2

Fermod F2135 Floor Guided Sliding Door System

General Characteristics

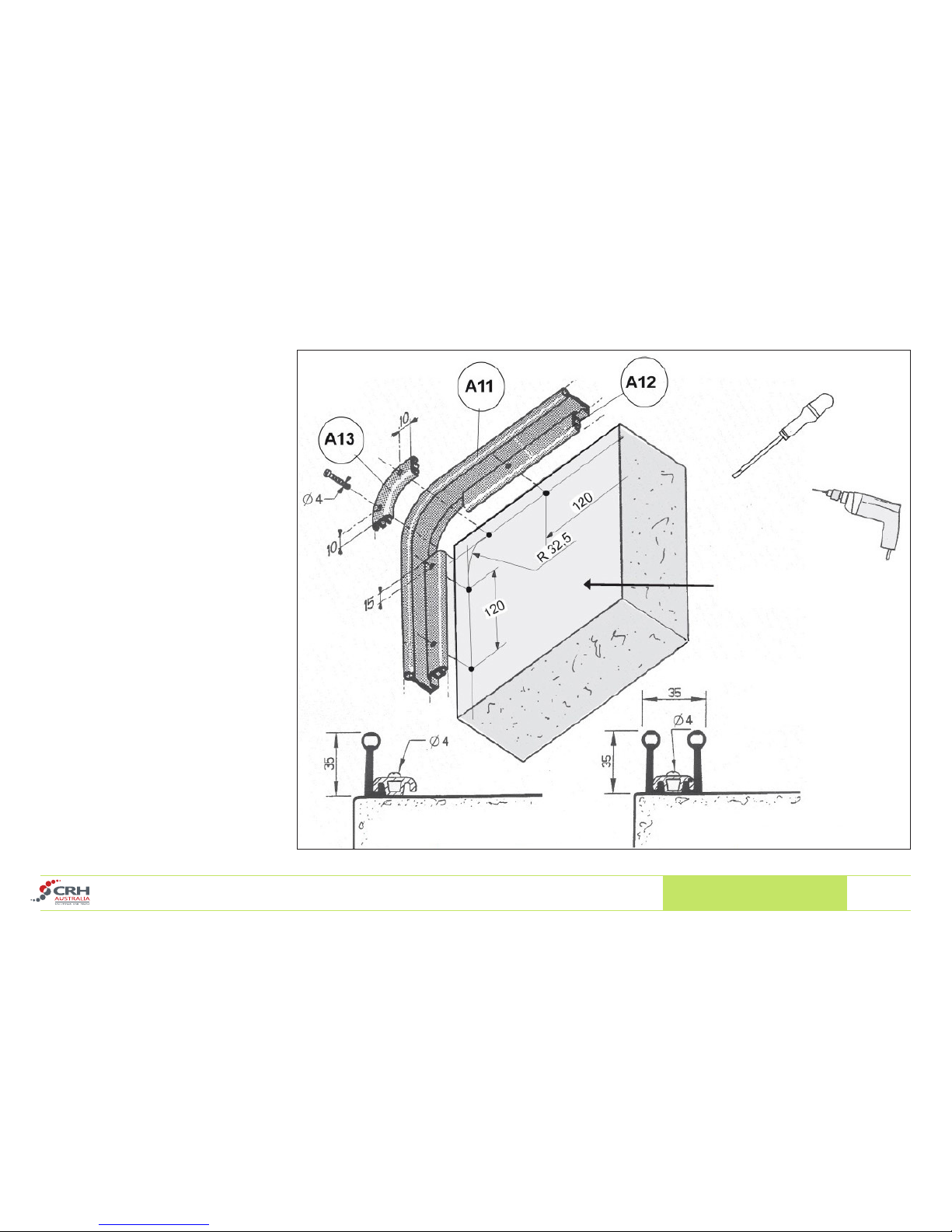

This is a manual system with an anodized rail designed to t horizontal sliding doors with specic characteristics, (isothermal, acoustical,

clean-rooms, dust tight).

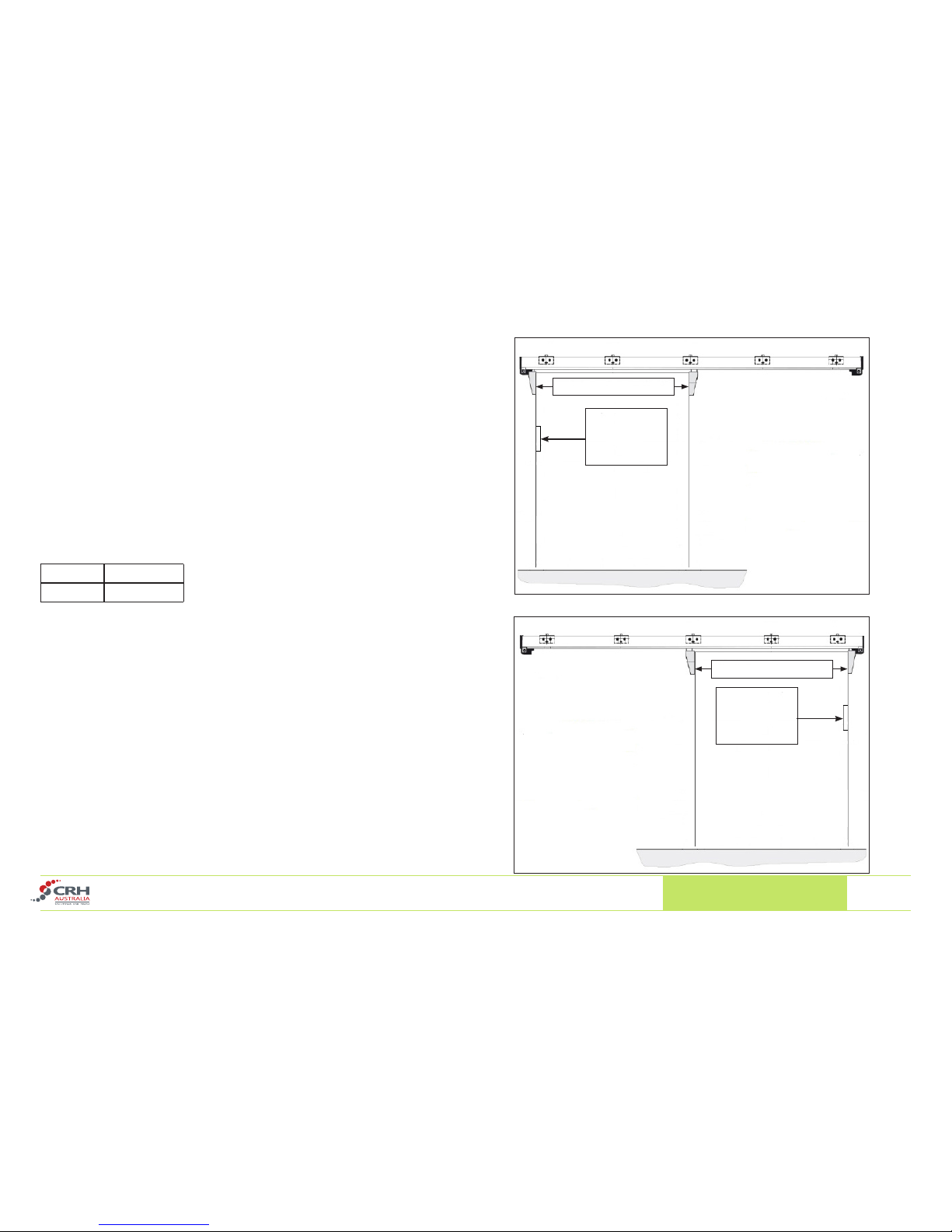

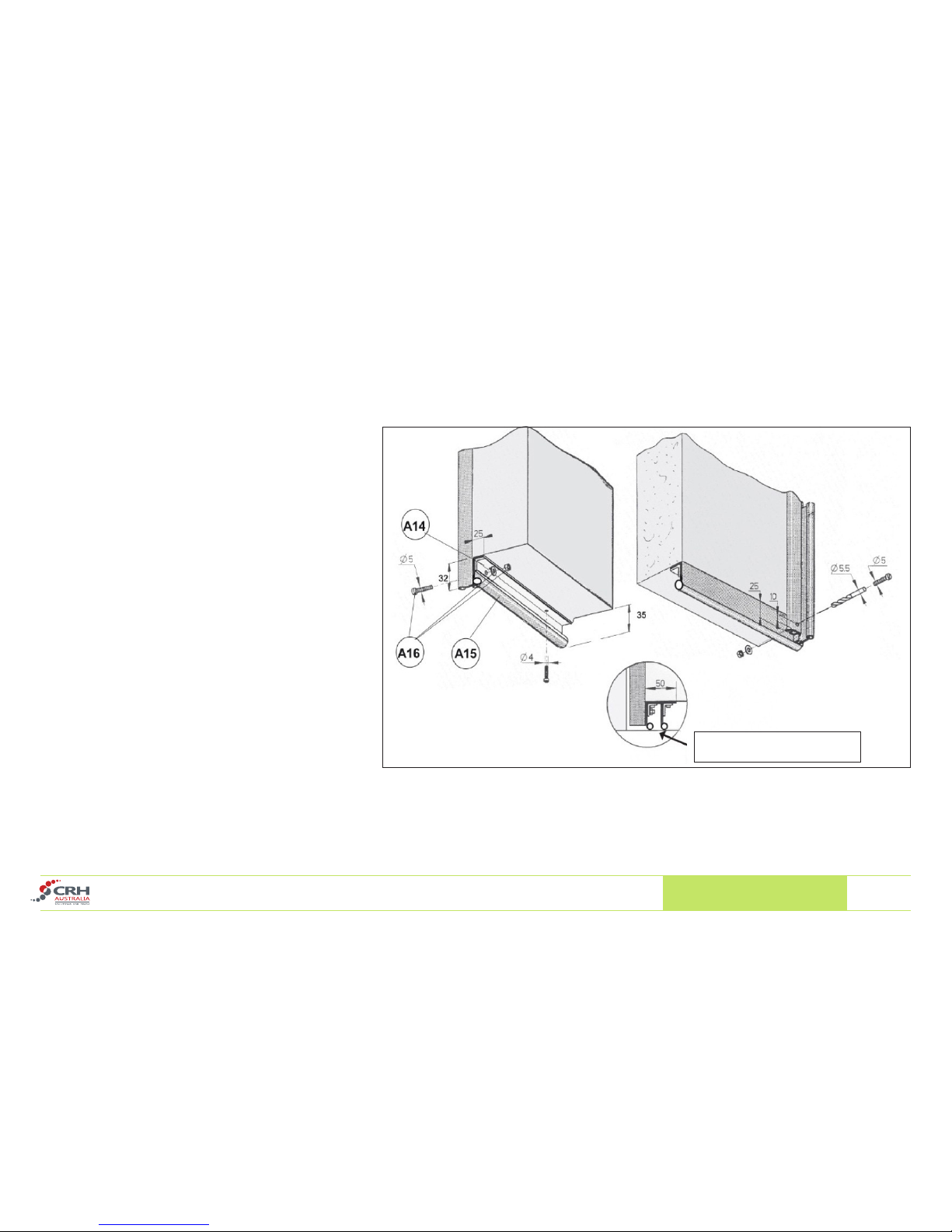

When the door is closed, tightness of the door against the frame is achieved by 2 rollers moving down the ramps and in against the door frame.

When the door is open, the 2 rollers come up the ramps and the door moves away from the oor & frame. This means that the door seals are

only in contact when the door is in a closed position. The rollers run eortlessly along the rail until they reach the end of the track stop.

This system is suitable for doors within the following specications:

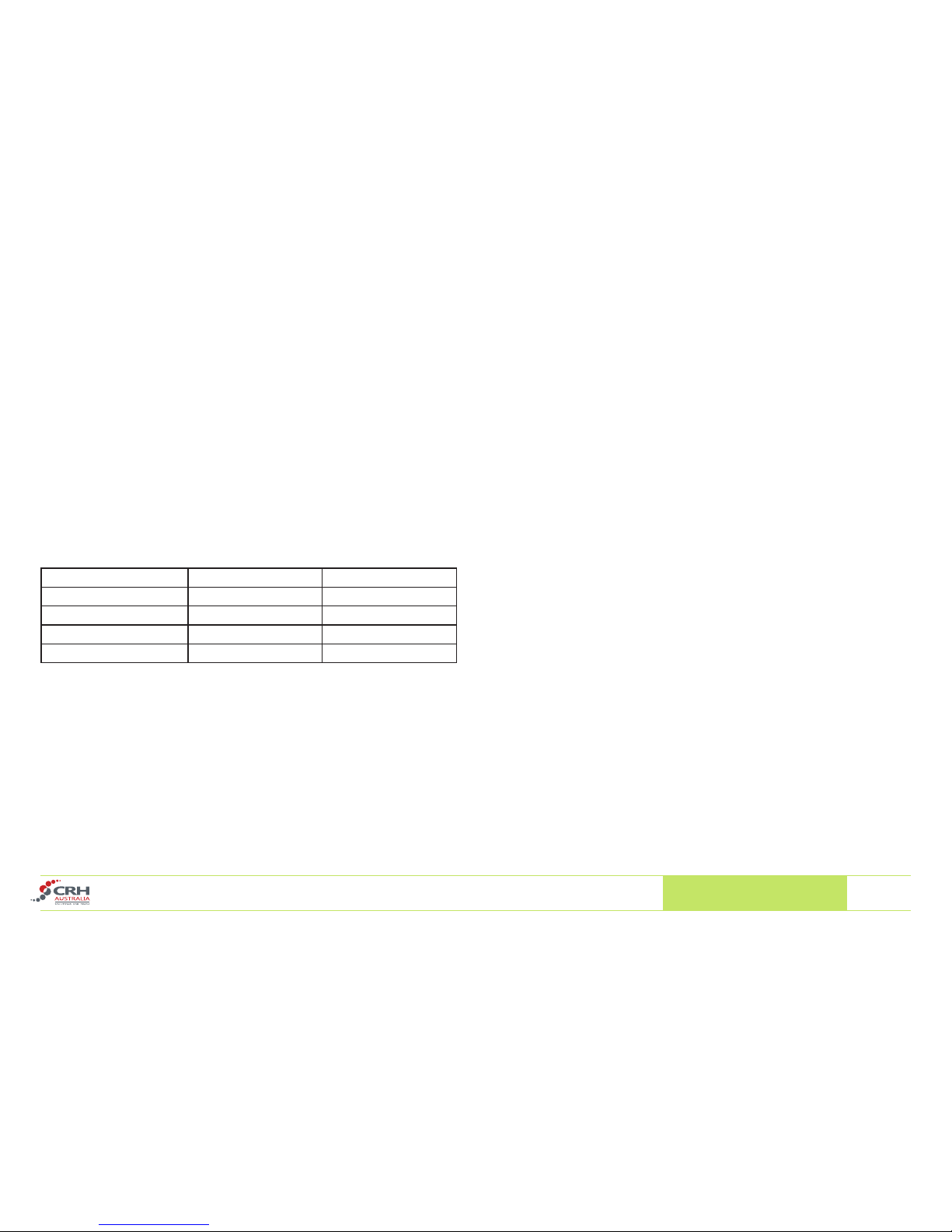

Specication Minimum Maximum

Door Blade Width 2001mm 2300mm

Door Blade Height - 2900mm

Door Blade Thickness 50mm 150mm

Door Weight - 120Kg

The operating temperature is between -30 °C and +55 °C.

The maximum noise level generated when the door operates is lower than 85dB.

The lever handle recommended for use with this system are as follows:

Internal Lever Handle :

F8530, F8530P (Packer)

External Lever Handle.

F8730-70/115K Used for door blades including gasket between 70mm and 115mm thick.

F8730-115/160K Used for door blades including gasket 115mm and 160mm thick.