FlowCon FAC6HP Owner's manual

ADDITION TO INSTALLATION AND OPERATION INSTRUCTION

1F95610 05/2013

FlowCon International assumes no responsibility for mistakes, if any, in any printed material.

COMMISSIONING METER

Denmark Dubai USA Brasil Singapore

FlowCon FAC6HP with optional software

- 1 -

FlowCon FAC6HP with optional software

Please see operation instruction for FlowCon

FAC6HP (1F95600) to learn how the commission-

ing meter is connected to a valve and how to mea-

sure relevant values.

Installing the software.

The software can be installed on Windows XP/

Vista/7 operating systems.

Install the software thus:

1. Install the drivers for the FlowCon FAC6HP:

1.a. Insert the CD in a CD drive of a computer

(not supplied by FlowCon), and if prompted

to, choose not to install the program.

1.b. Openthefolder“cp210x”(tondthefolder

choose to “explore” the CD) and start the

program inside this folder.

1.c. Please follow the steps on the screen to

complete the installation and launch the

program.

1.d. Click “Install” on the pop up window “Silicon

Laboratories CP210x USB to UARTBridge

Driver Installer” when prompted.

2. Install the software for the FlowCon FAC6HP:

2.a. Go to the root folder of the CD and start the

program “setup.exe”. If prompted, choose

to trust / install it (PcomPRO).

2.b. At the end of the installation (when the pro-

gram PcomPRO is rst started), you will

be asked to connect a FAC6HP to the

computer. Please turn on the FAC6HP (by

pressing any button), then connect the

computer and FAC6HP with the USB cable.

The USB port on the FAC6HP is located

inside the battery box at the back of the

device inside the rubber cover.

3. Import a valve list:

3.a. When a new FAC6HP is connected to the

computer, the program will prompt a need

tocreateareferenceleforthatparticular

FAC6HP (the program will idetify each

FAC6HP from its serial number).

Please

accept the creation of the reference

leand

await the process (this usually takes 4-5

minutes).

It is not necessary to have a FAC6HP connected

to the computer all the time working with the soft-

ware. However the list of available valves will be

imported from the FAC6HP and thus it is important

to connect it initially.

The program will wish to import the valve list from

each commissioning meter connected and by de-

fault only use valves for projects intended for a

specic commissioning meter included in the list

from that particular device.

Creating and editing projects.

The quick start offers either import of the current

project on any connected FAC6HP, creation of a

new project or opening a recent project located

in the program’s default folder. When creating

or editing any project, the program window is by

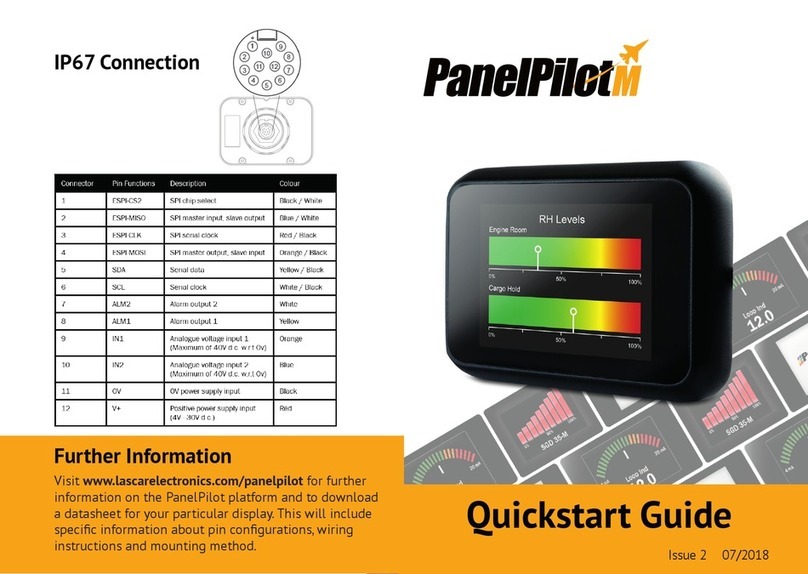

defaultdividedinto3mainparts,pleaseseegure

1. The buttons will be explained if the mouse is

kept over the button, besides table 1 consists of a

total list of buttons.

Please start all new projects by choosing the units

that you wish to use for that project (see the upper

leftpartofgure1).

After choosing the units, the setup of the project

shouldbedenedintheprojecttree.Theproject

tree is shown in the middle part of the screen

Denmark Dubai USA Brasil Singapore

1F95610 05/2013

FlowCon International assumes no responsibility for mistakes, if any, in any printed material.

COMMISSIONING METER

FlowCon FAC6HP with optional software

- 2 -

Note 1: However in the default project the levels are named

“Group 1”, “Group 2”, “Group 3” etc.

Figure 1

PcomPRO

File About

Menu

Units

- must be chosen

Multi-Block Window

- for setting up wafers

Title

Buttons

- mouse-over for explanations

Project Details

- auto hides

Main Parts: Valve List

- for selecting the

valves and cartridges

Project Tree

- overview of the

setup of the project

Project List

- details for the valves

in the project

(slightly left) - this is the overview of the project.All

valves must be listed under a group/level/area and

thus even large projects with many valves can be

sorted by dividing them into obvious groups/levels/

areas.

To add/remove more groups/levels/areas or valves

click the buttons just above the project tree. By

default, the naming of the groups/levels/areas are

“Level 1”, “Level 2”, “Level 3”

1

and so on, and the

naming of the valves are “Valve 1-1”, “Valve 1-2”,

“Valve1-3”andsoon,wheretherstnumbercor-

responds to the group/level/area number so that

valves in Level 2 will be named “Valve 2-1”, “Valve

2-2”, “Valve 2-3” and so on.

Each group/level/area and valve can be renamed

in the project tree by clicking 2 times on the cur-

rent name (please be sure not to double click). The

recommended maximum name length of the

group/level/areaand valvein total is 18 characters,

so abbreviations are recommended.

Depending on the system, it is recommended to

include one or two extra valves in each group/

level/areatodealwithvalvesnotspeciedonthe

drawings/plans.

Boththedenedvalvesandtheirsettingscanbe

altered on the commissioning meter if necessary,

but no new valves can be added (thus the above

recommendation).

All the valves imported from the FAC6HP are

shown in the valve list on the left side of the

screen, where they are divided into maker, then

type/series, then model and lastly size. To nd

fx. a FlowCon Green.0, choose FLOWCON, then

Green, then Green.0 and lastly 15-25mm.

To dene each valve in the project tree, nd the

respective valve in the left side of the screen, click

on it (the size) and then drag and drop it onto the

valve in the project tree to dene that particular

valve. To change an already dened valve, just

repeattheprocedureofdeningit(click,thendrag

and drop). If an already dened valve is dened

again, the previous valve and settings will be over-

writtenbythenewvalve.Toundoadenedvalve,

right-click it and choose “clear”.

1F95610 05/2013

FlowCon International assumes no responsibility for mistakes, if any, in any printed material.

COMMISSIONING METER

Denmark Dubai USA Brasil Singapore

FlowCon FAC6HP with optional software

- 3 -

Theright sideofthe screenisthe projectlist, where

the details for every valve can be seen. The cells

with green background can be edited and thus the

settings (of valves with adjustable settings) can be

changedtoreectthespeciedmaximumow.Af-

ter changing settings please press the reset button

(2 green arrows) to update the cells.

To save the project press the save button, which

will turn green when everything is saved and be

red when there has been changes to the project

since the last save.

Setting up wafers.

To make a wafer consisting of several stainless

steelcartridges, pleaseuse themulti-block window

by clicking the button with the circle and several

dots. Add a new multi-block for every new wafer

conguration. The multi-blocks can be named in

the same way as levels and valves (clicking twice).

Cartridges are added to a multi-block in the same

way that they are to valves (click, then drag and

drop). However, you will be prompted for how

many of this particular cartridge you wish to add

to the wafer and the summarized ow of the

cartridges will be added to the wafer. The multi-

plied cartridges will function as one, so in case

of alterations of numbers, the old cartridges will

need to be deleted (right-click and choose delete)

and new cartridges must be added. Adding an-

other cartridge to a wafer will not overwrite the old

cartridge(-s), but simply add the new cartridge to

thelistandtheowofthecartridgetothetotalow

of the wafer.

Whenthe waferis nished,it canbe addedto a

valve in the project tree like every other valve (click

then drag and drop). However as soon as a wafer

is added to a project, it is locked for further altera-

tions.

By clicking on each cartridge (type) in the wafer,

the cartridges can be checked to verify the ow

(which is shown in the lower part of the multi-block

window).

Exporting to/importing from FAC6HP.

When the project is ready to use, you can export it

to a commissioning meter thus:

1. Have the relevant project open in the program.

2. Turn on the commissioning meter and connect

it with the USB cable.

3. Press the export button (with the red arrows)

and choose “Yes” when prompted.

4. Wait while the project is transferred, then press

“OK”.

5. Now you can turn off the commissioning meter

and remove the USB cable.

To use the project in the memory of the commis-

sioning meter, please follow the notes in the general

instruction for the FAC6HP commissioning meter

in the chapter on memory and the section about

repeating measurements.

A project can also be imported from the commis-

sioning meter thus:

1. Have the program open.

2. Turn on the commissioning meter and connect

it with the USB cable.

3. Press the import button either from the quick

start or from the button with the blue arrow

(above an open project).

4. When prompted, choose a name for the project.

5. The setup will now be the same as for projects

made in the program, but the column “D.P.” will

be updated with the measured differential pres-

sures and the column “Auto Flow” with the sub-

sequentowrate.

Denmark Dubai USA Brasil Singapore

1F95610 05/2013

FlowCon International assumes no responsibility for mistakes, if any, in any printed material.

COMMISSIONING METER

FlowCon FAC6HP with optional software

- 4 -

Valve List

Hide/show the valve list

Metric: Change all sizes to mm

Imperial: Change all sizes to inches

Multi-Block

Show/Hide the multi-block (wafer)

window

Add a new multi-block (wafer)

* only available when the multi-block

window is visible

Project Tree

Add group/area/level

Add valve

Delete group/area/level or valve

Project List

Hide all except the project list or

show more than the project list

Show quick start

Start a new project

Save project

Show/Hide project details

Reset: Update the manually altered

cells

Export project to device

Import project from device

Export project to a .csv file

Table 1: List of buttons.

or

or

or

Warranty obligation.

Failure to abide by all recommendations as per

this installation and operation instruction will void

warranty.

Other FlowCon Measuring Instrument manuals