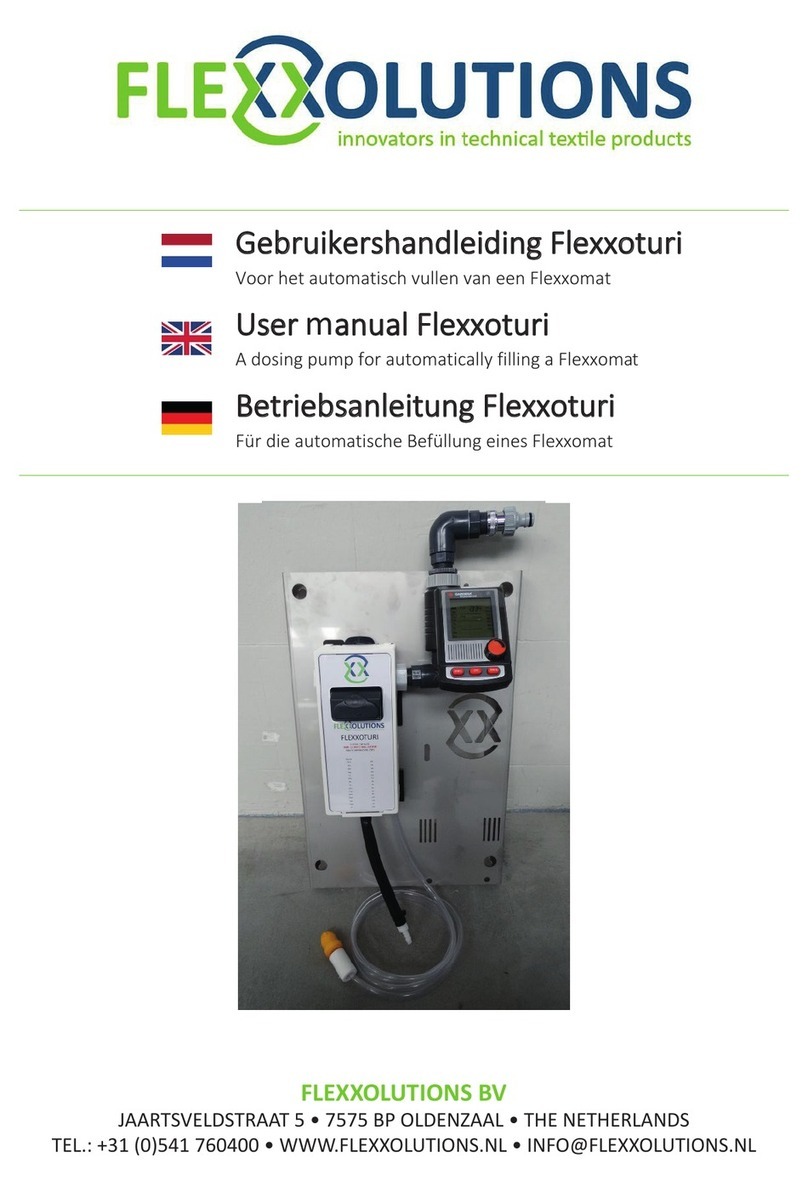

FLEXXOLUTIONS Flexxopomp C User manual

G

G

e

e

b

b

r

r

u

u

i

i

k

k

e

e

r

r

s

s

h

h

a

a

n

n

d

d

l

l

e

e

i

i

d

d

i

i

n

n

g

g

F

F

l

l

e

e

x

x

x

x

o

o

p

p

o

o

m

m

p

p

Voor het automatisch vullen van een Flexxomat

U

U

s

s

e

e

r

r

M

M

a

a

n

n

u

u

a

a

l

l

F

F

l

l

e

e

x

x

x

x

o

o

p

p

o

o

m

m

p

p

A dosing pump for automatically filling a Flexxomat

B

B

e

e

t

t

r

r

i

i

e

e

b

b

s

s

a

a

n

n

l

l

e

e

i

i

t

t

u

u

n

n

g

g

F

F

l

l

e

e

x

x

x

x

o

o

p

p

o

o

m

m

p

p

Für die automatische Befüllung eines Flexxomats

FFlleexxxxoolluuttiioonnssBBVV

Jaartsveldstraat 5

7575 BP Oldenzaal, NL

www.flexxolutions.com

FLEXXOLUTIONS BV

JAARTSVELDSTRAAT 5 • 7575 BP OLDENZAAL • THE NETHERLANDS

TEL.: +31 (0)541 760400 • WWW.FLEXXOLUTIONS.NL • INFO@FLEXXOLUTIONS.NL

m

GGeebbrruuiikkeerrsshhaannddlleeiiddiinnggFFlleexxxxooppoommppCC

Voor het automatisch vullen van een Flexxomat met vulstandsbewaking

U

U

s

s

e

e

r

r

M

M

a

a

n

n

u

u

a

a

l

l

F

F

l

l

e

e

x

x

x

x

o

o

p

p

o

o

m

m

p

p

C

C

A dosing pump for automatically filling a Flexxomat with disinfectant monitoring system

B

B

e

e

t

t

r

r

i

i

e

e

b

b

s

s

a

a

n

n

l

l

e

e

i

i

t

t

u

u

n

n

g

g

F

F

l

l

e

e

x

x

x

x

o

o

p

p

o

o

m

m

p

p

C

C

Für die automatische Befüllung eines Flexxomats mit Füllstandsüberwachung

FFlleexxxxoolluuttiioonnssBBVV

Jaartsveldstraat 5

7575 BP Oldenzaal, NL

www.flexxolutions.com

INHOUD

1 Algemene informae............................................................. 3

2 Componenten van de Flexxopomp C..................................... 3

3 Instellen van de Flexxopomp C............................................... 4

4 Storingsanalyse en foutzoeken.............................................. 5

CONTENT

1 General informaon.............................................................. 6

2 Components of the Flexxopomp C........................................ 6

3 Seng of the Flexxopomp C................................................. 7

4 Malfuncons and troubleshoong........................................ 8

INHALT

1 Allgemein.............................................................................. 9

2 Flexxopomp C Komponenten................................................ 9

3 Einstellung des Flexxopomps C............................................. 10

4 Fehleranalyse und Fehlerbehebung...................................... 11

pag. 2 pag. 3

Rev. Sept 2019

1Algemene informatie

B

B

e

e

w

w

a

a

r

r

e

e

n

n

v

v

a

a

n

n

d

d

e

e

g

g

e

e

b

b

r

r

u

u

i

i

k

k

s

s

h

h

a

a

n

n

d

d

l

l

e

e

i

i

d

d

i

i

n

n

g

g

De gebruikershandleiding (incl. de mede geldige documenten) dient gebruik gereed in de nabijheid van de Flexxopomp C bewaard

te worden!

P

P

r

r

o

o

d

d

u

u

c

c

t

t

a

a

a

a

n

n

s

s

p

p

r

r

a

a

k

k

e

e

l

l

i

i

j

j

k

k

h

h

e

e

i

i

d

d

Indien schade aan personen, componenten, de installatie of het milieu ontstaat door het niet of deels niet naleven van deze

gebruiksaanwijzing is Flexxolutions niet aansprakelijk. Bij ongeautoriseerde maatregelen vervalt de garantie. Flexxolutions neemt

noch aansprakelijkheid noch garantie als geen originele reservedelen worden gebruikt en het op basis hiervan tot persoonlijke,

installatie, machine- en-of componentschade of uitval leidt.

Aansprakelijkheid of garantie tegen Flexxolutions is uitgesloten indien het op een van de volgende oorzaken is terug te voeren:

-Onbevoegd vervoeren, monteren, in gebruik nemen, bedienen of onderhouden

-Niet opvolgen van de instructies in de gebruikershandleiding betreffende montage, ingebruikname, gebruik en

onderhoud

-Eigenhandige aanpassingen of bouwkundige wijzigingen

-Onzorgvuldige controle van onderdelen welke aan slijtage onderhevig zijn

-Onderhoudswerkzaamheden door onbevoegde personen

-Onbedoeld gebruik

-Invloeden van buitenaf

Indirecte gevolgschade – ongeachte haar aard, vorm en omvang – en normale slijtage (o.a. afdichtingen) kunnen onder geen

beding aansprakelijkheid bewerkstelligen en/of garantieverplichtingen oproepen. Corrosie veroorzaakt door elektrochemische

reacties (bv. aardingsfouten, pH-waarden van substraat) kunnen geen grond voor klachten zijn.

R

R

e

e

s

s

e

e

r

r

v

v

e

e

d

d

e

e

l

l

e

e

n

n

Alle reservedelen kunnen door Flexxolutions worden geleverd. Om reservedelen te bestellen, graag direct contact opnemen met

Flexxolutions.

B

B

e

e

d

d

o

o

e

e

l

l

d

d

g

g

e

e

b

b

r

r

u

u

i

i

k

k

De Flexxopomp C dient uitsluitend als doseerpomp gebruikt te worden. De Flexxopomp C is geschikt voor het toedienen van

verdund desinfectans vanuit een vloeistofcontainer naar het product dat gedesinfecteerd dient te worden.

2Componenten van de Flexxopomp C

C

C

o

o

m

m

p

p

o

o

n

n

e

e

n

n

t

t

e

e

n

n

v

v

a

a

n

n

d

d

e

e

F

F

l

l

e

e

x

x

x

x

o

o

p

p

o

o

m

m

p

p

C

C

NL Gebruikershandleiding Flexxopomp C

Aan/uit knop

Aansluiting

vloeistoftoevoer

(van de container)

Vloeistoftoevoer

(naar de mat)

Stekker 230 Volt

Slang voor aansluiting

vloeistofcontainer

Slang voor

aansluiting mat

Sensor voor

geleidingsmat

Bevestigings-

materiaal

Rev. Sept 2019

3Instellen van de Flexxopomp C

Volg voor het instellen van de Flexxopomp C de volgende stappen:

Foto/Afbeelding Beschrijving

Open de behuizing van de Flexxopomp C met een

schroevendraaier.

Stel de ‘Jumper’, afhankelijke van de gewenste hoeveelheid per

uur, in op 30, 60, 90 of 120 L/uur.

De aanbevolen instelling is een hoeveelheid van 30 L/uur.

De bovenste draaiknop ‘Sense’ is voor het instellen van de

gevoeligheid van de sensor in de mat. Deze is standaard ingesteld

op de helft (±60) en kan worden bijgesteld met behulp van een

schroevendraaier.

Voor een sterkere gevoeligheid draait u naar rechts.

0 – minst gevoelig = mat wordt natter

100 – meest gevoelig = mat wordt droger

De onderste draaiknop ‘Delay’ hoort op 0 te staan. Als dit nog niet

het geval is, zet dan de wijzer op 0 met behulp van een

schroevendraaier.

Sluit de behuizing van de Flexxopomp C met een

schroevendraaier.

Bevestig de zwarte ophangplaat op de gewenste plek door middel

van het meegeleverde bevestigingsmateriaal.

Vervolgens kan de Flexxopomp C hieraan opgehangen worden.

NL - Pagina 2 van 4

NL Gebruikershandleiding Flexxopomp C

Rev. Sept 2019

Sluit de slang vanuit de vloeistofcontainer aan op de pomp. LET

OP: dit is de linker aansluiting!!

Sluit de slang vanuit de mat aan op de pomp. LET OP: dit is de

rechteraansluiting!!

Sluit de sensoraansluiting aan op de pomp:

1) Druk de sensoraansluiting in de daarvoor bestemde

ingang in de pomp.

2) Druk het clipje naar beneden, zodat de aansluiting goed

aan de pomp bevestigd is.

4Storingsanalyse en foutzoeken

W

W

a

a

t

t

t

t

e

e

d

d

o

o

e

e

n

n

b

b

i

i

j

j

s

s

t

t

o

o

r

r

i

i

n

n

g

g

e

e

n

n

?

?

¾Informeert u bij storingen aan de Flexxopomp C de producent. Deze is op uw ervaring en terugkoppeling

aangewezen om continu verbeteringen aan het product te kunnen doorvoeren.

¾Waarschuwt u in geval van brand de lokale brandweer.

F

F

o

o

u

u

t

t

z

z

o

o

e

e

k

k

e

e

n

n

Een groot deel van de optredende storingen is meestal op een kleine fout of afwijking in het sy steem terug te voeren. Bewaart u

te allen tijde de rust en probeert u een overzicht van de situatie te verkrijgen. De meeste storingen zijn middels systematisch

storingzoeken gemakkelijk op te sporen en snel te verhelpen. Gebruikt u hiertoe ook de onderstaande tabel. Bij storingen welke

zich niet eenvoudig laten oplossen, neemt u contact op met de producent Flexxolutions.

G

G

e

e

v

v

a

a

a

a

r

r

t

t

i

i

j

j

d

d

e

e

n

n

s

s

g

g

e

e

b

b

r

r

u

u

i

i

k

k

GEVAAR TIJDENS GEBRUIK!

De Flexxopomp is niet ontworpen om te draaien zonder vloeistof! Dus bij een afgeklemde vloeistofaanvoer of een leeg

doseervat dient de pomp altijd direct uitgeschakeld te worden!

S

S

t

t

o

o

r

r

i

i

n

n

g

g

s

s

t

t

a

a

b

b

e

e

l

l

Storing Mogelijke oorzaak Maatregel

Verkeerde hoeveelheid De ‘Jumper’ is verkeerd ingesteld Open de behuizing en stel de ‘Jumper’

op juiste hoeveelheid in

Geen stroom Stekker niet in stopcontact en/of

zekering kapot

Stop stekker in stopcontact en/of

check de zekering

Lekkage in de pomp Slang in de pomp kapot Vervang de slang in de pomp

De pomp schakelt niet Check de aansluitingen Sluit aansluitingen proper aan

De pomp schakelt niet bij overlopende

mat

Gevoeligheid niet goed ingesteld Stel gevoeligheid hoger in (naar rechts)

De pomp schakelt niet bij droge matGevoeligheid niet goed ingesteldStel gevoeligheid lagerin (naar links)

De in dit document vermelde gegevens dienen als productbeschrijving. Een bindende uitspraak of een bepaalde toepassing mogelijk is kan hier

niet zonder project gerelateerd advies door de R&D-afdeling gedaan worden. De beschreven onderdelen ontslaan de gebruiker niet van zijn

eigen professionele beoordeling van de actuele situatie. De toegepaste materialen evenals het eindproduct is aan normale slijtage onderhevig.

T.g.v. veroudering kan de situatie wijzigen t.o.v. de uitgangssituatie. © Alle rechten behoren aan FLEXXOLUTIONS GFS BV. Vermenigvuldiging,

kopiëren of verspreiden van dit document of delen hieruit is niet zonder onze schriftelijke toestemming toegestaan. Op de diverse foto’s en

tekeningen in dit document zijn voorbeeldconfiguraties van het beschreven product weergegeven. Het geleverde product kan hiervan afwijken.

- - Einde van de gebruikershandleiding - -

NL

Gebruikershandleiding Flexxopomp C

pag. 4 pag. 5

Rev. June 2018

1General information

P

P

r

r

e

e

s

s

e

e

r

r

v

v

a

a

t

t

i

i

o

o

n

n

o

o

f

f

t

t

h

h

e

e

o

o

p

p

e

e

r

r

a

a

t

t

i

i

o

o

n

n

m

m

a

a

n

n

u

u

a

a

l

l

The operation manual (including valid documents) must be kept ready for use near the Flexxopomp!

P

P

r

r

o

o

d

d

u

u

c

c

t

t

l

l

i

i

a

a

b

b

i

i

l

l

i

i

t

t

y

y

For damage to persons, property, the environment and / or operating damage caused by the fact that this operating manual was

not, or not fully observed, the company Flexxolutions does not accept any liability. Unauthorized modifications will void the

warranty. The company Flexxolutions does not accept any liability nor warranty if, instead of an original spare part as

recommended in the operating manual or in the spare parts list, a different spare part is used, and Flexxolutions also does not

accept any liability nor warranty if using this non-genuine part leads to personal injury, material damage and / or failure. Warranty

and liability claims for damages to persons, property and the environment are excluded if they are caused by one or more of the

following reasons:

-Improper transport, installation, commissioning, operation or maintenance

-Failure to observe the instructions in the operating manual concerning assembly, commissioning, operation and

maintenance

-Unauthorized modifications or constructural alterations

-Inadequate monitoring of parts that are subject to wear

-Improperly executed repairs

-Usage not according to the intended purpose

-Impact of foreign objects

Indirect consequential damages – regardless of the type – and natural wear (seals etc.) shall under no circumstances give rise to

a liability or a warranty claim. Corrosion caused by electrochemical reactions (e.g. different ground potential, pH-value of the

substrate) or by microbial influences (e.g. bacteria, algae, fungi) does not constitute a defect (reason for complaint).

S

S

p

p

a

a

r

r

e

e

p

p

a

a

r

r

t

t

s

s

All spare parts can be delivered by Flexxolutions. To order spare parts, please contact Flexxolutions directly.

I

I

n

n

t

t

e

e

n

n

d

d

e

e

d

d

u

u

s

s

e

e

The Flexxopomp serves exclusively as a dosing pump. The Flexxopomp is suitable for the delivery of diluted disinfectants from a

liquid container to the product that needs to be disinfected.

2Components of the Flexxopomp

C

C

o

o

m

m

p

p

o

o

n

n

e

e

n

n

t

t

s

s

o

o

f

f

t

t

h

h

e

e

F

F

l

l

e

e

x

x

x

x

o

o

p

p

o

o

m

m

p

p

On/off button

Timer

Fluid supply

(from the container)

Fluid supply

(to the mat)

Power plug

230 V

EN User manual Flexxopomp

Rev. June 2018

1General information

PPrreesseerrvvaattiioonnoofftthheeooppeerraattiioonnmmaannuuaall

The operation manual (including valid documents) must be kept ready for use near the Flexxopomp!

PPrroodduuccttlliiaabbiilliittyy

For damage to persons, property, the environment and / or operating damage caused by the fact that this operating manual was

not, or not fully observed, the company Flexxolutions does not accept any liability. Unauthorized modifications will void the

warranty. The company Flexxolutions does not accept any liability nor warranty if, instead of an original spare part as

recommended in the operating manual or in the spare parts list, a different spare part is used, and Flexxolutions also does not

accept any liability nor warranty if using this non-genuine part leads to personal injury, material damage and / or failure. Warranty

and liability claims for damages to persons, property and the environment are excluded if they are caused by one or more of the

following reasons:

-Improper transport, installation, commissioning, operation or maintenance

-Failure to observe the instructions in the operating manual concerning assembly, commissioning, operation and

maintenance

-Unauthorized modifications or constructural alterations

-Inadequate monitoring of parts that are subject to wear

-Improperly executed repairs

-Usage not according to the intended purpose

-Impact of foreign objects

Indirect consequential damages – regardless of the type – and natural wear (seals etc.) shall under no circumstances give rise to

a liability or a warranty claim. Corrosion caused by electrochemical reactions (e.g. different ground potential, pH-value of the

substrate) or by microbial influences (e.g. bacteria, algae, fungi) does not constitute a defect (reason for complaint).

SSppaarreeppaarrttss

All spare parts can be delivered by Flexxolutions. To order spare parts, please contact Flexxolutions directly.

IInntteennddeedduussee

The Flexxopomp serves exclusively as a dosing pump. The Flexxopomp is suitable for the delivery of diluted disinfectants from a

liquid container to the product that needs to be disinfected.

2Components of the Flexxopomp

CCoommppoonneennttssoofftthheeFFlleexxxxooppoommpp

On/off button

Timer

Fluid supply

(from the container)

Fluid supply

(to the mat)

Power plug

230 V

EN User manual Flexxopomp

C

Rev. Sept 2019

3Setting of the Flexxopomp C

Follow the instructions below for setting the Flexxopomp C:

Photo/Figure Description

Open the housing of the Flexxopomp C with a screwdriver.

Set the ‘Jumper’, depending on the desired amount per hour, on

30, 60, 90 or 120 L/hour.

The recommended setting is 30 L/hour.

The upper turn button ‘Sense’ is meant for setting the sensitivity

of the sensor in the mat. Standard setting is ±60, but can be

adjusted with a screw driver. For a stronger sensitivity, turn to the

right.

0 – least sensitive = mat gets wetter

100 – most sensitive = mat gets dryer

The lower turn button ‘Delay’ should be on 0. If this is not the

case yet, then adjust the button to 0 with a screw driver.

Close the housing of the Flexxopomp C with a screwdriver.

Attach the black mounting plate to the desired location using the

supplied fixing material.

The Flexxopomp C can then be attached to this plate.

EN User manual Flexxopomp C

EN - Page 2 of 4

pag. 6 pag. 7

Rev. Sept 2019

Attach the hose from the fluid container to the pump.

ATTENTION: this is the left plug!!

Attach the hose from the mat to the pump.

ATTENTION: this is the rightplug!!

Attach the sensor connection to the pump:

3) Put the sensor plug in the intended input of the pump

4) Push the clip down, to make sure that the connection is

securely attached to the pump.

4Malfunctions and troubleshooting

W

W

h

h

a

a

t

t

t

t

o

o

d

d

o

o

w

w

h

h

e

e

n

n

m

m

a

a

l

l

f

f

u

u

n

n

c

c

t

t

i

i

o

o

n

n

s

s

o

o

c

c

c

c

u

u

r

r

?

?

¾In the event of a malfunction, inform the manufacturer of the failure. The manufacturer depends on your

experience and feedback in order to be able to implement continuous improvements to the product.

¾In case of fire, warn the local fire brigade.

T

T

r

r

o

o

u

u

b

b

l

l

e

e

s

s

h

h

o

o

o

o

t

t

i

i

n

n

g

g

A large proportion of the faults that occur can usually be traced back to a small error or anomaly in the system. Keep the peace

and quiet at all times and try to get an overview of the situation. Most failures can be easily detected and rectified quickly by

systematic troubleshooting. Please also use the table below. In case of malfunctions that cannot be easily solved, please cont act

the manufacturer Flexxolutions.

D

D

a

a

n

n

g

g

e

e

r

r

d

d

u

u

r

r

i

i

n

n

g

g

u

u

s

s

e

e

DANGER DURING USE!

The Flexxopomp is not designed to run without fluid! So if the liquid supply is blocked or the dosing vessel is empty,

the pump must always be switched off immediately!

M

M

a

a

l

l

f

f

u

u

n

n

c

c

t

t

i

i

o

o

n

n

t

t

a

a

b

b

l

l

e

e

Malfunction Possible cause Measure

Wrong capacity The ‘Jumper’ is set wrong Open the housing and set the ‘Jumper’

on right capacity

No power Plug not in socket and/or fuse broken Put plug in socket and/or check the fuse

Leakage in pump Hose in pump broken Replace the hose in the pump

The pump does not switch Plugs not properly connected Connect the plugs properly

The pump does not switch when

disinfectant is overflowing

Sensitivity not properly set Adjust the sensitivity to a higher level (to

the right)

The pump does not switch when the mat

is dry

Sensitivity not properly set Adjust the sensitivity to a lower level (to

the left)

The description in this operation manual is a general product description. A binding decision about intended use for a certain application can only be made by the

Flexxolutions R&D department. The description below does not hold the user free of his own professional behaviour and decision making regarding an actual

situation. The used materials in the product may be subject to normal wear. Due to normal wear and alteration the actual situation and specifications may deviate

from the start of the lifetime. © All rights belong to FLEXXOLUTIONS GFS BV. Multiplication, copying or distribution of this document or parts of the documents

prohibited except in the situation Flexxolutions give s prior his approval in written form. In this document drawings and pictures are used which show the standard

configuration. The actual situation may deviate from this.

- - End of the operation manual - -

EN User manual Flexxopomp C

Rev. June 2018

1General information

PPrreesseerrvvaattiioonnoofftthheeooppeerraattiioonnmmaannuuaall

The operation manual (including valid documents) must be kept ready for use near the Flexxopomp!

PPrroodduuccttlliiaabbiilliittyy

For damage to persons, property, the environment and / or operating damage caused by the fact that this operating manual was

not, or not fully observed, the company Flexxolutions does not accept any liability. Unauthorized modifications will void the

warranty. The company Flexxolutions does not accept any liability nor warranty if, instead of an original spare part as

recommended in the operating manual or in the spare parts list, a different spare part is used, and Flexxolutions also does not

accept any liability nor warranty if using this non-genuine part leads to personal injury, material damage and / or failure. Warranty

and liability claims for damages to persons, property and the environment are excluded if they are caused by one or more of the

following reasons:

-Improper transport, installation, commissioning, operation or maintenance

-Failure to observe the instructions in the operating manual concerning assembly, commissioning, operation and

maintenance

-Unauthorized modifications or constructural alterations

-Inadequate monitoring of parts that are subject to wear

-Improperly executed repairs

-Usage not according to the intended purpose

-Impact of foreign objects

Indirect consequential damages – regardless of the type – and natural wear (seals etc.) shall under no circumstances give rise to

a liability or a warranty claim. Corrosion caused by electrochemical reactions (e.g. different ground potential, pH-value of the

substrate) or by microbial influences (e.g. bacteria, algae, fungi) does not constitute a defect (reason for complaint).

SSppaarreeppaarrttss

All spare parts can be delivered by Flexxolutions. To order spare parts, please contact Flexxolutions directly.

IInntteennddeedduussee

The Flexxopomp serves exclusively as a dosing pump. The Flexxopomp is suitable for the delivery of diluted disinfectants from a

liquid container to the product that needs to be disinfected.

2Components of the Flexxopomp

CCoommppoonneennttssoofftthheeFFlleexxxxooppoommpp

On/off button

Timer

Fluid supply

(from the container)

Fluid supply

(to the mat)

Power plug

230 V

EN User manual Flexxopomp

Rev. June 2018

4Malfunctions and troubleshooting

WWhhaattttooddoowwhheennmmaallffuunnccttiioonnssooccccuurr??

¾In the event of a malfunction, inform the manufacturer of the failure. The manufacturer depends on your

experience and feedback in order to be able to implement continuous improvements to the product.

¾In case of fire, warn the local fire brigade.

TTrroouubblleesshhoooottiinngg

A large proportion of the faults that occur can usually be traced back to a small error or anomaly in the system. Keep the peace

and quiet at all times and try to get an overview of the situation. Most failures can be easily detected and rectified quickly by

systematic troubleshooting. Please also use the table below. In case of malfunctions that cannot be easily solved, please cont act

the manufacturer Flexxolutions.

DDaannggeerrdduurriinngguussee

DANGER DURING USE!

The Flexxopomp is not designed to run without fluid! So if the liquid supply is blocked or the dosing vessel is empty,

the pump must always be switched off immediately!

MMaallffuunnccttiioonnttaabbllee

Malfunction Possible cause Measure

Wrong capacity The ‘Jumper’ is set wrong Open the housing and set the ‘Jumper’

on right capacity

No power Plug not in socket and/or fuse broken Put plug in socket and/or check the fuse

Leakage in pump Hose in pump broken Replace the hose in the pump

The description in this operation manual is a general product description. A binding decision about intended use for a certain application can

only be made by the Flexxolutions R&D department. The description below does not hold the user free of his own professional behaviour and

decision making regarding an actual situation. The used materials in the product may be subject to normal wear. Due to normal wear and

alteration the actual situation and specifications may deviate from the start of the lifetime. © All rights belong to FLEXXOLUTIONS GFS BV.

Multiplication, copying or distribution of this document or parts of the documents prohibited except in the situation Flexxolutions give s prior

his approval in written form. In this document drawings and pictures are used which show the standard configuration. The actual situation may

deviate from this.

- - End of the user manual - -

EN User Manual Flexxopomp

Rev. Sept 2019

Attach the hose from the fluid container to the pump.

ATTENTION: this is the left plug!!

Attach the hose from the mat to the pump.

ATTENTION: this is the rightplug!!

Attach the sensor connection to the pump:

3) Put the sensor plug in the intended input of the pump

4) Push the clip down, to make sure that the connection is

securely attached to the pump.

4Malfunctions and troubleshooting

WWhhaattttooddoowwhheennmmaallffuunnccttiioonnssooccccuurr??

¾In the event of a malfunction, inform the manufacturer of the failure. The manufacturer depends on your

experience and feedback in order to be able to implement continuous improvements to the product.

¾In case of fire, warn the local fire brigade.

TTrroouubblleesshhoooottiinngg

A large proportion of the faults that occur can usually be traced back to a small error or anomaly in the system. Keep the peace

and quiet at all times and try to get an overview of the situation. Most failures can be easily detected and rectified quickly by

systematic troubleshooting. Please also use the table below. In case of malfunctions that cannot be easily solved, please cont act

the manufacturer Flexxolutions.

DDaannggeerrdduurriinngguussee

DANGER DURING USE!

The Flexxopomp is not designed to run without fluid! So if the liquid supply is blocked or the dosing vessel is empty,

the pump must always be switched off immediately!

MMaallffuunnccttiioonnttaabbllee

Malfunction Possible cause Measure

Wrong capacity The ‘Jumper’ is set wrong Open the housing and set the ‘Jumper’

on right capacity

No power Plug not in socket and/or fuse broken Put plug in socket and/or check the fuse

Leakage in pump Hose in pump broken Replace the hose in the pump

The pump does not switch Plugs not properly connected Connect the plugs properly

The pump does not switch when

disinfectant is overflowing

Sensitivity not properly set Adjust the sensitivity to a higher level (to

the right)

The pump does not switch when the mat

is dry

Sensitivity not properly set Adjust the sensitivity to a lower level (to

the left)

The description in this operation manual is a general product description. A binding decision about intended use for a certain application can only be made by the

Flexxolutions R&D department. The description below does not hold the user free of his own professional behaviour and decision making regarding an actual

situation. The used materials in the product may be subject to normal wear. Due to normal wear and alteration the actual situation and specifications may deviate

from the start of the lifetime. © All rights belong to FLEXXOLUTIONS GFS BV. Multiplication, copying or distribution of this document or parts of the documents

prohibited except in the situation Flexxolutions give s prior his approval in written form. In this document drawings and pictures are used which show the standard

configuration. The actual situation may deviate from this.

- - End of the operation manual - -

EN User manual Flexxopomp C

C

Rev. Sept 2019

1Allgemein

A

A

u

u

f

f

b

b

e

e

w

w

a

a

h

h

r

r

u

u

n

n

g

g

Die Betriebsanleitung (inkl. aller mitgeltenden Dokumenten) ist ständig griffbereit in der Nähe der Abdeckung aufzubewahren!

P

P

r

r

o

o

d

d

u

u

k

k

t

t

h

h

a

a

f

f

t

t

u

u

n

n

g

g

Wenn Personen-, Komponenten-, Installations- oder Umweltschäden durch Nichtbeachtung oder teilweise Nichtbeachtung dieser

Betriebsanleitung verursacht werden, haftet Flexxolutions nicht. Nicht autorisierte Maßnahmen führen zum Erlöschen der

Garantie. Flexxolutions übernimmt keine Haftung oder Garantie, wenn keine Original-Ersatzteile verwendet werden und führt auf

dieser Grundlage zu Personen-, Installations-, Maschinen- und Komponentenschäden oder Ausfällen. Eine Haftung oder

Gewährleistung gegenüber Flexxolutions ist ausgeschlossen, wenn sie auf einen der folgenden Gründe zurückzuführen ist:

-Unbefugter Transport, Montage, Inbetriebnahme, Betrieb oder Wartung

-Nichtbeachtung der Hinweise in der Betriebsanleitung bezüglich Montage, Inbetriebnahme, Gebrauch und Wartung.

-Eigenmächtige Umbauten oder bauliche Veränderungen

-Unachtsame Prüfung von Verschleißteilen

-Wartungsarbeiten durch Unbefugte

-Unbeabsichtigter Gebrauch

-Externe Einflüsse

Indirekte Folgeschäden - gleich welcher Art, Form und Größe - und normaler Verschleiß (einschließlich Dichtungen) können unter

keinen Umständen zu einer Haftung führen und/oder Gewährleistungsverpflichtungen begründen. Korrosion durch

elektrochemische Reaktionen (z. B. Erdungsfehler, pH-Werte des Substrates) kann kein Reklamationsgrund sein.

E

E

r

r

s

s

a

a

t

t

z

z

t

t

e

e

i

i

l

l

e

e

Alle Ersatzteile können von Flexxolutions geliefert werden. Um Ersatzteile zu bestellen, wenden Sie sich bitte direkt an

Flexxolutions.

B

B

e

e

s

s

t

t

i

i

m

m

m

m

u

u

n

n

g

g

s

s

g

g

e

e

m

m

ä

ä

ß

ß

e

e

V

V

e

e

r

r

w

w

e

e

n

n

d

d

u

u

n

n

g

g

Der Flexxopomp C dient ausschließlich als Dosierpumpe eingesetzt werden. Der Flexxopomp C eignet sich zur Verabreichung von

verdünnten Desinfektionsmitteln aus einem Flüssigkeitsbehälter an das zu desinfizierende Produkt.

2Flexxopomp C Komponenten

K

K

o

o

m

m

p

p

o

o

n

n

e

e

n

n

t

t

e

e

n

n

d

d

e

e

s

s

F

F

l

l

e

e

x

x

x

x

o

o

p

p

o

o

m

m

p

p

s

s

C

C

DE Betriebsanleitung Flexxopomp C

Einschaltknopf

Flüssigkeitszufuhr

(vom Behälter)

Flüssigkeitszufuhr

(zur Matte)

Stecker 230 Volt

Schlauch für

Anschluss Behälter

Schlauch für

Anschluss Matte

Sensor

Montagezubehör

pag. 8 pag. 9

Rev. Sept 2019

3Einstellung des FlexxopompsC

Führen Sie die folgenden Schritte aus, um den Flexxopomp C einzurichten:

Foto/Bild Beschreibung

Öffnen Sie das Gehäuse des Flexxopomps C mit einem

Schraubendreher.

Je nach gewünschter Quantität pro Stunde,stellen Sie den

‘Jumper‘ auf 30, 60, 90 oder 120 L/Stunde.

Die empfohlene Einstellung ist eine Quantität von 30 L/Stunde.

Der obere Drehknopf ‚Sense‘ dient zur Einstellung der

Empfindlichkeit des Sensors in der Matte. Er ist standardmäßig

auf die Hälfte (±60) eingestellt und kann mit einem

Schraubendreher geändert werden.

0 – niedrigste empfindlich: Matte wird nasser

100 – höchste empfindlich: Matte wird trockener

Zur Erhöhung der Empfindlichkeit nach rechts drehen.

Der untere Drehknopf ‚Delay‘ sollte nach 0 zeigen. Wenn das noch

nicht der Fall ist, stellen Sie den Zeiger mit einem

Schraubendreher auf 0.

Schließen Sie das Gehäuse des Flexxopomps C mit einem

Schraubendreher.

Befestigen Sie die schwarze Aufhängeplatte mit dem

mitgelieferten Befestigungsmaterial an der gewünschten Stelle.

Der Flexxopomp C kann dann daran aufgehängt werden.

DE Betriebsanleitung Flexxopomp C

DE - Seite 2 von 4

Rev. Sept 2019

Verbinden Sie den Schlauch vom Flüssigkeitsbehälter mit der

Pumpe. ACHTUNG: Das ist die linke Verbindung!!

Verbinden Sie den Schlauch von der Matte mit der Pumpe.

ACHTUNG: Das ist die rechte Verbindung!!

Schließen Sie den Sensoranschluss an die Pumpe an:

1) Schieben Sie den Sensoranschluss an dem

entsprechenden Eingang in die Pumpe.

2) Schieben Sie den Clip nach unten, so dass die Anschlüsse

fest mit der Pumpe verbunden ist.

4Fehleranalyse und Fehlerbehebung

W

W

a

a

s

s

i

i

s

s

t

t

b

b

e

e

i

i

S

S

t

t

ö

ö

r

r

u

u

n

n

g

g

e

e

n

n

z

z

u

u

t

t

u

u

n

n

?

?

¾Im Falle einer Fehlfunktion sollte der Hersteller über den Fehler informiert werden. Dies hängt von Ihrer

Erfahrung und Ihrem Feedback ab, um kontinuierliche Verbesserungen am Produkt durchführen zu können.

¾Im Brandfall ist die örtliche Feuerwehr zu benachrichtigen.

F

F

e

e

h

h

l

l

e

e

r

r

b

b

e

e

h

h

e

e

b

b

u

u

n

n

g

g

Ein großer Teil der auftretenden Fehler ist in der Regel auf einen kleinen Fehler oder eine Anomalie im System zurückzuführen.

Behalten Sie jederzeit die Ruhe und versuchen Sie, sich einen Überblick über die Situation zu verschaffen. Die meisten Störungen

lassen sich durch systematische Fehlersuche schnell und einfach erkennen und beheben. Bitte verwenden Sie auch die

untenstehende Tabelle. Bei Störungen, die nicht einfach zu beheben sind, wenden Sie sich bitte an den Hersteller Flexxolutions.

G

G

e

e

f

f

a

a

h

h

r

r

b

b

e

e

i

i

m

m

G

G

e

e

b

b

r

r

a

a

u

u

c

c

h

h

Die Flexxopomp ist nicht für den Betrieb ohne Flüssigkeit ausgelegt! Bei blockierter Flüssigkeitszufuhr oder leerem

Dosierbehälter muss die Pumpe immer sofort abgeschaltet werden!

F

F

e

e

h

h

l

l

e

e

r

r

t

t

a

a

b

b

e

e

l

l

l

l

e

e

Fehler Mögliche Ursache Maßnahme

Falsche Quantität Der ’Jumper‘ ist nicht richtig eingestellt Öffnen Sie das Gehäuse und setzen Sie

den ‘Jumper‘ auf die richtige Quantität

Kein Strom Stecker nicht in die Steckdose und/oder

Sicherung defekt

Stecker in Steckdose stecken und/oder

Sicherung kontrollieren

Leckage in der Pumpe Schlauch in der Pumpe defekt Ersetzen Sie den Schlauch in der Pumpe

Die Pumpe schaltet nicht Überprüfen Sie die Anschlüsse Verbinden Sie die Anschlüsse richtig

Die Pumpe schaltet nicht, wenn die

Matte überlauft

Empfindlichkeit ist nicht richtig

eingestellt

Empfindlichkeit höher einstellen (nach

rechts)

Die Pumpe schaltet nicht, wenn die

Matte trocken ist

Empfindlichkeit ist nicht richtig

eingestellt

Empfindlichkeit niedriger einstellen

(nach links)

Die Informationen in diesem Dokument dienen als Produktbeschreibung. Eine verbindliche Aussage, ob eine bestimmte Anwendung möglich ist, kann hier von der

F&E-Abteilung ohne projektbezogene Beratung nicht getroffen werden. Die beschriebenen Teile befreien den Anwender nicht von seiner eigenen professionellen

Einschätzung der aktuellen Situation. Die verwendeten Materialien und das Endprodukt unterliegen einem normalen Verschleiß. DasAltern kann die Situation im

Vergleich zur Ausgangssituation verändern. © Alle Rechte gehören FLEXXOLUTIONS GFS BV. Die Vervielfältigung, Vervielfältigung oder Verbreitung dieses

Dokuments oder Teilen davon ist ohne unsere schriftliche Zustimmung nicht gestattet. Die verschiedenen Fotos und Zeichnungen in diesem Dokument zeigen

beispielhafte Konfigurationen des beschriebenen Produkts. Die gelieferte Ware kann hiervon abweichen.

- - Ende von die Bedienungsanleitung - -

DE Betriebsanleitung Flexxopomp C

Rev. June 2018

4Fehleranalyse und Fehlerbehebung

WWaassiissttbbeeiiSSttöörruunnggeennzzuuttuunn??

¾Im Falle einer Fehlfunktion sollte der Hersteller über den Fehler informiert werden. Dies hängt von Ihrer

Erfahrung und Ihrem Feedback ab, um kontinuierliche Verbesserungen am Produkt durchführen zu können.

¾Im Brandfall ist die örtliche Feuerwehr zu benachrichtigen.

FFeehhlleerrbbeehheebbuunngg

Ein großer Teil der auftretenden Fehler ist in der Regel auf einen kleinen Fehler oder eine Anomalie im System zurückzuführen.

Behalten Sie jederzeit die Ruhe und versuchen Sie, sich einen Überblick über die Situation zu verschaffen. Die meisten Störungen

lassen sich durch systematische Fehlersuche schnell und einfach erkennen und beheben. Bitte verwenden Sie auch die

untenstehende Tabelle. Bei Störungen, die nicht einfach zu beheben sind, wenden Sie sich bitte an den Hersteller Flexxolutions.

GGeeffaahhrrbbeeiimmGGeebbrraauucchh

GEFAHR BEIM BETRIEB!

Die Flexxopomp ist nicht für den Betrieb ohne Flüssigkeit ausgelegt! Bei blockierter Flüssigkeitszufuhr oder leerem

Dosierbehälter muss die Pumpe immer sofort abgeschaltet werden!

FFeehhlleerrttaabbeellllee

Fehler Mögliche Ursache Maßnahme

Falsche Quantität Der ’Jumper‘ ist nicht richtig eingestellt Öffnen Sie das Gehäuse und setzen Sie

den ‘Jumper‘ auf die richtige Quantität

Kein Strom Stecker nicht in die Steckdose und/oder

Sicherung defekt

Stecker in Steckdose stecken und/oder

Sicherung kontrollieren

Leckage in der Pumpe Schlauch in der Pumpe defekt Ersetzen Sie den Schlauch in der Pumpe

Die Informationen in diesem Dokument dienen als Produktbeschreibung. Eine verbindliche Aussage, ob eine bestimmte Anwendung möglich ist,

kann hier von der F&E-Abteilung ohne projektbezogene Beratung nicht getroffen werden. Die beschriebenen Teile befreien den Anwender nicht

von seiner eigenen professionellen Einschätzung der aktuellen Situation. Die verwendeten Materialien und das Endprodukt unterliegen einem

normalen Verschleiß. Das Altern kann die Situation im Vergleich zur Ausgangssituation verändern. © Alle Rechte gehören FLEXXOLUTIONS GFS

BV. Die Vervielfältigung, Vervielfältigung oder Verbreitung dieses Dokuments oder Teilen davon ist ohne unsere schriftliche Zustimmung nicht

gestattet. Die verschiedenen Fotos und Zeichnungen in diesem Dokument zeigen beispielhafte Konfigurationen des beschriebenen Produkts. Die

gelieferte Ware kann hiervon abweichen.

- - Ende der Betriebsanleitung - -

DE Betriebsanleitung Flexxopomp

Rev. Sept 2019

Verbinden Sie den Schlauch vom Flüssigkeitsbehälter mit der

Pumpe. ACHTUNG: Das ist die linke Verbindung!!

Verbinden Sie den Schlauch von der Matte mit der Pumpe.

ACHTUNG: Das ist die rechte Verbindung!!

Schließen Sie den Sensoranschluss an die Pumpe an:

1) Schieben Sie den Sensoranschluss an dem

entsprechenden Eingang in die Pumpe.

2) Schieben Sie den Clip nach unten, so dass die Anschlüsse

fest mit der Pumpe verbunden ist.

4Fehleranalyse und Fehlerbehebung

WWaassiissttbbeeiiSSttöörruunnggeennzzuuttuunn??

¾Im Falle einer Fehlfunktion sollte der Hersteller über den Fehler informiert werden. Dies hängt von Ihrer

Erfahrung und Ihrem Feedback ab, um kontinuierliche Verbesserungen am Produkt durchführen zu können.

¾Im Brandfall ist die örtliche Feuerwehr zu benachrichtigen.

FFeehhlleerrbbeehheebbuunngg

Ein großer Teil der auftretenden Fehler ist in der Regel auf einen kleinen Fehler oder eine Anomalie im System zurückzuführen.

Behalten Sie jederzeit die Ruhe und versuchen Sie, sich einen Überblick über die Situation zu verschaffen. Die meisten Störungen

lassen sich durch systematische Fehlersuche schnell und einfach erkennen und beheben. Bitte verwenden Sie auch die

untenstehende Tabelle. Bei Störungen, die nicht einfach zu beheben sind, wenden Sie sich bitte an den Hersteller Flexxolutions.

GGeeffaahhrrbbeeiimmGGeebbrraauucchh

Die Flexxopomp ist nicht für den Betrieb ohne Flüssigkeit ausgelegt! Bei blockierter Flüssigkeitszufuhr oder leerem

Dosierbehälter muss die Pumpe immer sofort abgeschaltet werden!

FFeehhlleerrttaabbeellllee

Fehler Mögliche Ursache Maßnahme

Falsche Quantität Der ’Jumper‘ ist nicht richtig eingestellt Öffnen Sie das Gehäuse und setzen Sie

den ‘Jumper‘ auf die richtige Quantität

Kein Strom Stecker nicht in die Steckdose und/oder

Sicherung defekt

Stecker in Steckdose stecken und/oder

Sicherung kontrollieren

Leckage in der Pumpe Schlauch in der Pumpe defekt Ersetzen Sie den Schlauch in der Pumpe

Die Pumpe schaltet nicht Überprüfen Sie die Anschlüsse Verbinden Sie die Anschlüsse richtig

Die Pumpe schaltet nicht, wenn die

Matte überlauft

Empfindlichkeit ist nicht richtig

eingestellt

Empfindlichkeit höher einstellen (nach

rechts)

Die Pumpe schaltet nicht, wenn die

Matte trocken ist

Empfindlichkeit ist nicht richtig

eingestellt

Empfindlichkeit niedriger einstellen

(nach links)

Die Informationen in diesem Dokument dienen als Produktbeschreibung. Eine verbindliche Aussage, ob eine bestimmte Anwendung möglich ist, kann hier von der

F&E-Abteilung ohne projektbezogene Beratung nicht getroffen werden. Die beschriebenen Teile befreien den Anwender nicht von seiner eigenen professionellen

Einschätzung der aktuellen Situation. Die verwendeten Materialien und das Endprodukt unterliegen einem normalen Verschleiß. DasAltern kann die Situation im

Vergleich zur Ausgangssituation verändern. © Alle Rechte gehören FLEXXOLUTIONS GFS BV. Die Vervielfältigung, Vervielfältigung oder Verbreitung dieses

Dokuments oder Teilen davon ist ohne unsere schriftliche Zustimmung nicht gestattet. Die verschiedenen Fotos und Zeichnungen in diesem Dokument zeigen

beispielhafte Konfigurationen des beschriebenen Produkts. Die gelieferte Ware kann hiervon abweichen.

- - Ende von die Bedienungsanleitung - -

DE Betriebsanleitung Flexxopomp C

pag. 10 pag. 11

This manual suits for next models

1

Table of contents

Languages:

Other FLEXXOLUTIONS Water Pump manuals

Popular Water Pump manuals by other brands

Garland

Garland AMAZON 1209 XE 4T instruction manual

Edwards

Edwards iXH100 instruction manual

Zodiac

Zodiac FloPro e3 Instructions for installation & use

Crane

Crane PROSSER HYMERGIBLE 7-06000 Series Installation and operation manual

Pacific hydrostar

Pacific hydrostar 69746 Owner's manual & safety instructions

Hozelock

Hozelock aquaforce 6000 manual