Floorex Products Mastiff 200 Troubleshooting guide

Mastiff 200

SAFETY & OPERATORS MANUAL

& PARTS LISTING

CAUTION: Read the instruction manual before using the appliance.

V20191104

Mastiff 200

1800 356 673 1. 1800 - FLOOREX

Table of Contents

Specifications 2

Safety instructions 3

Safety instructions 4

Operating instructions 5

Operating instructions 7

Electrical safety 8

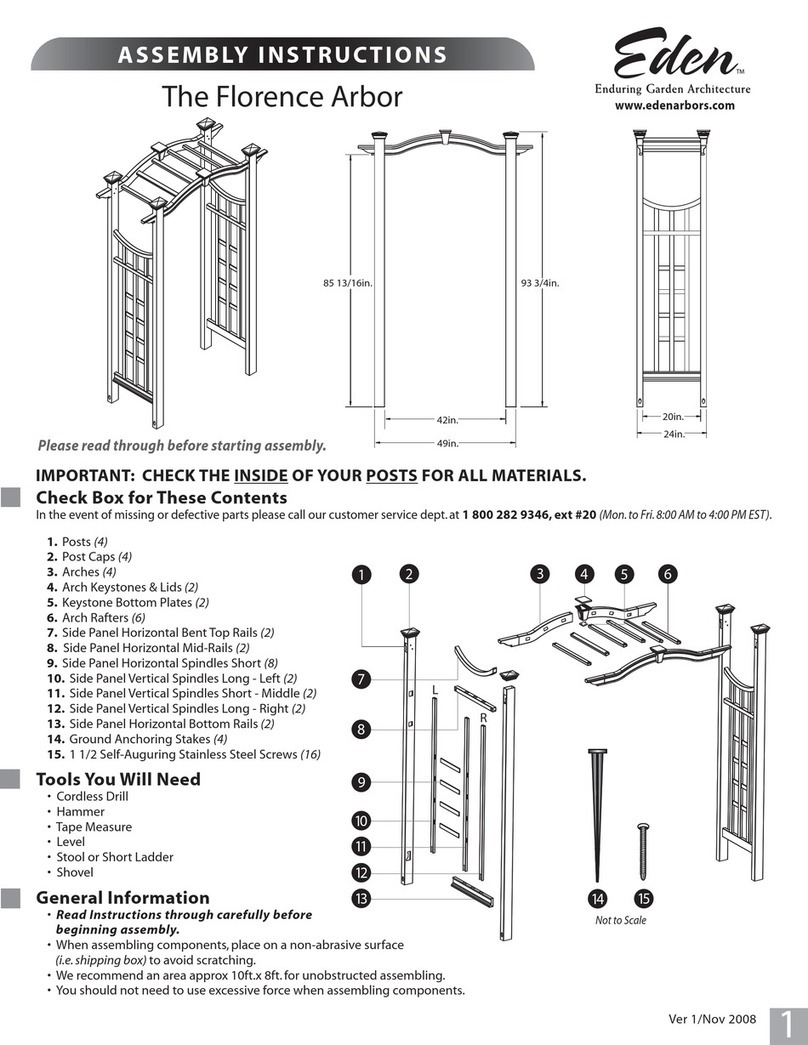

Parts Listing –Main Chassis - Petrol 9

Parts Listing –Main Chassis - 1 Phase 10

Parts Listing –Main Chassis - 3 Phase 11

Parts Listing –Inner Chassis –Petrol 12

Parts Listing –Inner Chassis –1 Phase 13

Parts Listing –Inner Chassis –3 Phase 14

Parts Listing –Bearings & Shaft 15

Parts Listing –Drum and Cutters 16

Wiring Diagram 1 Phase 17

Wiring Diagram 3 Phase 18

Mastiff 200

FLOOREX- 1800 2. 1800 356 673

Specifications

Mastiff 200

Weight

138kg

Dimensions

1000 x 617 x 1037 (Length X Width x Height)

Rated Voltage

9Hp Petrol / 230 Vac / 415 Vac

Rated Watts

NA / 2.2kW / 4kw / 5.5kw

Preparation Path

200mm

Drum Setups

Typical Drum Setups

Setup

Cutters

Spacers

General Purpose

78 Cutters

171

Fine

96

142

Mastiff 200

1800 356 673 3. 1800 - FLOOREX

Safety instructions

1. Read and understand the instructions on the machine and in this manual

and engine manual (if applicable). Different models may have different

parts and controls.

2. Equipment should only be operated by trained personnel, in good

physical condition and mental health (not fatigued). The operator and

maintenance personnel must physically be able to handle the bulk weight

and power of this machine.

3. This is a one person machine. Maintain a safe operating distance to other

personnel. Remember ‘one machine, one operator’.

4. This equipment is intended for commercial use.

5. For the operators’ safety and the safety of others, always keep all guards

and shrouds in place.

6. Never start or run machine when unattended.

7. This machine is intended for use on floor surfaces only.

8. Never start or run machine with handle folded or when disk(s) are not in

contact with the surface.

9. Do not lend or rent machine without the operating instructions for the

machine (and the engine, if applicable).

10. Wear clothing suitable for the job and for the work place including,

safety shoes, hard hat, hearing protection, non-fogging vented safety

goggles, and dust mask suitable for dust.

11. Keep body parts or any loose clothing away from moving parts. Failure to

comply could result in bodily injury.

Mastiff 200

FLOOREX- 1800 4. 1800 356 673

Safety instructions

12. Do not modify machine in any way. Only use genuine MASTIFF 200 parts

and accessories.

13. Repairs should be performed by qualified persons only.

14. Ensure parts have stopped moving and disconnect power or spark plug

when servicing or changing blades or accessories.

15. Never operate machine in rain or if heavy moisture is present. (other

than under the shroud)

16. Do not operate MASTIFF 200 with any guards, shrouds, covers or doors

removed or open.

17. The MASTIFF 200 can produce sound pressure levels greater than 85db.

The operator must wear approved safety ear protection.

18. Do not allow the supply cord to come in contact with the cutting

blade/head or other moving parts of this machine.

19. Petrol is extremely flammable and poisonous. Petrol should only be

dispensed in well ventilated areas, and only when engine is cool.

20. WARNING! POISONOUS EXHAUST GASES. Do not operate petrol

powered equipment without adequate ventilation. Carbon monoxide is

and invisible odorless gas that can harm or can kill you.

21. WARNING! Breathable silica may be generated by use and maintenance

of this machine. Silica can cause severe and permanent lung damage,

cancer, and or other serious diseases. Do not breathe the dust. Do not

rely on your sight or smell to determine if dust is in the air. Silica may be

in the air without a visible dust cloud. If air monitoring for silica is not

provided by your employer at your work site, you must wear appropriate

respiratory protection when operating or maintaining this equipment.

Consult your employer for proper respiratory protection.

Mastiff 200

1800 356 673 5. 1800 - FLOOREX

Operating instructions

1. Wear clothes suitable for the job and for the work place including, safety

shoes, hard hat, hearing protection, non-fogging vented safety goggles,

and dust respirator suitable for dust.

2. WARNING! POISONOUS EXHAUST GASES. Do not operate petrol

powered equipment without adequate ventilation. Carbon monoxide is an

invisible odorless gas that can harm or can kill you.

3. Be sure all equipment is tested and tagged prior to use on any job.

4. Inspect entire area to be ground before grinding and remove any bolts

or concrete nails (etc.) that could damage diamond tooling or machine

which could cause a hazardous situation.

5. Ensure there are no obstacles or existing structures that could present a

hazard to the operator. If so, take necessary action to eliminate the

hazard.

6. Install appropriate tooling into the machine. Only use genuine MASTIFF

200 tooling. Failure to comply could result in bodily injury.

7. Stand in front of the machine, put one foot on the front nudge bar and

use the lift hook to tilt the machine over onto its front.

8.

9. Inspect and install appropriate tooling and tighten using the left hand

nuts. One at a time.

Mastiff 200

FLOOREX- 1800 6. 1800 356 673

Operating instructions

10. Tilt machine back onto its wheel in the opposite manner to above.

11. Wind the height adjustment knob fully clockwise and pull the fast raise

lower lever towards you.

12. Connect machine to suitable power outlet. Only use heavy duty power

lead suitable for high current use (minimum 2.5 mm² cable), no longer

than 20 meters. (For petrol powered equipment, refer to engine manual

for startup procedure).

13. If no power is available within the specified distance, have a qualified

person install a suitable power outlet closer to your work. Alternatively

use 4mm² cable for up to 50 meters.

14. Connect a suitable dust extractor to the machine via a 50mm flexible

hose. The machine is designed to take the standard FLOOREX 50mm

hose ends to make connection of dust extractors easy and hassle free.

Alternatively, water spray using the supplied water connection point can

be used to suppress dust.

15. Keep machine clear of drainage pits and grates or any such hazard.

Failure to comply could result in bodily injury and or could damage the

machine or property.

16. Switch on the dust extractor or water spray.

17. Hold the handles firmly and switch the machine on by pushing the green

button. Or start the petrol engine.

18. If the over-current device trips it indicates a problem. (Undersize power

lead or poor power to GPO outlet). Refer above for recommendations on

power leads. Rectify problem or decrease load on grinder by using

tooling with more surface area. Continuing to use the MASTIFF 200

when constant tripping occurs, VOIDS THE WARRANTY!

Mastiff 200

1800 356 673 7. 1800 - FLOOREX

Operating instructions

19. This machine is designed to operate with the wheels in contact with the

floor at all times. Do not operate with wheels off the floor.

20. Push the fast raise lower lever forward then wind the depth control anti

clockwise to lower to tools onto the floor.

21. Once the tools start touching the floor you can rotate the hand wheel a

total of 8 more turns for maximum cut depth.

Mastiff 200

FLOOREX- 1800 8. 1800 356 673

Electrical safety

1. All electrical maintenance and repairs to be carried out by qualified

persons only.

2. CAUTION - Line terminals may be alive when main switch is in the off

position. Disconnect all power at source before performing any

maintenance or repairs.

3. WARNING - DO NOT operate the machine with any electrical panels open.

4. WARNING - The MASTIFF 200 has an overload switch and will trip when

under excessive load and will not allow the machine to be switched on if

it is overloaded. (Overload will need to be reset when safe to do so).

Continuing to use the MASTIFF 200 when constant tripping occurs, VOIDS

THE WARRANTY!

5. Never operate machine in the rain or if heavy moisture is present.

6. The overcurrent device is there to protect you and the machine from

harm. DO NOT alter or adjust the over load in any way. If it is faulty, only

replace with original part that is identical to the faulty one.

7. Never bypass over-current devices in this machine.

8. Never connect or disconnect power cables with voltage present or while

under load.

9. Disconnect all power connections and observe lock out / tag out

procedures before attempting to carry out any maintenance or repair on

any equipment.

10. Avoid any contact with any rotating parts or driven parts.

11. Never use equipment that has not been tested and tagged (including

cords).

12. Do not operate MASTIFF 200 with any covers or doors removed or open.

13. Before connecting the machine to power, check the condition of all power

leads and cables on, or used in conjunction with the machine. DO NOT

USE it if any fault(s) cuts; wear marks, Bare wires out of plugs or sockets,

etc. Get qualified persons to repair and re-tag it as required by

regulations in your country.

Mastiff 200

1800 356 673 9. 1800 - FLOOREX

Parts Listing –Main Chassis - Petrol

Mastiff 200

FLOOREX- 1800 10. 1800 356 673

Parts Listing –Main Chassis - 1 Phase

Mastiff 200

1800 356 673 11.1800 - FLOOREX

Parts Listing –Main Chassis - 3 Phase

Mastiff 200

FLOOREX- 1800 12. 1800 356 673

Parts Listing –Inner Chassis –Petrol

Mastiff 200

1800 356 673 13.1800 - FLOOREX

Parts Listing –Inner Chassis –1 Phase

Mastiff 200

FLOOREX- 1800 14. 1800 356 673

Parts Listing –Inner Chassis –3 Phase

Mastiff 200

1800 356 673 15.1800 - FLOOREX

Parts Listing –Bearings & Shaft

Mastiff 200

FLOOREX- 1800 16. 1800 356 673

Parts Listing –Drum and Cutters

Mastiff 200

1800 356 673 17.1800 - FLOOREX

Wiring Diagram 1 Phase

Mastiff 200

FLOOREX- 1800 18. 1800 356 673

Wiring Diagram 3 Phase

Mastiff 200

1800 356 673 19.1800 - FLOOREX

Floorex Products

Your complete supplier

of all your concrete

surface preparation

needs

•Diamond grinders

•Concrete Polishers

•Dust extraction

•Shotblasters

•Screed mixers

•Diamond Tooling

•Floor Scrapers

•Coating application

FLOOREX

PRODUCTS

11 Jennings Road

Swan Hill VIC.

3585

Web: www.floorex.com.au

Email: sales@floorex.com.au

Table of contents

Popular Lawn And Garden Equipment manuals by other brands

Backyard

Backyard SNOWSTORM Little Cloud instruction manual

Gardenline

Gardenline 81324-20 user manual

Koolatron

Koolatron Lentek YardControl+ YC12 Directions for use

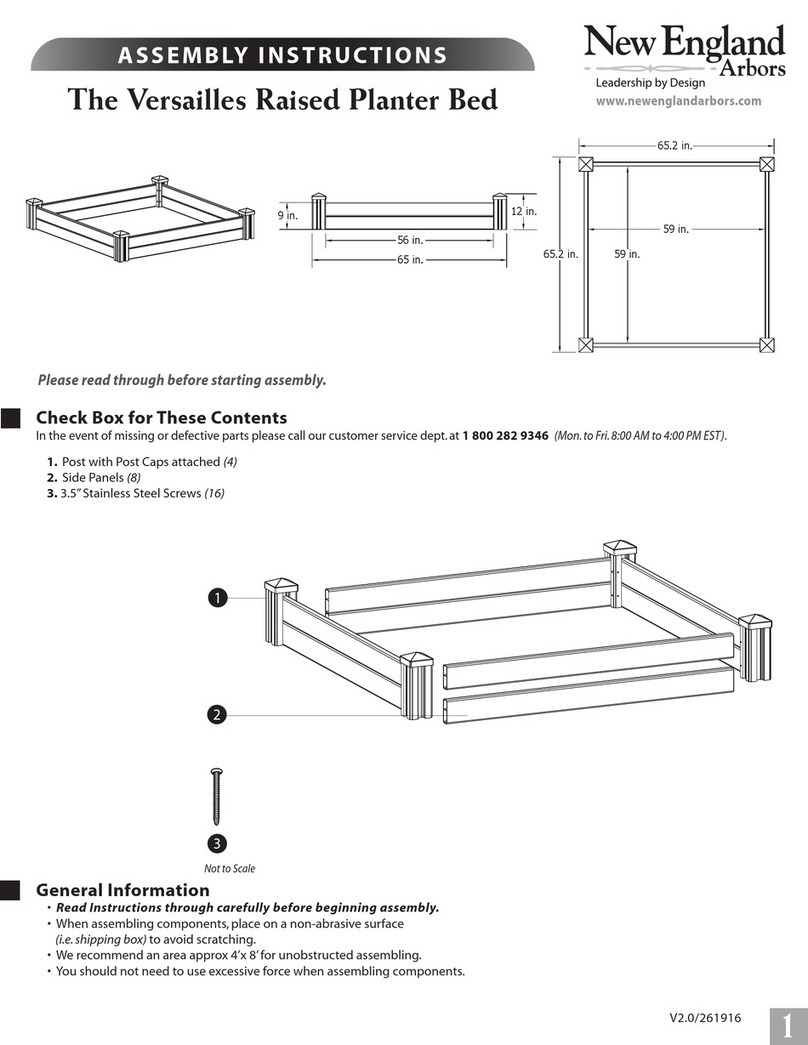

New England Arbors

New England Arbors The Versailles Raised Planter Bed Assembly instructions

Draper

Draper LAR1200 instructions

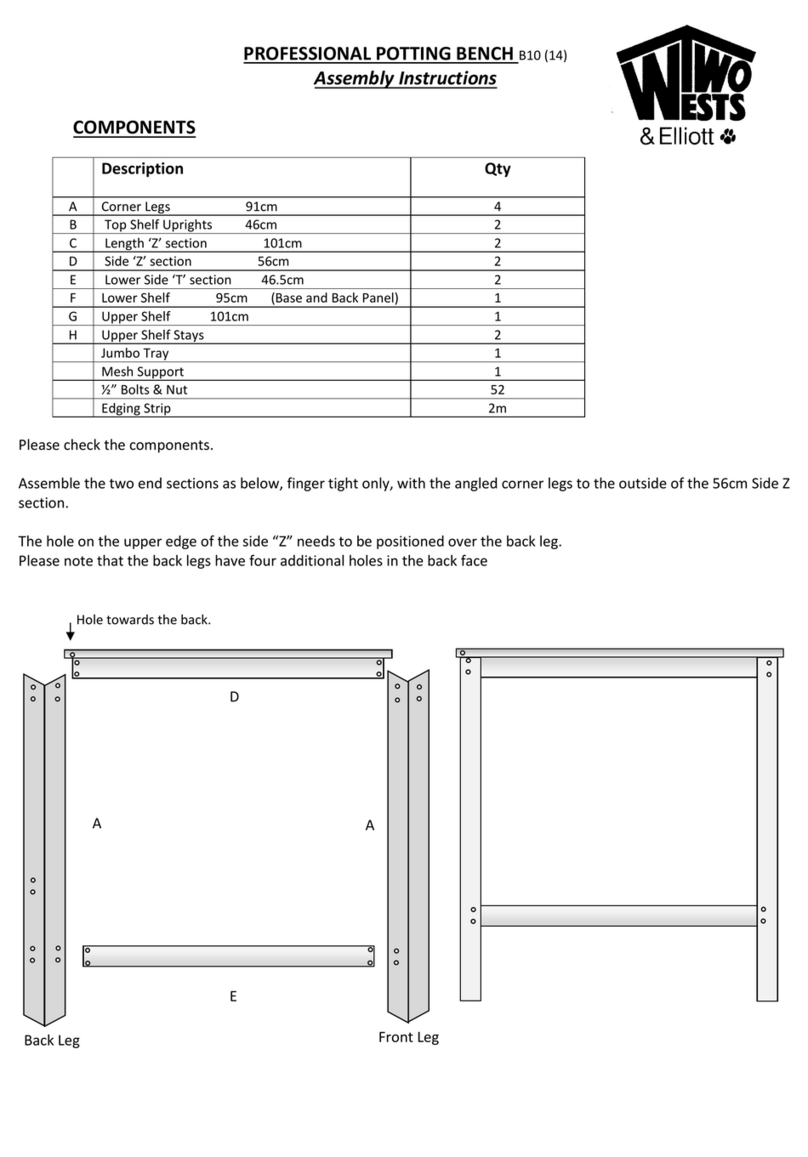

Two Wests & Elliott

Two Wests & Elliott B10 Assembly instructions