10

• Keep all parts of the body away from the cutter blade. Do not remove cut material

or old material to be cut when blades are moving. Make sure the switch is off when

clearing jammed material. A moment of inattention while operating the hedge trimmer

may result in serious personal injury.

• Carry the hedge trimmer by the handle with the cutter blade stopped. When

transporting or storing the hedge trimmer always fit the blade cover. Proper handling

of the hedge trimmer will reduce possible personal injury from the cutter blades.

• Hold the power tool by insulated gripping surfaces only, because the cutter blade

may contact hidden wiring or its own cord. Cutter blades contacting a “live” wire

may make exposed metal parts of the power tool “live” and could give the operator an

electric shock.

• Keep cable away from cutting area. The cable may be hidden in shrubs and can be

accidentally cut by the blade during operation.

• Perform visual inspection on the hedge being trimmed. Ensure that there are no

wire fences or foreign objects that may come into contact with the Pole Hedge Trimmer

during operation.

• If the cord becomes damaged during use, disconnect the cord from the supply

immediately. DO NOT TOUCH THE CORD BEFORE DISCONNECTING THE SUPPLY.

Do not use the Pole Hedge trimmer if the cord is damaged or worn.

• Inspect and maintain the Pole Hedge Trimmer regularly. Have the Pole Hedge

Trimmer repaired by an authorized repairer.

• Keep extension cord away from cutting blades.

• Never allow children or people unfamiliar with these instructions to use the Pole Hedge

Trimmer.

• Avoid using the Pole Hedge Trimmer, while people, especially children or pets are

nearby.

• Use the Pole Hedge Trimmer only in daylight.

• Never operate the Pole Hedge Trimmer with a damaged cutting blade.

• Switch on the Pole Hedge Trimmer only when hands and feet are away from the cutting

blades.

• Use only manufacturer’s recommended replacement parts and accessories.

• Always disconnect the Pole Hedge Trimmer from the mains power outlet and put the

blade cover on when leaving the Pole Hedge Trimmer unattended.

• Disconnect the Pole Hedge Trimmer from the mains power outlet before carrying out

any maintenance or cleaning work.

• When not in use, store the Pole Hedge Trimmer out of the reach of children

• Face the cutting blades away from yourself, other people and and animals while the

power is connected to the Pole Hedge Trimmer (especially during operation).

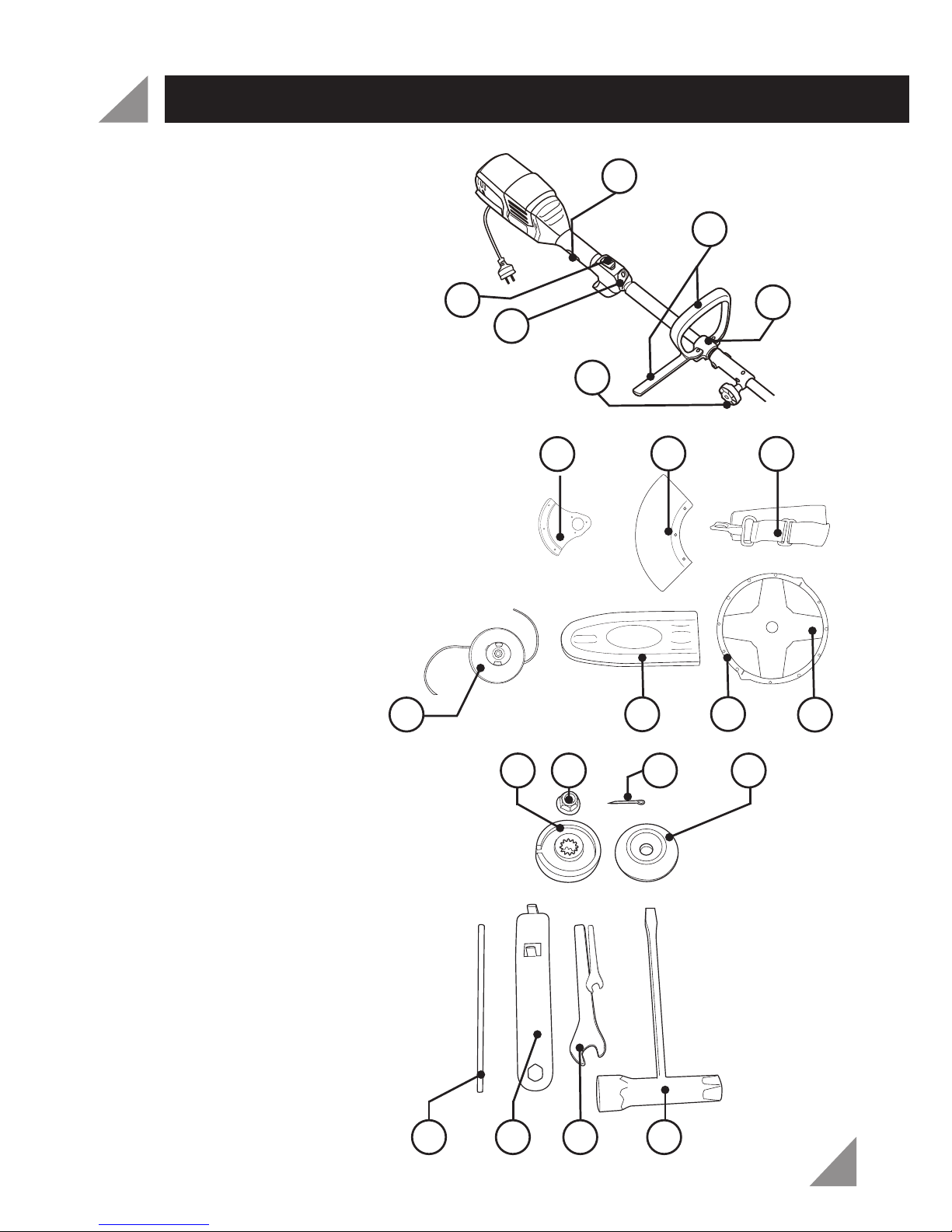

• Use both handles and shoulder strap.

• Keep ventilation openings clear of debris. Keep handles dry, clean and free of oil and

grease.

• Never reach underneath the Pole Hedge Trimmer cutting blades until it has completely

stopped and the power has been disconnected.

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning use of the appliance by a person

responsible for their safety.

HEDGE TRIMMER SAFETY WARNINGS