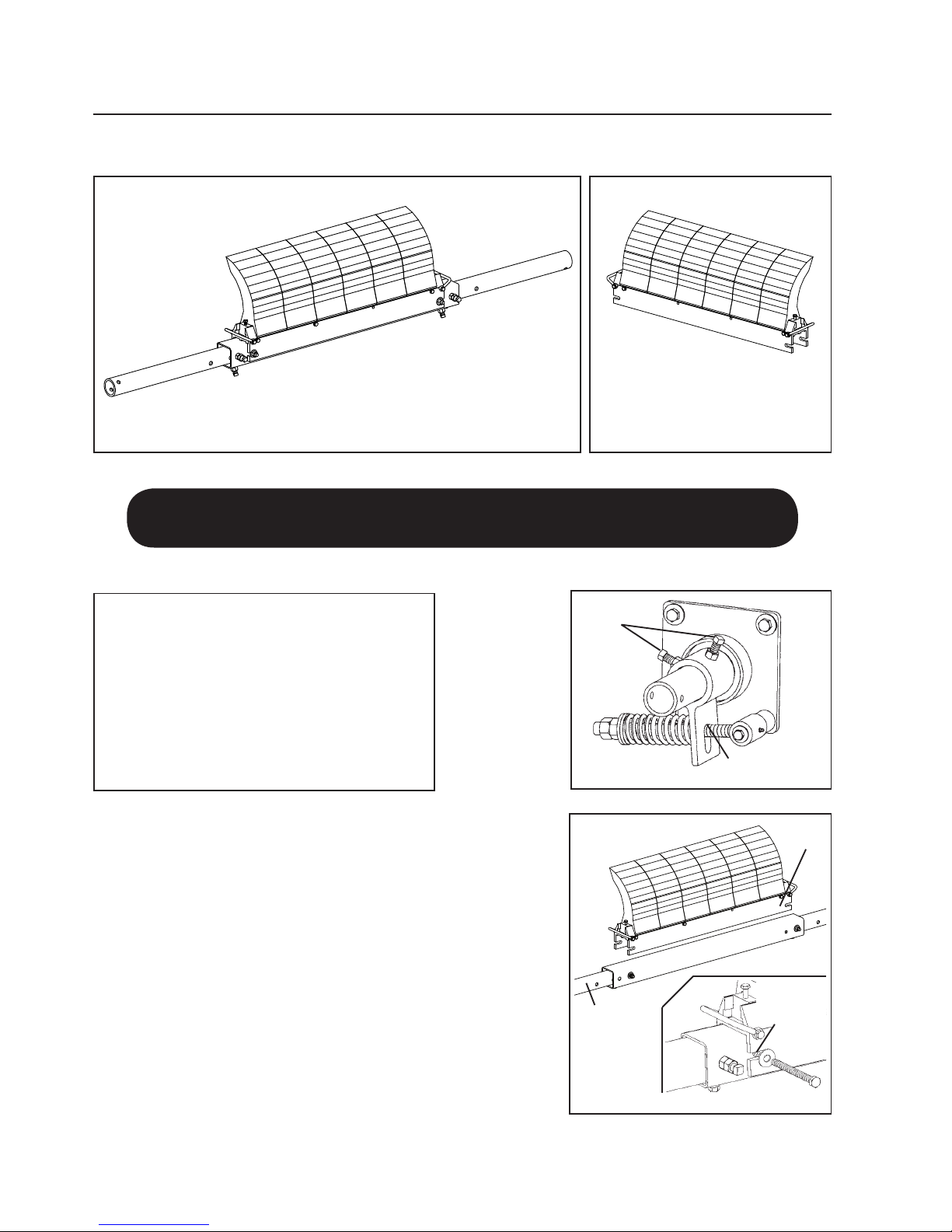

7. Centre the blades on the belt.

Slide the pole until the blades

are centreed or cover the belt’s

material path (Fig. 7). NOTE:

Standard blade coverage is

belt width minus 150mm. If

less blade coverage is required,

single blades can be removed

from the blade cartridge.

The blades do not have to be

centred in the cartridge. They

should be centred on the belt’s

material path.

8. Lock the extender poles in the centre pole. Tighten the two locking bolts and jam nuts on each end of the centre

pole (Fig. 8).

Install the tensioning system. For the PST Spring Tensioner go to step 9S. For the AWT Air/Water or PAT

Tensioner proceed to step 9A.

9S. Install the torque pivot rod. Remove the

adjusting nuts and springs from the rods.

The pivot rod base can be installed in any of

the four mounting plate holes. Determine

the rotation desired. Insert the pivot rod

mounting bolt through the chute wall and

the mounting plate and into the pivot rod

base and tighten (Fig. 9S).

10S. Slide the torque arm onto the pole end. Again ensuring the

correct pulling rotation, put the torque arm onto the pole end

and rotate it around until the torque pivot rod slides through

the slot (Fig. 10S).

11S. Reassemble the spring assembly. Slide the spring, washer and

bushings onto the pivot rod and turn the two adjusting nuts

so about 6mm of the rod is exposed above the nuts (Fig. 11S).

Complete steps 9S through 11S on the other side.

12S. Tension the blades to the belt. Rotate the blades until they contact the

belt. While holding the spring bushing flat on the torque arm, rotate the

torque arm until the pivot rod is against the end of the slot nearest the

pole. Tighten the locking bolts and jam nuts on the torque arm (Fig. 12S).

NOTE: The torque arm should be up against the mounting base.

Primary Cleaner Spring

Tensioner (PST)

4.1 MHCP Primary Cleaner (cont.)

Fig. 7 Fig. 8

Slide pole to center

blades or cover

belt’s material path

Remove

blade stop

to slide

blade(s)

off if

necessary

Tighten locking bolts and

jam nuts (both ends)

Slide pole to center

blades or cover

belt’s material path

Remove blade

stop to slide

blade(s) off if

necessary

Tighten locking bolts and

jam nuts (both ends)

Pivot Rod

Bushings

Adjusting

Nuts

Washer

Torque

Arm

Torque

Pivot Rod

Pivot Rod Base

Torque Pivot

Rod

Chute

Wall

(cut

away)

Pivot Rod

Mounting Bolt

Pivot rod against slot

end nearest the pole

Tighten

locking bolts

and

jam

nuts

Fig. 9S

Slide pole to center

blades or cover

belt’s material path

Remove blade

stop to slide

blade(s) off if

necessary

Tighten locking bolts and

jam nuts (both ends)

Pivot Rod

Bushings

Adjusting

Nuts

Washer

Torque

Arm

Torque

Pivot Rod

Pivot Rod Base

Torque Pivot

Rod

Chute

Wall

(cut

away)

Pivot Rod

Mounting Bolt

Pivot rod against slot

end nearest the pole

Tighten

locking bolts

and

jam

nuts

Fig. 10S

Slide pole to center

blades or cover

belt’s material path

Remove blade

stop to slide

blade(s) off if

necessary

Tighten locking bolts and

jam nuts (both ends)

Pivot Rod

Bushings

Adjusting

Nuts

Washer

Torque

Arm

Torque

Pivot Rod

Pivot Rod Base

Torque Pivot

Rod

Chute

Wall

(cut

away)

Pivot Rod

Mounting Bolt

Pivot rod against slot

end nearest the pole

Tighten

locking bolts

and

jam

nuts

Fig. 11S

Slide pole to center

blades or cover

belt’s material path

Remove blade

stop to slide

blade(s) off if

necessary

Tighten locking bolts and

jam nuts (both ends)

Pivot Rod

Bushings

Adjusting

Nuts

Washer

Torque

Arm

Torque

Pivot Rod

Pivot Rod Base

Torque Pivot

Rod

Chute

Wall

(cut

away)

Pivot Rod

Mounting Bolt

Pivot rod against slot

end nearest the pole

Tighten

locking bolts

and

jam

nuts

Fig. 12S

11

Pressure Chart

Blade

Width No. of

Blades kPamm in.

450 18" 3 55.2

600 24" 4 69.0

750 30" 5 89.6

900 36" 6 103.4

1050 42" 7 124.1

1200 48" 8 137.9

1350 54" 9 158.6

1500 60" 10 172.4

1650 66" 11 193.1

1800 72" 12 213.7

1950 78" 12 227.5

2100 84" 14 248.2

2250 90" 15 262.0

kPa setting is based on the number

of blades on the cleaner, not the

belt width.

Spring Length Chart

Blade

Width No. Of

Blades

White

Springs

Silver

Springs

Red

Springs

mm in. mm in. mm in. mm in.

450 18" 3 146 5 3/4" 162 6 3/8" 165 6 1/2"

600 24" 4 137 5 3/8" 159 6 1/4" 162 6 3/8"

750 30" 5 130 5 1/8" 156 6 1/8" 162 6 3/8"

900 36" 6 121 4 3/4" 156 6 1/8" 159 6 1/4"

1050 42" 7 114 4 1/2" 152 6" 159 6 1/4"

1200 48" 8 N/A N/A 149 5 7/8" 156 6 1/8"

1350 54" 9 N/A N/A 146 5 3/4" 156 6 1/8"

1500 60" 10 N/A N/A 146 5 3/4" 152 6"

1650 66" 11 N/A N/A 144 5 5/8" 152 6"

1800 72" 12 N/A N/A 140 5 1/2" 149 5 7/8"

1950 78" 13 N/A N/A 130 5 1/8" 146 5 3/4"

2100 84" 14 N/A N/A N/A N/A 146 5 3/4"

2250 90" 15 N/A N/A N/A N/A 144 5 5/8"

2400 96" 16 N/A N/A N/A N/A 140 5 1/2"

2550 102" 17 N/A N/A N/A N/A 140 5 1/2"

Spring tension is based on the number of blades on the

cleaner, not the belt width. Shading indicates preferred

spring option.

Section 4 – Installation Instructions

4.1 MHCP Primary Cleaner (cont.)

Fig. 13S

Locking Bolts

And Jam Nuts

Collapse

Air Bags

Connect lines

from air bags

Connect line

from site supply

Air/Water Control Box

Connect lines

from air bags

Connect line

from site

supply

Nitrogen Regulator

o

f Washer

o

rque Arm

Measure

from top

of washer

to top of

torque arm.

13S. Set the correct blade tension. Refer to the

chart or the decal on the mounting base

for the spring length required for the belt

width. Lightly pull the pivot rod toward

the end of the torque arm slot nearest the

pole and turn the adjusting nuts until

the required spring length is achieved

(Fig.13S). Complete steps 12S and 13S on

the other side. For best results, recheck

the spring length on the first side to insure

there has been no movement.

14S. Test run the cleaner. Run the conveyor for at least 15 minutes and

inspect cleaning performance. Check the spring lengths for proper

tensioning. Make adjustments as necessary.

NOTE: Tensioners are shipped with the air bags and torque arms attached to the

mounting bases.

9P. Tension the blades to the belt. Collapse both air bags (with C-clamps) and rotate

the blades until they are 25mm short of contact with the belt. Tighten the torque

arm locking bolts and jam nuts (Fig. 9P).

10P. Connect the supply lines and set tension pressure.

With the parts supplied, attach a line to each air

bag and run the lines to the outlet side of the PAT

control box (Fig. 10P). NOTE: Be sure lines are

safely away from the belt. Connect a line from the

inlet side of the box to the site’s supply or air tank.

Test the connections for leaks and set the pressure

per the chart on the control box (also shown below).

Take the pressure chart label from the instruction

packet and affix it in an easily accessible location

near the regulator for future reference.

11P. Test run the cleaner. Run the conveyor for at least 15 minutes and inspect cleaning

performance. Make adjustments as necessary.

Portable Air Tensioner (PAT)

Connect line

from site supply

or tank

Connect lines

from air bags

Fig. 10P PAT Control Box

Fig. 9P

Collapse

air bags

Locking bolts

and jam nuts

12 MHCP Primary Cleaner

Section 5 – Pre-Operation Checklist and Testing

5.1 Pre-Op Checklist

• Recheck that all fasteners are tightened properly

• Add pole caps

• Apply all supplied labels to the cleaner

• Check the blade location on the belt

• Be sure that all installation materials and tools have been removed from the belt and the conveyor area

5.2 Test Run the Conveyor

• Run the conveyor for at least 15 minutes and inspect the cleaning performance

• Check the tensioner spring for recommended length (proper tensioning)

• Make adjustments as necessary

NOTE: Observing the cleaner when it is running and performing properly will help to detect problems or

when adjustments are needed later.

13

Section 6 – Maintenance

Flexco belt cleaners are designed to operate with minimum maintenance. However, to maintain superior performance

some service is required. When the cleaner is installed a regular maintenance program should be set up. This program

will ensure that the cleaner operates at optimal efficiency and problems can be identified and fixed before the cleaner

stops working.

All safety procedures for inspection of equipment (stationary or operating) must be observed. The MHCP Primary

Cleaner operates at the discharge end of the conveyor and is in direct contact with the moving belt. Only visual

observations can be made while the belt is running. Service tasks can be done only with the conveyor stopped and by

observing the correct lockout/tagout procedures.

6.1 New Installation Inspection

After the new cleaner has run for a few days a visual inspection should be made to ensure the cleaner is

performing properly. Make adjustments as needed.

6.2 Routine Visual Inspection (every 2-4 weeks)

A visual inspection of the cleaner and belt can determine:

• If the spring length is the correct length for optimal tensioning.

• If the belt looks clean or if there are areas that are dirty.

• If the blade is worn out and needs to be replaced.

• If there is damage to the blade or other cleaner components.

• If fugitive material is built up on the cleaner or in the transfer area.

• If there is cover damage to the belt.

• If there is vibration or bouncing of the cleaner on the belt.

• If a snub pulley is used, a check should be made for material buildup on the pulley.

If any of the above conditions exist, a determination should be made on when the conveyor can be stopped

for cleaner maintenance.

6.3 Routine Physical Inspection (every 6-8 weeks)

When the conveyor is not in operation and properly locked and tagged out a physical inspection of the

cleaner to perform the following tasks:

• Clean material buildup off of the cleaner blade and pole.

• Closely inspect the blade for wear and any damage. Replace if needed.

• Check both cartridges for proper installation and condition. Replace if needed.

• Ensure full blade to belt contact.

• Inspect the cleaner pole for damage.

• Inspect all fasteners for tightness and wear. Tighten or replace as needed.

• Replace any worn or damaged components.

• Check the tension of the cleaner blade to the belt. Adjust the tension if necessary using the chart on

the cleaner or the one on Page 11.

• When maintenance tasks are completed, test run the conveyor to ensure the cleaner is performing

properly.

14 MHCP Primary Cleaner

6.4 Blade Replacement Instructions

Section 6 – Maintenance

Physically lock out and tag the conveyor at the power source

before you begin cleaner installation.

Tools Needed:

• Tape measure

• (2) 19mm wrench or crescent wrench

• 17mm wrench or crescent wrench

• (1) 14mm wrench or crescent wrench

• Wire brush (for cleaning pole)

• Small putty knife (for cleaning pole)

1. Remove the tension. Loosen the adjusting nuts on both sides and

turn them out until they are flush with ends of the pivot arm

(Fig. 1) or release pressure from air/nitrogen control unit. This

releases the tension of the blade on the belt.

2. Remove the worn blade cartridge. Remove two bolts on each end of

cartridge and remove the cartridge from the pole (Fig. 2). Clean all

fugitive material from the pole.

NOTE: If cartridge is hard to remove use a screwdriver or hammer to

loosen it and then remove.

Slide pole to center

blades or cover

belt’s material path

Remove blade

stop to slide

blade(s) off if

necessary

Tighten locking bolts and

jam nuts (both ends)

Pivot Rod

Bushings

Adjusting

Nuts

Washer

Torque

Arm

Torque

Pivot Rod

Pivot Rod Base

Torque Pivot

Rod

Chute

Wall

(cut

away)

Pivot Rod

Mounting Bolt

Pivot rod against slot

end nearest the pole

Tighten

locking bolts

and

jam

nuts

Fig. 1

MHCP Primary Cleaner SuperShear™ Replacement Blade

and Cartridge

Blade

Cartridge

6" of pole end

must extend

outside the

mounting base

on each side

Align holes

and install

bolts, washers

and nuts

Fig. 2

150mm of pole

end must

extend outside

the mounting

base on

each side

15

6.4 Blade Replacement Instructions (cont.)

Section 6 – Maintenance

4. Install the new cartridge. Slide the new cartridge onto the pole.

Align holes on pole and cartridge then install bolts, washers and

nuts to lock in cartridge (Fig. 4).

5. Reset the correct blade tension. Refer to the chart for the spring

length/kPa required for the belt width. For PST lightly pull the

pivot arm toward the end of the torque arm slot nearest the pole

and turn the adjusting nuts until the required spring length is

achieved (Fig. 5). Tighten jam nut. NOTE: The chart is also on the

cleaner’s pivot shaft bracket for future reference for retensioning

maintenance.

Test run the cleaner. Run the conveyor for at least 15 minutes and inspect the cleaning performance. Check the spring

length for proper tensioning. Make adjustments as necessary.

3. Change blades on cartridge. Be sure to install all new blades to

ensure even cleaning. To remove blades, unlock blade stop, remove

handle and loosen cartridge expansion bolts. Clean cartridge

before installing new blades. Install new blades then tighten

cartridge expansion bolts and reinstall blade stop handle (Fig. 3).

Cartridge

Expansion Bolts

Handle

Blade

Stop

Fig. 3

Blade

Cartridge

6" of pole end

must extend

outside the

mounting base

on each side

Align holes

and install

bolts, washers

and nuts

Fig. 4

Locking Bolts

And Jam Nuts

Collapse

Air Bags

Connect lines

from air bags

Connect line

from site supply

Air/Water Control Box

Connect lines

from air bags

Connect line

from site

supply

Nitrogen Regulator

o

f Washer

o

rque Arm

Measure

from top

of washer

to top of

torque arm.

Fig. 5

6" del eje

y se debe

extender fuera

de la base de

montaje de

cada lado

150mm of pole

end must

extend outside

the mounting

base on

each side

Spring Length Chart

Blade

Width No. Of

Blades

White

Springs

Silver

Springs

Red

Springs

mm in. mm in. mm in. mm in.

450 18" 3 146 5 3/4" 162 6 3/8" 165 6 1/2"

600 24" 4 137 5 3/8" 159 6 1/4" 162 6 3/8"

750 30" 5 130 5 1/8" 156 6 1/8" 162 6 3/8"

900 36" 6 121 4 3/4" 156 6 1/8" 159 6 1/4"

1050 42" 7 114 4 1/2" 152 6" 159 6 1/4"

1200 48" 8 N/A N/A 149 5 7/8" 156 6 1/8"

1350 54" 9 N/A N/A 146 5 3/4" 156 6 1/8"

1500 60" 10 N/A N/A 146 5 3/4" 152 6"

1650 66" 11 N/A N/A 144 5 5/8" 152 6"

1800 72" 12 N/A N/A 140 5 1/2" 149 5 7/8"

1950 78" 13 N/A N/A 130 5 1/8" 146 5 3/4"

2100 84" 14 N/A N/A N/A N/A 146 5 3/4"

2250 90" 15 N/A N/A N/A N/A 144 5 5/8"

2400 96" 16 N/A N/A N/A N/A 140 5 1/2"

2550 102" 17 N/A N/A N/A N/A 140 5 1/2"

Spring tension is based on the number of blades on the

cleaner, not the belt width. Shading indicates preferred

spring option.

Pressure Chart

Blade

Width No. of

Blades kPamm in.

450 18" 3 55.2

600 24" 4 69.0

750 30" 5 89.6

900 36" 6 103.4

1050 42" 7 124.1

1200 48" 8 137.9

1350 54" 9 158.6

1500 60" 10 172.4

1650 66" 11 193.1

1800 72" 12 213.7

1950 78" 12 227.5

2100 84" 14 248.2

2250 90" 15 262.0

kPa setting is based on the number

of blades on the cleaner, not the

belt width.

16 MHCP Primary Cleaner

6.5 Maintenance Log

Section 6 – Maintenance

Conveyor Name/No. _________________________

Date: ___________________ Work done by: ___________________ Service Quote #: ___________________

Activity:_____________________________________________________________________________________

_____________________

Date: ___________________ Work done by: ___________________ Service Quote #: ___________________

Activity:_____________________________________________________________________________________

_____________________

Date: ___________________ Work done by: ___________________ Service Quote #: ___________________

Activity:_____________________________________________________________________________________

_____________________

Date: ___________________ Work done by: ___________________ Service Quote #: ___________________

Activity:_____________________________________________________________________________________

_____________________

Date: ___________________ Work done by: ___________________ Service Quote #: ___________________

Activity:_____________________________________________________________________________________

_____________________

Date: ___________________ Work done by: ___________________ Service Quote #: ___________________

Activity:_____________________________________________________________________________________

_____________________

Date: ___________________ Work done by: ___________________ Service Quote #: ___________________

Activity:_____________________________________________________________________________________

_____________________

Date: ___________________ Work done by: ___________________ Service Quote #: ___________________

Activity:_____________________________________________________________________________________

_____________________

17

6.6 Cleaner Maintenance Checklist

Section 6 – Maintenance

Site: _____________________________ Inspected by: ______________________________ Date: _____________________________

Belt Cleaner: _____________________________________________ Serial Number: _________________________________________

Beltline Information:

Beltline Number: ____________________ Belt Condition: _______________________________________________________________

Belt Width: ¨600mm ¨750mm ¨900mm ¨1050mm ¨1200mm ¨1350mm ¨1500mm ¨1800mm ¨2100mm ¨2400mm

Head Pulley Diameter (Belt & Lagging):__________ Belt Speed:________ fpm Belt Thickness: __________

Belt Splice:__________ Condition of Splice:_________ Number of Splices:________ ¨Skived ¨Unskived

Material conveyed: ________________________________________________________________________________________________

Days per week run:_______________ Hours per day run:_______________

Blade Life:

Date blade installed:___________ Date blade inspected:___________ Estimated blade life:____________

Is blade making complete contact with belt? ¨Yes ¨No

Distance from wear line: Left _________ Middle _________ Right _________

Blade condition: ¨Good ¨Grooved ¨Smiled ¨Not contacting belt ¨Damaged

Measurement of spring: Required _________ Currently _________

Was Cleaner Adjusted: ¨Yes ¨No

Pole Condition: ¨Good ¨Bent ¨Worn

Lagging: ¨Side Lag ¨Ceramic ¨Rubber ¨Other ¨None

Condition of lagging: ¨Good ¨Bad ¨Other

Cleaner's Overall Performance: (Rate the following 1 - 5, 1= very poor - 5 = very good)

Appearance:¨Comments:____________________________________________________________________________________

Location:¨Comments:____________________________________________________________________________________

Maintenance:¨Comments:____________________________________________________________________________________

Performance:¨Comments:____________________________________________________________________________________

Other comments __________________________________________________________________________________________________

________________________________________________________________________________________________________________

________________________________________________________________________________________________________________

________________________________________________________________________________________________________________

________________________________________________________________________________________________________________

________________________________________________________________________________________________________________

________________________________________________________________________________________________________________

18 MHCP Primary Cleaner

Section 7 – Troubleshooting

Problem Possible Cause Possible Solutions

Poor cleaning

performance

Cleaner under-tensioned Adjust to correct tension – see spring length/kPa chart

Cleaner over-tensioned Adjust to correct tension – see spring length/kPa chart

Cleaner installed in wrong location Verify "C" dimension, relocate to correct dimension

Cleaner blade worn or damaged Replace cleaner blade

Rapid Blade Wear

Tension on cleaner too high/low Adjust to correct tension – see spring length/kPa chart

Cleaner not located correctly Check cleaner location for correct dimensions

Blade attack angle incorrect Check cleaner location for correct dimensions

Material too abrasive for blade Option: switch to alternate cleaner with metal blades

Mechanical splice damaging blade Repair, skive or replace splice

Centre wear on blade

(smile eect)

Blade wider than material path Replace blade with width to match material path

Tension on cleaner too high/low Adjust to correct tension – see spring length/kPa chart

Unusual wear or

damage to blade

Mechanical splice damaging blade Repair, skive or replace splice

Belt damaged or ripped Repair or replace belt

Cleaner not correctly located Verify "C" dimension, relocate to correct dimension

Damage to pulley or pulley lagging Repair or replace pulley

Vibration or noise

Cleaner not located correctly Verify "C" dimension, relocate to correct dimension

Blade attack angle incorrect Verify "C" dimension, relocate to correct dimension

Cleaner running on empty belt Use a spray pole when the belt is empty

Cleaner tension too high/low Adjust to correct tension or slight adjust to diminish

Cleaner locking bolts not secure Check and tighten all bolts and nuts

Cleaner not square to head pulley Verify "C" dimension, relocate to correct dimension

Material buildup in chute Clean up build-up on cleaner and in chute

Cleaner being pushed

away from pulley

Cleaner tension not set correctly Ensure correct tension/increase tension slightly

Sticky material is overburdening cleaner Increase tension; replace with cleaner with metal tips;

replace with larger size cleaner

Cleaner not set up correctly Conrm location dimensions are equal on both sides

19

8.1 Specications & Guidelines

Clearance Guidelines for Installation

Horizontal

Clearance Required

Vertical

Clearance Required

mm in. mm in.

175 7 475 19

Telescoping Pole Length Specifications

Cleaner Size

Max Overall

Pole Length

Centre Pole

Length

Maximum

Conveyor Span

mm in. mm in. mm in. mm in.

600 24 2050 82 700 28 1650 66

750 30 2200 88 850 34 1800 72

900 36 2350 94 1000 40 1950 78

1050 42 2500 100 1150 46 2100 84

1200 48 2650 106 1300 52 2250 90

1350 54 2800 112 1450 58 2400 96

1500 60 2950 118 1600 64 2550 102

1800 72 3250 130 1900 76 2850 114

2100 84 3550 142 2200 88 3150 126

Pole Diameter - 73mm

Pole Location Chart

A X Y C

500 254 365 445

525 267 365 451

550 279 365 460

575 292 365 467

600 305 365 476

625 318 365 483

650 330 365 492

675 343 365 502

700 356 365 511

725 368 365 518

750 381 365 527

775 394 365 537

800 406 365 546

825 419 365 556

850 432 365 565

875 445 365 575

900 457 365 584

925 470 365 594

950 483 365 606

975 495 365 616

1000 508 365 625

1025 521 365 635

1050 533 365 648

1075 546 365 657

1100 565 365 673

1125 581 365 686

1150 597 365 699

1175 610 365 711

1200 625 365 724

Specications:

• Maximum Belt Speed..........................................6 m/s

• Temperature Rating.............................................-35°C to 82°C

• Minimum Pulley Diameter ................................500 mm

• Blade Height.........................................................350 mm

• Useable Blade Wear Length................................200 mm

• Blades ....................................................................Polyurethane (proprietary blend for

abrasion resistance and long wear).

• Available for Belt Widths....................................600 to 2100 mm

Other sizes available upon request.

• CEMA Cleaner Rating........................................Class 5

Maximum Overall Pole Length

Maximum Conveyor Span

Centre Pole Length

Top of

washer to

top of

torque

arm

Pole Location Specs

A = Pulley Diameter + Lagging and Belt

C = Critical Spec to move location if necessary

AX

CY

Move Dim. C

on arc

Section 8 – Specs and CAD Drawings

Vertical

Horizontal

Spring Length Chart

Blade

Width No. Of

Blades

White

Springs

Silver

Springs

Red

Springs

mm in. mm in. mm in. mm in.

450 18" 3 146 5 3/4" 162 6 3/8" 165 6 1/2"

600 24" 4 137 5 3/8" 159 6 1/4" 162 6 3/8"

750 30" 5 130 5 1/8" 156 6 1/8" 162 6 3/8"

900 36" 6 121 4 3/4" 156 6 1/8" 159 6 1/4"

1050 42" 7 114 4 1/2" 152 6" 159 6 1/4"

1200 48" 8 N/A N/A 149 5 7/8" 156 6 1/8"

1350 54" 9 N/A N/A 146 5 3/4" 156 6 1/8"

1500 60" 10 N/A N/A 146 5 3/4" 152 6"

1650 66" 11 N/A N/A 144 5 5/8" 152 6"

1800 72" 12 N/A N/A 140 5 1/2" 149 5 7/8"

1950 78" 13 N/A N/A 130 5 1/8" 146 5 3/4"

2100 84" 14 N/A N/A N/A N/A 146 5 3/4"

2250 90" 15 N/A N/A N/A N/A 144 5 5/8"

2400 96" 16 N/A N/A N/A N/A 140 5 1/2"

2550 102" 17 N/A N/A N/A N/A 140 5 1/2"

Spring tension is based on the number of blades on the cleaner, not the

belt width. Shading indicates preferred spring option.

Pressure Chart

Blade

Width No. of

Blades kPamm in.

450 18" 3 55.2

600 24" 4 69.0

750 30" 5 89.6

900 36" 6 103.4

1050 42" 7 124.1

1200 48" 8 137.9

1350 54" 9 158.6

1500 60" 10 172.4

1650 66" 11 193.1

1800 72" 12 213.7

1950 78" 12 227.5

2100 84" 14 248.2

2250 90" 15 262.0

kPa setting is based on the number

of blades on the cleaner, not the

belt width.

20 MHCP Primary Cleaner

Section 8 – Specs and CAD Drawings

8.2 CAD Drawing - MHCP PST

Cleaner Blade

Width "A" No. Of

Blades

75929 600 450 3

75930 750 600 4

75931 900 750 5

75932 1050 900 6

75933 1200 1050 7

75934 1350 1200 8

75935 1500 1350 9

75936 1800 1650 11

76800 2100 1950 13

78955 2400 2250 15

POLE LOCATION CHART

Diameter X Y C

500 254 365 445

525 267 365 451

550 279 365 460

575 292 365 467

600 305 365 476

625 318 365 483

650 330 365 492

675 343 365 502

700 356 365 511

725 368 365 518

750 381 365 527

775 394 365 537

800 406 365 546

825 419 365 556

850 432 365 565

875 445 365 575

900 457 365 584

925 470 365 594

950 483 365 606

975 495 365 616

1000 508 365 625

1025 521 365 635

1050 533 365 648

1075 546 365 657

1100 565 365 673

1125 581 365 686

1150 597 365 699

1175 610 365 711

1200 625 365 724

365

530

"A" + 254mm

Table of contents

Other Flexco Ultrasonic Jewelry Cleaner manuals