FlexiForce ISTT Quick start guide

INSTALLATION, USE AND MAINTENANCE BY THE INSTALLER

© All rights reserved. FlexiForce®2017

User manual ISTT

ISTT & ISTT-125:

Industrial Spring Tensioning Tool

ISTT use in combination with FlexiForce spring fittings and 1”shaft

ISTT-125 use in combination with FlexiForce spring fittings and 1¼”shaft

Max. Torque 210Nm

Max. RPM 2500

www.flexiforce.com

GB

manual

Before you start; read this manual carefully and check the video on youtube

It is advised to practise the use of the tool in a test enviroment

If anything is unclear or should you have queries, please contact FlexiForce or you supplier

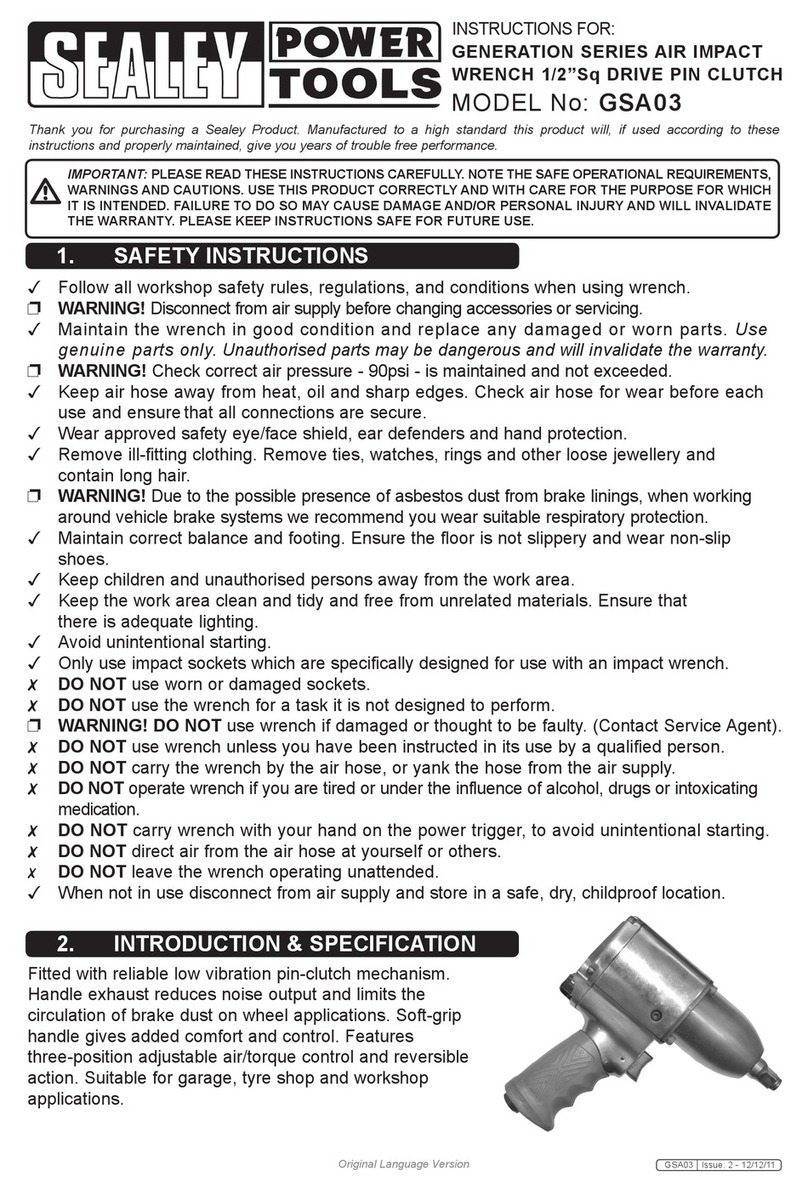

ATTENTION! GENERAL WARNINGS!

To use, operate and service this tool, a number of precautions must be taken.

For safety reasons pay heed to the warnings and instructions given below !

If in doubt, contact your supplier

9This manual has been written for use by experienced fitters and as such is not suitable for d.i.y. purposes or for use by

trainee fitters.

9This manual only describes the operation and servicing of the industrial spring tensioning tool.

9All safety warnings or remarks valid for the installation of the compleet sectional overhead door need to be considered

9Certain components may be sharp or have jagged edges. As such you are advised to wear safety gloves.

9The guarantee will terminate in case components will be added or changed without any consultation with the supplier

9During tensioning, springs can exert large forces. Ensure that you are standing in a steady position.

9Ensure that there is sufficient light during installation. Make sure that there is no one else present other than the fitters.

9All rights derived from this manual are reserved. Technical information is subject to change without notice

CHECK THE TOOL FOR DAMAGES BEFORE TENSIONING A SPRING, DO NOT USE THE TOOL WHEN DAMAGED

UNDER NO CIRCUMSTANCES DISASSEMBLE THE TOOL, BEFORE FIXING THE WINDING PLUG TO THE SHAFT !

ALWAYSE USE THE SICKLE LEVER TO SECURE THE TOOL

MAKE SURE THE GEAR COVER IS FIXED TO THE DRIVE UNIT BEFORE TENSIONING

MAKE SURE THE PROPER SIZE INSERT PIN IS USED ON THE SPRING WINDING PLUG

DO NOT EXCEED THE PRESCRIBED MAX. RPM AND MAX. TORQUE

ONLY USE ISTT ON 1” (25.4MM) SHAFT

ONLY USE ISTT-125 ON 1¼” (31.75MM) SHAFT

ONLY USE ON FF SPRING WINDING PLUGS

MAKE SURE THE INSERT PIN IS TIGHTENED CORRECTLY IN THE GEAR WHEEL

ALWAYSE USE THE RIGHT HAND DIRECTION OF THE DRILL TO WIND UP SPRINGS

USE PROPER DRILL

DO NOT DISMANTLE OR BEND AWAY THE SAFETY LEVER FROM THE DRIVE UNIT

CARRY OUT THE MAINTENANCE AS PRESCRIBED

With the proper maintenance and correct usage the ISTT is suitable to tension at least 3000 torsion springs without any problems.

User Manual ISTT www.flexiforce.com

GB

Maintenance and checks

Keep the teeth of the gear wheel clean and

greased.

Keep the bore of the gear wheel clean and

grease the surface of the bore before use.

Inspect the tool for wear, clearance, damage

before use. Do not use the spring tensioning

tool if safety is not assured !

95 122 991 rev. 30-10-2018 1

Maintenance and checks

Check dimensions A,B,C and D !

(See page 9,10 and 11)

Do not use the spring tensioning

tool if wear limits are crossed !

95 122 991 rev. 30-10-2018 2

1,5 mm

Keep sickle lever clean.

95 122 991 rev. 30-10-2018 3

Grease the nipple on the rear

after tensioning 50 springs

95 122 991 rev. 30-10-2018 4

Test run the device,the surplus of grease

will come out of the drive unit

1

3

45

6

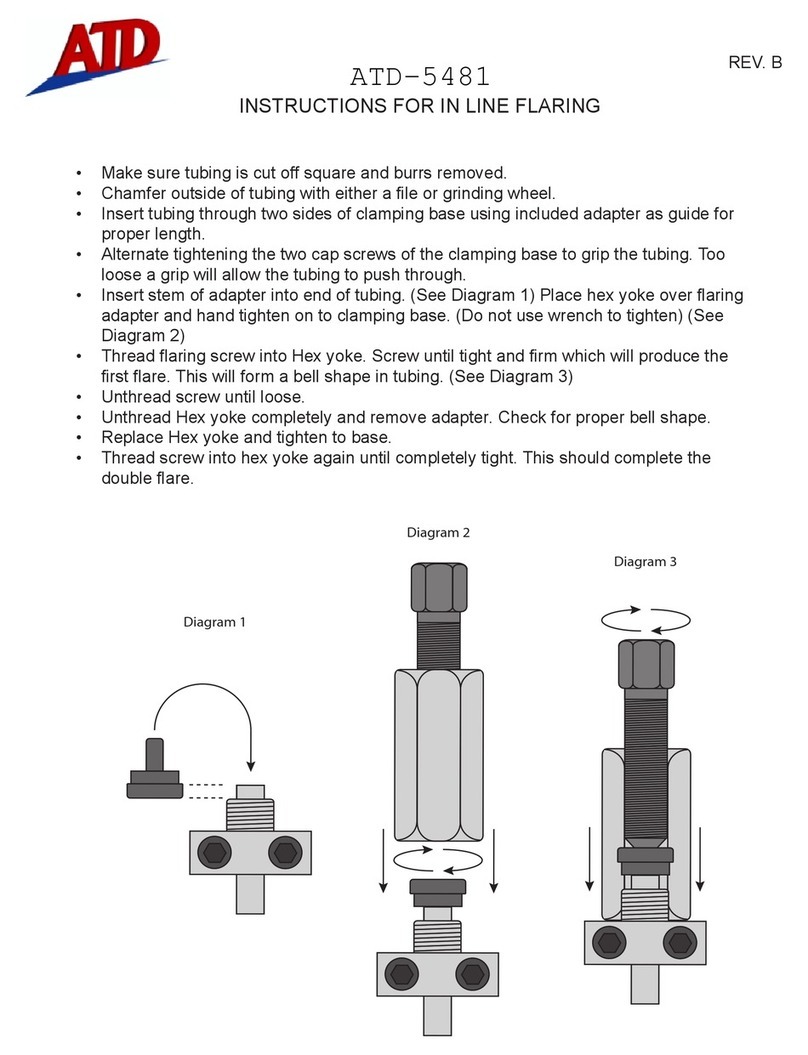

1 : Gear Cover

2 : Select Insert Pin

3 : Large Gear Wheel

4 : Insert Gear Wheel

5 : Sickle Lever

6 : Drive Unit

2

95 122 991 rev. 30-10-2018 5

24 mm

PP

+

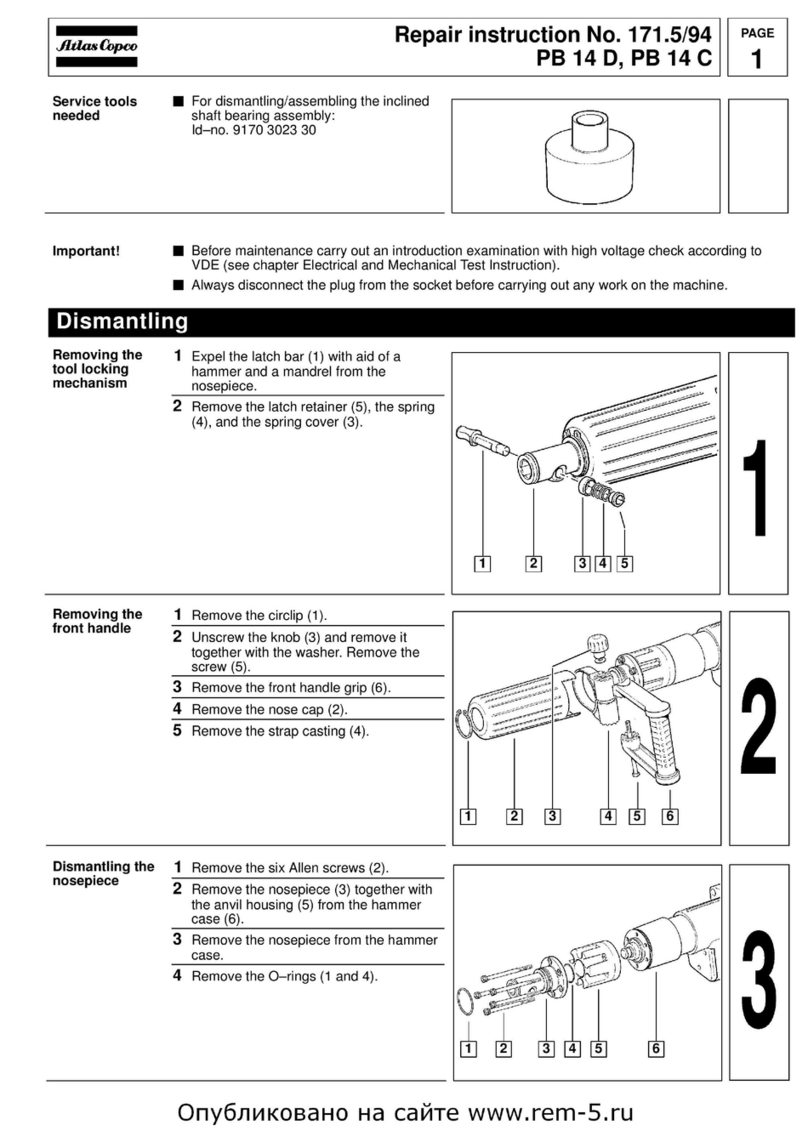

Suitable drill

Cordless drill: 18V n = 1500 RPM direction of rotation left hand and right hand.

Power drill: 230V, 750 W n = 2500 RPM max. direction of rotation left hand and right hand.

To wind up a spring always use the right hand direction of rotation of the drill.

Needed tools

95 122 991 rev. 30-10-2018 6

FF Sping plug SHAFT TOOL Insert Pin

FF200 1” ISTT Ø13,3x43

FF263 1” ISTT

FF375 1” ISTT

Ø16x33

FF375N 1” ISTT

FF600N 1” ISTT

FF600N125 1¼” ISTT-125

* Use with FF spring plugs only !!!

* Only use FF insert pins

1HYHUDOWHUWKHLQVHUWSLQVWR¿WWRWKHUEUDQGSOXJV

Select ISTT & Insert Pin

95 122 991 rev. 30-10-2018 7

NEVER USE THE ISTT-125 ON A 1” SHAFT !

95 122 991 rev. 30-10-2018 8

Check before using the tool !

Do not use the tool when the

wear limit is crossed

DIM. A

Max 2,5mm

95 122 991 rev. 30-10-2018 9

DIM.C

Max

9mm

DIM. B

Min 10mm

Check before using the tool !

Do not use the tool when the

wear limit is crossed

95 122 991 rev. 30-10-2018 10

DIM.D Max 1mm

Check before using the tool !

Do not use the tool when the wear limit is crossed

95 122 991 rev. 30-10-2018 11

24 mm 10Nm

95 122 991 rev. 30-10-2018 12

95 122 991 rev. 30-10-2018 13 95 122 991 rev. 30-10-2018 14

1”

1”

ISTT-125 GEARWHEEL

ISTT-GEARWHEEL

95 122 991 rev. 30-10-2018 15 95 122 991 rev. 30-10-2018 16

Check !!!

95 122 991 rev. 30-10-2018 17 95 122 991 rev. 30-10-2018 18

95 122 991 rev. 30-10-2018 19

//

95 122 991 rev. 30-10-2018 20

//

FF Spring plug Dim X

FF200 20,6mm

FF263 21,1mm

FF375 17,6mm

FF375N 17,6mm

FF600N(-125) 30,6mm

Dim X

95 122 991 rev. 30-10-2018 21

Click !!!

Check !!!

Check !!!

Click !!!

95 122 991 rev. 30-10-2018 22

95 122 991 rev. 30-10-2018 23

PP

95 122 991 rev. 30-10-2018 24

PP

95 122 991 rev. 30-10-2018 25 95 122 991 rev. 30-10-2018 26

95 122 991 rev. 30-10-2018 27

95 122 991 rev. 30-10-2018 28

Release tension

95 122 991 rev. 30-10-2018 29 95 122 991 rev. 30-10-2018 30

95 122 991 rev. 30-10-2018 31 95 122 991 rev. 30-10-2018 32

95 122 991 rev. 30-10-2018 33 95 122 991 rev. 30-10-2018 34

95 122 991 rev. 30-10-2018 35

Use of the ISTT / ISTT-125

Select the correct version ISTT for used

type of shaft

Make sure that one always uses the

DSSURSLDWHLQVHUWSHQ¿WWLQJWKHFRUUHVSRQGLQJ

plug! (page 7)

During tensioning the driveshaft of the device

will get warm, this is normal, the aluminium-

casing will absorbe the heat.

95 122 991 rev. 30-10-2018 36

This manual suits for next models

1

Table of contents

Popular Tools manuals by other brands

Matco Tools

Matco Tools MST7842 quick start guide

Gage Bilt

Gage Bilt GB110A Series Original instructions

Trelawny

Trelawny Single Scaler Standard Duty Operation and maintenance manual

stayer

stayer HD55BK operating instructions

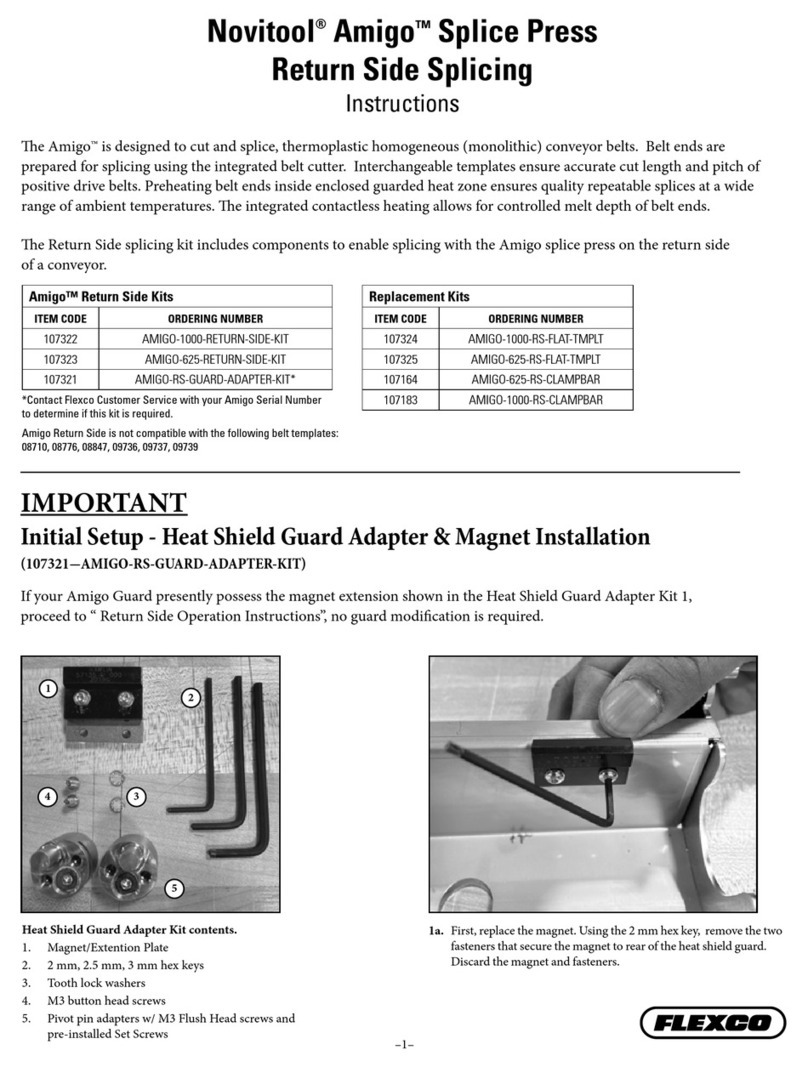

Flexco

Flexco AMIGO-1000-RETURN-SIDE-KIT instructions

RED LABEL

RED LABEL RL4TTP owner's manual