FlexiForce RS200 Instruction Manual

RS200 manual GB 2009 www.flexiforce.com

1

manual GB

rev.0 Feb-09

RS200

Hardware system for

residential (garage)

overhead doors

Built-in height 200mm, springs in front

INSTALLATION / MAINTENANCE / USAGE

© All rights reserved. FlexiForce® 2009

RS200 manual GB 2009 www.flexiforce.com

2

manual GB

rev.0 Feb-09

ATTENTION! GENERAL WARNING!

To install, use and maintain this door system safely, a number of precautions

must be taken. For the safety of all concerned, pay heed to the warnings and

instructions given below! If in doubt, contact your supplier.

SPECIAL SAFETY WARNINGS OR REMARKS IN THIS MANUAL ARE INDICATED

WITH THIS SYMBOL. READ THESE WARNINGS CAREFULLY!

9This manual has been written for use by experienced fitters and as such is not suitable for

d.i.y. purposes or for use by trainee fitters.

9This manual describes the installation of the hardware set components, door sections

(panels) and refers to installation manuals of the electrical operator. Be sure to

supplement this manual if needed with instructions for any additional components not

described in this manual.

9Before starting, read this manual carefully!

9Certain components may be sharp or have jagged edges. As such you are advised to wear

safety gloves.

9All the components which have been supplied are designed for use with this specific

overhead door. Replacement or adding additional components may have an adverse effect

on the safety of, and the guarantee on, the door. Also the CE-approval which has been

granted to this door will be cancelled when components are changed or installation is not

done according to this manual! Installer is responsible for this.

9Ensure that there is sufficient light during installation. Remove obstacles and dirt. Make

sure that there is no one else present other than the fitters. Other people (children!) may

get in the way or endanger themselves during the installation.

GUARANTEE, CONDITIONS AND TERMS

The general terms and conditions of delivery and payment issued by the Metaalunie and designated as

METAALUNIE CONDITIONS are fully applicable to all our quotations, contracts and their

implementation. We expressly reject all other terms and conditions. On request we will send you a copy

of these terms and conditions free of charge. A copy may also be downloaded from our website

www.flexiforce.com.

FlexiForce strives to deliver 100 % in conformance with the order. In practice, in spite of all our controls,

this is not always possible. However we will rectify any errors as quickly as possible, in order to minimise

the inconvenience caused to you or the user. As such, it is important that you inform us as soon as possible

about any problem with the delivery (include the order number and week of production) and give us the

opportunity to offer a suitable solution.

FlexiForce will only reimburse third party costs if we have given explicit permission for this in advance. The

reimbursement is based on normal rates and travelling expenses over distances of 1 hour away at most.

For large-scale projects we strongly advise you to first install 1 door completely before installing the other

doors. In this way, any errors can be detected early on and rectified comparatively cheaply.

This manual does not confer any rights. Technical modifications may be made without written notice.

FlexiForce has endeavoured to design and put together this hardware set in conformance with the

applicable CE-norms. However, we recommend to check our configuration against any local national

specification.

RS200 manual GB 2009 www.flexiforce.com

3

manual GB

rev.0 Feb-09

FlexiForce has applied the mandated INITIAL TYPE TESTING for doors described in this manual, at the

SP-Institute in Sweden (as Notified Body Nr. 0402). The INITIAL TYPE TESTING REPORT that has been

rewarded, can be transferred to the door producing company. This is needed to complete your CE files

according to product standard EN13241-1. Contact FlexiForce for acquiring this report.

APPLICATION RANGE

FlexiForce has developed a new hardware system for garage overhead doors. The system includes the

following features:

•Suitable for single and double garages, Wmax = 5.000 mm, Hmax = 3.000 mm.

•For double doors, the horizontal track set can be reinforced with side plate RX560L/R

•Advised max door weight is 165 kg. Each spring break device is approved to 125kg.

•CE approved when selecting the proper FlexiForce components.

We wish you every success with the installation of this hardware set. If anything is unclear or should

you have queries, you should of course contact Flexi-Force B.V. or your supplier.

This set has to be completed with the assembled door sections. Panels brands and types according to

the list of approved panels.

NB! FlexiForce has introduced a new system for shaft installation, so called SUPERCLICK®.

There is a separate manual available for this system (attachment). In this manual, the

SuperClick® system is marked with this sign:

NB! FlexiForce recommends to apply our “light” hardware range for garage doors. In this manual

only “light” components are selected.

Attention! In this set, the fixing material required to install the track set to the building is not

included. It is the responsibility of the qualified door installer to make sure that the building

(stone, concrete, wood, etc.) is strong enough at the points of fixation to ensure a reliable

construction. The door installer has to select proper fixing materials.

RECOMMENDED ADDITIONAL MANUALS

RS200 manual GB 2009 www.flexiforce.com

4

manual GB

rev.0 Feb-09

IN THIS MANUAL:

-Attention, general warnings 2

-Guarantee, terms and conditions 2

-Applicationrange 3

-Recommended additional manuals 3

-Tools for correct and rapid assembly 5

-Applied fixation materials 5

-RS200 System overview 6

-Installing vertical track system 7

-Installing horizontal track system 8

-Shaft system installation 11

-Panel <> Hardware installation 14

-Cables & Torsion springs 17

-Finishingthedoor 19

-Optional: E-operation 23

-Panelassembly 24

-Troubleshooting 27

-Dismantling the overhead door 28

-Maintenance and replacement of parts 29

RS200 manual GB 2009 www.flexiforce.com

5

manual GB

rev.0 Feb-09

TOOLS FOR CORRECT AND RAPID ASSEMBLY

(Battery) drill with Bit 4,0 mm

Bit 4,5 mm

Bit 6,5 mm

Plug 10 mm

Plug13mm

Hexagonal key 4 mm

Socket screw spanner 8mm (in)

Ring /open ended spanner 10 mm

Ring /open ended spanner 13 mm

Ring /open ended spanner 15 mm

Ring /open ended spanner 17 mm

Socket wrench with ¼” square

Wrench

Gluing clamp

Cord

Water level (hose)

2 blocks of ca. 20 en 40mm in height

Measuring equipment

APPLIED FIXATION MATERIALS

The applicable fixation material is described in the drawings of this manuals. Below an overview

of the applied fasteners and optional alternatives.

1055BV, self-tapping screw Alternatives: 1055D, screw, 6,3x25mm, with drill-point

Max torque 10Nm, key 10 1053BV, screw 6,3x35mm

1053D, screw 6,3x35mm, with drill-point

1054-25, 1054-35, screw with socket hex cap, drill point

1054W-25, 1054W-35, screw with socket hex cap (RAL9010)

Optional: 1055CAP10, white (RAL9010) cover for screws (key 10)

1070B35, bolt M8x25 1006B, press bolt 1062B, bolt M6x16

1068M, nut M8 1062M, nut M6 1062M, nut M6

Max. torque 13Nm, key 13 Max. torque 9,1Nm, key 10 Max. torque 5,3Nm, key 10

1071BC, bolt M8x12, SuperClick® secure bolt NB! Fixation material for installing to wall and

Max. torque 10Nm, key 13 ceiling is not included in this manual!

RS200 manual GB 2009 www.flexiforce.com

6

manual GB

rev.0 Feb-09

RS200 SYSTEM OVERVIEW

B = H – 175mm for manual operated doors

B = H – 0mm for e-operated doors

Shaft system

with torsion springs, spring break devices

drums, spring fittings, cables, etc.

RS200H10etc.

Horizontal double track set

Connection horizontal

tracks

RSV10etc

Vertical set with track, side seal and

vertical angle

Door panels, sections

With end caps, hinges, bottom

brackets, bottom astragal and seal,

top roller carriers, windows, etc.

RS200 : top view

RS200 manual GB 2009 www.flexiforce.com

7

manual GB

rev.0 Feb-09

INSTALLING VERTICAL TRACK SYSTEM

RS200 manual GB 2009 www.flexiforce.com

8

manual GB

rev.0 Feb-09

VERTICAL TRACK SET

HORIZONTAL TRACK SET

OPTIONAL: REINFORCEMENT HORIZONTAL TRACK SET

For heavy doors, the horizontal track could be optionally reinforced with plate RX560R/L.

RS200 manual GB 2009 www.flexiforce.com

9

manual GB

rev.0 Feb-09

INSTALLATION WALL CONSOLES

Traditional installation

SuperClick® installation

RS200 manual GB 2009 www.flexiforce.com

10

manual GB

rev.0 Feb-09

CONNECTION HORIZONTAL TRACKS (OPTIONAL)

L = days opening width + 134mm

SUSPENSION HORIZONTAL TRACK TO CEILING

CLICK!

RS200 manual GB 2009 www.flexiforce.com

11

manual GB

rev.0 Feb-09

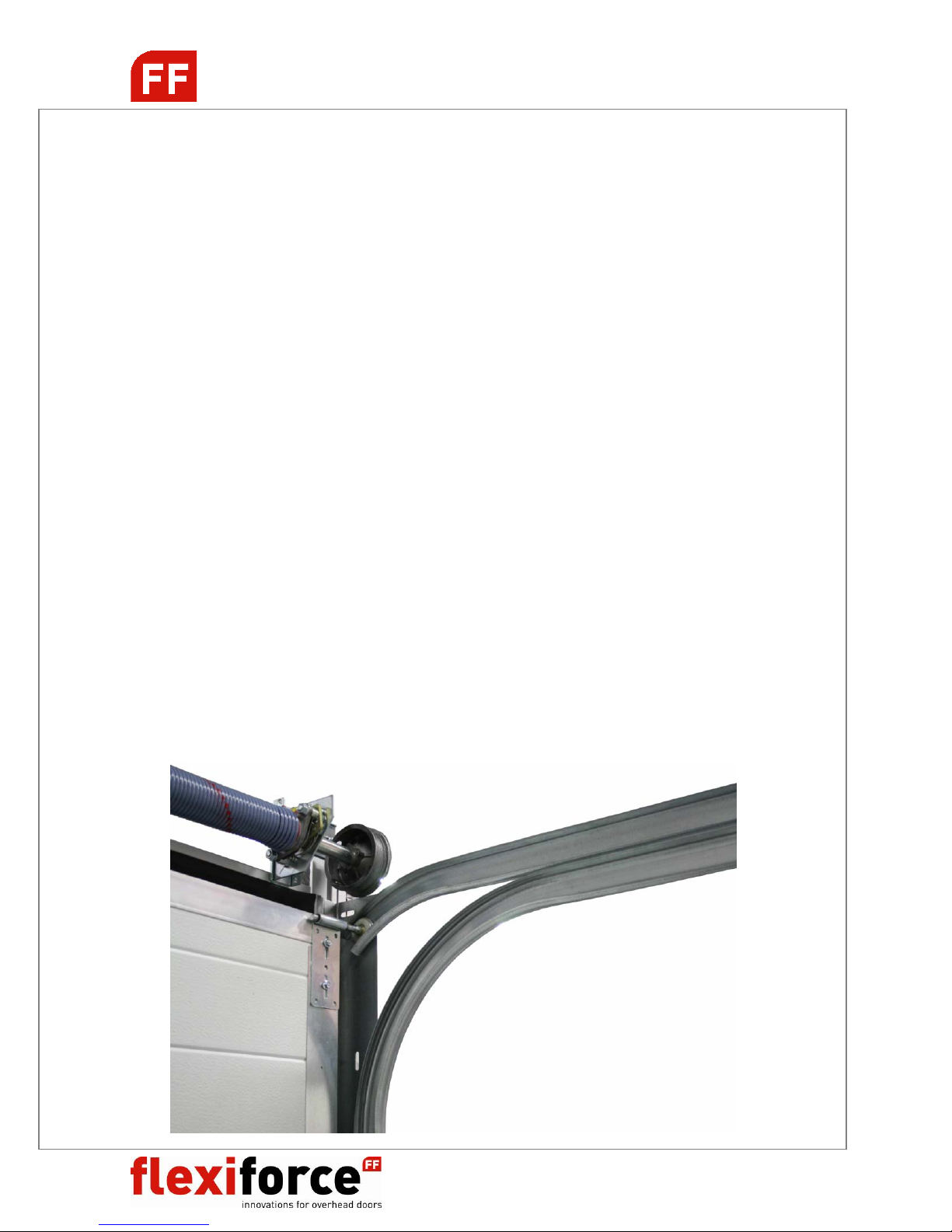

SHAFT SYSTEM INSTALLATION

DOOR W<3000mm

CENTRAL SHAFT SUSPENSION (3 ALTERNATIVES)

USA-MINI 312RM

312R

Central shaft suspension

Torsion springs

with spring fittings and spring break devices

Cable drums

No key-way: FF4X8, FF400-8(S), FF0402

Without key-way

tube shaft

RS200 manual GB 2009 www.flexiforce.com

12

manual GB

rev.0 Feb-09

SHAFT SYSTEM INSTALLATION

DOOR W>3000mm (double doors)

CENTRAL SHAFT SUSPENSION (W>3000mm)

Traditional installation SuperClick® installation

Torsion springs

with spring fittings and spring break devices

Cable drums

With key-way: FF-4-13, FF05NL12 etc.

Central shaft suspension

With coupler and 2 bearing plates

(310CL/CR or USA-MINI)

With key-way

tube key-wayed shaft

Max 23 Nm

RS200 manual GB 2009 www.flexiforce.com

13

manual GB

rev.0 Feb-09

FIXATION TO THE LINTEL

Traditional installation SuperClick® installation

RS200 manual GB 2009 www.flexiforce.com

14

manual GB

rev.0 Feb-09

PANEL <> HARDWARE INSTALLATION

RS200 manual GB 2009 www.flexiforce.com

15

manual GB

rev.0 Feb-09

Alternative hinges: 411-series

RS200 manual GB 2009 www.flexiforce.com

16

manual GB

rev.0 Feb-09

INSTALLATION TOP PANEL / TOP ROLLER CARRIER

Close the door and secure the door panel. Loosen the two self-tapping screws (1055BV) securing the

top roller holder (417S) so that it can be displaced with a slight tick. Press the top panel against the

side (upper) seal and slide the top roller holder as far as possible downwards and fix all screws.

(minimum play between door panel and seal). The bearing roller lies snugly in the rounding of the

bearing tracks.

Alternative top roller carrier: adjustable 419S-series

RS200 manual GB 2009 www.flexiforce.com

17

manual GB

rev.0 Feb-09

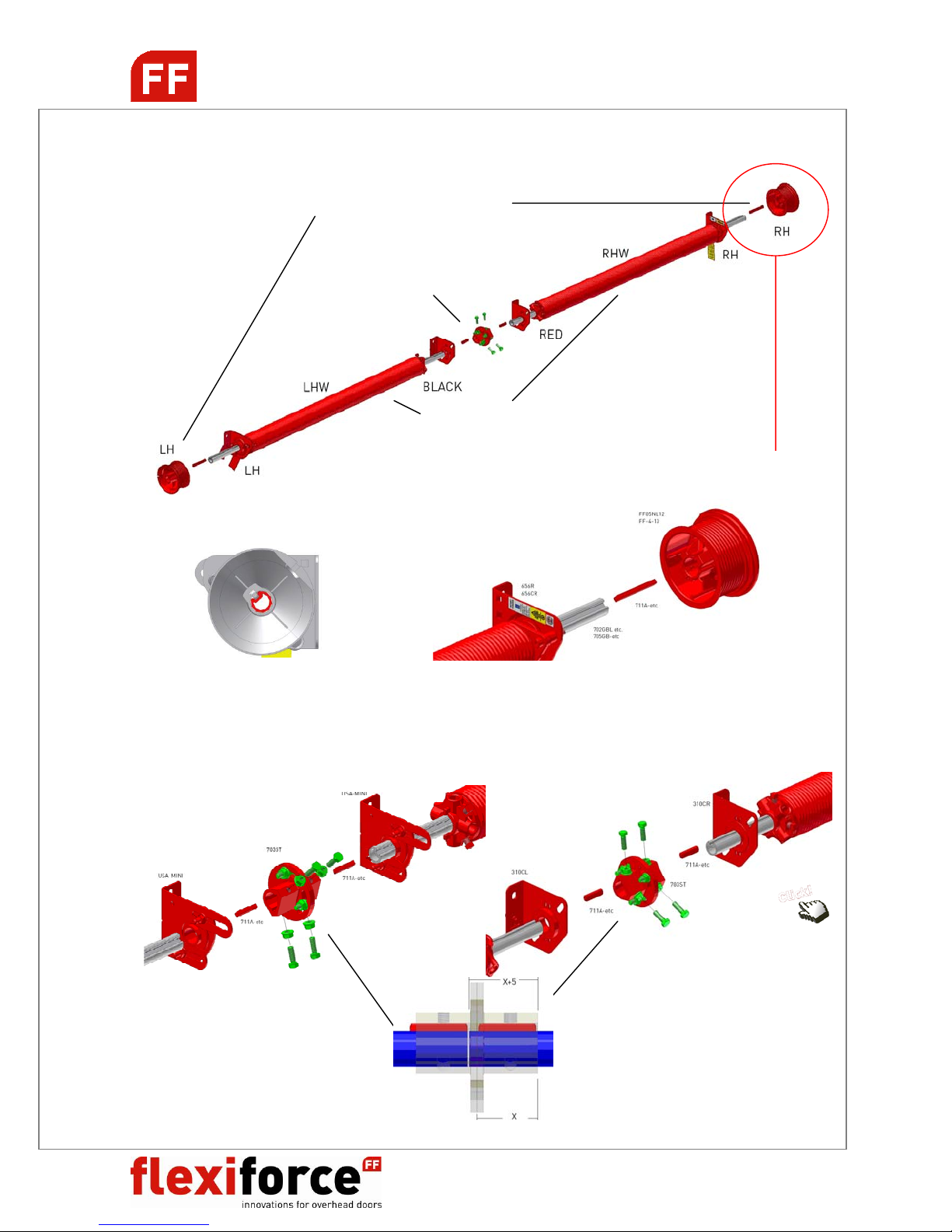

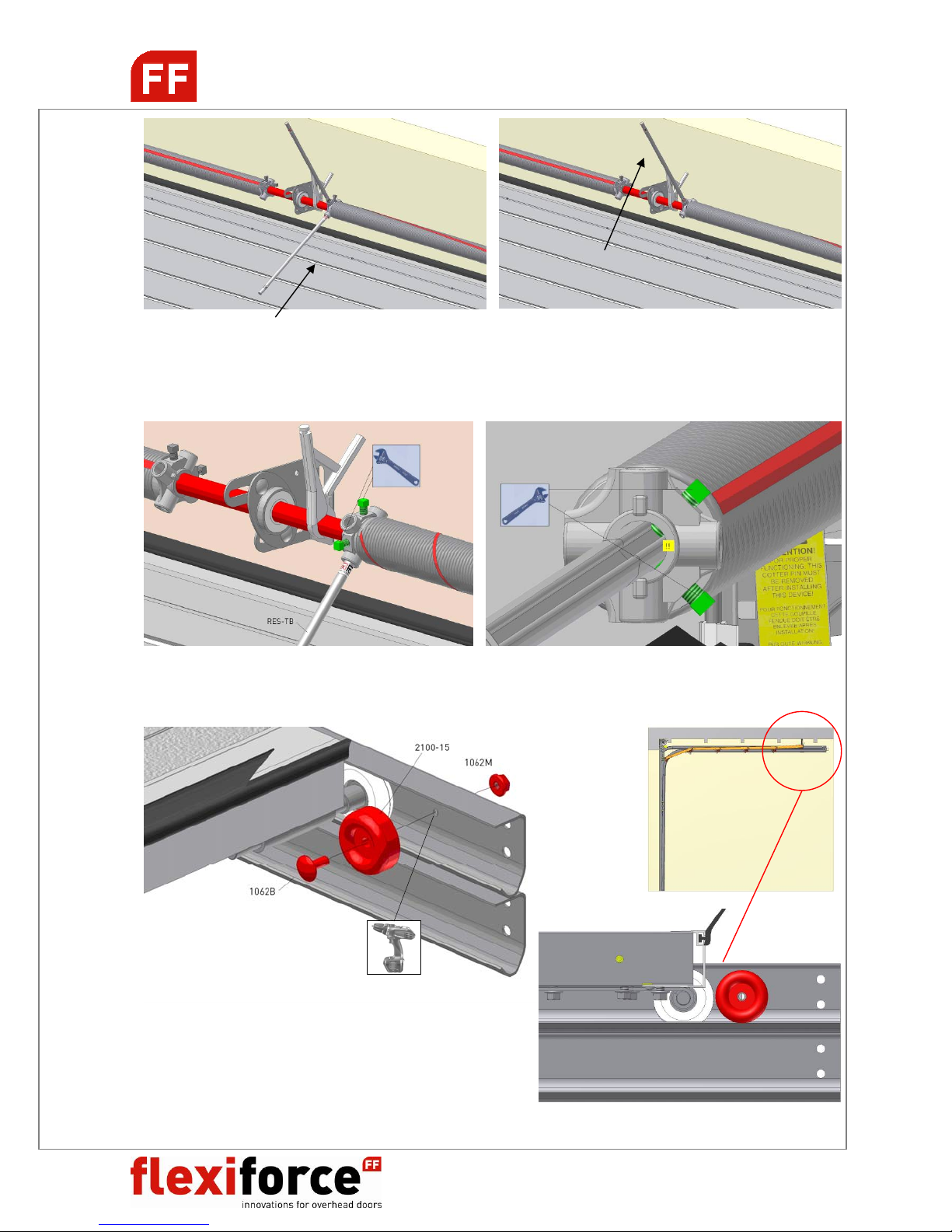

CABLES & TORSION SPRINGS

! Cable running behind the rollers to the cable drums

Without key-way: Fix shaft with clamp. Hook the cable connection in the drum.

Rotate the drum for winding the cable. Position drum on the shaft.

Max 10Nm

RS200 manual GB 2009 www.flexiforce.com

18

manual GB

rev.0 Feb-09

With key-way:

NB! See separate manual spring break device installation: 656Manual GB.pdf

TORSION SPRING TENSIONING

CAUTION!

Torsion springs are subject to considerable tension! Proceed at all times with extreme caution.

Installation, maintenance and repair should be carried out only by experienced and properly trained

overhead door fitters. Use correctly fitting and properly maintained tension levers (FlexiForce

code RES-TB).

Number of turns on the torsion springs:

Height (H) 4 panels 5 panels

2000mm 7.1 turns 6.8 turns

2125mm 7.6 turns 7.3 turns

2250mm 8.0 turns 7.7 turns

2375mm 8.4 turns 8.7 turns

2500mm 8.5 turns 9.2 turns

5 panels 6 panels

2750mm 9,4 turns 9,2 turns

3000mm 10,3 turns 10,0 turns

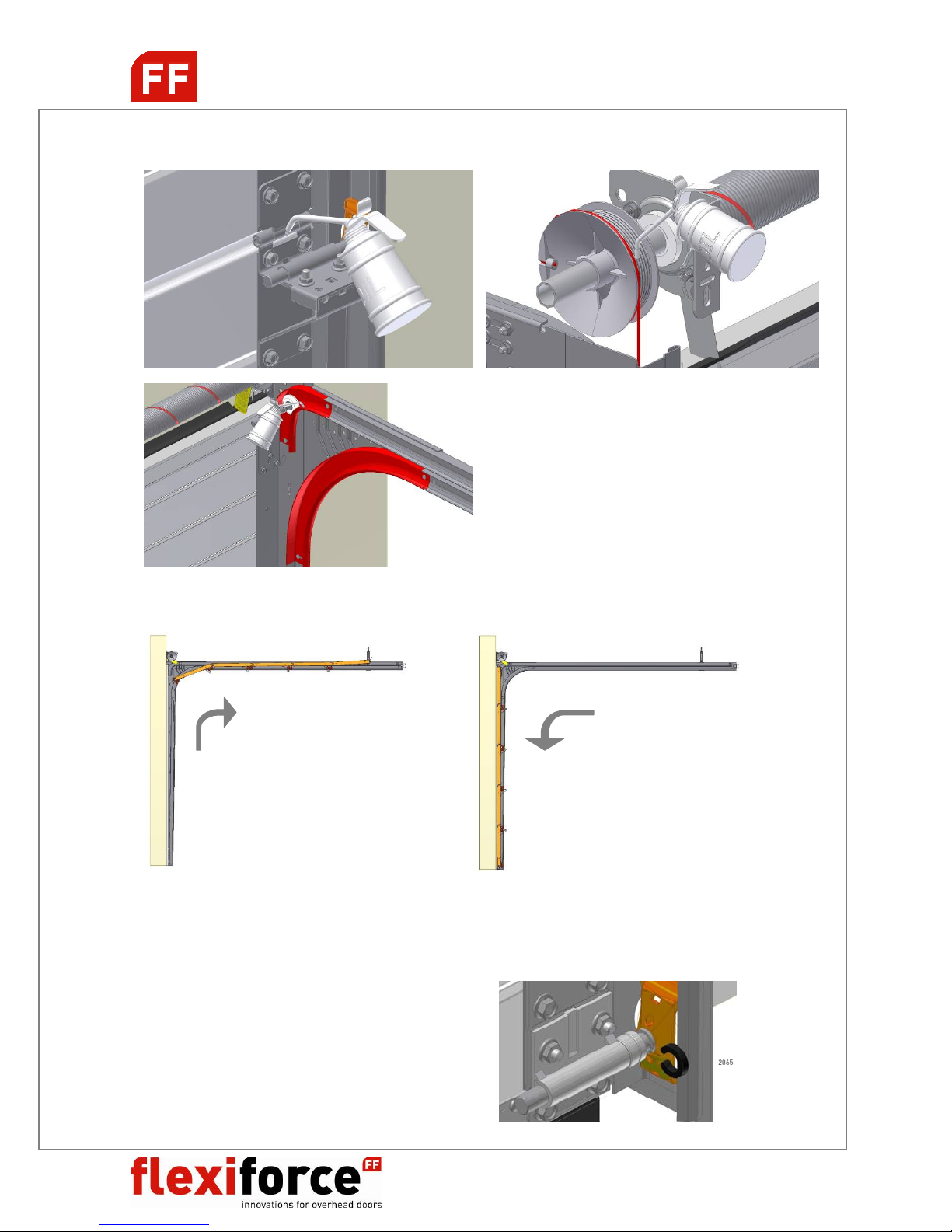

Insert the 1st tension lever completely into the slot. Turn the 1st tension lever a quarter turn such

that the spring is tensioned.

Max

23 Nm

RS200 manual GB 2009 www.flexiforce.com

19

manual GB

rev.0 Feb-09

Insert the 2nd lever completely into the next slot. Take over the tension of the spring from the 1st tension

lever to the 2nd tension lever. Remove the 1st tension lever from the slot. Turn the 1st tension lever a

quarter turn such the spring is tensioned. Repeat until number of turns is achieved. Then fix the spring

plug to the shaft. Check the door balance and adjust the springs if necessary (equally both springs!)

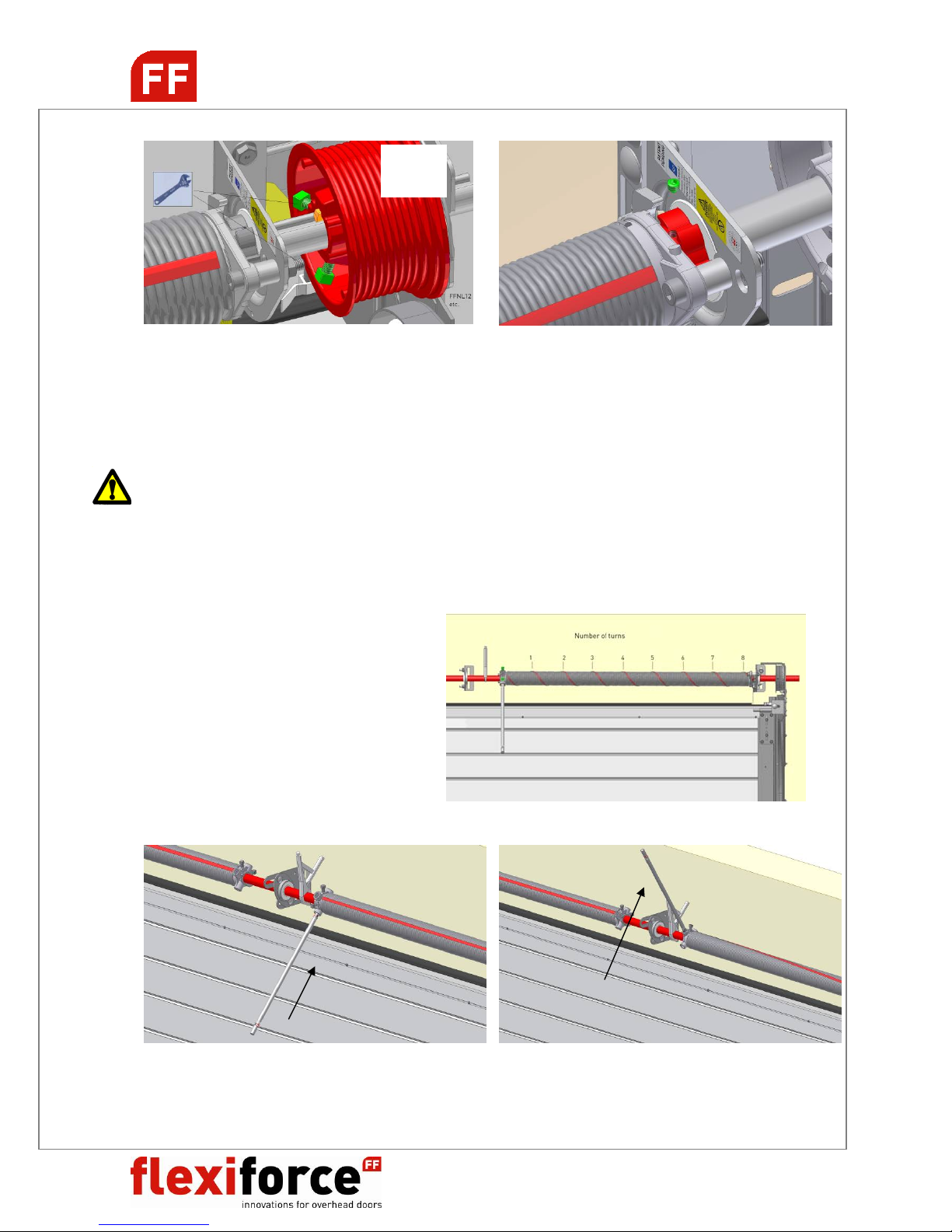

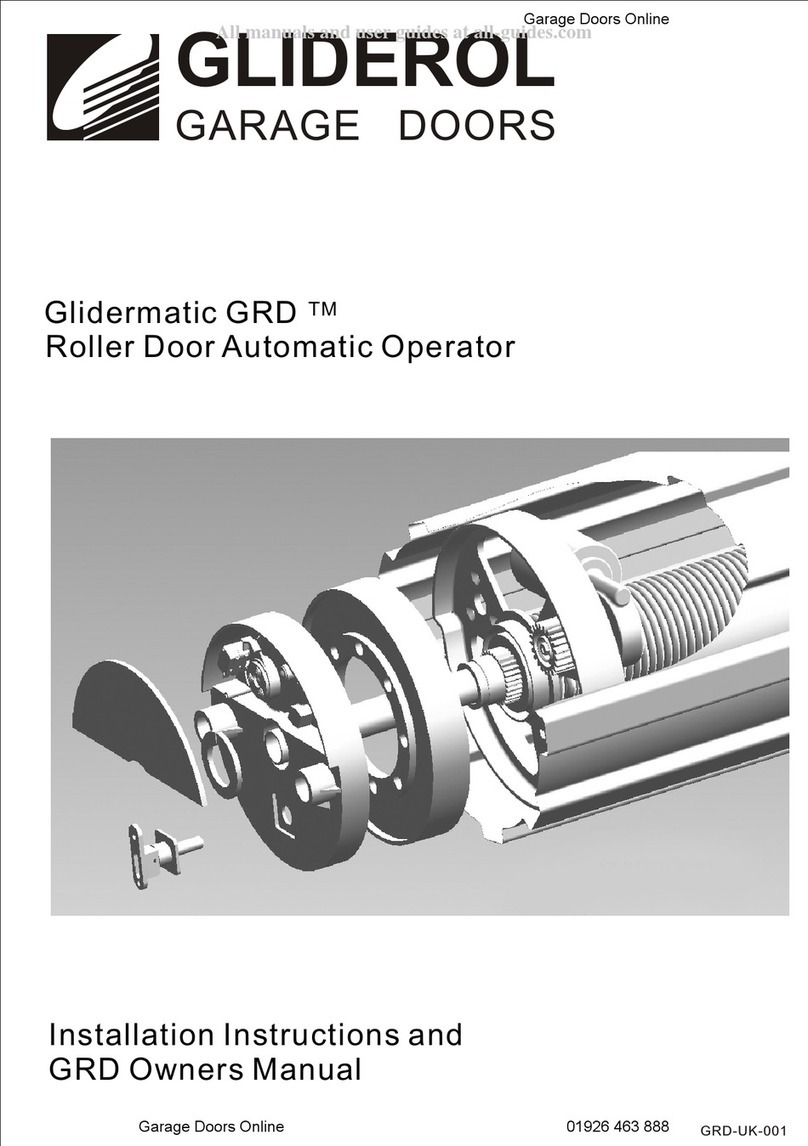

FINISHING THE DOOR

Max 25 Nm

RS200 manual GB 2009 www.flexiforce.com

20

manual GB

rev.0 Feb-09

GREASING DOOR PARTS

RE-ADJUSTING THE DOOR

Open and close the door for checking all the settings.

When the door panel is not hanging completely horizontally in the lifting cables in (almost) closed

conditions there are several options for fine adjustment.

A. Loosen the securing bolts of the cable drum and the drum relative to the tube shaft.

B. When a coupling is employed this may be adjusted to ensure a better horizontal setting.

Horizontal movement of the door can be limited

(to max. 5mm) by installing 2065 distance rings on the

roller shafts.

Table of contents

Other FlexiForce Garage Door Opener manuals

Popular Garage Door Opener manuals by other brands

Chamberlain

Chamberlain 9601 owner's manual

GOGOGATE

GOGOGATE Garage Door Opener user manual

Gliderol

Gliderol Glidermatic GRD installation instructions

SAMT

SAMT RGD350 Installation instructions and user guide

Quantum

Quantum 3214 Owner installation and user manual

Chamberlain

Chamberlain POWER DRIVE PD420 owner's manual