Mighty Seven DG-585 User manual

1

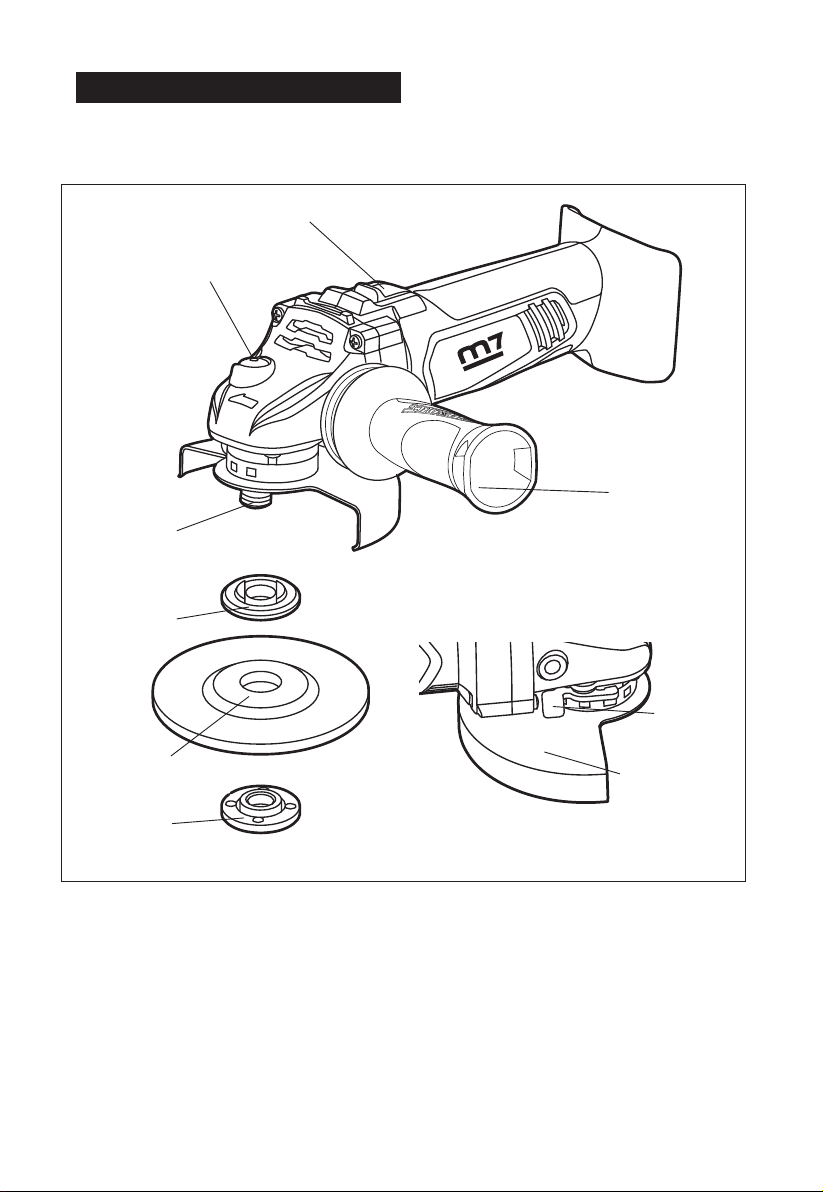

DESCRIPTION OF THE TOOL

OPERATING CONTROL

Switch button

Spindle-lock button

Grinding wheel

Spindle

Side handle

Guard-

adjusting

lever

Wheel guard

Inner flange

Outer flange

1

2

Rated speed 8000 RPM

Wheel diameter 5" (125 mm)

Arbor size M14*2

Tool weight (without battery) 3.2 lbs.(1.46kg)

SPECIFICATIONS

2

3

3

GENERAL SAFETY RULES

WARNING: Read all instructions. Failure to

follow all instructions listed below may result in

SAVE THESE INSTRUCTIONS

The term “power tool” in all of the warnings listed

below refers to your main operated (corded)

power tool or battery operated (cordless) power

tool.

1. WORK AREA SAFETY

1) Keep your work area clean and well lit.

Cluttered or dark areas invite accidents

2) Do not operate power tools in explosive

environments, such as in the presence of

create sparks, which may ignite the dust or

fumes.

3) Keep children and bystanders away while

operating a power tool. Distractions may cause

you to lose control.

2. ELECTRICAL SAFETY

1) Avoid body contact with grounded surfaces,

such as pipes, radiators, ranges, and

refrigerators. There is an increased risk of

electric shock if your body is grounded.

2) Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with grounded power tools.

reduce the risk of electric shock.

3) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

4) Do not abuse the cord. Never use the cord for

carrying, pulling, or unplugging the power tool.

Keep the cord away from heat, oil, sharp edge,

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

5) When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk

of electric shock.

6) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD

reduces the risk of electric shock.

Use the battery only with the charger listed:

BATTERY PACK CHARGER

DB1840 or DB-1850

3.PERSONAL SAFETY

1) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while tired or under

A moment of inattention while operating power

tools may result in serious personal injury.

2) Use safety equipment. Always wear eye

protection. Safety equipment, such as dust

mask, non-skid safety shoes, hard hat, and

hearing protection, when used for appropriate

conditions, will reduce personal injuries.

3) Avoid accidental starting. Make sure that the

switch is in the “OFF” position before plugging

the tool into an electrical outlet. Carrying

plugging in power tools that have the power

switch “ON” invites accidents.

4) Remove any adjusting key or wrench before

turning the power tool on. A wrench or key left

attached to a rotating part of the power tool

may result in personal injury.

5) Do not overreach. Keep proper footing and

balance at all times. This enables better

control of the power tool in unexpected

situations.

6) Dress properly. Do not wear loose clothing or

jewelry. Keep your hair, clothing, and gloves

away from moving parts. Loose clothes,

jewelry, or long hair can be caught in moving

parts.

7) If devices are provided for the connection of

dust extraction and collection facilities, make

sure that these are connected and properly

used. Use of these devices can reduce dust-

related hazards.

8) Use clamps or another practical way to

support and secure the workpiece to a stable

platform. Holding the work by hand or against

your body leaves it unstable and may lead to

loss of control.

9) Do not use on a ladder or unstable support.

Stable footing on a solid surface enables

better control of the power tool in unexpected

situations.

DC-18

3

4

4

10)Keep handles dry, clean, and free from oil and

grease. Slippery hands cannot safely control

the power tool.

11)Always wear safety glasses with side shields.

Everyday glasses may have impact-resistant

lenses, but they are NOT safety glasses.

Following this rule will reduce the risk of eye

12)Protect your lungs. Wear a face or dust mask

if the operation is dusty. Following this rule will

13)Protect your hearing. Wear hearing protection

during extended periods of operation.

Following this rule will reduce the risk of

4.POWER TOOL USE AND CARE

1) Do not force the power tool. Use the correct

power tool for your application. The correct

safely at the rate for which it was designated.

2) Do not use the power tool if the switch does not

turn it ON and OFF. Any power tool that cannot

be controlled with the switch is dangerous and

must be repaired.

3) Disconnect the plug from the power source

and/or the battery pack from the power tool

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

4) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions

to operate the power tool. Power tools are

dangerous in the hands of untrained users.

5) Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tool’s operation. If damaged, have

the power tool repaired before use. Many

accidents are caused by poorly maintained

power tools.

6) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

7) Use the power tool, accessories, blades, etc.

in accordance with these instructions and in

the manner intended for the particular type of

power tool, taking into account the working

conditions and the work to be performed. Use

of the power tool for operations different from

those intended could result in a hazardous

situation.

8) Hold power tools by the insulated gripping

surfaces when performing any operation in

which the cutting tool may contact hidden

wiring or its own cord. Contact with a “live”

wire will also make exposed metal parts of the

tool “live” and can shock the operator.

9) Know your power tool. Read the product

manual carefully. Learn the applications and

hazards related to this tool. Following this rule

10)Save these instructions. Refer to them

frequently and use them to instruct others

who may use this tool. If you lend this tool

to someone else, also lend them these

instructions.

5.BATTERY TOOL USE AND CARE

1) Make sure that the switch is in the OFF

position before inserting the battery pack.

Inserting the battery pack into power tools that

have the switch ON invites accidents.

2)

manufacturer. A charger that is suitable for one

when used with another battery pack.

3)

designated battery packs. Use of any other

4) When the battery pack is not in use, keep it

clips, coins, keys, nails screws, or other small

one terminal to another. Shorting the battery

5) Under abusive conditions, liquid may be

liquid contacts eyes, additionally seek medical

cause irritation or burns.

6) Battery tools do not have to be plugged into

in operating condition. Be aware of possible

hazards when not using your battery tool or

4

5

when changing accessories. Following this rule will

7) Do not place battery tools or their batteries

8) Do not crush, drop or damage the battery

pack. Do not use a battery pack or charger that

has been dropped or received a sharp blow.

Properly dispose of a dropped or damaged

battery immediately.

9)

Properly dispose of a dropped or damaged

battery immediately.

10)Batteries vent hydrogen gas and can explode

in the presence of a source of ignition, such

as a pilot light. To reduce the risk of serious

exploded battery can propel debris and

chemicals. If exposed to such debris or

area with water.

11)Do not charge a battery tool in a damp or wet

location. Following this rule will reduce the risk

of electric shock.

12)Under extreme usage or temperature

conditions, battery leakage may occur.

13)

If liquid contacts eyes, seek medical help.

irritation or burns.

14)If liquid comes in contact with your skin,

wash immediately with soap and water, then

15)If liquid from the battery gets in your eyes,

minutes, and then seek immediate medical

attention. Following this rule will reduce the

6.SERVICE

1)

repair person.

2) When servicing a power tool, use only identical

replacement parts.

3) Follow instructions in the Maintenance section of

this manual. Use of unauthorized parts or failure

to follow Maintenance instructions may create a

ADDITIONAL SAFETY

INSTRUCTIONS FOR GRINDING

OPERATIONS

1. Use only wheel types that are

recommended for your power tool and the

wheel. Wheels for which the power tool was

not designed cannot be adequately guarded

and are unsafe.

2. The grinding surface of centre depressed

wheels must be mounted below the plane

of the guard lip. An improperly mounted

wheel that projects through the plane of the

guard lip cannot be adequately protected.

3. The guard must be securely attached

to the power tool and positioned for

maximum safety, so the least amount of

wheel is exposed towards the operator.

The guard helps to protect the operator

from broken wheel fragments, accidental

contact with wheel and sparks that could

ignite clothing.

4. Wheels must be used only for

recommended applications. For example:

do not grind with the side of cut-off wheel.

Abrasive cut-off wheels are intended for

peripheral grinding, side forces applied to

these wheels may cause them to shatter.

that are of the correct size and shape

for your selected wheel. Proper wheel

the possibility of wheel breakage. Flanges

for cut-off wheels may be different from

grinding wheel flanges.

6. Do not use worn down wheels from larger

power tools. A wheel intended for a larger

power tool is not suitable for the higher speed

of a smaller tool and may burst. SP

5

6

SAFETY RULES FOR CHARGER

1) Before using battery charger, read all

instructions and cautionary markings in this

manual and on the battery charger, the battery

and the product using the battery to prevent

damage.

CAUTION: To reduce the risk of electric

shock or damage to the charger and battery,

charge only those lithium-ion rechargeable

charger’s label. Other types of batteries may

2) Do not use the charger outdoors or expose it

to wet or damp conditions. Water entering the

charger will increase the risk of electric shock.

3) Use of an attachment not recommended or

sold by the battery-charger manufacturer may

persons.

4) Do not abuse the cord or charger. Never use

the cord to carry the charger. Do not pull the

charger cord to disconnect the plug from

receptacle. Damage to the cord or charger

could occur and create an electric shock

hazard. Replace damaged cords immediately.

5) Make sure that the cord is located so that it

will not be stepped on, tripped over, come in

contact with sharp edges or moving parts,

This will reduce the risk of accidental falls,

the cord, which could then result in electric

shock.

6) Keep cord and charger from heat to prevent

damage to housing or internal parts.

7) Do not allow gasoline, oils, petroleum-based

products, etc. to come in contact with plastic

parts. These materials contain chemicals that

can damage, weaken, or destroy plastic.

8) An extension cord should not be used unless

absolutely necessary. Use of an improper

and electric shock. If an extension cord must

be used, make sure that:

The pins on plug of extension cord are the

same number, size and shape as those of the

plug on charger.

The cord is properly wired and in good electrical

condition

The size is large enough for AC ampere rating

The Cord Length (Feet) 25’ 50’ 100’

Cord Size (AWG) 16 16 16

NOTE: AWG = American Wire Gauge

9) Do not operate the charger with a damaged

cord or plug, which could cause shorting and

electric shock. If damaged, have the charger

repaired or replaced by an authorized service

technician at Service Center.

10)Do not operate the charger if it has received

a sharp blow, been dropped, or has

otherwise been damaged in any way. Take

it to an authorized service technician at

Service Center for an electrical check to

determine if the charger is in good working

order.

11)Do not disassemble the charger. Take it to

an authorized service technician at a

Service Center when service or repair is

required. Incorrect reassembly may result in

12)Unplug the charger from the electrical outlet

before attempting any maintenance or

cleaning to reduce the risk of electric shock.

13)Disconnect charger from the power supply

when not in use. This will reduce the risk of

electric shock or damage to the charger if

metal items should fall into the opening. It

will also help prevent damage to the charger

during a power surge.

14)Risk of electric shock. Do not touch the

uninsulated portion of output connector or

uninsulated battery terminal.

15)Save these instructions. Refer to them

frequently and use them to instruct others

who may use this tool. If you lend this tool to

someone else, also lend these instructions

to them to prevent misuse of the product and

possible injury.

6

7

7

WARNING: Some dust created by power Cutting

contains chemicals known to cause cancer,

birth defects or other reproductive harm. Some

examples of these chemicals are:

lead from lead-based paints

Arsenics and chromium from chemically

reacted lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment.

ACCESSORIES

Angle Grinder 1

Charger 1

Battery pack 2

Be sure to check the accessories as it is subject

to change by areas and models.

OPERATION

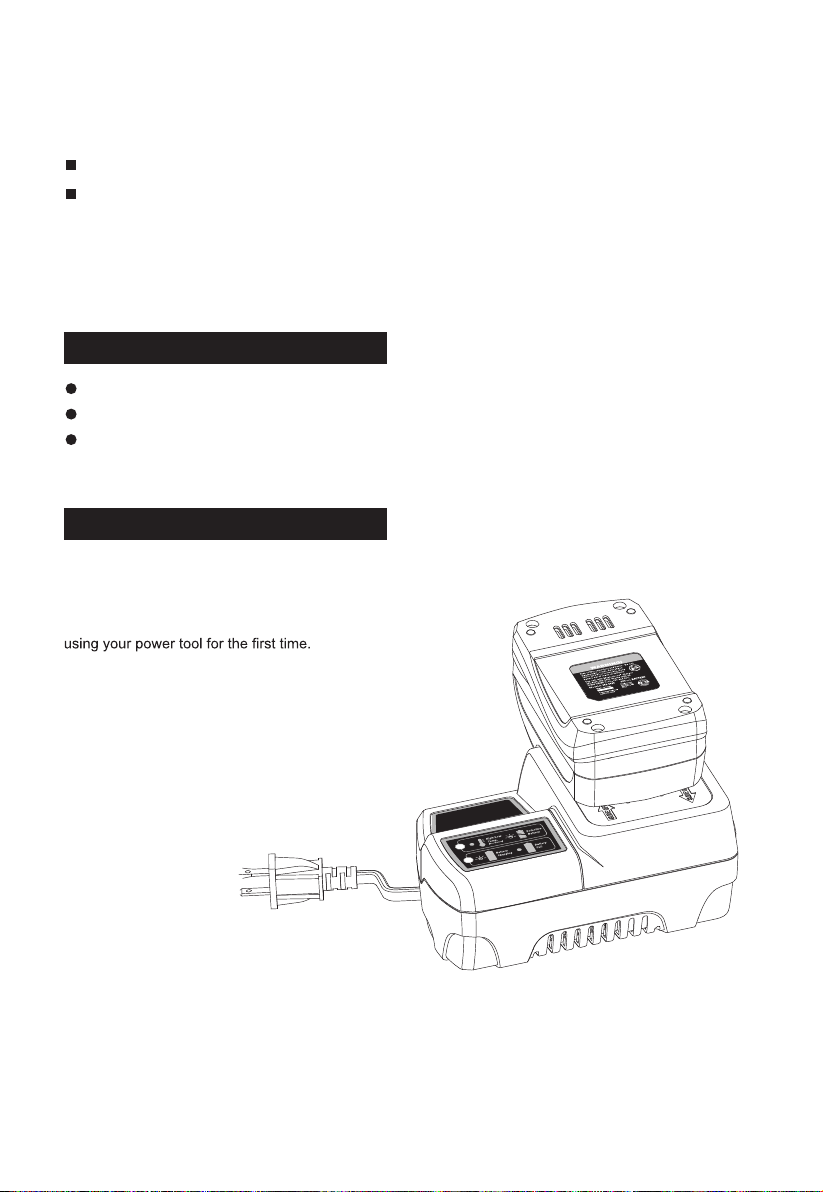

1.BATTERY CHARGING

The battery is supplied partially charged. To

ensure full capacity of the battery, completely

charge the battery in the battery charger before

A fully discharged battery pack will charge

in 50 minutes for DB1840 in a surrounding

temperature between 32° F (0° C) and 104° F

(40° C).

1. Charge the Lithium-Ion battery pack with the

correct charger.

2. Connect the charger to a power supply.

3. Align the raised ribs of the battery pack with

the slot in the charger.

4. Slide the battery pack onto the charger .

5. The charger will communicate with the

battery pack to evaluate the condition of the

battery pack.

6. The POWER BAR LED lights will cycle from

right to left during charging. This is part of the

normal charging operation.

7. After charging is complete, the green LED

on the charger will come on and the POWER

BAR LED lights will go displayed when the

POWER BAR button is pressed while the

battery pack is on the charger.

8. The battery pack will fully charge if left on the

charger, but it will not overcharge.

NOTE: For your convenience, the charger can

operate with most generators and inverters

rated at 300 watts or higher.

7

8

8

2. LED FUNCTIONS OF CHARGER

3. POWER BAR

This Lithium-Ion battery pack is equipped with a POWER BAR, which is used to display the battery

pack’s remaining run time. Press the POWER BAR button to display the LED lights. The LED lights

will stay lit for approximately 4 seconds.

NOTE: The POWER BAR can be used whether the battery is attached or removed from tool.

LED INDICATOR BATTERY PACK RED LED GREEN LED ACTION

HI/LO TEMP.

(SEE MANUAL) Hot/Cold battery On Off Charging will begin when

battery returns to 0oC-40oC

DEFECTIVE

BATTERY Defective Flashing Off Battery pack or Charger is

defective

BATTERY

CHARGING Charging Off Flashing Charging

BATTERY

FULL Fully charged Off On Charging is complete

Maintenance charging

4. LOW-BATTERY CAPACITY INDICATOR

If LED worklights on the POWER BAR begins

trigger switch on the angle grinder is

depressed, the battery pack’s power has run

out, and the battery pack should be recharged.

Unlike other battery pack types, Lithium-Ion

battery packs deliver fade-free power for their

entire run time. The tool will not experience a

slow, gradual loss of power as you work. To

signal that the battery pack is at the end of its

run time and needs to be charged, the power

to the tool will drop quickly. The POWER BAR

when the battery is completely discharged.

When this happens, remove the tool from the

workpiece, and charge the battery pack as

needed.

NOTE: The POWER BAR may also display four

temperature situation.

5. WHEN TO CHARGE THE

BATTERY PACK

The Lithium-Ion battery can be charged at any

time and will not develop a “memory” when

charged after only a partial discharge. It is not

necessary to run down the battery pack charge

before recharging. Remove the battery pack

from the tool when convenient for you and your

job.

Use the POWER BAR to determine when you

need to recharge the battery pack.

80-100% Charge

60-79% Charge

40-59% Charge

20-39% Charge

Under 20% Charge

Completely Discharged

High/low temperature

You can “top-off” your battery pack’s charge

before starting a big job or long period of use.

8

9

WARNING:

If any part is broken or

missing, DO NOT attempt to plug in the

power cord, attach the battery, or operate

the tool until the broken or missing part is

replaced. Failure to do so could result in

possible serious injury.

WARNING:

Do not attempt to mod -

ify this tool or create accessories not rec -

ommended for use with this tool. Any such

could result in a hazardous condition lead -

ing to possible serious injury.

WARNING:

Your tool should never

be connected to the power source when

you are assembling parts, making adjust -

ments, installing or removing application

tools, cleaning, or when it is not in use.

Disconnecting the tool will prevent acci -

dental starting, which could cause serious

personal injury.

CONTENTS

,hcnerw,eldnahedis,rednirgelgnasseldroC

5” grinding wheel and instruction

manual.

UNPACKING

1. Carefully remove the tool and any

accessories from the box. Make sure that all

items listed in the packing list are included.

2. Inspect the tool carefully to make sure

that no breakage or damage occurred

during shipping.

3. Do not discard the packing material

until you have carefully inspected and

satisfactorily operated the tool.

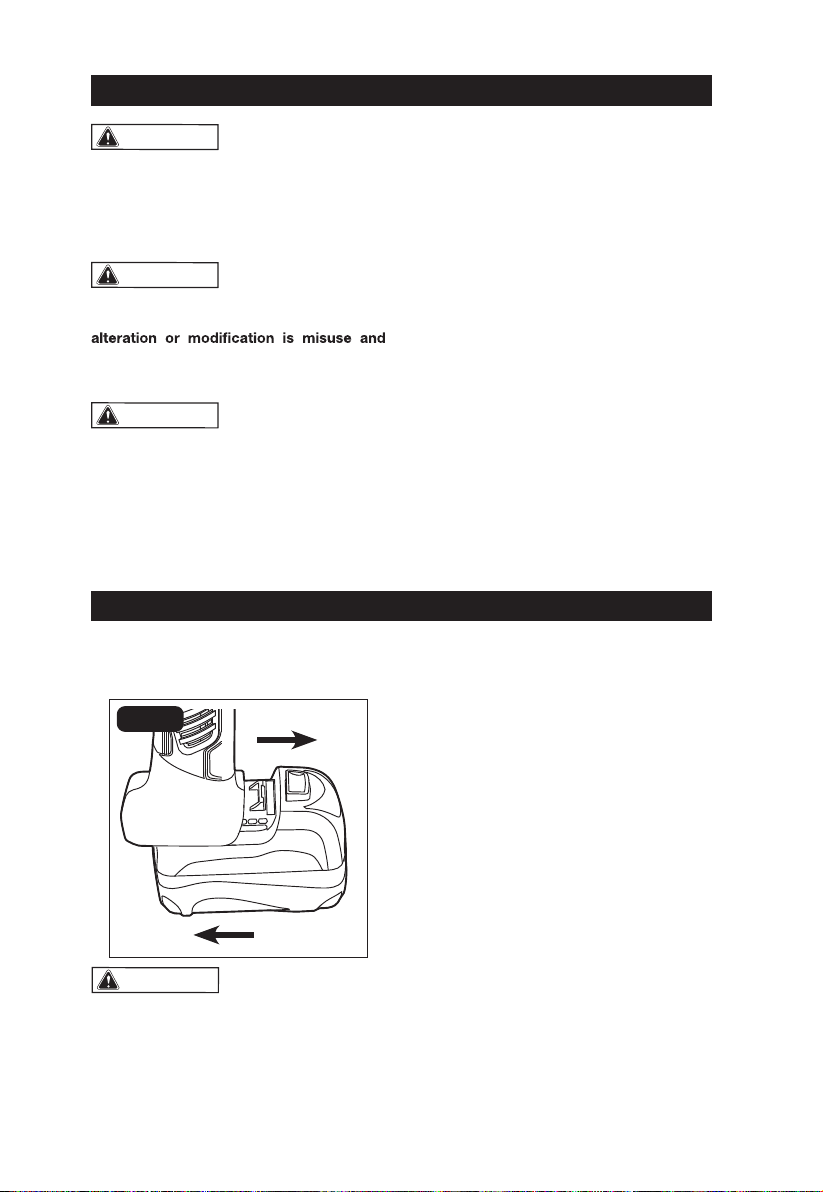

TO ATTACH THE

BATTERY PACK (FIG. 1)

FIG. 1

Attach

Detach

WARNING:

To avoid the possibility

of accidental starting, always take care not

to activate the trigger switch when you are

attaching the battery pack or performing other

adjustments to the tool.

1. Make sure that the angle grinder is

turned off.

2. Align the raised rib on the battery pack

with the grooves on the bottom of the tool,

and then attach the battery pack to the

angle grinder.

NOTICE: When attaching the battery pack

to the tool, make sure that the raised plat -

form on the pack aligns with the grooves

on the bottom of the tool and that the

latches snap properly into place. Improper

assembly of the battery pack can cause

damage to internal components.

TO DETACH BATTERY

PACK (FIG.1)

1. Make sure that the angle grinder is

turned off.

ASSEMBLY

OPERATION

9

10

2. Depress the battery-release button

located on the front of the battery pack to

release the battery pack.

3. Pull the battery pack forward to remove it

from the tool.

ON/OFF SWITCH (FIG. 2)

WARNING:

Firmly grasp the body of

the tool and the side handlebefore starting.

The tool is switched “ON” with the switch

button located at the top of the motor housing.

The switch can be locked in the “ON” position,

a convenience for long grinding operations.

The symbol “O” on the motor housing

indicates OFF; the symbol “l” indicates ON.

1. To turn the tool ON without locking it,

slide the switch button forward by applying

pressure only at the rear portion of the button.

2. To unlock the switch and turn the tool

OFF, press and release the rear portion of

the switch button; it will return to the OFF

position automatically.

FOR CONTINUOUS

OPERATION (FIG. 2)

1. Push the switch button forward to the ON

position and press the front of the button

down until the switch clicks into position.

2. To unlock the switch and turn the

tool OFF, press the rear of the button.

INSTALLING THE SIDE

HANDLE (FIG. 3)

The side handle is used to guide and

balance the tool and can be threaded into

the front housing on either side of the

tool, depending on personal preference

and comfort. Use the side handle for

safe control and ease of operation.

WARNING:

Failure to remove the

battery pack from the cordless angle grinder

when assembling parts, making adjust -

ments, or changing application tools could

result in accidental starting and cause seri -

ous injury.

1. Remove the battery pack from the

angle grinder.

2. The side handle may be installed on

the right side or the left side of the tool.

Thread the side handle into the desired

operating position.

3. Securely tighten the side handle by

turning it clockwise.

OPERATION

FIG. 2 Switch button

FIG. 3

10

11

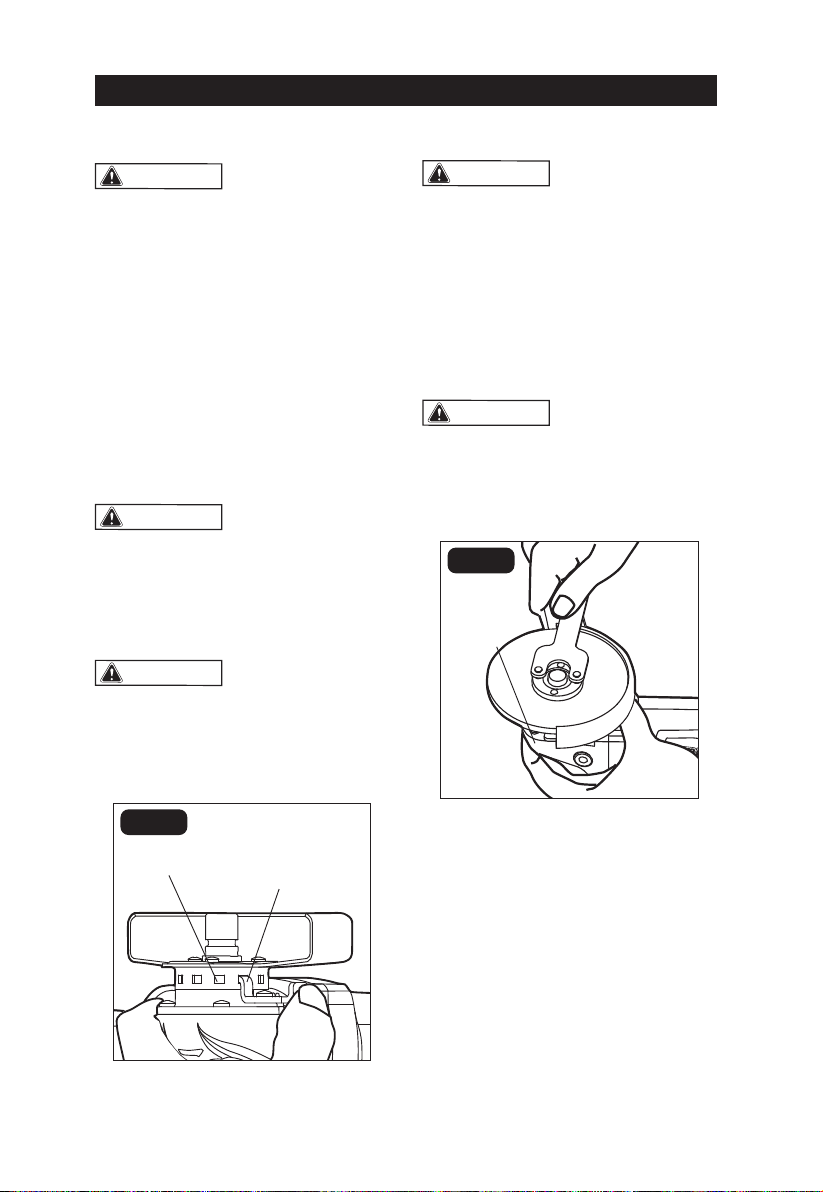

ADJUST THE GUARD (FIG. 4)

WARNING:

Failure to remove the

battery pack from the cordless angle grinder

when assembling parts, making adjust -

ments, or changing application tools could

result in accidental starting and cause seri -

ous injury.

1. Remove the battery pack from the

angle grinder

2. Press the guard-adjusting lever, and hold

it to loosen the guard.

3. Rotate the guard to the desired position

and make sure that the lever lines up with

notches on the guard.

4. Release the guard-adjusting lever to lock the

guard; verify that the lever secures the guard.

WARNING:

ALWAYS use the guard

when grinding with a grinding wheel. It has

been designed for use only with the guard

attached. Attempting to use the grinder

with the guard removed will result in loose

particles being thrown against the opera -

tor and possibly serious personal injury.

WARNING:

Only use the guard with

grinding wheels. Make sure that the guard-

adjusting lever secures the guard before

operation. Keep the guard between you

and wheel. Do not direct the guard open -

ing towards your body.

MOUNTINGTHE WHEEL (FIG. 5-6)

WARNING:

Only use grinding

wheels for which the maximum safe operat -

ing speed is rated at or above 11000 RPM.

Use only Type 27 wheels with the thickness

of 1/4” (6 mm), such as the one provided with

this product. Never attach a Type 1 straight

or cut-off wheel to this angle grinder. This

product is only designed for grinding. Use

for any other purpose is not recommended

and creates a hazard, which will result in se -

rious injury.

WARNING:

Failure to remove the

battery pack from the cordless angle

grinder when assembling parts, making

adjustments, or changing application tools

could result in accidental starting and

cause serious injury.

FIG. 5

Spindle-lock

button

1. Remove the battery pack from the

angle grinder.

2. Make sure that the guard is securely in

place. Depress and hold the spindle-lock

button. Loosen the outer flange with the

supplied wrench while holding the spindle-

lock button down (FIG. 5).

3. Place the inner flange on the spindle;

make sure that the flange is positioned so

that the shape of the opening in the flange

corresponds with the shape at the base of

the spindle.

OPERATION

FIG. 4

Guard-adjusting

lever

Notch on the

guard

11

12

4. Place the grinding wheel on the spindle.

Check the rated speed on the grinding

wheel. DO NOT use a wheel with a rated

speed lower than the speed shown on the

grinder nameplate.

5. Thread the outer flange on the spindle

with the flat side of the flange facing up,

making sure that the opening in the wheel is

positioned around the raised portion of the

outer flange (FIG. 6).

6. Press the spindle-lock button to prevent

movement of the spindle.

;desserpednottubkcol-eldnipsehtpeeK.7

ybegnalfretuodedaerhtehtnethgit

turning it clockwise with the wrench (FIG. 6).

WARNING:

Keep the guard between

you and the wheel. Do not direct the guard

opening toward your body.

FIG. 6

Outer flange

Inner

flange

Spindle

Grinding wheel

GRINDING OPERATION (FIG. 7)

WARNING:

Only use grinding wheels

for which the maximum safe operating speed

is rated at or above 11000RPM. Never use

damaged or imbalanced grinding wheels.

Do not exceed the recommended wheel

diameter. Grinding wheel type 27 is

recommended for use on this grinder.

WARNING:

Firmly grasp the body of

the tool and the side handle before starting.

1. If you have just installed an accessory or are

beginning a period of work, test it by letting

it spin for one minute before applying it to

the workpiece. Out-of-balance or damaged

accessories can mar workpiece, damage the

tool, and cause stress that may cause accessory

failure.

2. Use a clamp, vise or other practical means to

hold your work, freeing both bands to control

the tool.

3. Hold tool securely with both hands.

4. start the tool.

5. Allow accessory to come to full speed before

beginning work.

6. Control pressure to surface contact between

accessory and workpiece. Too much pressure

slows speed.

7. When finished, turn off the tool and make

sure it comes to a complete stop before laying

it down.

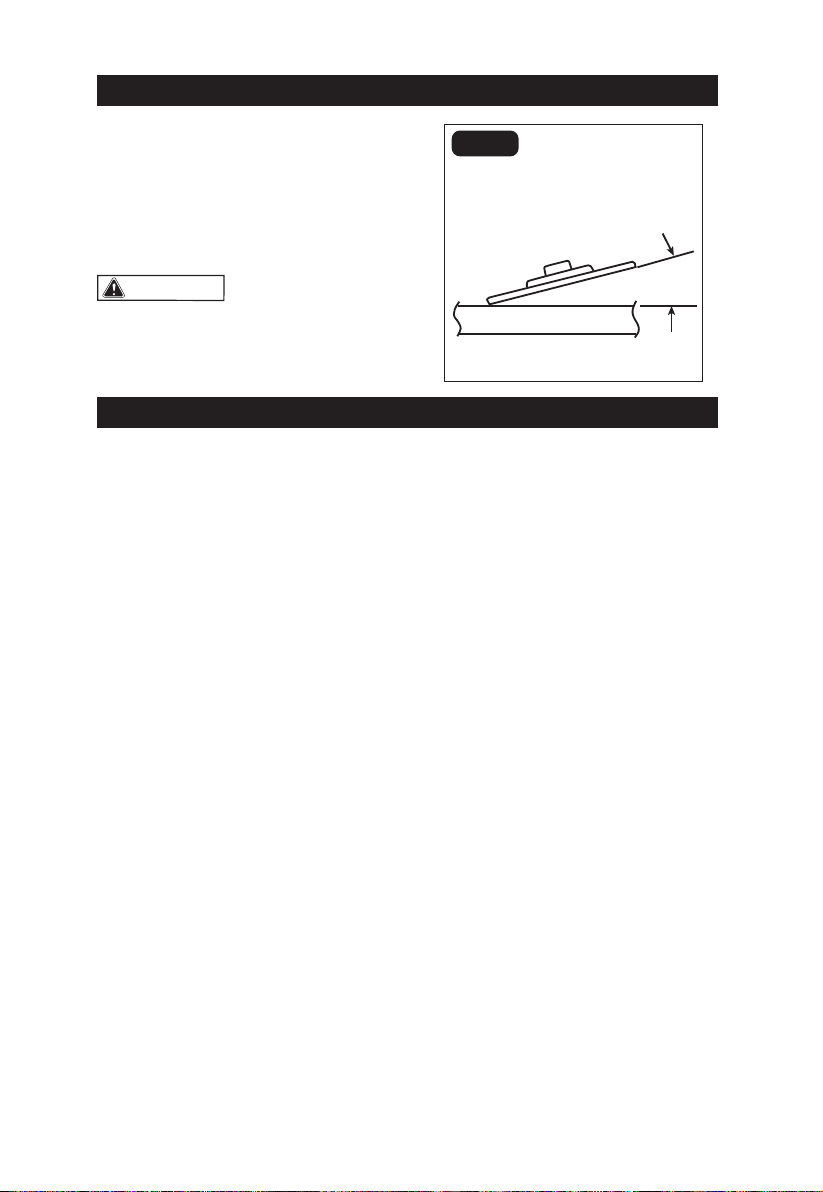

GRINDING TIPS

•Use a clamp, vise or other practical means

to hold your work, freeing both hands to

control your tool. Firmly grasp the body of tool

and the side handle before starting and while

the tool isin operation.

•Efficient grinding is achieved by controlling

the pressure and keeping the angle between

the wheel and the workpiece at 10° to 15°

(FIG. 7). If the angle is too shallow the tool is

difficult to control. If the angle is too steep,

the pressure is concentrated on a small area,

causing burning tothe work surface.

•Move the angle grinder back and forth with

moderate pressure to avoid discoloring the

workpiece, overheating the workpiece and

creating ridges.

• Never use a cut-off wheel to grind a

work piece.

•Always hold the tool properly so that sparks

and grinding dust fly away from the body.

• Start the tool before applying the

accessory to workpiece and let the tool come

to full speed before contacting the workpiece.

Lift the tool from the workpiece before turning

the tool OFF.

OPERATION

12

13

• When using a new grinding disc, do not

move the disc in a forward direction on the

workpiece. Doing so will cause the edge of the

disc to cut into the surface of the workpiece.

While grinding, the direction of movement

should be backward, toward the operator

(FIG 7).

WARNING:

Sparks are generated

when grinding metal. Take care that no

combustible material presented in the area of

flying sparks.

GENERAL MAINTENANCE

Using compressed air may be the most

effective cleaning method. Always wear

safety goggles when cleaning tools with

compressed air. Periodic maintenance

allows for long life and trouble-free operation.

A cleaning, lubrication and maintenance

schedule should be maintained.

1. Avoid dropping or otherwise causing impact

to the tool and keep it from oil and grease.

2. Inspect the screws periodically. If the

screws loosen, tighten them immediately, to

avoid serious accident.

3. Clean all parts of the tool; clean dust and

debris from vents. Keep the tool clean, dry

and free of oil or grease.

4. Avoid using solvents when cleaning

plastic parts. Most plastics are susceptible

to damage from various types of commercial

solvents and may be damaged by their use.

Use clean cloths and mild soap to remove

dirt, dust, etc.

LUBRICATION

All of the bearings in this product are

lubricated with a sufficient amount of

high grade lubricant for the life of the

unit under normal operating conditions.

Therefore, no further lubrication is required.

STORAGE AND HANDLING OF

GRINDING WHEELS

When not in use, grinding wheels should

be stored carefully in a rack or box to

protect them from chipping or breakage.

All grinding wheels must be handled

carefully to prevent dropping and bumping.

OPERATION

MAINTENANCE

10°~ 15°

FIG. 7

13

14

TROUBLESHOOTING

PROBLEM CAUSE OF THE PROBLEM SOLUTION

The motor stops

running Battery is empty Charge the battery pack

The angle grinder

does not work

The switch is in the “ON”

position when attaching the

battery pack

Turn off the angle grinder first and

re-start the tool

The tool is running

slowly Thegrinder wheel is worn outReplace the grinding wheel on the tool

TOOL MAINTENANCE

WARNING: Before any work on the

machine itself, remove the battery pack from

the angle grinder.

1. Inspect the screws periodically. If the

screw loosen, tighten them immediately, to

avoid serious accident.

2. Inspect tool cords periodically. If damaged,

have repaired at your nearest Authorized

Service Center.

3. Clean all parts of the tool; clean dust and

debris from vents. Keep the tool clean, dry

and free of oil or grease.

4. All service MUST only be performed by

Authorized Service Center. ALWAYS

use only accessories that are recommended

for this tool.

5. Avoid using solvents when cleaning plastic

parts. Most plastics are susceptible to damage

from various types of commercial solvents and

may be damaged by their use. Use clean cloths

and mild soap to remove dirt, dust, etc.

WARNING: Do not allow the water entering

the motor and the tool full immersed in the

ware, which will result in motor malfunction and

electric shock.

Store the batteries below 35 °C

Do not store batteries in high temperature or

high humidity environments.

It is recommended to store the batteries fully

charged.

ENVIRONMENT PROTECTION

1. Tool, accessories and packaging should be

sorted for environment-friendly recycling.

2. Power tools and accessories at the end of

their service life still contain large amounts of

valuable raw materials and plastics which can

likewise be fed back into a recycling process.

3. Some dust created by working contains

harmful chemicals must be collected by

special garbage re- cycle site.

SERVICE

1.

2. Warranty do not apply in case of normal wear,

overload or improper use of the tool.

In case of guarantee, repair or purchase of

replacement parts, always contact the qualified

service center.

And supplied with the efficient service card and

invoice.

14

15

Serial Number: Please refer to the tool

Cordless Angle Grinder with Battery Pack

Item No.: DG585 / DB1850 (Tool / Battery Pack)

18~20 Vd.c., 5.0 Ah, Li-ion Battery, 5” Angle Grinder

n0= 8000 rpm

of (MD) Machinery Directive 2006/42/EC, (LVD) Low Voltage Directive 2006/95/EC, (EMC)

Electromagnetic Compatibility Directive 2004/108/EC and Directive 2011/65/EU on ROSH and their

amendments and is manufactured and tested according to the following standards:

EN 60745-1, EN 60745-2-2, EN 55014-1, EN 61000-3-2, EN 61000-3-3, EN 55014-2, and EN 50581

Declared in: Taichung, Taiwan

Dated:2018/01/01

Jonney Chen

Declared by: QA Manager

Manufacturer:

Mighty Seven International Co., Ltd.

No. 70-25, Ching Quang Rd., Wujih Dist.,

Taichung City, 41466 Taiwan

http://www.mighty-seven.com

King Tony France

3 Rue des imprimeurs ZI République Nord 1.

86000 POITIERS FRANCE

TEL: (+33)5-49-30-30-90

E-MAIL: christian.aubineau@kingtony.eu

Signature

Original Language

ECDECLARATION OFCONFORMITY

30

Jay Lin

15

16

1/2" Dr. Cordless Impact Wrench

ltem No DG-585

K02

K01

K03

31

5" Cordless Angle Grinder

16

17

DG-585

NO. PART NO. DESCRIPTION Q'TY

1 DG-585P01 Wrench

2 DG-585P02 Outer Flange 1

3 DG-585P03 Inner Flange 1

4 DG-585T04 Tapping Screw ( 3PCS ) 1SET

5 DG-585P05 Plate 1

6 DG-585P06 Guard 1

7 DG-585T07 Screw With Washer ( 4PCS ) 1SET

8 DG-585P08 Output Shaft 1

9 DG-585P09 Plain Washer 1

10 DG-585P10 Slotted Shoulder Screw 1

11 DG-585P11 Lever 1

12 DG-585P12 Compression Spring 1

13 DG-585P13 Gear Case Cover 1

14 DG-585P14 Bevel Gear 1

15 DG-585P15 Oil Impreging Bearing 1

16 DG-585P16 Spindle Lock 1

17 DG-585P17 O Ring 1

18 DG-585T18 Tapping Screw ( 4PCS ) 1SET

19 DG-585P19 Pin Knob 1

20 DG-585T20 Spring 1SET

NO. PART NO. DESCRIPTION Q'TY

22 DG-585P22 Gear Case 1

23 DG-585P23 Bevel Pinion 1

24 DG-585P24 Ball Bearing 1

25 DG-585P25 Circlips For Shaft 1

26 DG-585P26 Rubber Ring 1

27 DG-585P27 Bearing Retainer 1

28 DG-585P28 Rotor 1

29 DG-585P29 Ball Bearing 1

30 DG-585P30 1

31 DG-585P31 Stator 1

32 DG-585P32 PCB Assembly 1

33 DG-585P33 Switch Button 1

34 DG-585P34 Left Housing 1

35 DG-585P35 Switch Actuator 1

36 DG-585P36 Spring 1

37 DG-585P37 Right Housing 1

38 DG-585T38 Tapping Screw ( 4PCS ) 1SET

K01 DG-585K01 Spindle ASSY ( 8~14 ) 1SET

K02 DG-585K02 Gear Case ASSY (15,16,17

,19,20 ) 1SET

K03 DG-585K03 "Rotor ASSY (23,24, 2 5

,27,28,29 ) 1SET

21 DG-585P21 Handle 1

32 17

18

18

1

DESCRIPTION DE L'OUTIL

COMMANDE DE FONCTIONNEMENT

Interrupteur

Bouton de verrouillage de la broche

Disque de meulage

Broche

Poignée latérale

Levier de

réglage de

la garde

Garde de

protection

Bride intérieure

Bride extérieure

19

This manual suits for next models

1