Contents

Alcatel - High Vacuum Technology - User’s Manual ADP/ADS

ADP/ADS

User’s manual

1/3

Edition 04 - May 98

A - Introduction

■ADP/ADS Series One ............................................. A 10

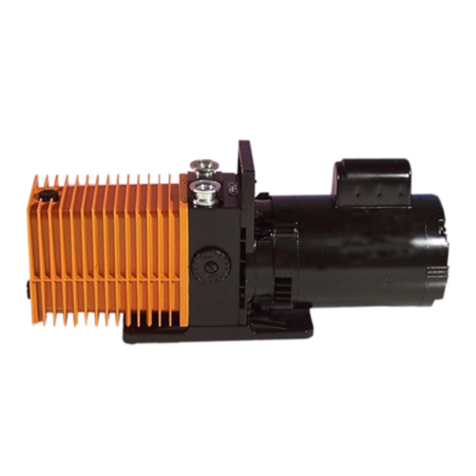

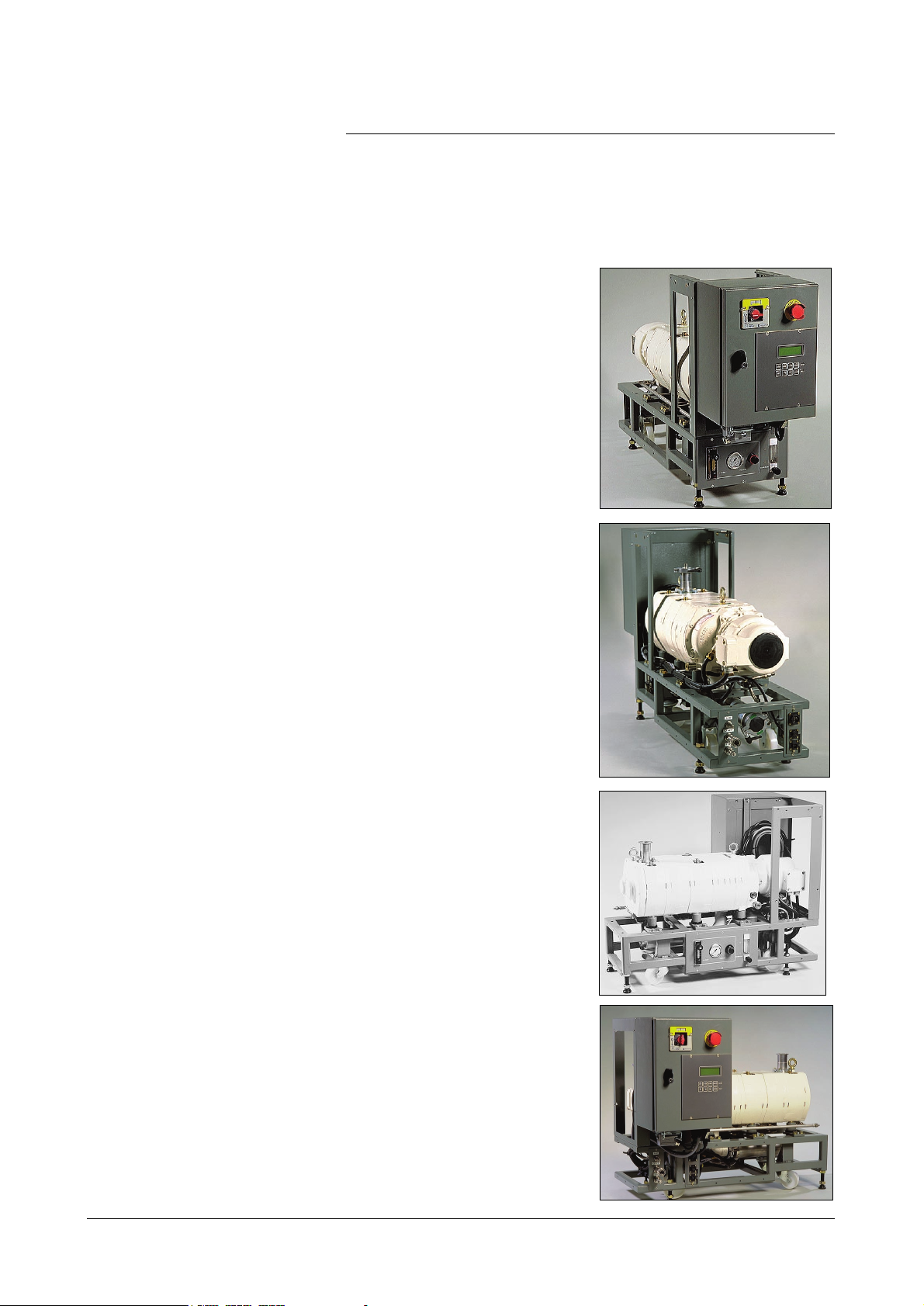

■The various versions of ADP Series One ...................... A 20

■ADP/ADS Serie One Dry pumps

for semi-conductor’s industry ....................................... A 30

■Types of monitoring systems ...................................... A 40

■Dry pump operational principle ................................. A 50

■The accessories ....................................................... A 60

■Technical characteristics............................................. A 70

B - Start-up

■Safety instructions .................................................... B 00

■Unpacking / Storage ............................................... B 10

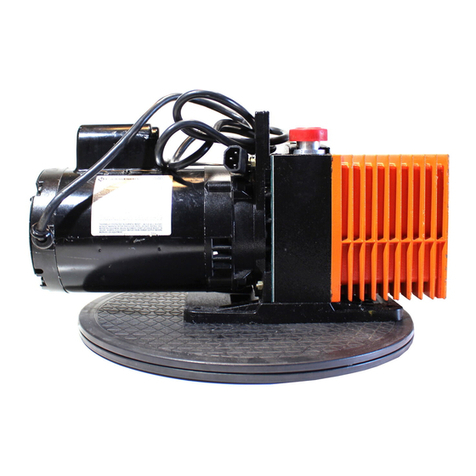

■Positioning the pump in pumping installation ................. B 20

■Installing anti-vibration pads........................................ B 30

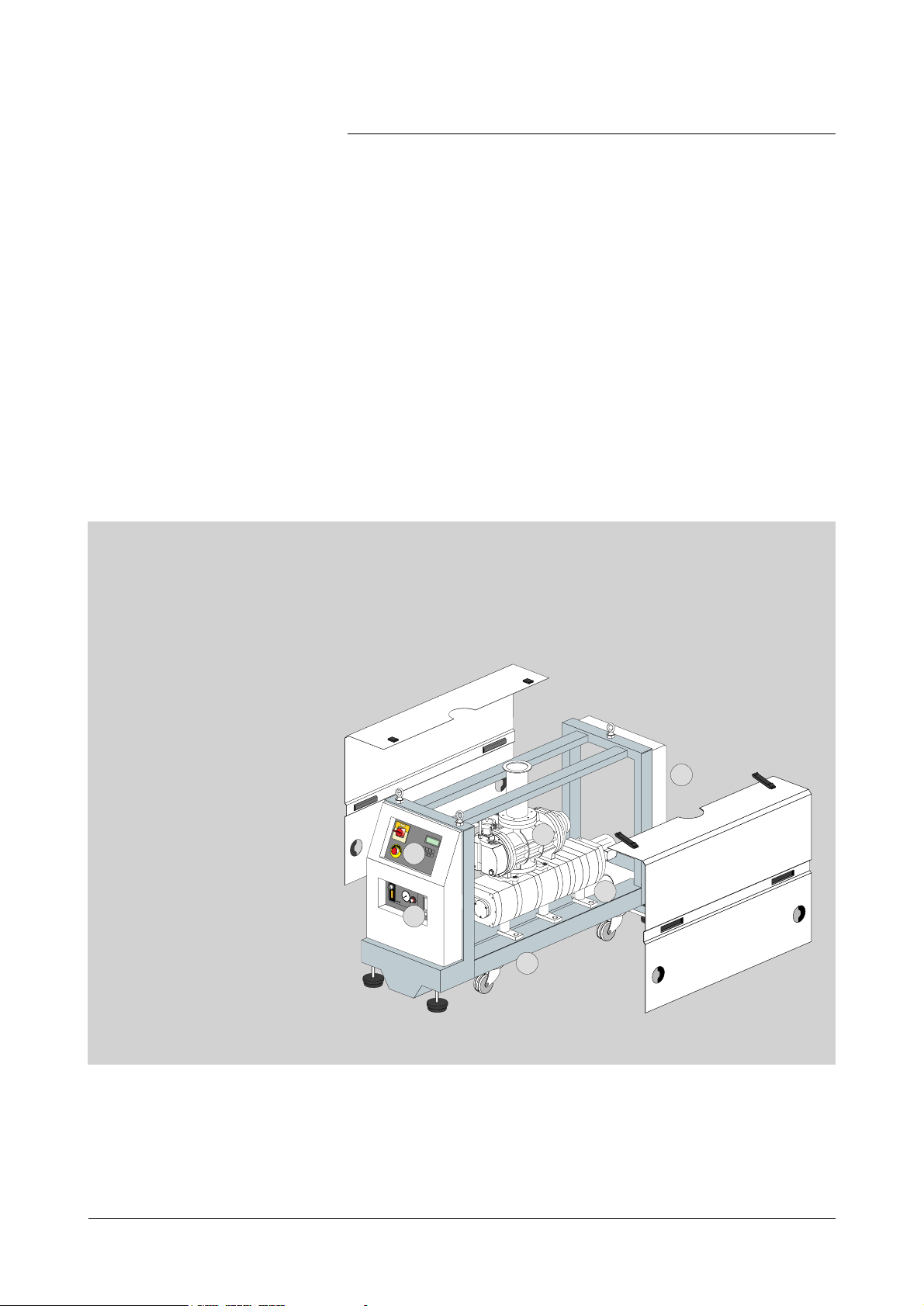

■Modular version - Layout .......................................... B 40

■Filling the pump oil housings ...................................... B 50

■Connection to the cooling circuit ............................... B 60

■Inert gas purge connection (N2 plug) .......................... B 70

■Nitrogen purge flow sensor ....................................... B 80

■Connection to the pumping circuit ............................. B 90

■

Electropneumatic exhaust valve connection (withdrawal)

B 100

■Pump power supply ............................................... B 110

■

Water flowrate and gas purge according to processes

... B 120

■Checking the rotational direction .............................. B 130

■Remote control plug connection (M3 monitoring) ......... B 140

■Remote control plug connection (M1 monitoring) ......... B 141

■RS 232 or RS 485 link wiring.................................. B 150

■Use of the Serial link (Service centers)........................ B 160

■Installation of silencer heating kit............................... B 170