Floorex Products Satellite 760-6 Generation3 User manual

Satellite 760-6 Generation3

Safety & Operators

& Parts Manual

CAUTION: Read the instruction manual before using the appliance.

V08072015

SATELLITE 760-6 Generation3 Page 1 / 24

Floorex Products 1800 356 673

Contents

Specifications........................................................................................................................................................ 2

Safety instructions ................................................................................................................................................ 3

Safety instructions ................................................................................................................................................ 4

Operating Instructions........................................................................................................................................... 5

Operating Instructions........................................................................................................................................... 6

Handle Positions ................................................................................................................................................... 7

Tooling position & Magnetic plugs .......................................................................................................................... 8

Axle height adjustment.......................................................................................................................................... 9

Display Functions ................................................................................................................................................ 10

Electrical safety................................................................................................................................................... 11

Problem solving .................................................................................................................................................. 12

Diamonds ........................................................................................................................................................... 13

Diamonds ........................................................................................................................................................... 14

Parts listing Main................................................................................................................................................. 15

Parts Listing Handle ............................................................................................................................................ 16

Part Listing Handle Lock ...................................................................................................................................... 17

Parts Listing HVA Meter ....................................................................................................................................... 18

Parts Listing Main Electrical Box ........................................................................................................................... 19

Parts Listing Tooling Disk..................................................................................................................................... 20

Warranty ............................................................................................................................................................ 21

Page 2 / 24 SATELLITE 760 Generation3

1800 356 673 Floorex Products

Specifications

Satellite 760-6 Generation3

Weight

315kg (359kg including 4 weights)

Head Pressure

185kg - 288kg

Dimensions

843 x 1094 x 1547 (Width x Height x Length)

Rated Voltage

400 Volt 50 Hz

Rated Watts

8800W (16A)

Grinding Path

760 mm

SATELLITE 760-6 Generation3 Page 3 / 24

Floorex Products 1800 356 673

Safety instructions

Read and understand the instructions on the machine and in this manual and engine manual (if applicable).

Different models may have different parts and controls.

Equipment should only be operated by trained personnel, in good physical condition and mental health (not

fatigued). The operator and maintenance personnel must physically be able to handle the bulk weight and

power of this machine.

The SATELLITE 760-6 Generation3 must only be used according to the instructions given in this manual. Any

other work methods or practices could result in injury or death

The SATELLITE 760-6 Generation3 has different positions in which the handle can be locked into. These are

described in this manual as ‘OPERATE’, ‘TOOLING POSITION’ and LIFT/STORAGE’. See Handle Positions for

diagrams of these positions. When to use and when not to use these positions is described throughout this

manual

This is a one person machine. Maintain a safe operating distance to other personnel. Remember ‘one

machine, one operator’.

This equipment is intended for commercial use.

For the operators’ safety and the safety of others, always keep all guards and shrouds in place.

The weights are there to assist the machine in operation. Always remove them from the handle before folding

it to the tooling mode or storage mode

Never start or run machine when it is unattended.

Check for wear on magnetic plugs every 3 hours of use

This machine is only intended for use on floor surfaces such as concrete, terrazzo and other hard floor

surfaces.

The handle height is adjustable with different positions for operator comfort. These positions are shown next

to the locking mechanism as ‘OPERATE’. The SATELLITE 760-6 must never be started or used with the handle

in any other position other than the ‘OPERATE’ positions’

Never attempt to adjust the handle position when the machine is in operation.

Never start or run machine with the handle folded or when disk(s) are not in contact with the surface.

Do not lend or rent machine without the operating and safety instructions for the machine (and the engine, if

applicable).

Wear clothing suitable for the job and for the work place including, safety shoes, hard hat, hearing protection,

non-fogging vented safety goggles, and dust mask suitable for dust.

Keep body parts or any loose clothing away from moving parts. Failure to comply could result in bodily injury.

Page 4 / 24 SATELLITE 760 Generation3

1800 356 673 Floorex Products

Safety instructions

Do not modify machine in any way. Only use genuine SATELLITE parts and accessories.

Repairs should be performed by qualified persons only.

Ensure parts have stopped moving and disconnect power or spark plug when servicing or changing blades or

accessories.

Never operate machine in rain or if heavy moisture is present.

Petrol is extremely flammable and poisonous. Petrol should only be dispensed in well ventilated areas, and

only when engine is cool.

WARNING! POISONOUS EXHAUST GASES. Do not operate petrol powered equipment, including generators,

without adequate ventilation. Carbon monoxide is and invisible odourless gas that can harm or can kill.

Do not operate SATELLITE 760-6 with any covers or doors removed or open.

The SATELLITE 760-6 can produce sound pressure levels greater than 85db. The operator must wear

approved safety ear protection.

Do not allow the supply cord to come in contact with the cutting blade/head or other moving parts of this

machine.

SATELLITE 760-6 Generation3 Page 5 / 24

Floorex Products 1800 356 673

Operating Instructions

Wear clothes suitable for the job and for the work place including, safety shoes, hard hat, hearing protection,

non-fogging vented safety goggles, and dust respirator suitable for dust.

The SATELLITE 760-6 Generation3 must only be used according to the instructions given in this manual. Any

other work methods or practices could result in injury or death

WARNING! Disconnect power before moving the Handle to the ‘TOOLING POSITION’or ‘LIFT’ positions.

WARNING! POISONOUS EXHAUST GASES. Do not operate petrol powered equipment, including generators,

without adequate ventilation. Carbon monoxide is and invisible odourless gas that can harm or can kill.

Be sure all equipment is tested and tagged prior to use on any job.

Inspect entire area to be ground before grinding and remove any bolts or concrete nails (etc) that could

damage tooling or the machine and which could cause a hazardous situation.

Ensure there are no obstacles or existing structures that could present a hazard to the operator. If so, take

necessary action to eliminate the hazard.

Fold handle to the ‘TOOLING’ position and ensure it is locked in place, then tilt machine back so handle is

resting along the floor.

The machine takes a set of three (3) tools. Be sure the tools are of even height.

Install appropriate diamond tooling or other available tooling into the machine. Only use genuine SATELLITE

tooling. Failure to comply could result in bodily injury. See section ‘TOOLING POSITION’ for illustrations on

how to remove and install tooling

Tilt machine back onto the disk and put the handle in one of the ‘OPERATE’ positions. Adjust the position to

one that you are comfortable with.

Never attempt to adjust the handle position when the machine is in operation.

Connect machine to suitable power outlet. Only use heavy duty power lead suitable for high current use

(preferably 2.5mm² cable), no longer than 15 meters.

If no power is available within the specified distance, have a qualified person install a suitable power outlet

closer to your work. Alternatively use 4mm² cable for up to 40 meters.

Connect a suitable dust extractor to the machine via a 38 or 50mm flexible hose. The machine is designed to

take the standard 50mm hose ends to make connection of dust extractors easy and hassle free.

Keep machine clear of drainage pits, grates, steps or major lips or such hazard. Failure to comply could result

in bodily injury and or could damage the machine or property.

Ensure machine is on a level surface and handle is in one of the ‘OPERATE’ positions

This machine is designed to operate with the wheels in contact with the floor at all times. Do not operate with

wheels off the floor.

Page 6 / 24 SATELLITE 760 Generation3

1800 356 673 Floorex Products

Operating Instructions

The SATELLITE 760-6 Generation3 has axle height adjustment to make it easy to adjust the machine so it

doesn’t cause fatigue on the operator. To set axle height, adjust the axle height leaver to the vertical position,

or midpoint. This is a good starting point. After initial operation the axle can be adjusted. The axle lever must

be set as far back (toward operator) as possible without creating excess force on the operator during

operation.

Switch on the dust extractor.

Hold the handles firmly and switch the SATELLITE 760-6 Generation3 on by pushing the green button.

The controls on the SAT760-6 Generation3 include an over load device. It is there to protect the controls and

motor from irreparable damage. If it trips it indicates a problem. (i.e.; undersize power lead or poor power to

your power supply). Refer earlier in this section for recommendations on power leads. Rectify the problem or

decrease load on the Satellite 760-6 by using tooling with more surface area, or place weights supplied on the

brackets on handle for this purpose.

Continuing to use the SATELLITE 760-6 when constant tripping occurs, VOIDS THE WARRANTY.

Do not attempt to make any adjustments while the machine is in operation. Any adjustments must only be

performed when machine is stopped and power disconnected.

In the event of the machine pulling to one side all the time; adjust the axle height to obtain the best result.

(See ‘AXLE HEIGHT’). This machine is designed to operate with the wheels in contact with the floor at all

times. Do not operate with wheels off the floor.

After a few minutes of grinding check the wear of the diamond tooling. This will pay handsomely if the

diamonds are wearing out fast due to soft concrete / abrasive concrete. There is a wide range of diamonds

available to suit every need. See Section ‘DIAMOND TOOLING SELECTION GUIDE’.

Check for wear on magnetic plugs every 3 hours of use

See Section ‘PROBLEM SOLVING’ for tips on how to grind faster on tough concrete and how other problems

can be rectified.

WARNING! As with any diamond tooling, breathable silica may be generated by use and maintenance of this

machine. Silica can cause severe and permanent lung damage, cancer, and or other serious diseases. Do not

breathe the dust. Do not rely on your sight or smell to determine if dust is in the air. Silica may be in the air

without a visible dust cloud. If air monitoring for silica is not provided by your employer at your work site, you

must wear appropriate respiratory protection when operating or maintaining this equipment. Consult your

employer for proper respiratory protection.

SATELLITE 760-6 Generation3 Page 7 / 24

Floorex Products 1800 356 673

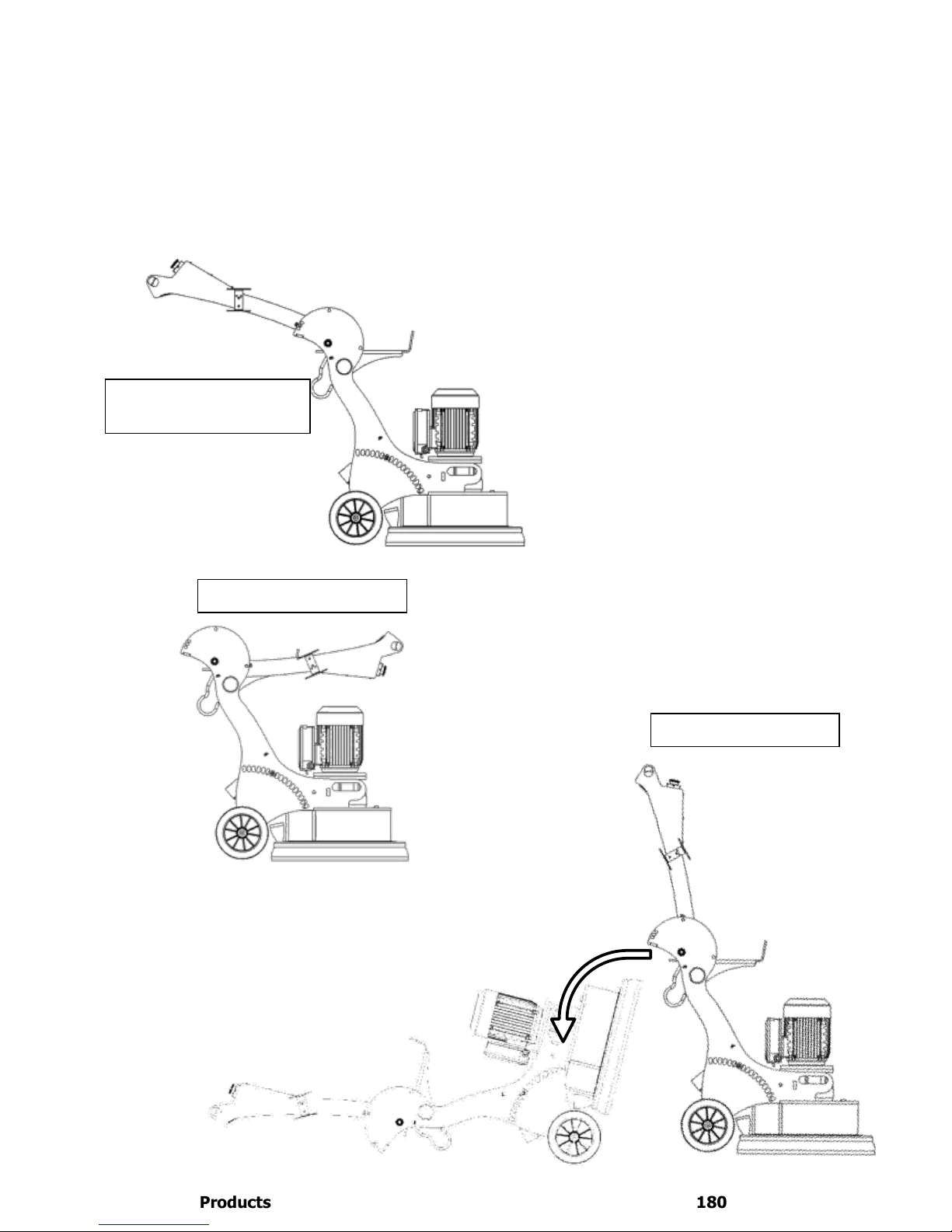

Handle Positions

The handle on this machine can be locked in different positions for different purposes. These positions must

only be used for the purpose intended as outlined in this manual. . Failure to comply could result in bodily

injury.

These positions are shown below and when and where to use them is outlined throughout this manual.

Operate Position (3

positions available)

Lift / Storage Position

Tilt Onto Back

Tooling Position

Page 8 / 24 SATELLITE 760 Generation3

1800 356 673 Floorex Products

Tooling position & Magnetic plugs

To remove tooling from the magnetic plugs, Tilt the machine to the tooling position as per instructions in the

operating instructions and grasp hold of the diamond disk and give it a sharp pull away from the main black

disk.

To remove the plug from the main black disk strike the black disk beside the taper insert as shown below.

The magnetic plugs must be cleaned from dust and other debris every time you change satellite disks. The

insert should go in all the way up into the plug up to the step on the insert. If not, Clean out the hole in the

plug where the insert goes. Ensure there are no particles or pieces of steel (such as staples ETC). The hole

where the insert goes in the plug can be cleaned with a screwdriver to remove packed dust etc.

Ensure the insert is not worn to less than 20mm diameter where the blade runs on the insert. This is

equivalent to the diameter of the section above it.

Put the insert through the satellite disk and install the two parts onto the plug ensuring the insert goes

completely into the plug.

SATELLITE 760-6 Generation3 Page 9 / 24

Floorex Products 1800 356 673

Axle height adjustment

This machine is designed to operate with the wheels in contact with the floor at all times. Do not operate with

wheels off the floor.

The axle lever must be set as far back (toward operator) as possible without creating excess force on the

operator during operation.

Page 10 / 24 SATELLITE 760 Generation3

1800 356 673 Floorex Products

Display Functions

The Generation3 Grinders feature a display screen with a backlight. This is a new feature that greatly

enhances the user experience in that the operator knows what the machine is doing, taking a lot of the guess

work out of the job.

There are 3 things the meter measures.

Voltage

Amps Draw

Hours Run

When you first plug the machine in, the display will be similar to the “READY” screen below.

This Screen shows the voltage of the supply and also the hours that machine has been running for.

When you start to use the machine the “RUNNING” display will show. This screen shows the Voltage and the

amps while the machine is in operation. The bottom line shows the LOAD as a percentage of motor power

available. Running the machine over 100% for extended periods will result in the overload tripping to protect

the machine.

With the HVA meter on the satellite it is now possible to check a lot of the things your electrician will check if

there are power issues. Common problems that can be identified are;

Voltage drop when under load due too long or under size extension leads. This often causes the Amps to

increase in proportion to the voltage loss.

High amps when voltage is still within 10% of normal. Caused by high load jobs like aggressive diamonds or

when polishing.

Hours run is only counted when machine is being used (over 0.5 Amps) and counted with accuracy of two

decimal places

The first decimal place is a 10th of an hour being 6 minutes

The second decimal place is a 10th of 6 minutes being 36 seconds.

413.5V 15.7A

LOAD 95%

RUNNING Screen

415.5V 0.0A

0000001.01 HOURS

READY Screen

SATELLITE 760-6 Generation3 Page 11 / 24

Floorex Products 1800 356 673

Electrical safety

All electrical maintenance and repairs are to be carried out by qualified persons only.

CAUTION - Line terminals may be alive when main switch is in the off position. Disconnect the machine

completely before performing any maintenance or repairs.

WARNING - DO NOT operate the machine with any electrical panels open.

WARNING - The controls on the SATELLITE 760-6 Generation3 include an over load device. It is there to

protect the controls and motor from irreparable damage. If it trips it indicates a problem. (i.e.; undersize

power lead or poor power to your power supply). Refer earlier in this manual for recommendations on power

leads. Rectify the problem or decrease load on the Satellite 760-6 by using tooling with more surface area, or

place weights supplied on the brackets on handle for this purpose.

Continuing to use the SATELLITE 760-6 when constant tripping occurs, VOIDS THE WARRANTY!

Never operate machine in the rain or if heavy moisture is present.

The overload is there to protect you and the machine from harm. DO NOT bypass or adjust the over load in

any way. If it is faulty, only replace with original part that is identical to the faulty one.

Never bypass over current devices in this machine.

Never connect or disconnect power cables with voltage present or while under load.

Disconnect all power connections and observe lock out / tag out procedures before attempting to carry out

any maintenance or repair on any equipment.

Avoid any contact with any rotating parts or driven parts.

Never use equipment that has not been tested and tagged (including cords).

Before connecting the machine to power, check the condition of all power leads and cables on, or used in

conjunction with the machine. DO NOT USE it if any faults, cuts, wear marks, etc… Get qualified persons to

repair and re-tag it as required by regulations in your country.

Connect machine to suitable power outlet. Only use heavy duty power lead suitable for high current use

(preferably 2.5 mm2 cable), no longer than 15 meters.

If no power is available within the specified distance have a qualified person install a suitable power outlet

closer to your work. Alternatively use 4 mm² cable for up to 40 meters.

Do not operate SATELLITE 760-6 with any covers or doors removed or open.

Page 12 / 24 SATELLITE 760 Generation3

1800 356 673 Floorex Products

Problem solving

Diamond Grinding has many variables. When you understand some of these, you can solve a lot of problems

without a lot of bother and expense.

NOTE: THIS IS A GUIDE ONLY

PROBLEM

CAUSE

REMEDY

EXPLAINATION

Machine will not start

/ run.

No power is present at

cable end.

Check the power is present

with another tool.

Using another tool confirms power

is present

Machine is trying to

start on glue or other

sticky substance.

Clear a patch with a scraper

and grind into the glue a

little at a time.

This means it only tackles a small

amount of glue at a time and

keeps the glue residue coated with

dust, preventing glue sticking and

building up on the diamonds.

Power lead is too small

in capacity or too long.

Upgrade the power lead to

2.5mm² (15meters max) or

4mm² (40 meters max).

The long / small capacity cable is

too restrictive and can’t allow

enough power through for the

machine to start / run properly.

Use weight on the handle.

The weight on the handle reduces

the load on the machine thus

reducing the current.

Machine is not

grinding at all.

No blades /

accessories in unit.

Fit blades. Note; check wear

on machine.

Very hard concrete or

glazed topping on

concrete.

Turn dust extractor down /

restrict flow. Only just

control the dust from

escaping.

The extra dust accumulating on

the floor acts as an abrasive

between the segments and the

floor thus exposing the diamonds

better.

Place river sand or cement

on the floor.

The sand is an abrasive as

described above.

Use softer grade of diamond

tooling.

The softer grade will expose the

diamonds better.

Use coarser diamond

tooling.

The coarser diamond tooling can

get through hard toppings without

wearing out the diamonds too

fast.

Reverse the rotation of the

machine (switch on the

bottom of the motor box)

The tooling exposes the diamonds

when reversed. This works best

when using plugs.

The diamonds are

wearing out too fast.

The concrete is:

*Soft

*Abrasive

*Rain Damaged

*A rough finish

(Scarified or shot

blasted).

Use a powerful dust

extractor to remove as much

dust as possible.

The dust, as described acts as an

abrasive between the segments

exposing the diamonds

prematurely, wasting them.

Use harder diamond matrix.

The harder segments don’t expose

as easily.

Use tooling with more

segments or area² of

segment.

The tooling with more segments

or area² doesn’t have the same

weight on them, reducing wear.

The diamonds are too

soft or too few.

Use weights on the handle

This reduces the weight on the

diamonds thus reducing the wear

on them.

SATELLITE 760-6 Generation3 Page 13 / 24

Floorex Products 1800 356 673

Diamonds

ST7-S08016

8 Segment Diamond Wheel•

For Hard Concrete / Soft Matrix •

Colour - Black •

Grit Size - 16#

10mm Segment

ST7-S03016

3 Segment Diamond Wheel•

For Very Hard Concrete / Soft Matrix

Colour - Grey •

Grit Size - 16 #

10mm Segment

ST7-H12030

12 Segment Diamond Wheel•

For Very Soft or abrasive concrete / Hard Matrix •

Colour - Blue •

Grit Size - 30/40#

10mm Segment

ST7-H03030

3 Segment Diamond Wheel•

For Hard Concrete / Hard Matrix •

Colour - Orange •

Grit Size - 30/40#

10mm Segment

ST7-S06030

6 Segment Diamond Wheel•

For Hard Concrete / Soft Matrix •

Colour - Brown •

Grit Size - 30/40#

10mm Segment

This list is only showing the Satellite 7” Disks, Many other types of tooling is available for polishing, Removal,

cleaning, and even sanding timber. Contact your representative for more information or go to www.floorex.com.au

Page 14 / 24 SATELLITE 760 Generation3

1800 356 673 Floorex Products

Diamonds

ST7-H09030

9 Segment Diamond Wheel•

For Medium to Soft Concrete - Hard Matrix

Colour - White

Grit Size - 30/40#

10mm Segment

ST7-S03030

3 Segment Diamond Wheel•

For Very Hard Concrete - Soft Matrix •

Colour - Gold •

Grit Size - 30/40#

10mm Segment

ST7-H09080

9 Segment Diamond Wheel•

For Soft to Medium - Medium to Hard Matrix •

Colour - Green •

Grit Size - 80#

10mm Segment

ST7-H09150

9 Segment Diamond Wheel•

For Soft to Medium - Medium to Hard Matrix •

Colour - Red •

Grit Size - 150#

10mm Segment

ST7-S09150

9 Segment Diamond Wheel•

For Hard Concrete / Soft Matrix •

Colour - Yellow •

Grit Size - 150#

10mm Segment

This list is only showing the Satellite 7” Disks, Many other types of tooling is available for polishing, Removal,

cleaning, and even sanding timber. Contact your representative for more information or go to www.floorex.com.au

SATELLITE 760-6 Generation3 Page 15 / 24

Floorex Products 1800 356 673

Parts listing Main

Page 16 / 24 SATELLITE 760 Generation3

1800 356 673 Floorex Products

Parts Listing Handle

SATELLITE 760-6 Generation3 Page 17 / 24

Floorex Products 1800 356 673

Part Listing Handle Lock

Page 18 / 24 SATELLITE 760 Generation3

1800 356 673 Floorex Products

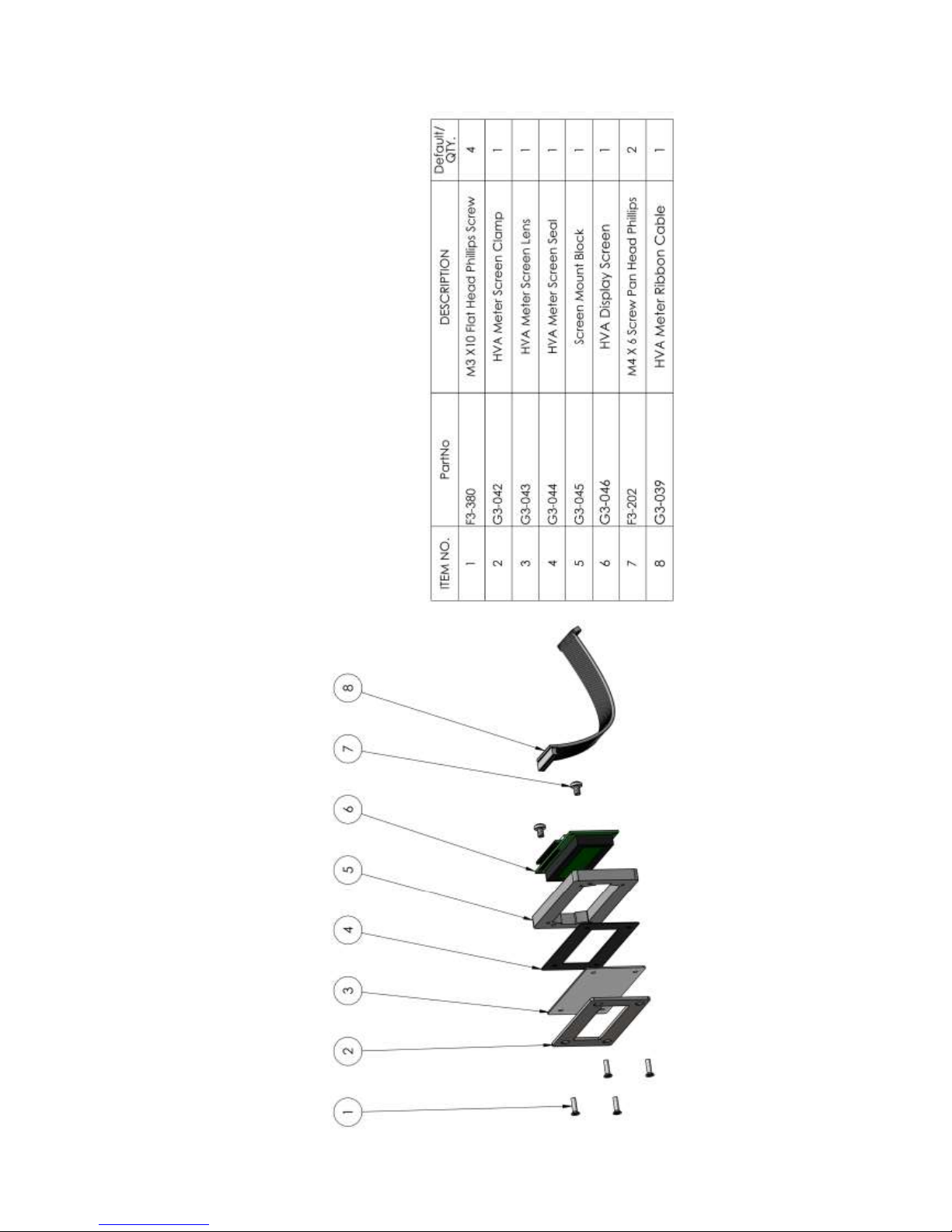

Parts Listing HVA Meter

SATELLITE 760-6 Generation3 Page 19 / 24

Floorex Products 1800 356 673

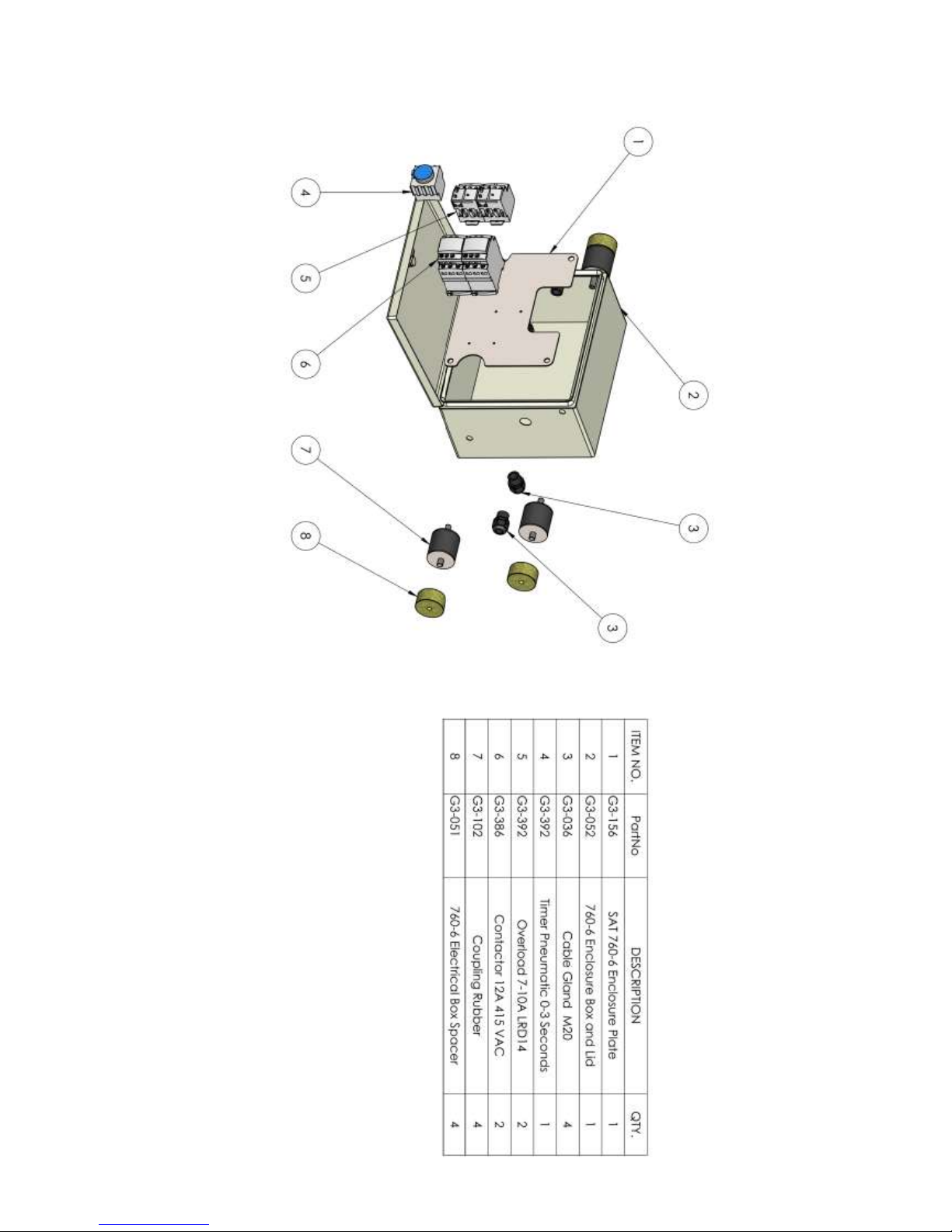

Parts Listing Main Electrical Box

Table of contents

Popular Grinder manuals by other brands

Parkside

Parkside PWS 230 SE Operation and safety notes

Metabo

Metabo WE 14-150 Plus Instructions for use

Lindahl & Nermark

Lindahl & Nermark LSG 150 H manual

Bosch

Bosch GWS Professional Series Original instructions

Kwik-Way

Kwik-Way 800-553-5953 user manual

Bernhard

Bernhard Express Dual 3000 User guide/instruction manual

Makita

Makita DGA504RTJ instruction manual

Graphite

Graphite 59G062 Translation of the original instructions

Pentair

Pentair HYDROMATIC HPD200 Installation and service manual

Makita

Makita M9513 instruction manual

Ingersoll-Rand

Ingersoll-Rand G1 Series Maintenance information

Parkside

Parkside PWSA 20-Li F4 Translation of the original instructions