Floorwash 1400 Instruction manual

MANUALOFUSE ANDMAINTENANCE

1400

2

Foreword 3

Manualcontent, useandmaintenance 3

Storageofmanualofuseandmaintenance 3

Machinedelivery 3

Floorwashtechnical description 3

Serial number 3

Generalsafetyrules 3

Recommendations 4

Warnings 5

Technicaldata 6

Spareparts 7

Packagingspecifications anddimensions 8

Machineunpacking 8

Machine assembly 9

Howtoget started 10

ON/OFF 11

Functioning 12

Transport 14

Aftercleaning 14

Maintenance 16

Troubleshootingtips 17

3

FOREWORD

It isofoutmostimportanceto keepthemachineat its maximum efficiency bycarrying outthe

maintenancedescribedin this manualcarefully. It isimportant to keepthis instruction manual

inasafeplacesothat it canbereferredtowhenever necessary. Forfurtherrequirements,please

contact ourcustomerservice centreoryournearest authorized dealer.

MANUAL CONTENT,USE AND MAINTENANCE

The following manual hasbeendrawnuptoprovidecustomerswith allnecessaryinformationin

ordertousethemachineassafelyandsmoothlyaspossible.

STORAGEOF MANUAL OF USE ANDMAINTENANCE

Themanualof useandmaintenance shouldbe keptin a safeandeasyaccessible place in the

immediate proximityto the machine.Toavoid compromisingits readability, keepthis manual

awayfromsourcesofheat,liquids ordetergents.

MACHINEDELIVERY

TheFloorwashmachineisdelivered inaprotective packaging.Ensurethat the packagingis

fully intact andthat there arenosignsoftemperingwhen the productistakenover. The customer

shouldnotifyourcustomerserviceimmediatelyincaseofdamages.

Floorwash TECHNICALDESCRIPTION

The Floorwash is a mechanical floor scrubber-dryerthat ensures effective cleaning

surfaces including uneven superficies. Thecombined mechanical action of brush,water and

centrifugal forcewill guaranteethebestresultswith minimumeffort.It cleans,rubsandcollects

the filth andit isperfect forconstantandfrequentuse.Thisscrubberdryerisparticularly suited

forthe treatment andcleaning offloorsmadeofterracotta, pottery, setts,clinker,rubber,resin,

marble,linoleum, rawconcrete, flagstone, serizzo,granite,stone,carpetsandrugs.

SERIALNUMBER

Thelabel with the serial numberis located below the machine,in the underlying part of the

external left side.That numbershall be always notified for technical assistance or request of

spareparts.

GENERAL SAFETY RULES

Thisfloorscrubber-dryeriseasy touse;anyway, itisnecessarytoread thefollowing rulescarefully

inordertoavoiddamagestoboththeoperatorandthemachine.

4

Recommendations

• Themachine isnot intended to be usedbypersons(including children)

whosephysical,sensoryandmentalcapacities areimpaired,orwith lack

ofthe necessaryexperienceandknowledge,unlessthey aresupervised

or instructed in its use by personsresponsible fortheir safety.

• Children shall be supervised to ensure that they do not play with the

machine.

• Ifthe powersupplyisdamaged,itshallbereplaced bythe manufacturer

orits authorizedtechnical assistance.

• Thismachine issuitable forindoor use only.

• Do not use the machine on slopes.

• Incase ofemergency,removethe power cable fromthe outlet promptly.

• Unplug the power cable from the outlet before maintenance is

performed.

• Use only brushes provided with the machine or supplied by an

authorised dealer and/or reseller to avoid compromising safety and

warranty.

• The machine shall not be left unattended, but stored in a protected

areato prevent the machine frombeing moved accidentally.

5

Warnings

Alwaysunplug the power cable fromthe outlet when not in use

or beforeadjustmentsand maintenance areperformed.

Do not useorkeepthe machine outside in wet conditions,and

avoid direct exposureto rain.

Do not hold the plug ormachine with wet hands.

Themachine issuitable forusein dry conditions at a

temperature range of +5°Cto +35°C(+41°Fto +95°F).

Thepower outlet socketof the machine shallbe connected to

an approved earth.

Do not insert objects through openings.Do not usewhen

openings areclogged.

Protect the machine fromsunlight and UVradiation.

Do not suckgases,liquids or potentially explosiveand

combustible dusts.Thesesubstances maycorrode materials

usedin the construction of the machine.

Follow the basic safety rules for usein hazardousareas,such as

service station or gasdistributors.

Do not usethe machine in potentially explosiveatmospheres.

Do not place containersholding liquidson the machine.

Do not pull the power cable to carrythe machine.

Keepthe electrical cable away fromsourcesofheat.

Forusein workenvironments,do not hit shelves orscaffoldings

where there isa riskof objects falling.Theusershall be equipped

with adequate safetyequipment (gloves,footwear,helmet,

goggles,etc.).

6

Request original spareparts only to dealers and/orauthorized

resellersin case ofpartsreplacement ormaintenance.

Checkthe machine in anauthorizedservice centre at leastonce

ayear.

Organizethe disposalof waste materialscomplying scrupulously

with current regulations.

TECHNICAL DATA Floorwash 1400

Machineheight 140mm 140mm

Machinewidth 285mm 385mm

Machinelength 330mm 330mm

Frontbrush Ø86-700g/m

Rearbrush Ø54-1145g/m

Workingwidth 250mm 350mm

Workcapacity 280mq/h 500mq/h

Induction motorpower 400W -110V60Hz

Totalstoragecapacity 4l

Recoverytankcapacity 1l 1,8l

Totalemptyweight 10kg 11kg

5,5 in

11 in

13 in

14 in

5,382 sq ft/hr

400W - 110V 60Hz

1,05 gal

0,48 gal

24 lb

ø 86 - 700 rpm/m

ø 54 - 1145 rpm/m

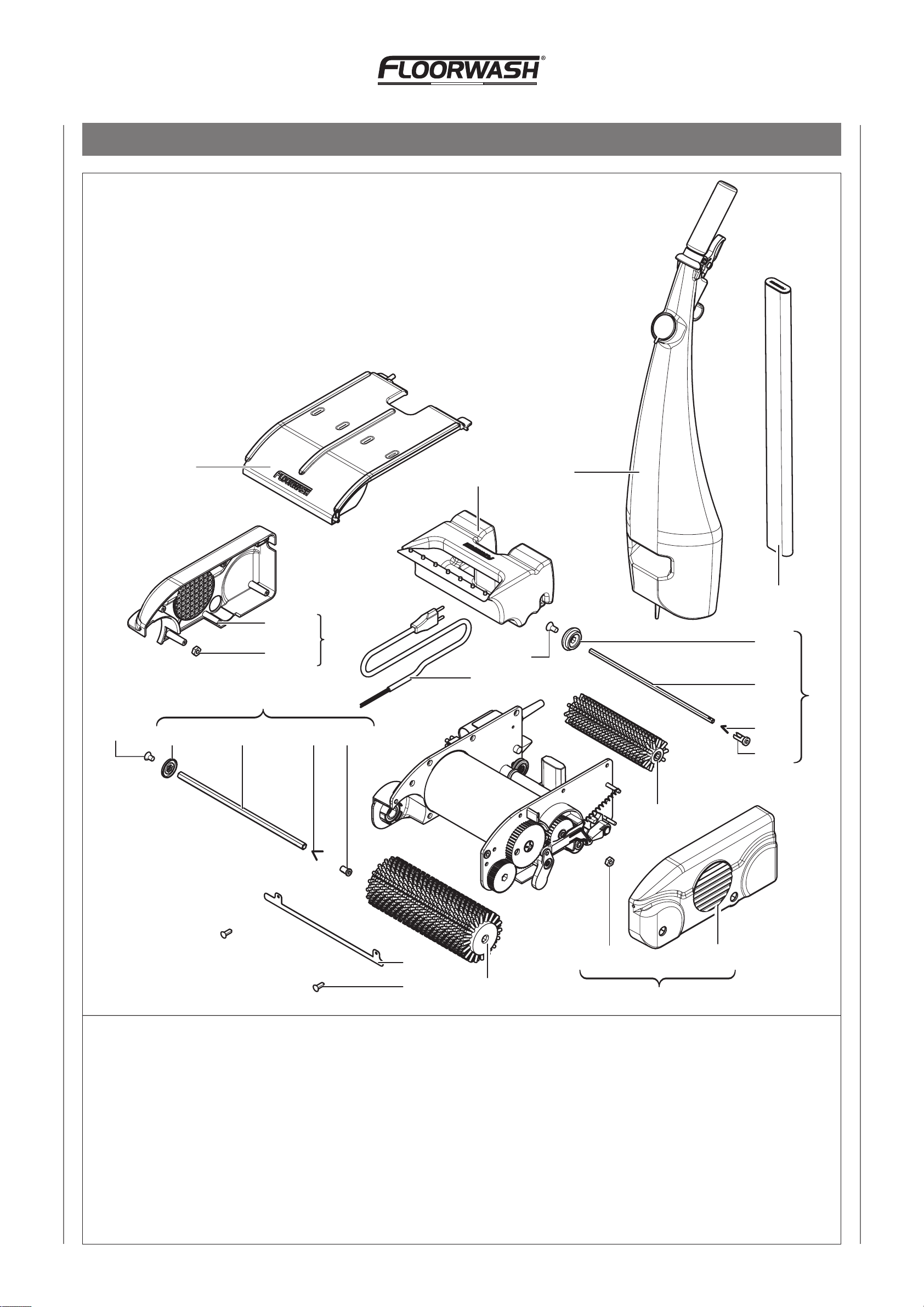

7

41

15

50

38 51

18C 18D

VIT17 18A 18B

DAD2

37A

29

VIT19

39

16

DAD2 1A

1

18

VIT18

20A

20C

20D

20B 20

37

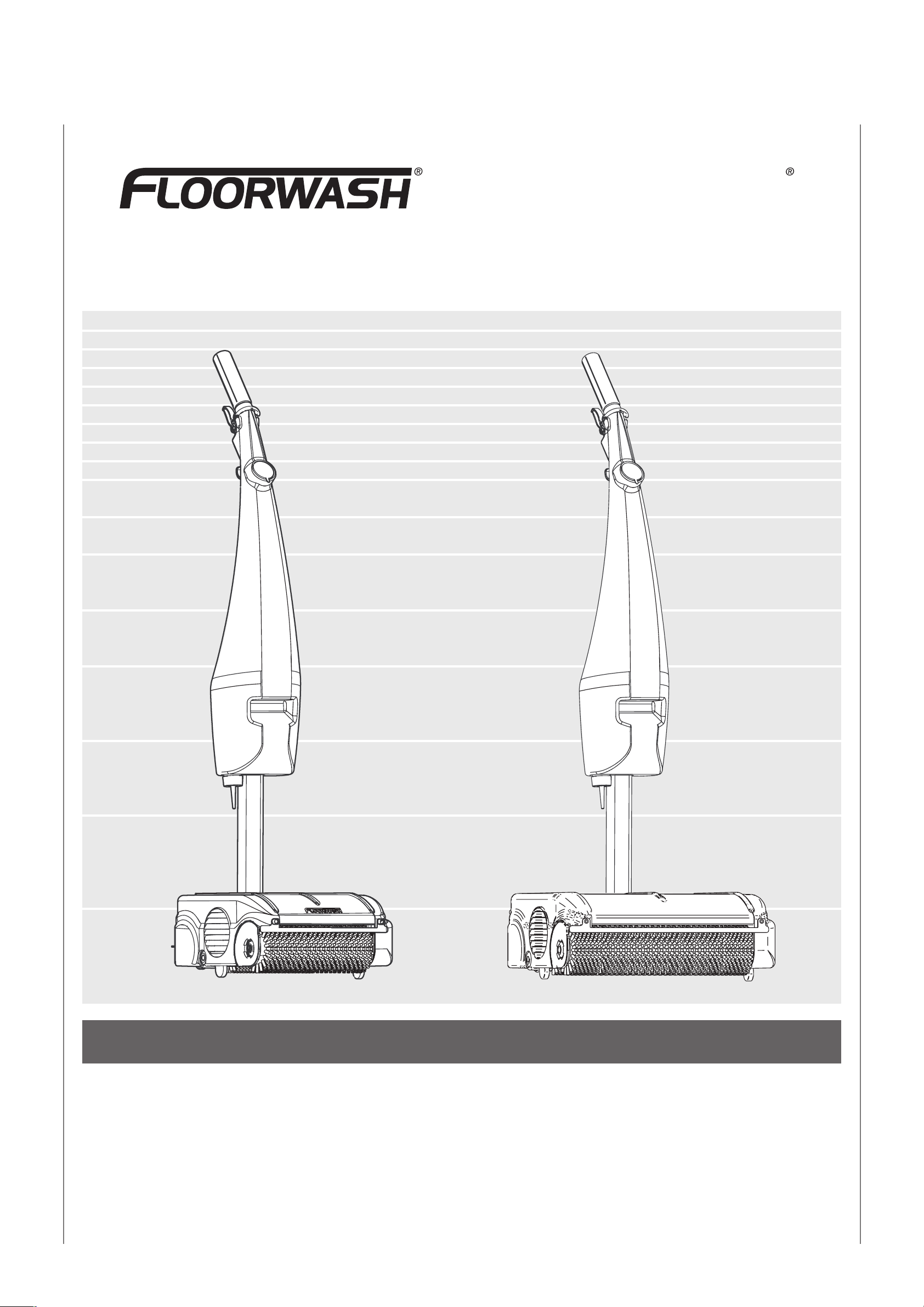

SPARE PARTS

1 COMPLETE NYLON EXTERNAL LEFT SIDE

1A NYLON EXTERNAL LEFT SIDE

DAD2 LOW SQUARE NUT 4MA

CA MACHINE BODY

15 UNIVERSALREAR BRUSH

16 UNIVERSAL FRONT BRUSH

18 COMPLETE HEXAGONSPRING PLUNGER CH10

18A HEXAGON PLUNGER INSERT BUTTON CH10

18B HEXAGON PLUNGER CH10

18C SPRING LATCHFORHEXAGONPLUNGER CH10

18D HEXAGON PLUNGER EJECT BUTTON CH10

20 COMPLETE HEXAGONSPRING PLUNGER CH7

20A HEXAGON PLUNGER INSERT BUTTONCH7

20B HEXAGON PLUNGER CH7

20C SPRING LATCHFORHEXAGON PLUNGER CH7

20D HEXAGON PLUNGER EJECT BUTTON CH7

37 COMPLETE NYLON EXTERNALRIGHTSIDE

37A NYLON EXTERNAL RIGHTSIDE

38 COMPLETE COVER

41 COMPLETE HANDLE

50 COMPLETE TANK

51 WASTE WATERTANK

8

PACKAGINGSPECIFICATIONS ANDDIMENSIONS

TheFloorwashmachineisdelivered inaprotective

packaging.

Ensurethatthe packaging isfully intact andthatthereare

nosignsoftemperingwhentheproductistakenover. In

caseofdamage,the customershallnotify ourcustomer

serviceimmediately.

MACHINE UNPACKING

Follow the procedurebelow:

1 Place thepackagingonthefloor/worktable softlybylaying it downontheright part.

2 Opentheexternalcardboardbyusingapairofscissors,whennecessary.(Donotuseanutility

knife).

3 Remove themachinebody, tankandextensibletube,andplacethemonthefloorsoftly.

4 Keep the cardboard boxand its components away fromsourcesof heat, in a dry and easily

accessibleplace.

Donotbreakor throwthepackaginganditscomponentsaway sothat itcanbeused

againforfuturetransportation.

For your safety, wearprotectivegloveswhen carryingouttheseoperations,inorderto

avoidinjuriesincaseofaccidental contact withsharp edgesof thecardboardbox,direct

contact with detergentresiduesormetaledges.

35 80

31

9

CLACK!

h2

h3

h1

CLACK!

MACHINEASSEMBLY

Follow the procedure below:

The Floorwashmachinehasafastassemblysystemsinceno tools arerequired.

Donotuse anytoolto avoidinjuriesordamagetothemachine.

1Place the bodyofthe machineonastablesurface

without slopes.

2Insert thehandleintheaxleofthemachinebody.

3Insertthe tankinthehandleatthe

desired height(3differentheights).

4Insertthesmall transparent watertubeintherelief

valvesituatedonthelowerpartofthetank.

5Hooktheelectrical cordintoitsappropriate

seatsituatedatthetopendofthetank.

10

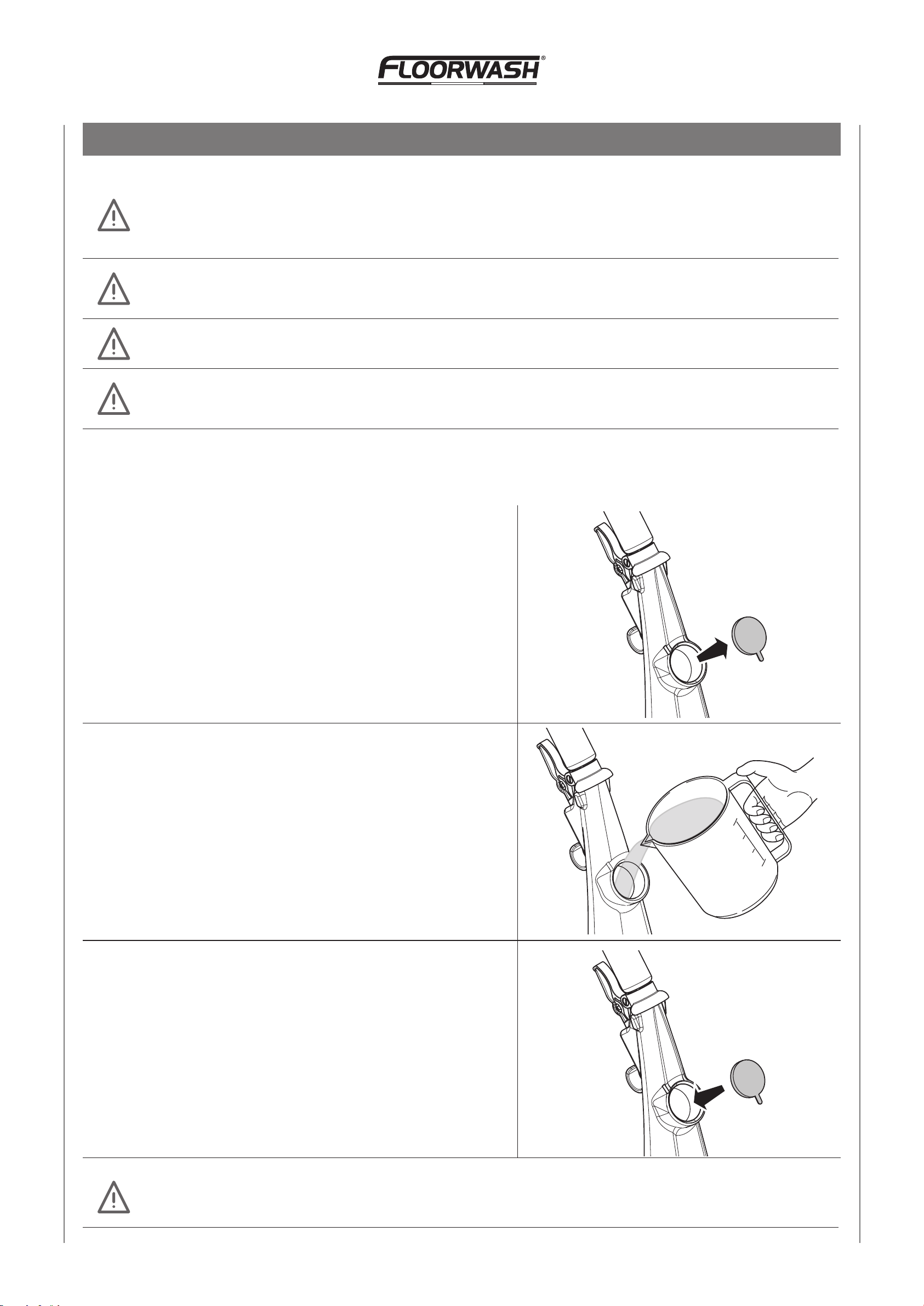

HOW TOGET STARTED

TheFloorwashmachineisamechanicalcollectiondevicethat canachieve

excellent resultsevenwiththeuseof waterwithout detergent.

An excellentresult is achievedwith theuseof specificdetergents.

Themachinecomes with universal brushes(gr0.12).Anyway,itispossibletorequest

specificbrushes toourcustomerserviceaccordingtothetypeofsurfacetobetreated.

Usefoam-controlled detergents toavoid excessivefoaming. Do notusepureacids.

Wearprotectiveglovesbeforehandlingdetergents,alkaline oracidsolutions toavoid

hand injuries.

1Removethe tankcap.

2Pourtheliquid,cleanwaterand/ordetergentin

theconcentrationspecifiedonthelabel.

3Replacethe tankcap.

Fill thetankwith cleanwaterand/ordetergent foramaximum of2lt.

Use wateratatemperaturenotexceeding 40° below10°C.( 104°F– 50°F).

No chemicals in tank pre-treat oor with

sprayer bottle before cleaning with machine

11

1

2

3

ON/OFF

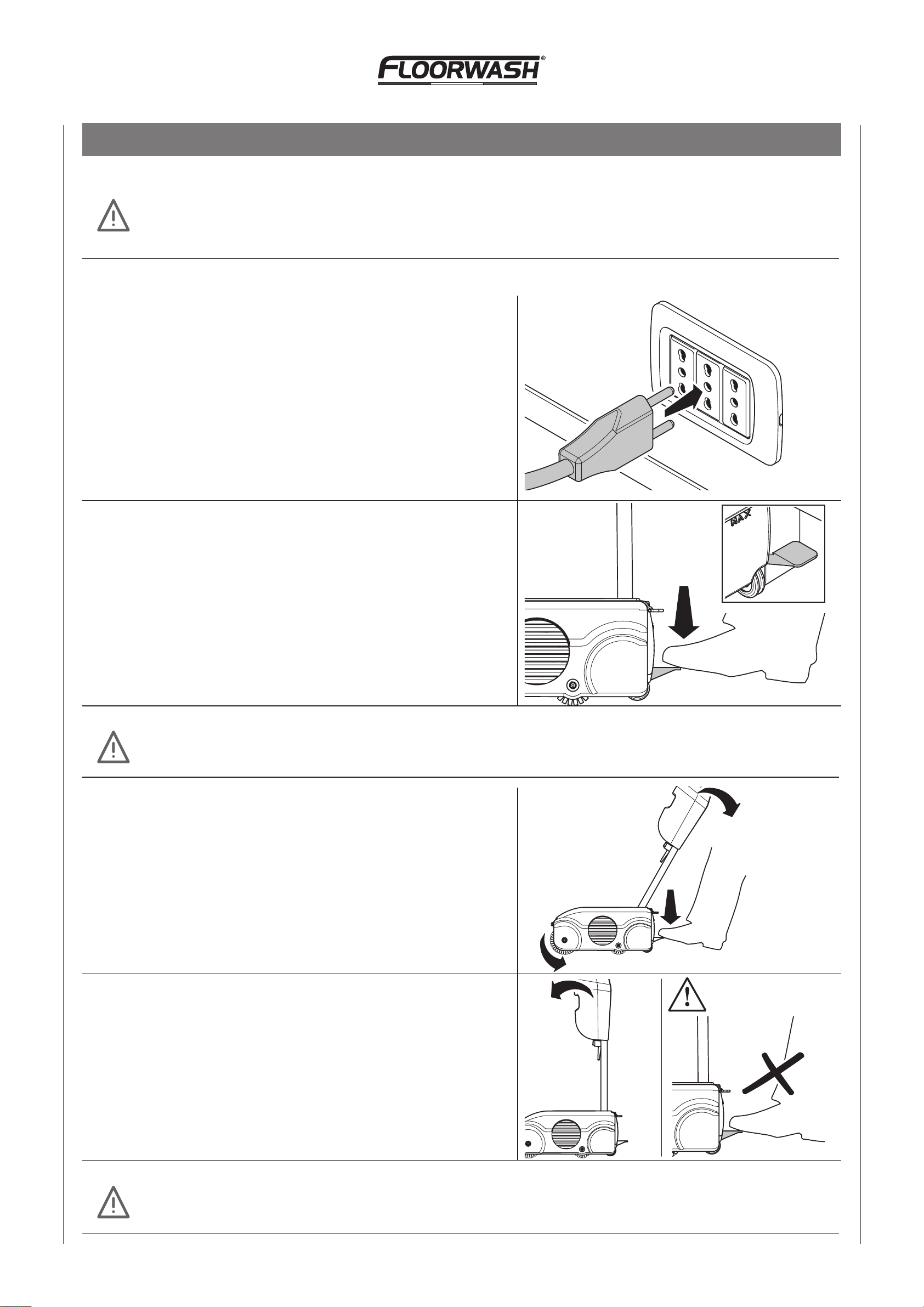

Beforethe start-upof the device,checkthatthe electrical cordand the machineare

not malfunctioninginanyway.Ifthisisnot thecase,donotusethe deviceand

contactour servicecentre assoon aspossible.

1Insert theplugina230-voltwalloutlet.

2Pressthe kick-startpedalsituated atthe bottom-

rightsideofthemachine.

Itisimportant topressthekick-start pedalcompletelybefore loweringthetanktowards

you,so astoavoidanydamagetothecentralaxleof themachinebody.

3Whilepressing thekick-startpedal, lowerthetank

towardsyouslowly.Atthispoint,themachine

will switchonautomaticallyandbrusheswill start

rotating.

4Themachinewill switchoffautomaticallywhen

returningthetanktoavertical position(rest

position).

Donotpressthekick-start pedalwhenreturningthetanktotheoriginal position.

120

12

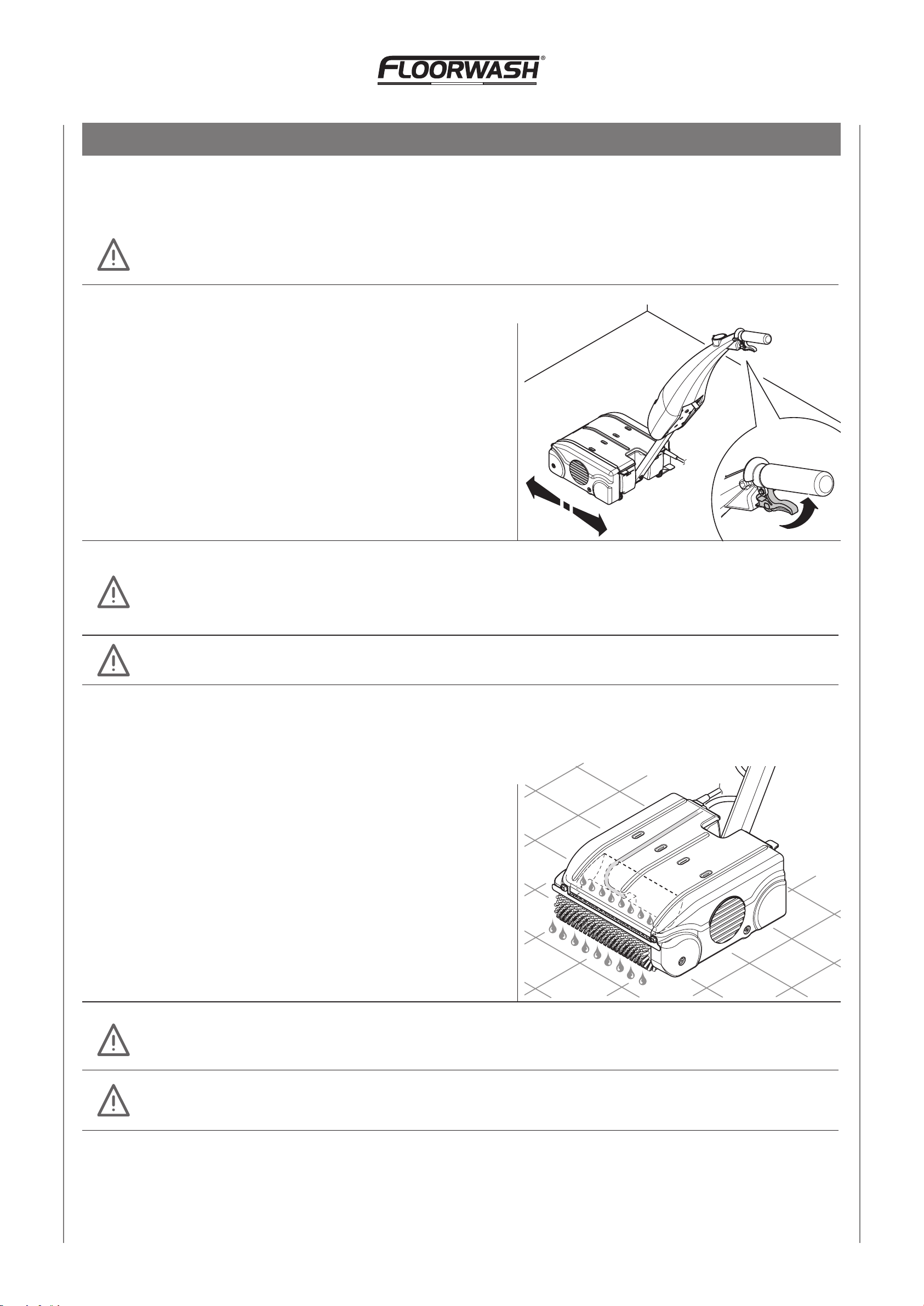

FUNCTIONING

Checkthat all stepsdescribedabovehavebeencompletedcorrectly beforeusingthe machine.

Beforestarting thewashingprocedurewith themachine,removeanysolidresidualsuchas

dustlumps,stones,glass,paperetc.fromthesurfacewhichhastobetreated.

1Afterthe enginehasturnedon,movethe

machinebackandforthwith linear movements.

Theleverplacedbeneaththehandlewill allow

youtodispensetheliquid previouslypouredin

thetank.

Theengineofthismachinehasasafetydevicethat will turnthemachineoffintheevent

ofanoverload.Inthiscase,restthemachinefor15minutes,andthencontinuefrom

where you leftoff. Iftheengine doesnot functionproperly,contact ourservicecentre.

Donot makecircular movementswiththemachinesothat itcancollectthedispensed liquid.

2Afterpulling thelever,theliquidwill distribute

uniformlyonthefrontcylinder brush.

Inthe ongoingstage justpulltheleverhalfway;intheretuningstage,releasethelever,thus

allowingtheliquid recovery.

Inthereturningstage,themachineshallpassthroughthesamehallway of the ongoing

stage, thus allowing acompleterecoveryofthedispensed liquid.

13

3Therecoveryofthedispensedliquid occurs

automatically bymeansofmechanicalcollection.

Theliquidwill flowintothewastesituatedinthe

lowerpartofthemachine.

Itisimportanttoemptythe waste when the seep liquidreachesthe maximummarkprinted

onthe backof the waste, thus avoidinganaccidental releaseof the same.

14

TRANSPORT

Totransportthemachinesafely,follow thesesteps:

Checkthatthetankisplaced inavertical positionbeforemovingthemachine.Theelectrical

cordshallbeunplugged fromtheoutlet.

1The machinehastwo rubberwheelssituated

inthelowerpart.Bypullingthetanktowards

you,without pressingthekick-start pedal,

thefrontpartofthemachinewill belifted up,

guaranteeinganeasytransportation.

Iftheliquid inthewastehasreachedthehighestlevel, itisnecessaryto emptyitbeforecarrying

the machine.

2It ispossibletolift theentiremachineup,inorder

tomoveit toanupperfloorofthehouse,by

usingthedesignatedslit situatedonthelower

partofthetank.

Donotlift themachineupbyusingtheupperknobofthetank.

Fortransportationwithvehicles,ensurethe machinesothatitcannotinanywaymove.

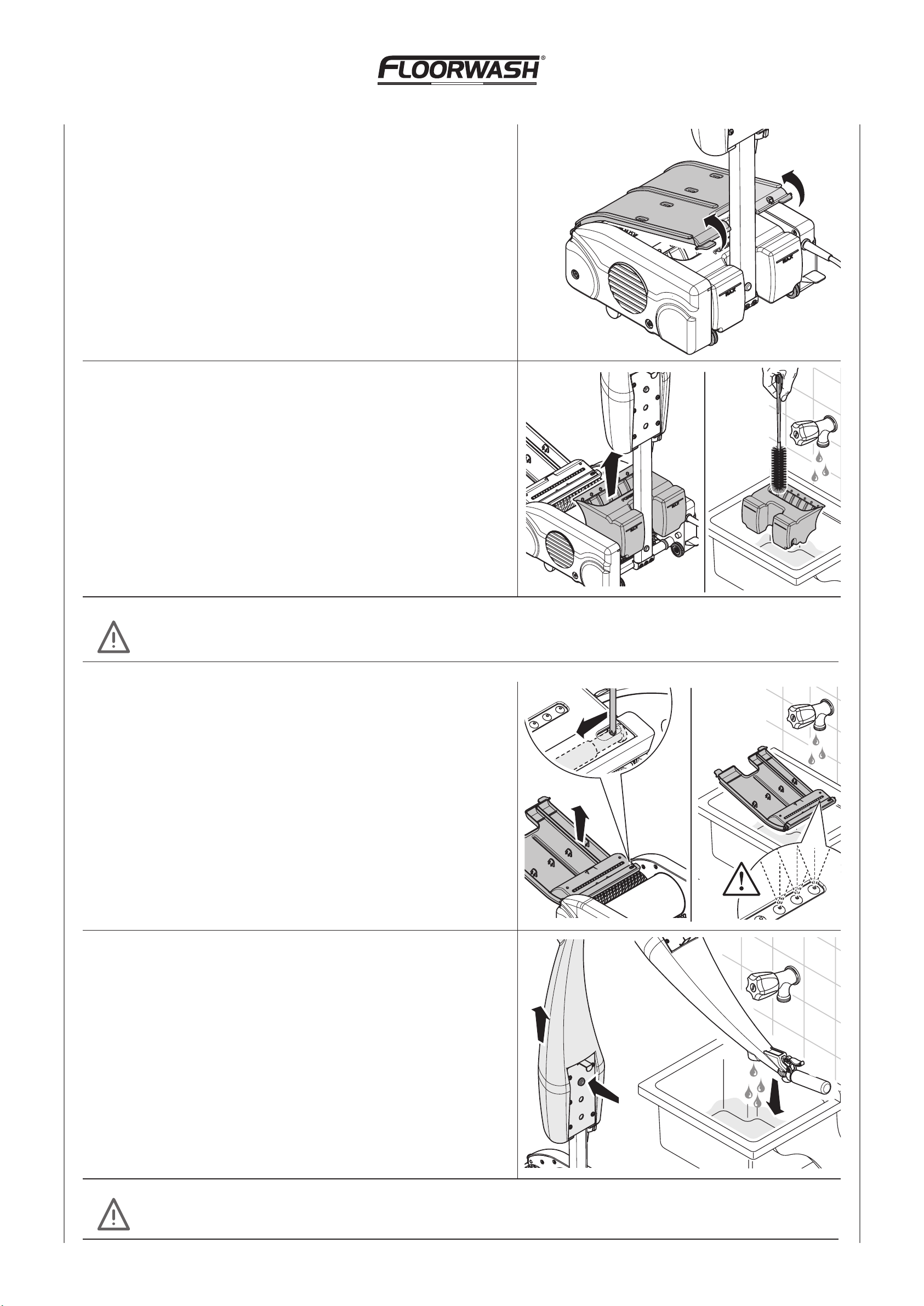

AFTERCLEANING

Aftercleaning,follow thesesteps:

Before carrying out anyoperation, checkthatthe electrical cord is unplugged fromtheoutlet.

Wearprotective gloves whencarryingout theseoperations,inordertoavoiddirect contact

withdetergent residuesor metaledges

OFF

CLACK!

15

1Opentheuppercoverofthe machinebypushing

thetwo lateral hooksup.

2Removeandemptythedirty waterwaste.Washit

with runningwater and,ifnecessary,useaspatula

toremoveanyresidualfromthebottom.

Thestainless-steel sheetwelded to thewasteisnotremovable.Donot tryto removeit.

3Unhookthe uppercoverandwashit

gently with runningwater.Check that

thedriptrayandthewatertube

arenotclogged.

4Unhookanddraintheclean watertank2

fromanyresidualofwater and/ordetergent.

Donot placethefootonthemachine bodywhilecarryingout thisoperation.

1

2

3

1

2

16

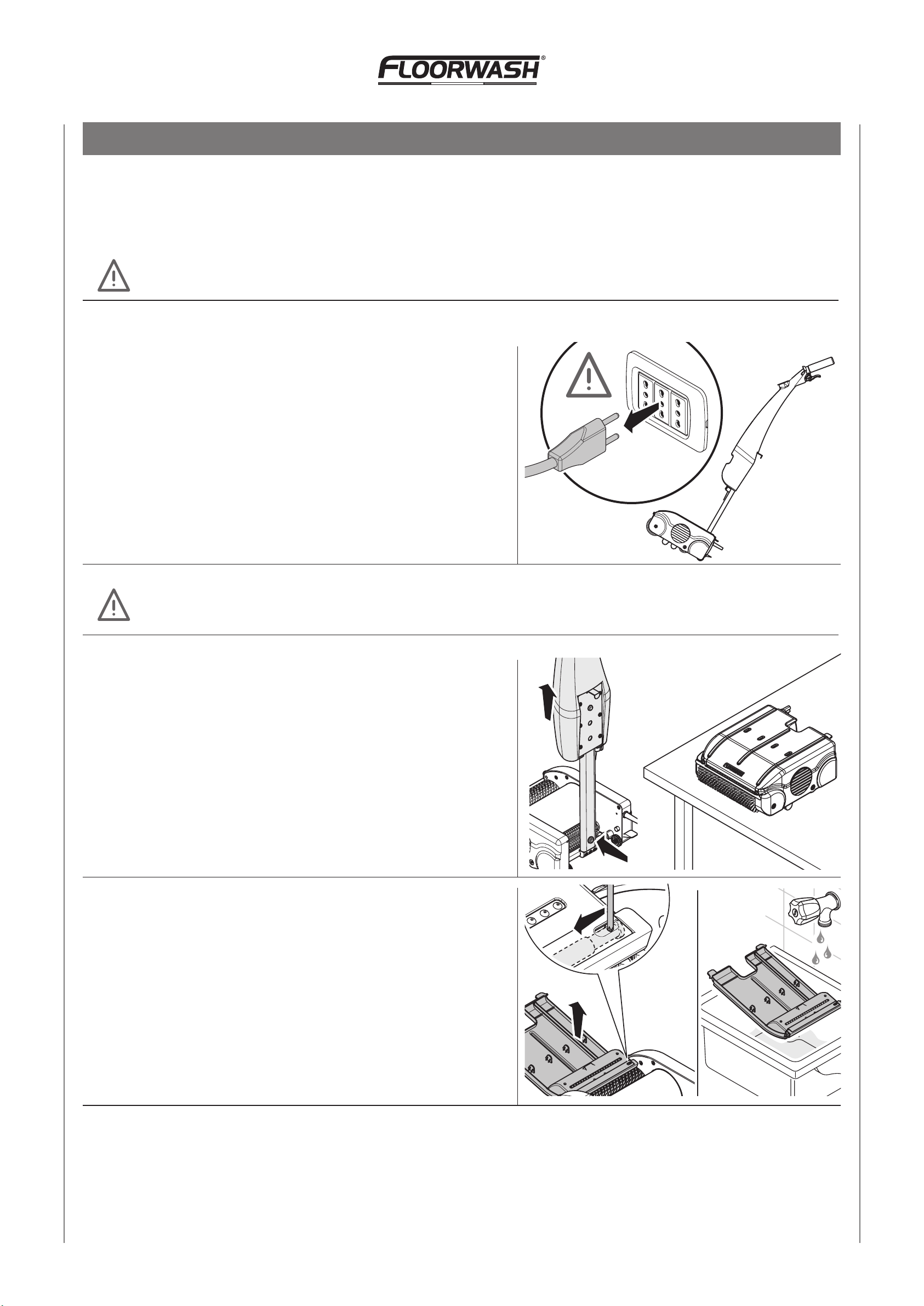

MAINTENANCE

Aregularmaintenancekeepsthemachinesafeandalwaysreadytouse.Carryoutthe following

operations:

Beforecarryingout anyoperation, checkthatthe electrical cordis unpluggedfromtheoutlet.

1Keepthemachineinasafeplacetoensureits

maintenance.

Wear protectivegloveswhencarryingout theseoperations,inorderto avoid direct contact

withmetal edgesorsharpplasticparts.

2Unhookthe handlefromthemachinebodyand

placeit onaworktable.

3Unhooktheuppercoverofthe machineand

washit thoroughlywith running water.

1

2

1

2

17

4Remove thebrushesbypressing thebutton

placedontheleft sideofthemachine.

Use adamp cloth toclean theinternal sides

ofthemachinewhile checking that

seals arenotclogged.

Donot cleanthemachine withsteamcleaners.

TROUBLESHOOTINGTIPS

Thefollowing areexamplesofsomeproblemsthat mayarise.

Ifaftercompleting theverifications listedbelow,youdonotachievepositiveoutcomes,please

contact ourservice supportimmediately.

Themachine doesnot work

Checkthat the power cordplug is inserted correctly. (230V)Checkthat the power cord is not

damagedorhasgotstripes.

Theengine turnsonbut brushesdonot rotate

Unplugthe powercable andcheckthat the central conveyorbelt isable to rotatebytrying to

moveit byhand.

Thefreshwater tank loses

Checkthatthewatervalve ofthecable isfully screwedtothe tank.

Checkthatthedrivecableanchoredtotheleveroftheliquid distributionisnottootaut.

Checkthat the tankisfully intact andthat therearenoholesand/orcracks.

Themachinedoesnot distribute well the washwater

Makesurethat the drip tray placed underthe cover isnot clogged. Checkthat the transparent

tubeisnotcloggedorcrimped.

Themachinedoesnot collect water

Checkthat the wasteisproperly insertedandthat the coveriscompletely closedandattached

tothe body.Checkthat the washwater dropsonaregularbasiswhenyoupull the lever.Check

that the brushesarenottoo worn.

2

1

1

3

3

2

120

18

NOTES

NamcoManufacturing

1651Blalock Rd,Houston, TX77080,U.S.A.

Tel. 1-800-634-5816Fax713-932-9254

bryan@namcomfg.com www.namcomfg.com

1729 Brittmoore Rd, Houston, TX 77043

Table of contents

Other Floorwash Scrubber manuals

Popular Scrubber manuals by other brands

Amperes Electronics

Amperes Electronics iPX5455 instruction manual

HAL Extraction

HAL Extraction 85U Safety and operating manual

Krüger Technology

Krüger Technology KF36E manual

Global

Global 293052 instruction manual

Advance acoustic

Advance acoustic Hydro-Retriever 4500 462000 Service manual

Vacula

Vacula Drainman Classic Operation manual