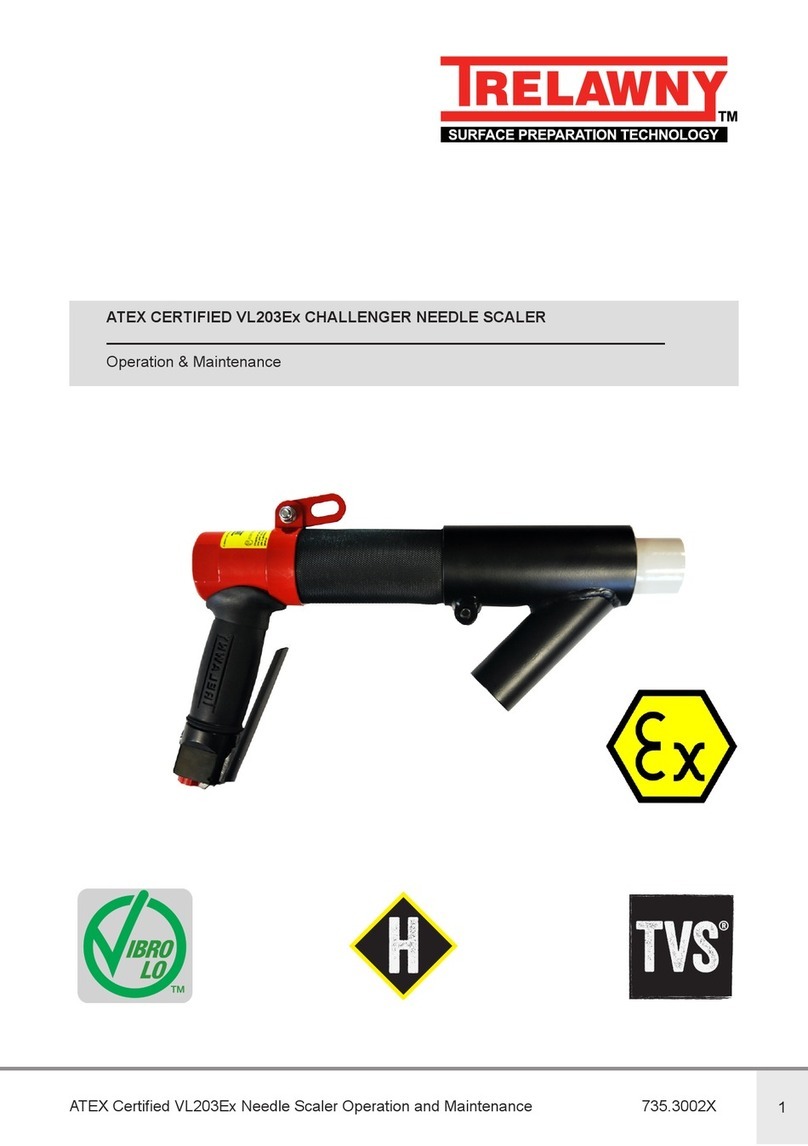

Trelawny Single Scaler Standard Duty User manual

Scaling Hammers

Operation and Maintenance Manual

www.trelawnyspt.co.uk

OPERATION

General Information

Before operating Trelawny Scaling

Hammers, this manual must be read and

understood by the operator, if in any

doubt, ask your supervisor before using

this equipment. Local safety regulations

must be followed at all times. Failure to

follow these instructions could result in

damage to the Scaler and/or personal

injury.

Trelawny SPT Ltd disclaims all

responsibility for damage to persons or

objects arising as a consequence of

incorrect handling of the tool, failure to

inspect the tool for damage or other

faults that may influence it’s operation

prior to starting work, or failure to follow

the safety regulations listed or applicable

to the job site.

The standard scaling tools are primarily

designed for removal of heavy rust and

scale.

The heavy-duty versions is suitable for

concrete reduction and the removal of

laitance from concrete.

These tools must not be used in a

fixture.

Note: Cruciform headed pistons are

suited to the removal of heavy rust and

scale and for the reduction of concrete

where a smoother finish is required;

these will reduce the aggregate as well

as the concrete surface.

Bush Hammer style headed pistons are

best suited to concrete reduction and for

laitance removal; these also reduce the

damage caused to the aggregate,

ensuring that a stronger bond is created

with the next layer.

Air Supply

The compressed air must be free from

water and dirt. The installation of a filter/

regulator/lubricator air preparation set

(with moisture trap) adjacent to the tool

is strongly recommended.

Always clear the air hose before

connection to the tool. Ensure that no

moisture (condensation) is present in the

air hose.

Ensure that a minimum 10mm (3/8”)

bore air hose is used and that all

couplings are secure, leak free and in

good condition.

Limit the length of air hose to 10M (33ft).

Where extra length is necessary, for

each additional 15M (50ft) of air hose

used, the pressure drop is approximately

0.16bar (3psi).

Correct operating pressure is 6.2bar

(90 psi).

Do not let the operating pressure fall

below 5.5bar (80p.s.i.) or rise above

6.9bar (100 psi) absolute maximum.

The compressor must be able to supply

a minimum of 7.0 lps (15cfm) for Single

Scalers and 12 lps (25cfm) for Triple

Scalers, (Free air, not displaced as

quoted by some compressor

manufactures).

In particularly cold weather it is

recommended that a proprietary anti-

freeze lubricating oil is used.

Safety

Always, read instructions first before use.

Do wear Personal Protective Equipment

including safety goggles, footwear, ear

defenders and gloves. In some

environments it will be necessary to wear

facemasks or breathing apparatus.

Do be aware that this tool is not

electrically insulated.

Do keep hands and clothing away from

moving parts.

Do ensure that this tool is lubricated

daily.

Do be aware that the tool can create

dust and

flying debris.

Do be aware of others working around

you.

Do store this tool in a secure and dry

environment.

Always observe safe-working

practices at all times.

Do not allow the tool to run unattended.

Do not use this tool in potentially

explosive environments.

Do not drag this tool by the air hose.

Do not use the Scaler as a lever.

Do not use petrol (gasoline), thinners or

any other high flash point solvent to

clean the tool.

Do not modify this tool in any way, as

this will invalidate the warranty and could

lead to serious injury.

Risk of Hand-arm

Vibration injury

These tools may cause Hand-arm

Vibration Syndrome injury if their use is

not adequately managed.

We advise you to carry out a risk

assessment and to implement measures

such as; limiting exposure time [i.e.

actual trigger time, not total time at

work], job rotation, ensuring the tools are

used correctly, ensuring the tools are

maintained according to our

recommendations, and ensuring that the

operators wear personal protective

equipment [PPE] particularly gloves

and clothing to keep them warm and

dry.

Employers should consider setting up a

programme of health surveillance to

establish a benchmark for each operator

and to detect any early symptoms of

vibration injury.

We are not aware of any PPE that

provides protection against vibration

injury by attenuating vibration emissions.

See ‘Specifications’ section for

vibration emission data.

Further advice is available from our

Technical Department.

Recommended

lubricants

Oil the tool daily before use. Put a few

drops of one of the following zinc free air

tool lubricants through the air inlet.

SHELL S22 or R10

CASTROL Hyspin ZZ32

Cleaning

At intervals of no more than 40 hours or

if operation becomes unproductive and

the piston shows signs of sticking,

dismantle and clean with a highly refined

paraffin.

Immediately after cleaning, thoroughly oil

the tool with one of the recommended

lubricants.

Starting work

Prior to operating the tool check: -

That all fittings are secure, free from

leaks and air hoses are in good

condition.

That the air pressure is correct for this

tool 6.2 bar (90 p.s.i.). Put a few drops of

recommended lubricant into the air inlet

of the tool.

To operate the tool, which is dependant

on the type of lever fitted, for those fitted

with a safety lever, first push thumb

button forwards and then for both styles

of lever, pull the lever towards the

handle grip to start the tool, then apply

the cutter heads to the surface being

prepared.

To switch off, simply release the

throttle lever.

Care must be taken to avoid damaging

or tripping over the air hose. Maintain

contact with the work surface with

sufficient pressure only to keep the tool

from bouncing off. Excessive pressure

can prevent the tool from working to its

full capacity. Handled correctly the

Scaler will work quickly and efficiently.

lever roll pin (8), and then remove the

throttle lever (7). Rotate the tool 180

degrees in the vice to access the valve.

Unscrew the valve cap (1) using a

screwdriver, check the valve cap 'O'Ring

(2), remove the spring (3), push out the

valve stem (4) and remove the 'O'Ring

(5). Check the valve and 'O'Ring for

wear.

Assembly (Workshop)

Before any assembly takes place,

ensure all parts are clean and have a

film of air tool oil lubrication unless

otherwise stated. Avoid lubricating oil or

grease contaminating the threads of the

end cap (17), the threads within the bore

of the bodies (23/24) and the tapers on

piston and cutter heads. The end caps

will require securing with a thread-

locking adhesive. It is good practice to

renew all ‘O’ Rings (2/5) and the brush

seals (22). Replace any parts showing

signs of wear; paying particular attention

to the small bore of the cylinder.

Head Assembly - Taper Fit (On-Site)

Thoroughly clean around area of cutter

head and piston. Remove all traces of

debris/oil from the taper on the piston

(20) and internal taper of the cutter head

(25/26/27) by cleaning with suitable oil

free solvent. Place the tool in a position

where the end cap is on a solid surface;

Select one of the cleaned new cutter

heads and place on to the taper of the

piston. Using a soft-faced hammer

deliver a sharp blow to the cutter head.

Head Assembly - taper fit (Workshop)

Remove all traces of oil and dirt etc, from

the taper diameter on the piston (20) and

cutter head (25/26/27) by cleaning with

suitable oil free solvent. Fit the piston

into the cylinder (21) as shown in the

service layout. Place the assembly onto

a solid surface; fit a new brush-seal (22)

over the piston and into the recess of the

cylinder. Select one of the cleaned new

cutter head and place on to the taper of

the piston. Using a soft-faced hammer

deliver a sharp blow to the cutter head.

Note: If you are re-fitting a used cutter

head to the piston it is essential that the

internal diameter of the cutter head is re-

surfaced using a medium grade of emery

cloth - this will ensure a good fit between

cutter head and piston, do not use

adhesive of any description on the

taper.

If the taper has expanded to much on

the old cutter heads, they may not stay

on the piston, replacements will be

required.

One Piece Piston and Piston/Cylinder

assembly (Workshop)

Lubricate the piston (20/33) and cylinder

bore (21/29) and push the piston into the

cylinder bore.

Excessive operator pressure will not

improve the tool efficiency but will

cause premature tool failure and

operator fatigue.

Never allow the tool to run continuously

whilst not in contact with the surface

being prepared.

Please be aware: that this tool will

reduce in power or stop working if the

end cap (17) has become unscrewed.

Maintenance

Maintenance must only be carried out by

a competent person. Disconnect the

tool from the air supply before

carrying out any of the following

operations.

Clean all debris from the exterior of the

tool.

Head removal - Taper Fit (On site)

Lay the scaling hammer on a solid

surface with the cutter head (25/26/27)

facing uppermost. Place the head

removal washer (32) between the cutter

head and the body; insert the removal

pin (31), into cutter head hole (refer to

diagram for pictorial illustration).

Wearing safety glasses and using a

medium size hammer give a sharp blow

to the head of the pin, which will release

the cutter head from the piston.

One Piece Piston & Piston/Cylinder

Assembly removal (Workshop)

Hold the scaler body (24) in a vice, using

the flats provided and with the end cap

uppermost. On triple scalers, secure the

tool in a vice, clamping on all three cutter

heads (On one piece pistons take care

not to clamp on the ground surfaces).

Unscrew the end cap (17). Remove

spring cap (19) and spring (18) from the

end cap. From the bottom of the body,

push up the cutter head to remove the

piston assembly.

Head removal - Taper Fit (Workshop)

Lay the piston and cylinder assembly on

a solid surface with the cutter head

facing uppermost. Place the head

removal washer (32) between the cutter

head and the cylinder; insert the removal

pin (31), into cutter head hole (refer to

diagram for pictorial illustration).

Wearing safety glasses and using a

medium size hammer, give a sharp blow

to the head of the pin, which will release

the cutter head from the piston. Inspect

all components for wear, replace as

necessary.

Valve body servicing (Workshop)

Clamp the handle (10) assembly firmly in

a soft face jawed vice (valve body end)

throttle lever upper most. Using a 3mm

diameter pin punch, remove the throttle

Lay the tool on a bench with the body

(23/24) on its side and Insert the cylinder

assembly into the body.

Valve Body assembly (Workshop)

Clamp the handle (10) assembly firmly in

a soft faced vice (valve body end), insert

new valve stem 'O'Ring (5) into valve

body (6), followed by the valve stem (4),

spring (3), then the valve cap (1)

complete with its 'O'Ring (2), tighten the

valve cap with a screwdriver.

Rotate assembly 180 degrees in vice.

Using a 3mm diameter pin punch locate

and align the throttle lever (7) in position,

then drive in the throttle lever roll pin (8)

into the pin location.

FINAL ASSEMBLY (Workshop)

Assemble the end cap (17), fit spring

(18) into the end cap and fit spring cap

(19) into the end cap as shown in the

service layout.

Select as required, a piston/cutterhead,

insert into the body (23/24) and apply a

few drops of air tool lubricant to the top

of the piston(s).

Hold the handle (10) in a soft faced vice

ensuring the screw cap threads are

uppermost.

Remove all traces of oil from the

screwed cap threads and threads of the

body by cleaning with suitable oil free

solvent.

Apply a bead of Loctite 243 sealant to

the first 3 threads of the end cap.

Screw end cap assembly into the body

until finger tight and using a suitable

spanner torque down to 55N.m. (40

lbs.ft).

Disposal

When the tool and its accessories are

taken out of service for disposal, it is

recommended that: - They are rendered

unusable to prevent improper re-use.

They are dismantled into component

form, segregated according to material

composition and disposed of using waste

recycling processes specified by local

regulations.

Machinery Directive

Information

This machine has been designed and

produced in accordance with the

following directives: 2006/42/EC

Machinery Directive

and applicable harmonised standard:

EN ISO 1 1148-4:2010

Trelawny tools are thoroughly tested

under specified conditions in accordance

with applicable internationally recognised

standards.

MAINTENANCE

STANDARD & HEAVY DUTY SINGLE AND TRIPLE SCALING HAMMERS

EXPLODED VIEW

EXPLODED VIEW

STANDARD & VIBRATION REDUCED SINGLE SCALING HAMMER

PARTS LIST

Item

No Part No Description Item

No Part No Description

1615.3021 Valve Cap 19 615.5361 Spring Cap

2809.0139 O’ Ring - Valve Cap 20 612.5301 Piston (Std taper fit)

3712.3022 Valve Spring 21 613.5301 Cylinder (Std taper fit)

4618.3022 Valve Stem 22 614.5301 Brush Seal

5809.0089 O’ Ring - Valve Seat 23 611.5301 Triple Scaler Body (Std taper fit)

6616.5321 Valve Body 611.5355 Triple Scaler Body (H/Duty)

*423.5321 Valve Body Assembly 24 411.5101 Single Scaler Body (Std & H/Duty)

7716.3000 Throttle Lever 411.5121 Single Scaler Body (Vibration Reduced,

Std and H/Duty)

*716.1000 Throttle Safety Lever 25 426.5351 Cruciform Head (Taper Fit)

8813.0108 Roll Pin 26 426.5352 Bush Hammer Head (Taper Fit)

9711.5301 Adaptor 27 606.5303 Beryllium Copper Head (Taper Fit)

10 624.5301 Main Handle (Standard Tools)

624.5350 Main Handle (Vibration Reduced) 29 613.5303 Cylinder (H/Duty)

11 717.5301 Rubber Grip

12 625.5301 Locknut 31 827.0428 Cutterhead Removal Pin

13 810.9001 Sealing Washer 32 633.5301 Cutter Head Removal Washer

14 634.5301 Hexagon Plug 33 612.5320 Single Piece H/Duty Piston (Cruciform)

15 822.5302 Side Handle Grip 612.5325 Single Piece H/Duty Piston (Bush)

16 422.5315 Side Handle

17 615.5341 Screwed Cap 36 719.1380 Flexible Connector

18 712.5301 Compression Spring 37 821.2000 Hose Clamp

*Items not shown in exploded view

*633.5301 Single Scaler Vacuum Shroud

*437.5300 Triple Scaler Vacuum Shroud

*731.0120 Vacuum Shroud Seal

TROUBLE SHOOTING

Poor performance or lack of

power Low air pressure. Ensure that the air pressure is correct at 90psi, max 100psi.

If tool has been left for some time without use, the oil

may dry out slightly causing a sticky residue. Strip tool down and re-oil.

Tool worn out, can you feel side ways movement

between the piston and cylinder bore. Replace the piston and cylinder, along with a new bush

seal.

Tool continues to run with

trigger released Valve seal may have become dislodged through the tool

being disconnected with the trigger in the open position. Ensure that the trigger has not been taped or wired in the

open position.

Do not use quick release couplings to switch tool off.

Tapered cutterhead will not

stay on piston To high an air pressure being used, piston hits bottom of

cylinder causing head to be jettisoned. Ensure that the air pressure is correct at 90psi, max 100psi.

Traces of oil remained on the tapered surfaces when

replacing cutter head. Ensure that the cutterhead and pistons tapers are

completely free of oil, use a good degreasing agent and

clean cloth prior to assembly.

TECHNICAL SPECIFICATIONS

Declared vibration emission value are in accordance with BS EN 12096: 1997

(k)= the factor of uncertainty, which allows for variations in measurement and production. Vibration data figures are tri-axial, which gives total vibration

emission.

Risk of Hand Arm Injury

Because of various factors, the range of vibration emission during intended use can vary.

The vibration is dependent on the task, the operators grip, and feed force employed etc.

Noise level measured in accordance with EN ISO 15744: 2008

Vibration measured in accordance with EN ISO 28927:2012 and EN ISO 20643:2005

Trelawny Surface Preparation Technology operates a policy of continuous product development and refinement and therefore reserves the right to

change technical specifications and product designs without giving prior notice.

© Copyright 2009, Trelawny SPT Limited, CV31 1XT. UK All rights reserved. Any unauthorised use or copying of the contents or part thereof is

prohibited. This applies to trademarks, model denominations, part numbers and drawings.

Use only genuine Trelawny spares.

The use of non-Trelawny spare parts invalidates the warranty.

Model Single Scaler

Standard Duty Single Scaler

Heavy Duty

VL Single

Scaler

Standard Duty

VL Single Scaler

Heavy Duty Triple Scaler

Standard Duty Triple Scaler

Heavy Duty

Piston Diameter 27mm (1.06”) 27mm (1.06”) 27mm (1.06”) 27mm (1.06”) 27mm (1.06”) 27mm (1.06”)

Piston Length 68.6mm (2.7”) 111.75mm (4.4”) 68.6mm (2.7”) 111.75mm (4.4”) 68.6mm (2.7”) 111.75mm (4.4”)

Piston Stroke 26.0mm (1.023”) 26.5mm (1.04”) 26.0mm (1.023”) 26.5mm (1.04”) 26.0mm (1.023”) 26.5mm (1.04”)

Blows Per Minute 3000 2400 3000 2900 3 x 3000 3 x 2400

Air Consumption 3.3lps 7.0 cfm 3.7 lps (8 cfm) 3.3 lps (7.0 cfm) 4.25 lps (9.0 cfm) 5.2 lps (11 cfm) 7.0 lps (15 cfm)

Air Pressure 6.2 bar (90psi) 6.2 bar (90psi) 6.2 bar (90psi) 6.2 bar (90psi) 6.2 bar (90psi) 6.2 bar (90psi)

Air Inlet 3/8” NPT (c/w 3/8”BSP Adapter)

Length 465mm (18.3”) 465mm (18.3”) 515mm (20.3”) 515mm (20.3”) 450mm (17.7”) 450mm (17.7”)

Working Height 152.5mm (6.0”) 160mm (6.3”) 140mm (5.5”) 160mm (6.3”) 152.5mm (6.0”) 160mm (6.3”)

Weight 2.5kg (5.5 lbs) 2.6kg (5.7 lbs) 2.46kg (5.42lbs) 2.49kg (5.49”lbs) 3.7 kg (8.1 lbs) 5.2 kg (11.4 lbs)

Noise Level LpA dB (A) 88.1 93.9 92.5 90.9 92.7 98.3

Noise Level LwA bD (A) 101.1 106.9 106.3 104.5 105.7 111.3

Vibration Level m/s2

Primary 6.8 (k) 6.96 (k) 3.7 (k) 4.5 (k) 13.4 (k) 8.7 (k)

Vibration Level m/s2

Secondary 31.4 (k) 26.0 (k) 9.9 (k) 9.4 (k) 12.0 (k) 13.5 (k)

NOTES

NOTES

Trelawny SPT Ltd

13 Highdown Road, Sydenham Industrial Estate, Leamington Spa,

Warwickshire, CV31 1XT, United Kingdom

Telephone: +44 (0)1926 883781 - Fax: +44 (0)1926 450352

Email: [email protected].uk

© TSPT UK 2009 Part No: 735.5300 issue 03/10/17 www.trelawnyspt.co.uk

This manual suits for next models

5

Table of contents

Other Trelawny Tools manuals

Trelawny

Trelawny VL203Ex Troubleshooting guide

Trelawny

Trelawny SF11EX User manual

Trelawny

Trelawny VLSF1EX User manual

Trelawny

Trelawny LPS55 User manual

Trelawny

Trelawny VL223EX Series User manual

Trelawny

Trelawny Trident Neptune User manual

Trelawny

Trelawny SF3EX User manual

Trelawny

Trelawny Vibro Lo Troubleshooting guide

Popular Tools manuals by other brands

CONTINENTAL RAILWORKS

CONTINENTAL RAILWORKS 60 Series Manual for use

Silverline

Silverline 46pc manual

gilles.tooling

gilles.tooling u2-Y01 owner's manual

Numa

Numa Patriot 45 Care & maintenance

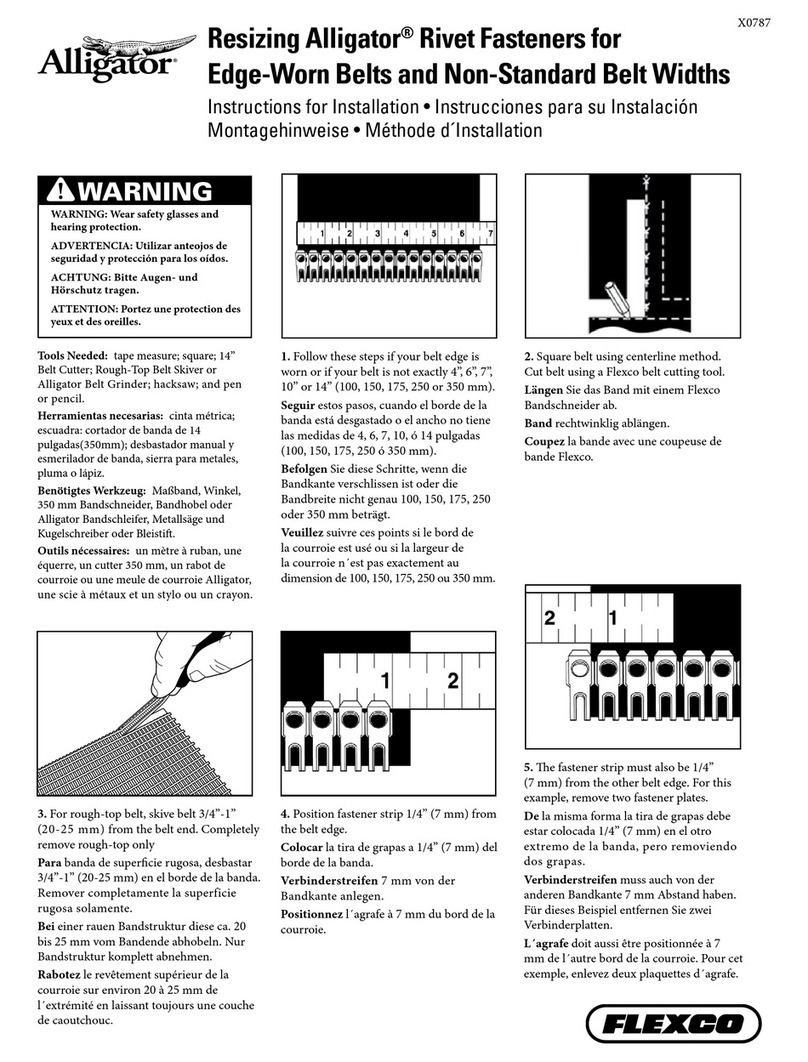

Flexco

Flexco Alligator Series Instructions for installation

BRINKMAN

BRINKMAN CJWINTER 192 Series instruction manual