5

INSTALLATION

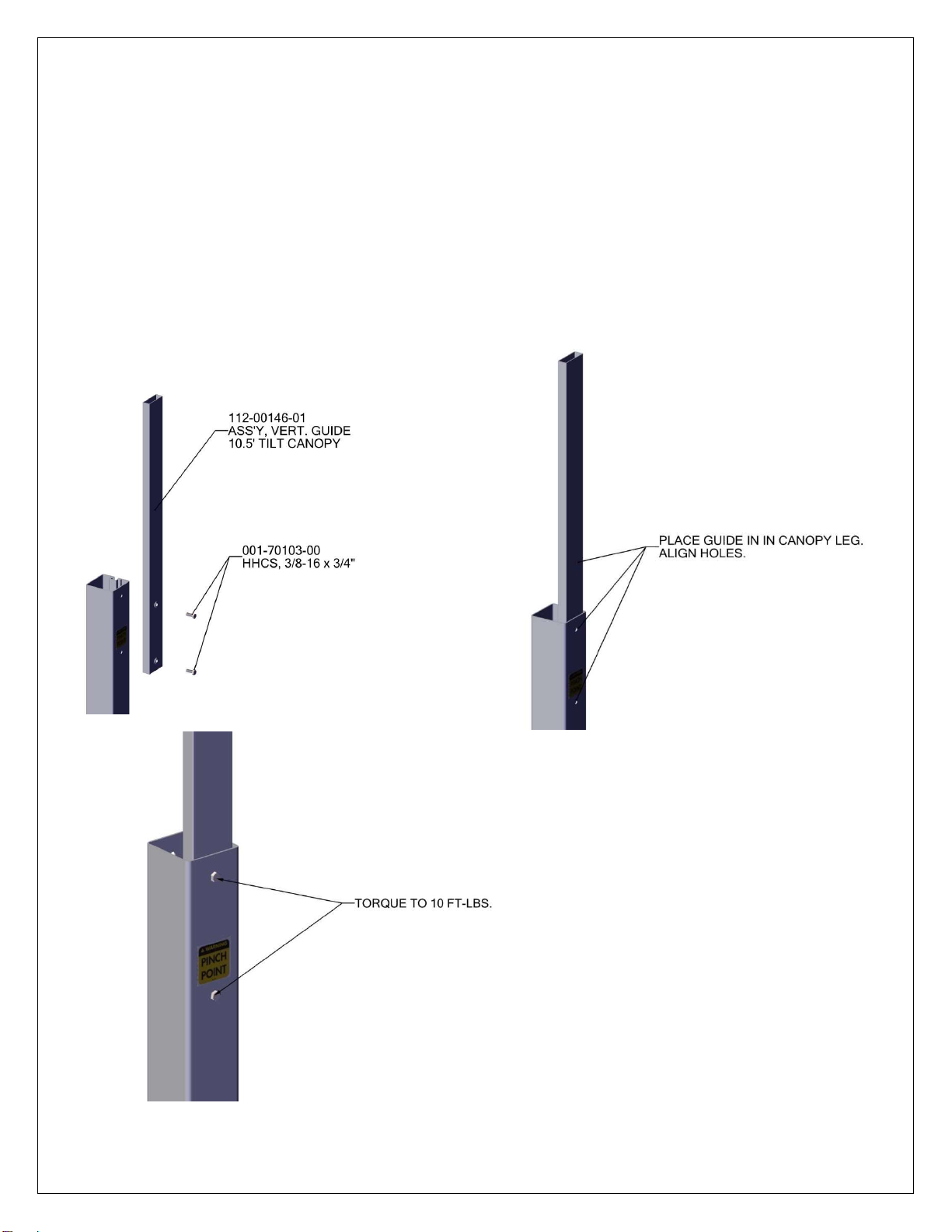

TILT BRACKETS / RECIEVER MOUNT / ACTUATORS

STEP 1

-PLACING CANOPY LEGS

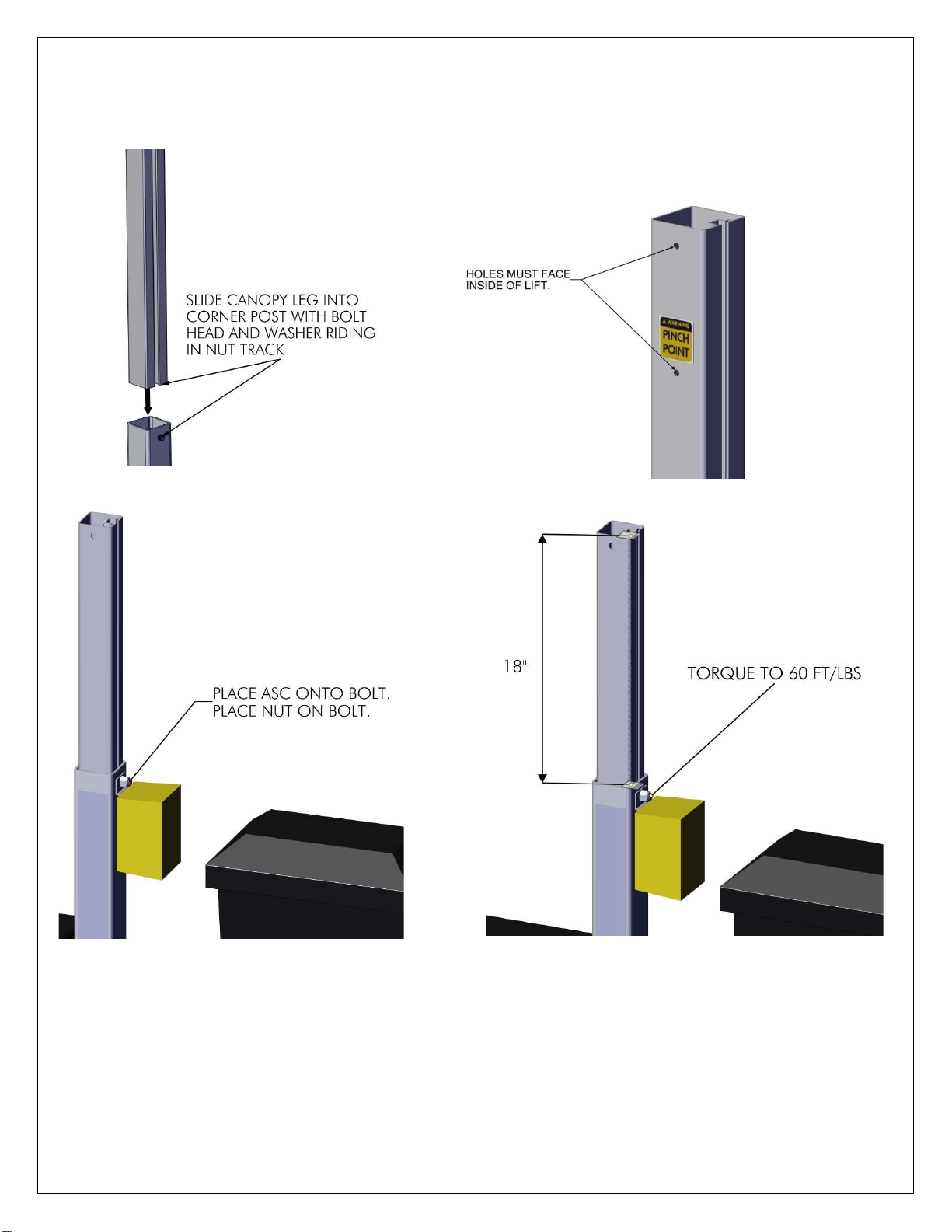

INSERT A CANOPY LEG (INCLUDED IN CANOPY HOOPS) IN EACH OF THE CORNER

POSTS. TILTING LEGS (002-00170-00, SHOWN BELOW) ARE PLACED IN PIVOTING SIDE

(SHORE-END) CORNER POSTS. NON-TILTING LEGS (002-00172-00) ARE PLACED IN

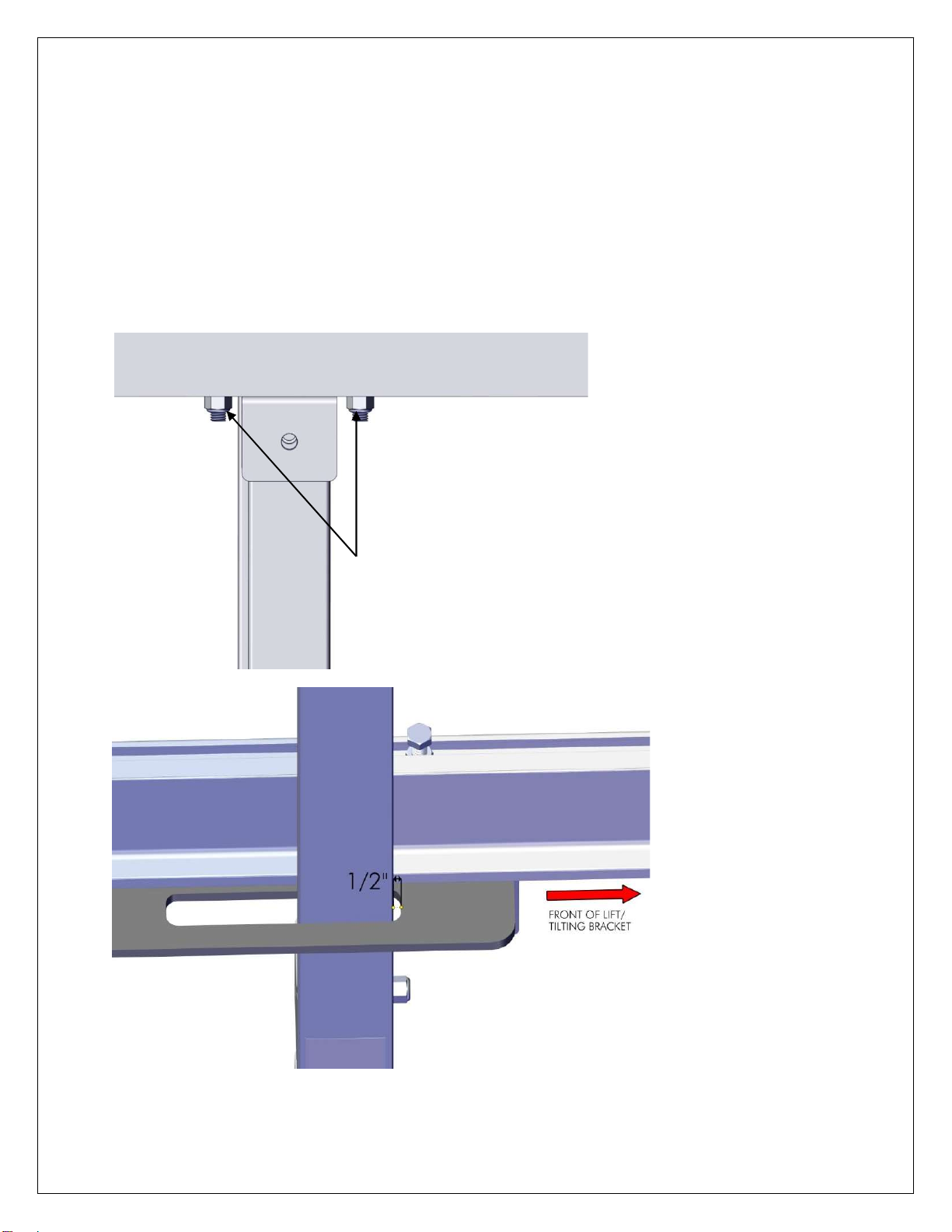

NON PIVOTING SIDE CORNER POSTS. ATTACH USING A ½-13 x 1 1/4” BOLT, FLAT

WASHER, AND NYLOCK NUT (INCLUDED WITH CANOPY HOOPS). (FIG. 1).

PLACE BOLT AND WASHER IN CORNER POST. (FIG. 2).

SLIDE CANOPY LEG INTO CORNER POST. BOLT AND WASHER ARE INSERTED INTO

CANOPY LEG NUT TRACK. (FIG. 3).

WHEN PLACING NON-TILTING LEG INTO CORNER POST, FACE HOLES TOWARDS

INSIDE OF LIFT (FIG. 4).

PLACE ASC ONTO BOLT. (FIG. 5).

LEG MUST BE INSERTED TO HAVE 18 INCHES ABOVE CORNER POST.

PLACE NUT ON BOLT. TORQUE TO 60 FT-LBS. (FIG. 6).

FIG. 1

INCLUDED

WITH HOOP

HARDWARE

CARD

CANOPY INSERT