FloJak F-50 Assembly instructions

www.flojak.com www.flojak.comwww.flojak.com

© copyright 2012 Flojak™ | a division of Bal-Cor Industries, LLC

INSTALLING FLOJAK INTO THE WELL

The FloJak is easier to install with two or three extra people...one to lift the center

of the arch, and the others to guide and lower the pump into the well. The drop-

line is a critical safety measure that may be used to help you lower your FloJak

into the well while reducing the risk of dropping it. The ring-end must be anchored

securely to a point close to the well head.

1. Carefully guide the FloJak into the well. DO NOT FORCE IT. I you

encounter resistance, lift it a few feet and try a different route.

2. When FloJak is fully inserted, secure the hanger over the top edge of your

well casing by tightening the 4 bolts with a 9/16” wrench. BE CAREFUL-

DO NOT OVER TIGHTEN or you could crack the well casing.

3. Pull the lowering rope up until tight and secure it to the metal loop welded

to the side of the hanger bracket. The rope can assist you if you decide to

remove the pump in the future for any reason.

4. If using a Well-Bonnet, slip it over the well-cap or any wires, and close up

the gaps using the Velcro fastener. Cinch the base of your bonnet in place

around the well casing using the drawstring.

If you are using a PowerJak or MiniJak lift-assist, follow the installation directions

included with your PowerJak handle kit.

Instruction & Assembly

Flojak F-50 thru F-150

PUMP OPERATION

Prior to regular use, it is recommended that you decontaminate your well and

newly installed pump by pouring a half gallon of clear, unscented bleach into the

well opening. Wait an hour or so and then pump several gallons of chlorinated

water through your FloJak and any piping or hoses used to transport water.

Within a day or two, fresh water will replace the chlorinated water in your well,

and the smell will dissipate. If you need to use the water immediately, use smaller

quantities of bleach until you can just begin to smell it in the pumped water. You

can lter chlorine with the right lters, and bleach dissipates in air. A large surface

area container for storage will help.

Operating FloJak is simple. Lift the Tee-handle to a comfortable pumping height

and stroke up and down to produce water through the handle, on the down

stroke. Initial priming from 50 feet below the surface (for example) will require

about ten 22-24” strokes. If you are using an assist handle, the strokes will be

shorter (but will require much less effort). Without the Jak assist handles, it takes

about 7 average strokes to produce a gallon of water.

FloJak is equipped with a ball-valve below the handle which allows you to keep

an uphill-prime if you are pumping up an incline to a tank, garden or into your

home through an exterior faucet.

FloJak comes with a PVC hose tting on the handle. You may attach an optional

6-foot or 50-foot “GatorHyde” hose capable of 200 PSI pumping pressures. The

longer hose can be attached to any unrestricted outdoor faucet for supplying

water into your house for sinks, tubs or ushing.

The “prime” in the top of your pump will leak down to at least the “weep hole”

level which is approximately 4 feet below the surface (marked by the yellow label).

This will help avoid freezing in colder temperatures.

Thank you for purchasing the FloJak™. Although capable of greater lift, this pump

is warranted and recommended for general, non-commercial use at pumping

depths requiring up to 150 feet of lift. It is guaranteed to be free of material

and workmanship defects impacting operation for two years from the date of

purchase. If you have questions, please feel free to contact us online at www.

ojak.com, or call our helpful customer care line toll free at 1-855-435-6525, M-F,

8:30-4:30 CST.

BEGINNING

Please take 10 minutes or so to familiarize yourself these instructions thoroughly

before you assemble and install your FloJak. You may also want to watch a

short assembly video on the “Installation” page at FloJak.com. FloJak is easy to

assemble but requires that you follow specic steps and pay close attention to

detail.

ASSEMBLY REQUIRES A FEW ADDITIONAL ITEMS:

1. PVC cleaner, primer and medium bodied PVC glue (any hardware store or

home-center)

2. Clean, disposable rag for glue clean up

3. Tape measure for determining depth to static water

4. 9/16” wrench for the hanging bracket

5. Standard hacksaw

6. Additional rope as needed for lowering deeper than 50 feet

7. Coated rubber grip gloves for lowering the system into the well, plus two

or three friends to help with the weight of lowering longer systems.

ATTENTION-The directions provided by your PVC cleaner, primer glue maker

must be followed strictly, particularly if you are attempting to glue your FloJak

in extreme heat or cold. Your pump must be glued 24 hours prior to handling or

exposure water and weight. To ensure good glue joints plan your well installation

for the day after glue-up. Failed glue joints are avoidable with care, and are your

responsibility. For more information on glue application, go to www.oatey.com and

click on the “How to Use” link to helpful YouTube Videos.

WARNING-When lowering the FloJak into your well, the pump and piping

assembly weighs approximately 41 lbs per 50 feet. You must lower the unit into

your well utilizing a rm grip in the piping, plus the lowering rope. Rubber gripping

gloves are highly recommended.

NOTE:Your FloJak comes from the factory with about 60 feet of lowering cord.

If you are lowering the pump more than 50 feet, you will need additional rope or

cable with a working load rating of at least three times the weight of your pump

assembly.

FloJak must be assembled in 5-foot sections to an “ideal length”. The ideal length

of an assembled FloJak, will reach from the surface, to a depth of 10-20 feet

below the “static water level” while staying at least 10 feet from the bottom of

the well. Static water level is the distance from the surface to water. It is usually

much less than the drilled depth of the well itself. Prior to

assembly, determine the “ideal length” by gathering some

information about the well.

NOTE-to avoid the possibility of electrical shock

ensure that all power to the existing pump and well

area, has been disconnected at the main distribution

panel, and the pump breaker. It is recommended

that you use a qualied, licensed electrician who

is a certied well technician! It is your responsibility

to ensure that all applicable local and state regulations,

requirements and codes are adhered to.

UNDERSTAND THOROUGHLY PRIOR TO INSTALLATION

1CONT. PAGE 4

2 3

The FloJak system may be inserted into most wells without removing the existing

pump. With no pump installed, the FloJak can be congured to work in well

casings as small as 3 inches in diameter. To install the hanging bracket as it

comes, the casing must be 4”.

If there is a submersible pump in your well, the rst step is to ensure an adequate

clearance in the well casing. Insert the ared end of one of the 1 ¼” x 5’ sections

of pipe into the well casing. If there is clearance, determine the static water level

and well depth using the drop-line supplied with your kit as a measuring device.

To use the cord, tear it through the blue FloJak label (which MUST be removed

prior to pump installation).

1. Lower the metal ring-end of the drop

line into the well until you hear it

“splash” which indicates the static

water level. Mark the line with a knot,

pull it up, and measure the distance

from the knot to the ring. This will

be the distance from the surface to

the static water level below. Your

assembled FloJak needs to be

assembled at least 10 feet longer.

2. Remove the knot and lower as much

line into the well as possible to ensure

that your FloJak will be at least 10 feet

above the silty/sandy bottom of the

well.

TIP- If the drop line goes slack when

checking for well-depth, then the weighed

end is either on the bottom, or has hit an obstruction. Gently pull up so as not

to tangle the cord with existing pump wires or plumbing and then retry. If your

weighted line hangs straight at 110 feet,(for example) then you have adequate

clearance for a 100 foot FloJak pump.

Note-If you require additional pipe lengths to accommodate a deeper static water

level, then you may order 50’ kits at www.ojak.com. Do not attempt to use “off

the shelf” PVC. The FloJak is capable of lifting water over the 150 foot rating.

Doing so is an understandable choice in emergency, but will void the warranty.

Record the static water level and the information you gathered about well depth,

and then determine the “ideal length” of the pump…in 5 foot increments.

EXAMPLE: Say your static water level is 24 feet from the surface, and the well

bottom is 56 feet. The “ideal length” for your pump assembly will be 35, 40 or 45

feet…which is at least 10 feet below static water level, and at least 10 feet from

the bottom. Do not feel that you must use every section of pipe. What

you need is the “ideal length.”

Pump

Section

Well Casing

Large & Small

Pipe Sections

Glue These

Sections First

www.flojak.com www.flojak.comwww.flojak.com

GLUE UP AND ASSEMBLY

The glued and assembled pump assembly will need a roomy place to lay straight

and cure for 24 hours. A reasonably level yard is a perfect spot. The rst step

is to lay the components out in the order that they will be assembled. Start by

placing the pump section, pointed toward your well opening. It comes pre-

assembled from the factory and will go into the well rst. The other end of the

layout (away from your well) will be the top section. It has a metal hanging bracket

pre-attached and yellow “weep hole” labels on both the larger and smaller pipe

sections. These two sections are paired, and must remain together always.

Lay your “Pump Section” on the ground with the gray foot-valve pointed toward

the well. Step off the “ideal length” of your pump and lay the

“Top Section” (with the yellow labels) on the ground with

the yellow labels pointed toward your well. Between the pre-

assembled “pump” and “top” sections, you will lay out the

rest of the 5 foot sections in pairs of small and large pipe.

Both the small and large pipe sections should

point “ared-end” toward the well.

Lay everything out in an open,

fairly level area.

CRITICAL-Before gluing anything, read, understand

and follow the instructions for your PVC cleaning and

priming solutions, and the adhesive. Glue joints are

critical, and are your responsibility. Short cuts could

result in pump failure or dropping your pump into

the well. Also, the factory-knots on the drop- line are

for positioning only, and must be checked and tied

adequately. PVC Cement typically has a 2 year shelf life.

Gluing can ONLY occur one section at a time. Do not try to pre-glue multiple 5

foot sections. The pump must be assembled by gluing “one” 5 foot section of

small pipe rst, followed by quickly sliding and attaching a glued section of larger

pipe over the small pipe. The glue-up will start at the pump end nearest your well

as follows:

1. Remove the label from the pump by

pulling the cord through it.

2. To make assembly easier, pull the

small (3/4”) pump rod section out of

the pump housing 12”.

3. Prep and quickly glue the ared end of

one ve foot length of the smaller pipe

onto the extended pump rod section.

4. Next prep and glue matching sections

of the larger diameter pipe. Quickly

slide the large pipe (before the glue

sets) over the small pipe (which was

just glued in step 3), and onto the

waiting end of the pump.

5. Repeat steps 3 and 4, until you have

assembled enough sections to

reach the “ideal length” for your

well.

6. From the “hanger” end of the

assembly, push the extended

¾” pipe into the assembly until it

bottoms out. Cut the excess ¾”

pipe off at aprox. 2” above the

debris cap. (See top illustration)

7. Glue the handle assembly and ball

valve together as shown, and then

glue the assembly to the cut off

3/4” pipe extending through the

debris cap of the top section.

8. Ensure that the metal hanging

bracket is secured tightly to the

top section using a 9/16” wrench.

9. Check to ensure that the lowering cord knots

are secured to both the foot valve and the ring.

10. Wait 24 hours without moving the glued

assembly, prior to installing into the well.

CONT. FROM PAGE 3 4 5 6

This manual suits for next models

1

Popular Water Pump manuals by other brands

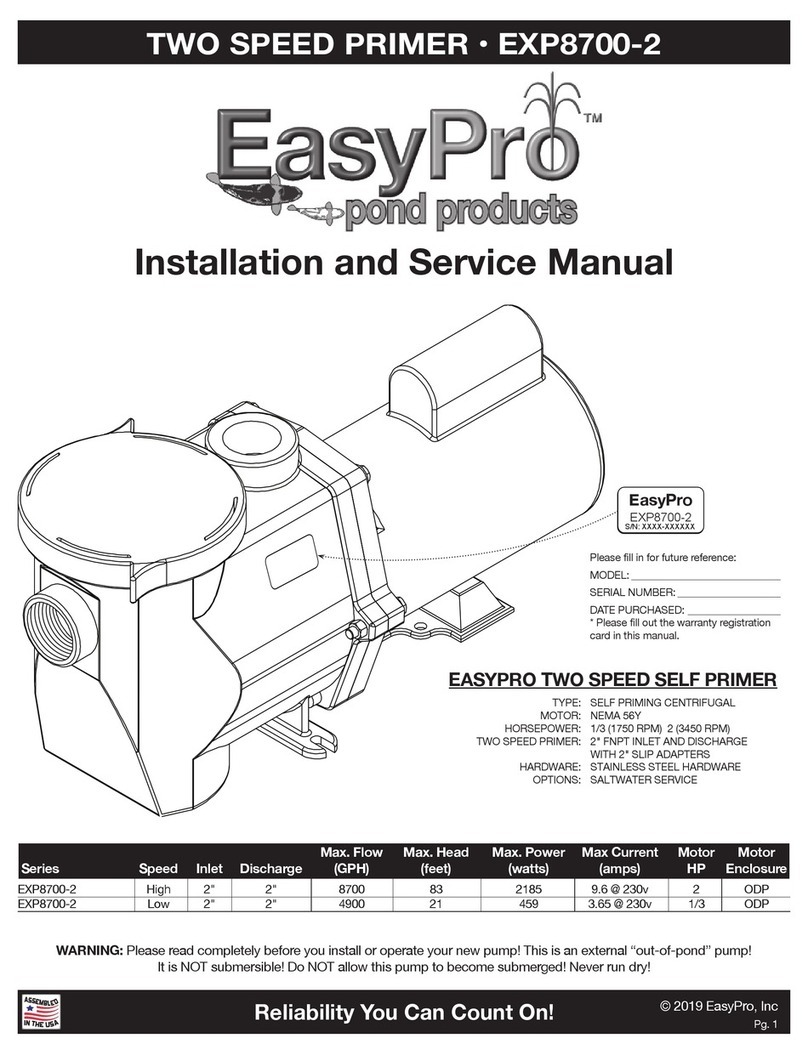

EasyPro

EasyPro EXP8700-2 Series Installation and service manual

SAER Elettropompe

SAER Elettropompe NCB Use and maintenance manual

Idex

Idex VIKING PUMP 4124B Series Technical & service manual

IKA

IKA Vacstar control operating instructions

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 811/4A3-B Installation, operation, and maintenance manual with parts list

Levitronix

Levitronix PuraLev 600MU user manual