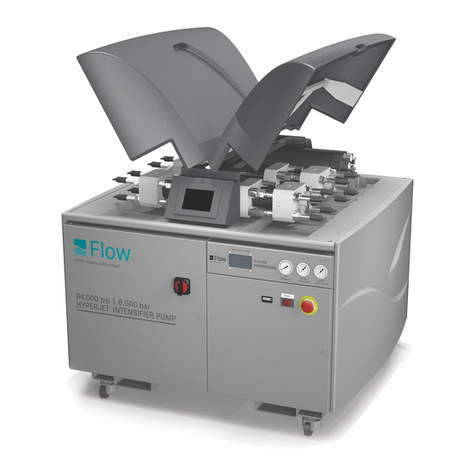

Troubleshooting

Intensifier weep hole identification

Water leaking from weep holes can provide clues to

the condition of components, depending on the tem-

perature and force of the water.

Included with this manual is an intensifier troubleshoot-

ing illustration that identifies the weep holes described

below.

Check valve outlet body

Leakage can be caused by the following:

•Loose high-pressure connection

•Cracked or scored check valve outlet body

•Scored high-pressure tubing

Repair any problems immediately.

Main check valve body

Leakage can be caused by a loose connection and/or a

cracked or scored main body, insert, or outlet body.

Repair any problems immediately.

End cap

High-pressure water seal seepage is the most common

cause for end cap weep hole leakage. It can be caused

by a loose end cap, failure of the high-pressure seal be-

tween the cylinder and check valve main body, failure

of check valve body o-rings, or a cracked or scored

high-pressure water cylinder or check valve main body.

Cold water leaking from this weep hole can be caused

by a damaged o-ring on the check valve body or a

damaged high-pressure seal, whether or not the inten-

sifier is running.

Check leakage quantity. If seepage is very gradually in-

creasing, has not suddenly appeared, is no more than

lukewarm, and is less than two teaspoons

(0.8 oz/23 ml) per stroke, it is safe to continue to oper-

ate the pump. See Intensifier Service Notes.

End bell

The weep hole is drilled into the void separating the

hydraulic oil cylinder and the high-pressure water cylin-

der. Hydraulic oil leakage can be caused by:

•Failure of the end bell hydraulic oil seal and/or

•Cracked or scored end bell or plunger

Leakage is usually due to end bell oil seal damage.

Normal oil seal leakage can be up to one drip per hour.

Water leakage from the end bell weep hole is usually

caused by failure of the high-pressure water seal lo-

cated in the end of the cylinder, but can also result

from a cracked or scored high-pressure water cylinder

or plunger.

Check leakage quantity. If seepage very gradually

increases, has not suddenly appeared, is no more than

lukewarm, and is less than two teaspoons

(0.8 oz/23 ml) per stroke, it is safe to continue to

operate the pump. See Intensifier Service Notes.

© Flow International Corporation M-310 | 7

ESL Intensifier