Specifications

Contact FLOW Technical Service for further information.

Also see the system drawings in Chapter 5.

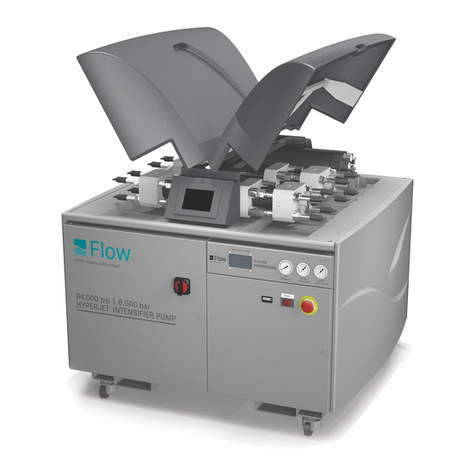

Dimensions

(with covers closed) 60 L x 40 W x 41 in. H

................................1524 L x 1016 W x 1042 mm H

(with covers open) 60 L x 40 W x 52 in. H

................................1524 L x 1016 W x 1321 mm H

Nominal crankcase RPM 50Hz 60Hz

30 hp....................................................716 709

50 hp..................................................1154 1114

Operating pressure...................55,000 psi (3790 bar)

Max. generated pressure ..........60,000 psi (4140 bar)

Filtration provided...............0.5 micron and 1 micron

Min. required inlet water flow rate

30 hp ...............................................2 gpm @ 57 psi

50 hp ...............................................3 gpm @ 65 psi

Low inlet water pressure switch threshold

........................................................................£15 psi

To ensure proper inlet water pressure, a boost pump may

be required.

Req. inlet water temperature range

.........................................55°F–70°F (12.7°C–21°C)

If plant inlet water temperature is outside of this range,

contact Flow Technical Service

Air.........................................90–120 psi (6.2-8.3 bar)

....................................dry and filtered to 10 microns

Drain............212°F (100°C) water at 0.9 gpm (30 hp)

.....................212°F (100°C) water at 1.5 gpm (50 hp)

Max. UHP orifice size

30 hp .......................................................-12 orifice

50 hp .......................................................-16 orifice

Voltage

Nominal

system

voltage **

Horsepower

(hp)

Frequency

(Hz)

Phase

200 * 50 *

200 * 60 *

208 * 60 *

230 * 50 *

240 30/50 60 3

380 * 60 *

400 30/50 50 3

480 30/50 60 3

500 * 60 *

* Not supported.

** Utilization voltage is often referenced, which will be

3-5% lower than the nominal system voltage. Where

referenced, the utilization voltage is equivalent to the

nameplate voltage of a product.

Crankcase oil

Use of Shell Morlina 100 Hydraulic Oil (ISO 100) is

recommended, but other manufacturer's equivalents

can be used.

When operating the pump in an environment with an

ambient temperature greater than 86°F (30°C), a

heavier oil is recommended to be used. Contact Flow

Technical Services for additional information.

Reservoir

capacity

2.0 qt (1.9 liter)

Maintain oil level between the high and low

level marks on the dipstick.

6 | M-416 ©FlowInternationalCorporation

HYPLEX PRIME PUMP

Maintenance & Service Manual