Safety tips

•Do not allow the waterjet stream to touch any part of

your body—it will cause serious injury.

•Do not point the waterjet at anyone.

•During equipment maintenance, take the system out

of service. The controls must be properly locked and

marked with a warning sign.

•All personnel required to perform any system operat-

ing or service function must pay particular attention

to all warning signs and notices posted in the plant

and on the equipment.

•All protective guards, shields, and covers must be in

place on the equipment at all times.

•First aid facilities must be provided in convenient lo-

cations throughout the plant. These locations must

be known by all personnel.

•Always keep the work area around the equipment

clean and free of debris. Oil spillage results in slip-

pery floors and must be cleaned up immediately.

•Any unfavorable conditions that may result in injuries

must be reported to the plant supervisor without

delay.

•As a general practice, it is recommended that safety

shoes, glasses, and hearing protection be worn by all

personnel working around the equipment. Do not

wear rings, watches, or necklaces when working

around any equipment that has moving parts.

Mechanical system

•Don’t start the system unless you know how to stop

it.

•Never maintain, service, or clean around the equip-

ment while it is operating.

•Use only the correct tools—wrong tools can cause in-

jury or costly damage to equipment.

•Never climb on or around the equipment on make-

shift devices. Use only approved catwalks, ladders, or

platforms.

•Do not exceed specified pressure setting limits for

pneumatic or hydraulic components. Exceeding

these limits may result in serious injury to personnel

or damage to the equipment.

•Shield and bundle equipment hoses and cables so

they do not obstruct the operator’s freedom of

movement.

•Be alert at all times when working around the

equipment.

•Clear all tools, parts, and rags from moving parts

after servicing the equipment.

Electrical system

•Only properly trained personnel shall perform elec-

trical and/or electronic troubleshooting and servicing

of electrical devices.

•Always assume that power is ON in all electrical

systems. Always check and lock out the main power

switches before servicing the equipment. Post a sign,

"Maintenance in Progress —Do Not Energize."

•Be aware that live electrical circuits are present in the

control console whenever the master disconnect is

on, regardless of whether the E-Stop is engaged.

•Disconnect circuit breakers and lock them in the

OFF position before servicing the electrical system.

If this isn’t possible, have someone stand by to pre-

vent someone from powering up the system.

•Take extra precautions when servicing the power sys-

tem in a damp environment.

•Never alter or bypass protective interlocks or devices

unless specifically instructed to do so, and only if all

precautions are followed.

•You must give capacitors sufficient time for discharge.

If this is not possible, discharging should be done

manually and with care.

•Do not use jumper wires across fuses, fuse holders,

or breakers.

•Make sure all tools are properly insulated for the job.

•Use only proper test apparatus; check regularly to

make sure it is working correctly.

•Use caution when connecting a test probe to test

points.

•All replacement wires must conform to the manufac-

turer’s specifications, including color coding, wire

numbers, and size.

•Close the control panel doors or junction box covers

after servicing.

8 | M-376 © Flow International Corporation

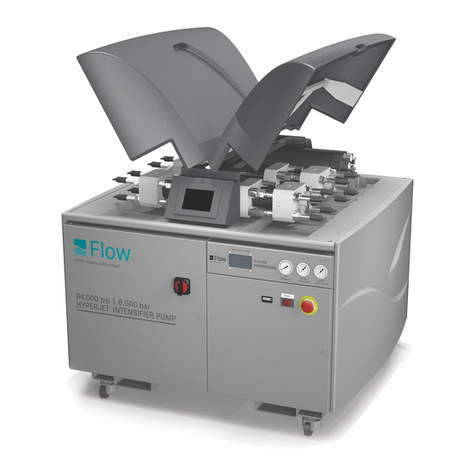

94K HYPERPRESSURE INTENSIFIER