Flexo-Technic FLEXO PLATE CUTTER User manual

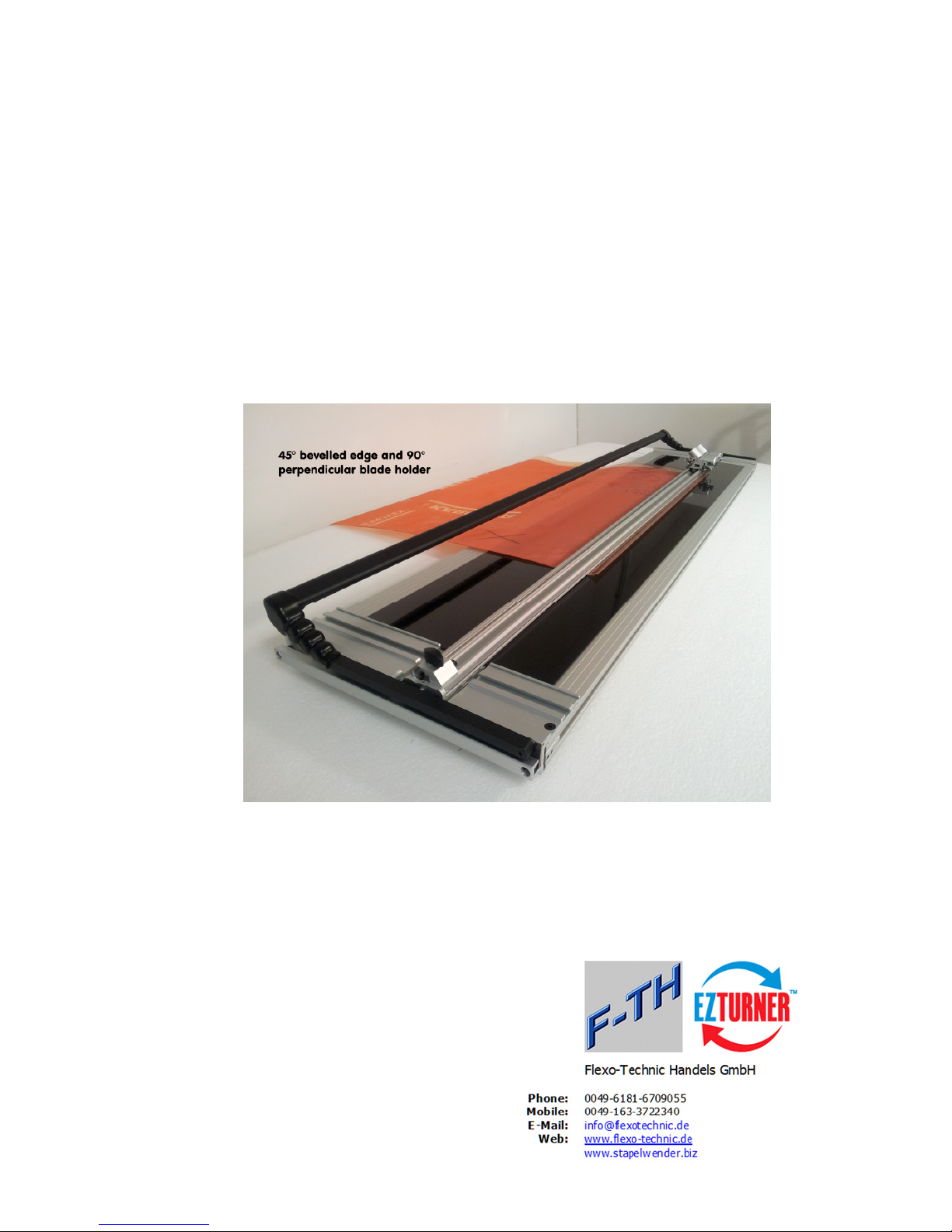

FLEXO PLATE CUTTER 90°+ 45°

Inspired Design - Precision Engineering

USER INSTRUCTIONS

Thank you for choosing the FLEXO PLATE CUTTER PLATE CUTTER Every effort has been

made to bring you a precision engineered product with the promise of many years of valuable

service. In order to obtain maximum benefit from your machine please read these instructions

carefully.

1 Contents 1

2 Identification

2.1 Know your FLEXO PLATE CUTTER

3 Operation

3.1 The Blade Cartridges

3.2 General Purpose Cutting 1

3.3 General Purpose Cutting 2

4 Maintenance

4.1 Maintenance/Cleaning and Lubrication

5 Specialist Uses

5.1 Cutting Flexo Plates

2.1 Your Flexo Plate Cutter 2.1

Know your FLEXO PLATE CUTTER

Cutterbar

Cutter - Available in four sizes:

■FLEX 100 101cm

■FLEX 120 122cm

■FLEX 150 157cm

■FLEX 220 218cm

40” cutting length

48” cutting length

62” cutting length

86” cutting length

(with 6 rubber feet*)

(with 6 rubber feet*)

(with 8 rubber feet*)

(with 10 rubber feet*)

FEET TO BE EQUALLY SPACED ALONG THE LEFT AND RIGHT EDGES OF THE BASE.

You should have:

Cutting Mat

Pack of 100 Medium Duty Blades

3mm Allen key

Manual

MEDIUMDUTY

Bevel Blade

Holder

Base

Vertical Blade Holder

End of Cut

Limit Stop

End Plate

3.1

Operation

The Blade Cartridges

3.1

BEVEL BLADE HOLDER

VERTICAL BLADE HOLDER

D

■Both the bevel and vertical blade holders are fitted with Blade Cartridges, to release the cartridge from either of the

blade holders slacken the blade clamping screw (B) and pull the cartridge out, gripping the black plastic pin (A).

The blade is held onto the cartridge by a strong magnet, place the blade between the two raised edges and slide it so

the back edge of the blade touches the depth adjustment screw. To adjust the blade depth turn the adjustment screw

(C) clockwise to extend the blade length and counter-clockwise to reduce it. Always check that the blade is properly

located in the cartridge before loading it into the blade holder.

Each cartridge has a different coloured label to help with identification and calibration if pre-set to suit different

thicknesses of material..

■The standard blade used with the Flexo Plate Cutter is the Medium Duty Utility blade (D).

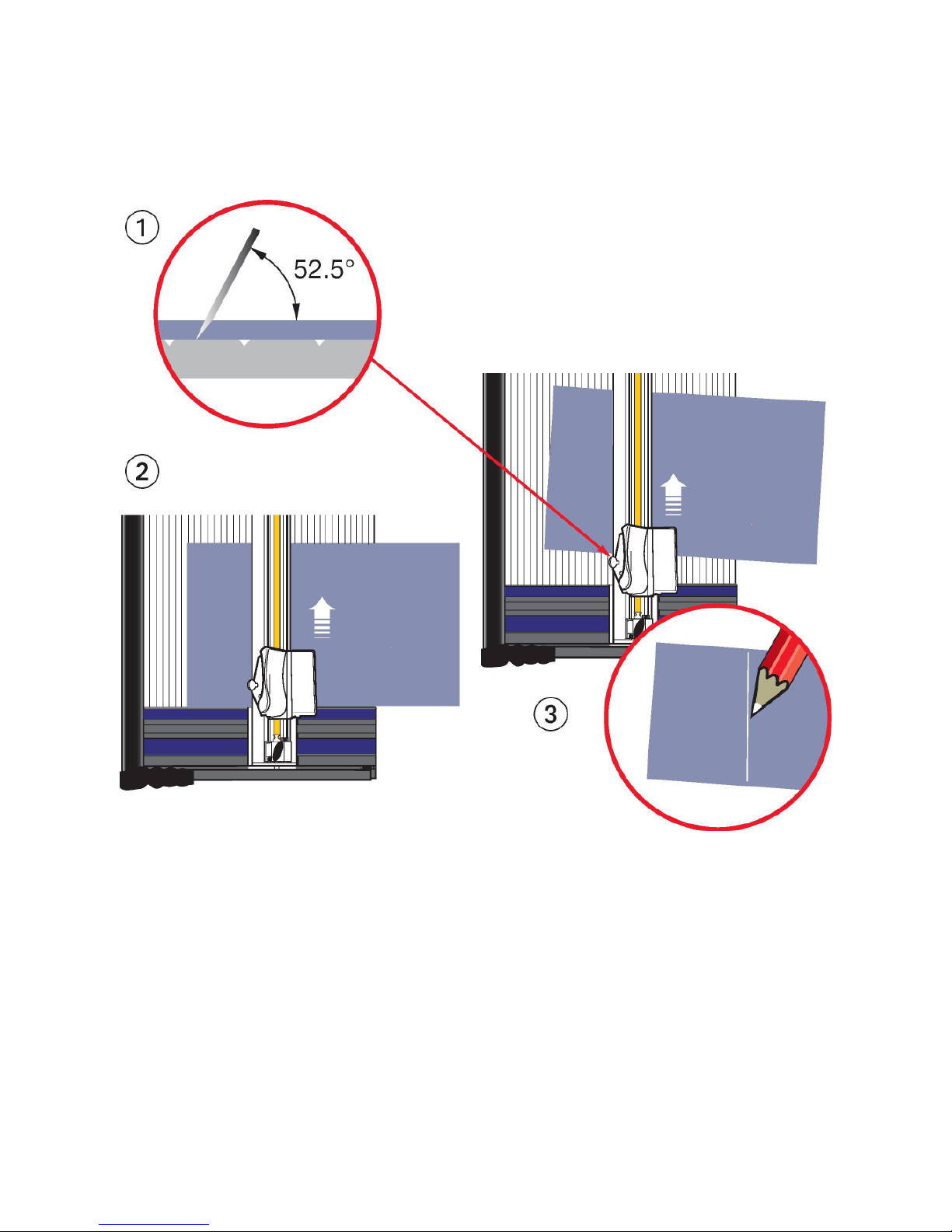

3.2 Operation 3.2

General Purpose Cutting 1

The Flexo Plate Cutter is a general purpose machine that will cut a large range of materials up to 3 mm thick with the

standard medium duty blade.

■IMPORTANT: It is important that the table surface the cutter is used on is relatively flat. If not the base and cutter bar

may not clamp the material properly allowing it to move whilst being cut.

© The cutting head has two blade holders, a vertical cutter on the right hand side and a bevel cutter on the left.

© To load material into the machine raise the long black handle and place the material under the cutter bar. Should the cut

need to be perpendicular (90 degrees) to the edge of the material position it against the End Plate to align it.

© Alternatively place the material forward of the End Plate and align the blade with the desired cutting line. Lower the black

handle to clamp the material in place.

The Flexo Plate Cutter is normally operated from the end of the machine such that the cutter head is pulled towards

the operator when cutting,

3.3

Operation

General Purpose Cutting 2

3.3

Bevel Cutting

Always adjust the blade depth so that the

smallest amount of blade is exposed to just cut

through the material, it will produce a better

quality cut and require less effort. There is a

groove along the base plate which

accommodates the tip of the blade when

cutting. Thin materials may need the cutting

mat to support them to avoid the material being

pressed into the groove which will produce

inconsistent and unsatisfactory results.

© A cutting mat must always be used when bevel cutting thick materials as the blade may run outside the groove and

damage the base plate.

DO NOT REST YOUR HAND ON THE LONG LIFTING HANDLE WHILST CUTTING

BECAUSE THE BLADE PENETRATION WILL BE REDUCED.

©

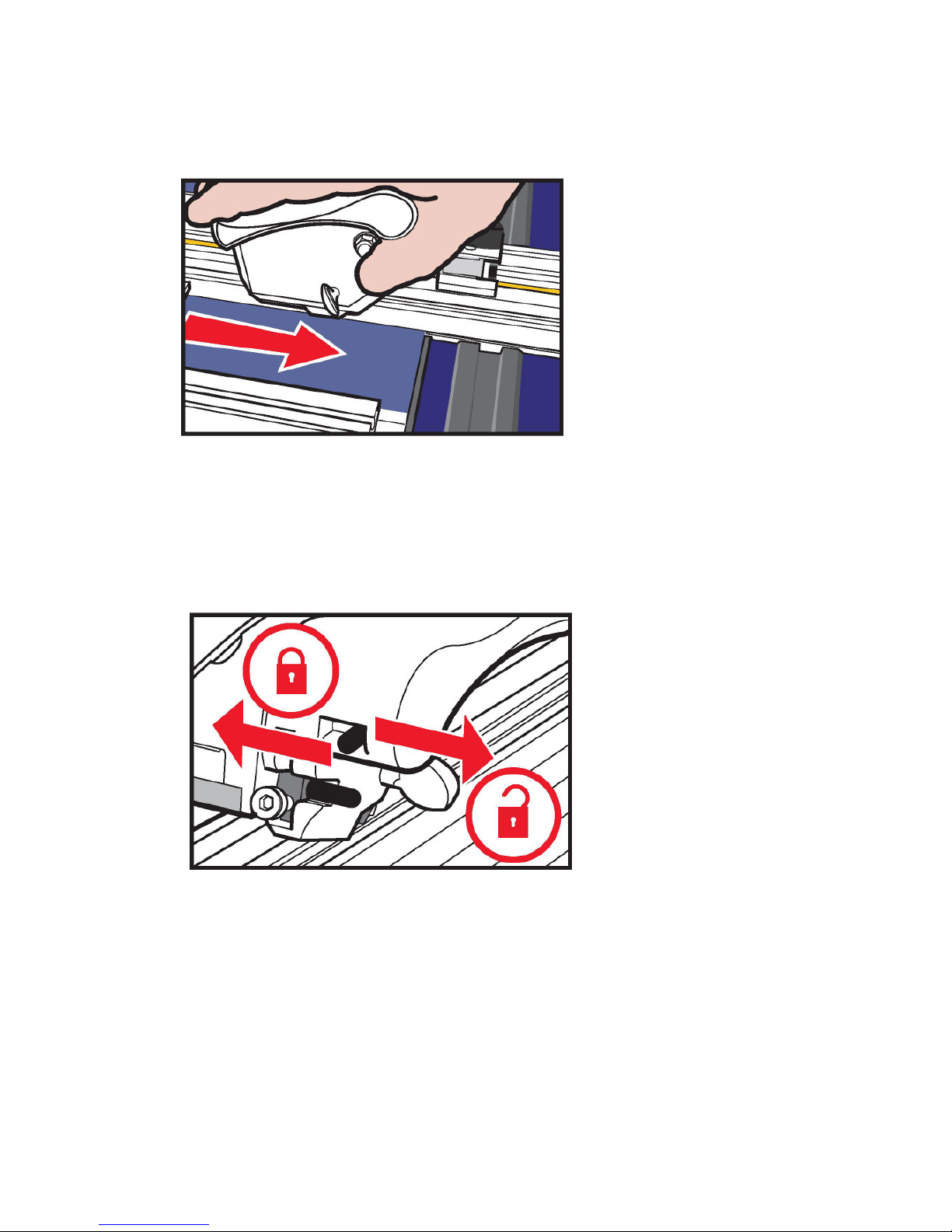

Vertical Cutting

The vertical cutter can also be used with or without a cutting mat, this will help to produce a better quality cut on most

materials. The blade depth should be set just long enough for the tip to penetrate the material being cut.

© The vertical cutter has a two way lock which can lock the blade in the down or up position. Slide the black pin to the left

to lock and to the right to release.

DO NOT REST YOUR HAND ON THE LONG LIFTING HANDLE WHILST CUTTING

BECAUSE THE BLADE PENETRATION WILL BE REDUCED.

4.1 Maintenance 4.1

■MAINTENANCE

Your cutter is a precision made machine and will give many years of accurate and reliable service if you follow

these few simple steps.

Keep all liquids ( including tea and coffee) away from the machine - spillages spoil the machines performance and

materials cut upon it.

Dust/vacuum daily, for stubborn stains use detergent/ water mix firstly applied to a cloth.

Cover the machine overnight with a plastic or fabric sheet.

If you need to move the machine away from the bench when it is not in use, store it either flat or if you have to stand it

on end fasten the end of cut stop and use a strong elastic band to fix the cutter head to it. Then stand it on its top end

leaning against a stable support.

Please note:- Standing the cutter on end should be avoided if possible but, providing it is done carefully no harm will

come to it.

In the event of heavy soiling on any part of the machine solvents can be used for cleaning but-

Apply the solvent to a cloth and not directly on the cutter.

Read and comply with the solvents safety instructions.

Do not allow solvent to come in contact with any printed or plastic parts of the machine.

■CLEANING AND LUBRICATION OF THE CUTTER BAR

As above, clean the two guide bars using solvent on a cloth being careful not to get solvent on the measuring scale.

Lubricate using petroleum jelly or a firm grease, again apply it to a cloth then wipe it along the guide bars. Do not apply

too much grease a thin smear is all that is required.

Oil can be used lightly on the lift and hold, pivot lift arm hinges and cutter bar pivots.

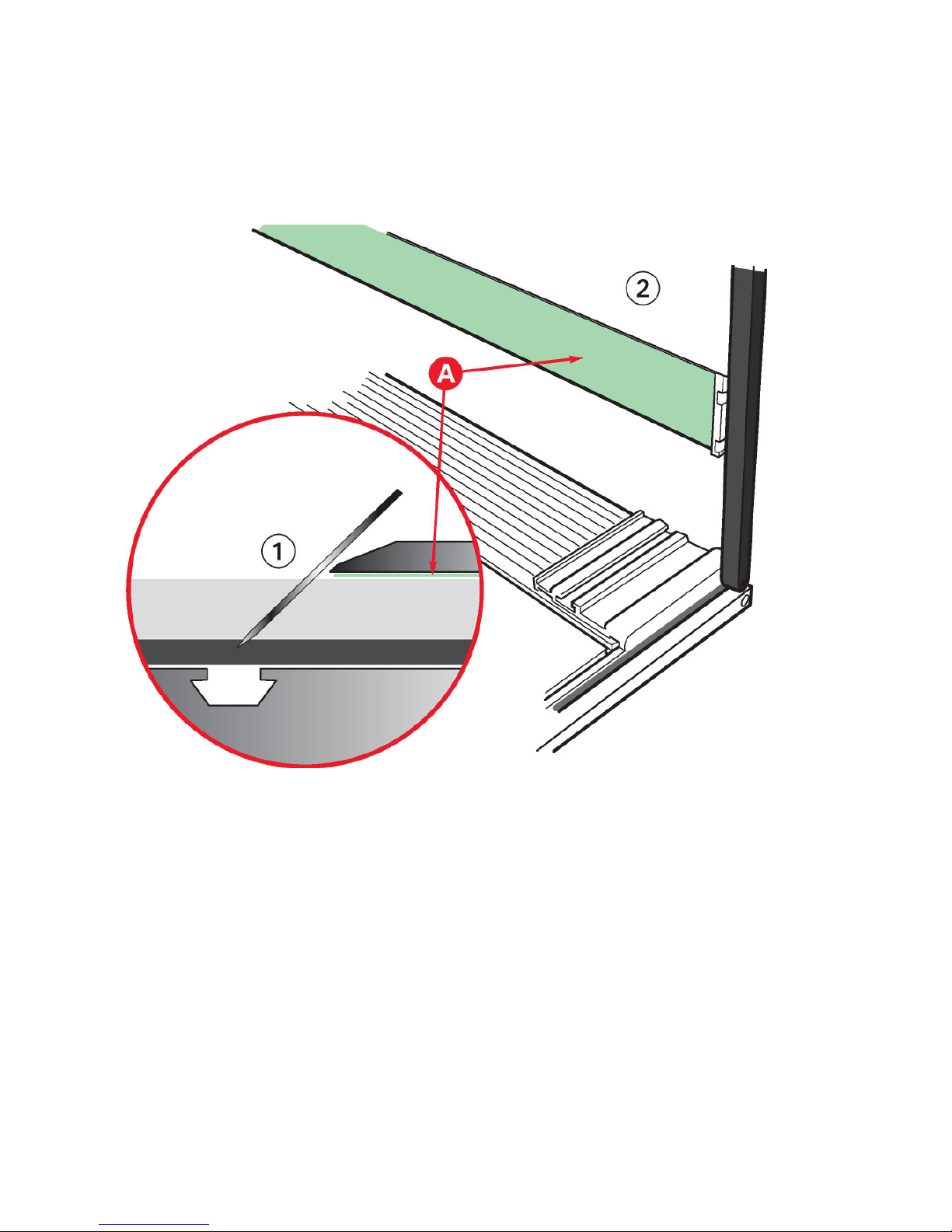

5.1 Specialist Uses 5.1

Cutting Flexo Plates

© When cutting Flexo Plate always use the cutting mat supplied to cut onto and ensure the blade depth is set to a

minimum to cut through the material thickness.

© It is important that the silicon grip tape (A) on the underside of the cutter bar is kept clean to hold the flexo in place. If it

becomes dirty through use clean it with a cloth moistened with diluted detergent.

Helpful hints:

■To eliminate entry and exit burrs, push the blade into the flexo, through the base, to start your cut.

■If you cut with the base side up place the foam protector sheet (used for shipping between each flexo plate), on the base

board, to protect the emulsion side from scratching.

■To stabilize the plate for ultra-fine trimming, try starting your cut 2cm (1”) in from the edge. Come back and complete the

cut from the edge.

■To obtain smooth clean edges and avoid fracturing (especially on thicker flexo plates) make multiple passes and

frequent blade changes.

Table of contents