SPY PIG TRACKING SYSTEMS User manual

o p e r at i n g

instructions

Spy®

pig tracking

systems

models pt101, PT107, PT275,

PT750, PTR & PTS

2

The SPY®Pig Tracking System meets the Electromagnetic Compatibility

and Low Voltage Directive. This product is a Class B, Group 1 ISM

equipment according to CISPR 11. Group 1 ISM product: A product in

which there is intentionally generated and/or used conductively coupled

radio-frequency energy which is necessary for the internal functioning

of the equipment itself. Class B products are suitable for use in

domestic establishments and in establishments directly connected to

a low voltage power supply network which supplies buildings used for

domestic purpose.

is a registered trademark of SPY Inspection Equipment,

Houston, Texas, United States.

A copy of this Operating Instructions Manual can be downloaded on our

website at spyinspect.com.

welcome

Thank you for purchasing a SPY®Pig Tracking System.

SPY®Inspection Equipment and our SPY®brand of Coating Inspection,

JeepMeter and Pig Tracking Equipment has been serving companies all

over the world for over 65 years. With the purchase of this high precision

instrument you can now enjoy access to worldwide service and support

only SPY®and our vast Distributor network can offer.

For more information about SPY®brand equipment please visit our

website at spyinspect.com.

3

Table

of

contents

Pig Tracking Systems Overview . . . . . . . . . . . . . . . . . . . . . . 4

Electromagnetic Transmitters General Information . . . . . . . . . . 6

Technical Specifications (PT101, PT107) . . . . . . . . . . . . . . . . . 8

Technical Specifications (PT275, PT750) . . . . . . . . . . . . . . . . 9

Replacing the Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pig Tracker Receiver (PTR) . . . . . . . . . . . . . . . . . . . . . . . . 12

PTR Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setup and Free Air Test for the PTR . . . . . . . . . . . . . . . . . 14

Before Launching the Transmitter . . . . . . . . . . . . . . . . . . . . 15

Launching and Tracking . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pinpointing a Stuck Pig . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Pig Tracker Sensor (PTS) . . . . . . . . . . . . . . . . . . . . . . . . 18

PTS Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

PTS Individual Modules . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Mounting Hardware for PT275 . . . . . . . . . . . . . . . . . . . . 22

Mounting Hardware for PT750 . . . . . . . . . . . . . . . . . . . . 23

Maintenance & Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Related Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4

pig

tracking

systems

overview

SPY®Inspection Equipment manufactures a complete line of portable

and “On-Pipe” pig tracking and locating systems. Pig Tracking refers

to monitoring the passage of a pig as it moves past prescribed and

monitored points along the pipeline. Pig Locating refers to pinpointing

a pig that has become stuck or lost in a given pipeline or pipe manifold

system on land or at sea.

Unfortunately, carbon steel pipe acts as an ideal electromagnetic shield,

which limits the possible methods of transmitting a signal through the

pipe wall to a sensor. The common methods used to sense the passage

of a pig or attempt to locate it are: mechanical; radioactive; acoustic;

magnetic; and electromagnetic.

Mechanical systems have several drawbacks. They are invasive into the

line, which makes them a potential environmental and safety hazard. They

are subject to contamination by materials in the pipe, which can prevent

them from operating correctly. They are also subject to mechanical wear

and damage, which will prevent them from operating properly.

Radioactive systems have two main drawbacks. One of which, the

radioactive nature of the transmitting device itself makes people

extremely skittish in regards to using it. The second is that the transmit-

ting distance is very limited which makes it primarily usable only when

the “outside-the-pipe” sensor is directly attached to the pipe.

5

Acoustic systems generate an audible signal, which can be picked up

by external sensors, but only when there is sufficient acoustic coupling

between the transmitter and the wall of the pipe. This usually limits their

use to lines filled with liquid, and as you might expect lines which do not

operate in a high noise environment such as sub-sea lines.

Magnet equipped pigs operate well for tracking. They are not of any use

in locating a stuck pig as it is practically impossible to locate them when

they are not in motion. This is simply due to the physics of the type of

signal generated.

SPY®portable systems utilize an electromagnetic transmitter, which is

attached to, embedded in, or travels with the pipeline pig, and a receiver/

wand that will pick up the signal from those transmitters at a distance

allowing for significant ground cover. This signal is a low frequency signal

that operates in the magnetic range of the electro-magnetic spectrum,

which allows the signal to penetrate the steel pipe wall to transmit a

given distance through the ground.

SPY®Inspection Equipment offers two “On-Pipe” systems. One is

designed to work with our electromagnetic transmitters. The other

system is designed to work with magnet equipped pigs with magnets

of sufficient strength to create a field strength of at least one (1) Gauss

outside of the pipe.

6

Electromagnetic

Transmitters

general

information

SPY®Inspection Equipment transmitters pulse at approximately one

pulse every second, which helps to identify this signal over spurious

random noise that the receiver may pick up. This pulse can easily be

detected by using our pig tracker receiver (PTR) and by many other

electromagnetic receivers on the market.

The PT-101 and PT-107 are designed to be mounted in a Poly foam

cavity pig. The PT-275 and PT-750 can be placed in a cavity pig,

mounted to a mandrel pig, or towed behind another pig for ease of use.

These transmitters are “O” ring sealed (water tight) and capable of

working in high-pressure environments (see page 7). Their main bodies

are constructed of rugged carbon steel. Care should be exercised

when exposing them to harsh chemicals. Check with the factory for

chemical compatibility.

Our electromagnetic transmitters utilize off the shelf batteries for easy

inexpensive replacement capability. While these batteries provide

ample life for the transmitters in service, it is prudent practice to use

fresh batteries prior to each new use. Please note that you should

check the expiration date on the batteries that you purchase as older

batteries with reduced life might be sold at retail outlets.

7

NOTE! GROUND COVER OR WATER DOES NOT SIGNIFICANTLY

IMPACT THE SIGNAL PRODUCED BY OUR TRANSMITTERS. THE

WALL THICKNESS OF THE CARBON STEEL PIPE IS THE MOST

IMPORTANT FACTOR TO BE CONSIDERED. IT IS ALSO IMPORTANT

WHEN USING THE TRANSMITTER WITH A STEEL MANDREL PIG TO

ENSURE THAT AT LEAST 1⁄2 OF THE TRANSMITTER IS OUTSIDE OF

THE STEEL MANDREL.

Other than replacing the batteries or “O”rings, each transmitter is

essentially maintenance free. Please note that if the transmitters are

damaged by abrupt stops or by valve gates etc., they may require repair

at the factory prior to re-use. Please inspect them after each use for

obvious damage. This could result in significantly lower repair charges.

8

technical

specifications

MODEL PT101 PT107

Minimum Pipe Size 2” – 4” 2” – 8”

[50.8mm – 101.6mm] [50.8mm – 203.2mm]

Transmitter Length 4.1875” [106.4mm] 6.3125” [160.33mm]

Transmitter Diameter 1” [25.4mm] 1.25” [31.75mm]

Maximum Hours 60 Hours 60 Hours

of Signal

Batteries Required 1 Lithium 3V 1 Lithium 3V

Maximum Pickup 15’ – 20’ 20’ – 25’

Range (free air) [4.72M – 6.096M] [6.1M – 7.62M]

Ground Cover Depth 4’ [1.23M – 1.83M] 6’ – 8’ [1.83M – 2.44M]

Pickup Range

Maximum Operation 1000 PSI [69 Bar] 1000 PSI [69 Bar]

Pressure

Temperature Range -20oF – 180oF -20oF – 180oF

[-29oC – 82oC] [-29oC – 82oC]

*Minimum Pipe Bend 2” – 5D* 2” – 5D*

(Medium – High 3” – 4” 3D* 3” – 8” 3D*

Density Polly Pig)

9

technical

specifications

MODEL PT275 PT750

Minimum Pipe Size 6” [152.4mm] and Up 12” [304.8mm] and Up

Transmitter Length 7.5” [190.5mm] 13.875” [352.4mm]

Transmitter Diameter 3” [76.2mm] 3.5625” [90.5mm]

Maximum Hours 200 Hours 500 Hours

of Signal

Batteries Required 4 “AA” Batteries 8 “C” Alkaline

Maximum Pickup 60’ – 75’ 100’

Range (free air) [18.29M – 22.86M] [30.5M]

Ground Cover Depth 15’ [4.6M] 25’ – 30’ [7.6M – 9.1M]

Pickup Range

Maximum Operation 2000 PSI [138 Bar] 3000 PSI [207 Bar]

Pressure

Temperature Range -20oF – 180oF -20oF – 180oF

[-29oC – 82oC] [-29oC – 82oC]

*Minimum Pipe Bend 3D* 3D*

(Medium – High

Density Polly Pig)

10

IMPORTANT:New batteries should be installed before every use to

ensure a strong signal. Once new batteries have been installed and the

end cap attached, the transmitter is “ON” and transmitting.

replacing

the

batteries

PT101 (1) 3V LITHIUM. Unscrew and remove the end

cap by turning the center of the transmitter counter-

clockwise. Insert the 3V lithium battery with the negative

terminal toward the spring inside the transmitter body

and the positive button toward the removable end cap.

Put both halves of the transmitter back together and tighten securely.

PT107 (1) 3V LITHIUM. Unscrew and remove the end

cap by turning the cap counter-clockwise. Insert the

3V lithium battery with the negative terminal toward

the spring inside the transmitter body and the positive

button toward the removable end cap. If in doubt,

observe the red decal on the outside of the transmitter body for proper

orientation. Replace the end cap and tighten securely.

PT275 (4) 1.5V AA ALKALINE. Locate the removable

end cap. It does not have multiple screw penetrations.

Unscrew the removable end cap by turning it counter-

clockwise. Do not attempt to remove the other end cap,

as it will result in damage to the transmitter. Before

installing the batteries, look into each of the battery tubes to ensure the

spring contacts are clean and free of foreign material. Also inspect the “O”

ring primary and secondary seals to ensure that they are in place, clean and

without cuts or abrasions. If in doubt replace the “O” rings to ensure against

media penetration that could result in significant repairs being required for

11

PT750 (8) 1.5V C ALKALINE CELL. Locate the removable

end cap of the PT-750. It does not have multiple screw

penetrations. Unscrew the removable end cap by turning

it counter-clockwise. Do not attempt to remove the other

end cap, as it will result in damage to the transmitter.

When the end cap is removed, you will see the black

battery holder assembly. Remove this. It will come out easily. You will see

four (4) individual battery holders on each side. Make sure prior to inserting the

batteries that all contacts are clean. Place the negative ends of the batteries into

each holder towards the spring. Press down and push back on the positive end

until it snaps into place. If the batteries are not properly installed, a protection

circuit will prevent the transmitter from operating. This is also a good time to

inspect the “O” ring seal to ensure that it is in place, clean and without cuts or

abrasions. If in doubt replace the “O” ring to ensure against media penetration

that could result in significant repairs being required for the transmitter. If the

“O” ring needs to be replaced or is overly snug, a thin coat of petroleum jelly will

help. Replace the battery holder assembly by placing the end with the springs

back into the transmitter body first and with the spine holding the individual

battery holders together opposite the other internal assembly in the transmitter

tube. Replace the removable cap and secure it snugly with a wrench.

CAUTION! NEVER REMOVE THE WHITE PIECE INSIDE THE

TRANSMITTER AS IT WILL RESULT IN SIGNIFICANT DAMAGE.

NOTE: IT IS IMPORTANT TO USE NEW BATTERIES WITH EACH JOB.

the transmitter. If the “O” ring needs to be replaced or is overly snug, a thin

coat of petroleum jelly will help. Install the batteries with the positive and

negative ends facing towards the removable cap as indicated by the sticker

immediately viewable upon removing the cap. One side (2 batteries) is to be

loaded positive end out, and the other side, negative end out. Screw on the

end cap and tighten securely with a wrench. If the batteries are not properly

installed no damage will be done; however the transmitter will not operate.

12

pig

tracker

receiver

(ptr)

The Pig Tracker Receiver (PTR) consists of the electronics and wand

as a set. The PTR is a very sensitive analog receiver that is designed

to pick up the low-level electromagnetic pulses provided by the

transmitters. The system is designed to provide you visual and audible

indication of the transmitter signal.

Audible indication of the signal is provided by means of a beep that

pulses with each sensed signal from the transmitter. Visual indication

is provided by means of an analog sweep meter. The meter hand

pulses with each received pulse. It also sweeps in a wider arc as the

signal strength increases and lessens as the transmitter moves away

from the receiver.

Battery status indication is provided by means of a red indicator light

that will illuminate when the “OFF/ON” switch is in the “ON” position

if the batteries are in good condition. If it does not illuminate, replace

the batteries.

Adjustment is provided for “Gain” via a knob on the front panel. “Gain”

can be thought of as sensitivity adjustment.

The PTR also provides for a remote signal, which can be sent to a

separate device to allow for remote registering of transmitter pulses.

The sensitivity that is essential to pick up these low-level

electromagnetic signals, is also a weakness in that it subjects the unit

to potential false signal trips. The more gain you can set without false

triggering, the better.

13

ptr

specifications

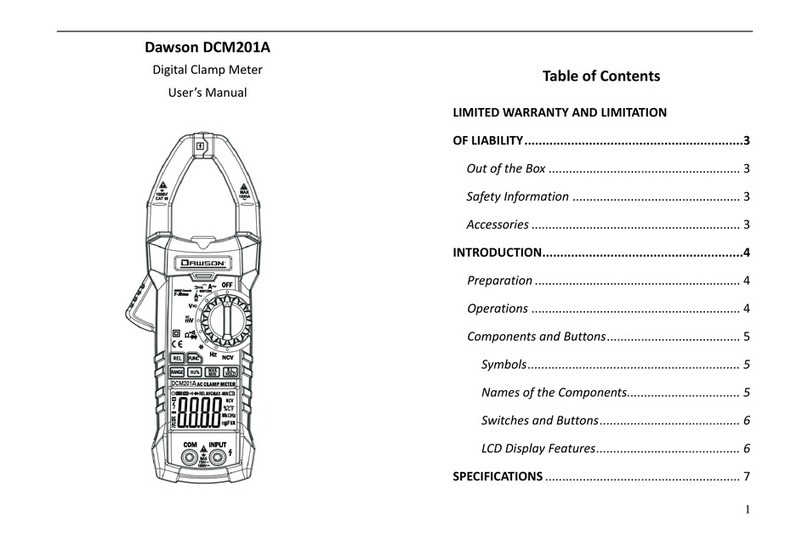

MODEL PTR

Frequency 23 Hz Receive

Battery 2 x 9 Volt

Battery Life 50 Hours

Display Type LCD

Signal Indicator Type Audible / Visual

Unit Weight (lb) 1.5

Unit Dimensions (L x W x H) 7.5” x 5.25” x 2.5”

Factory Warranty 12 Month

Domestic & International Standards CE Compliant

On/Off

Bat Switch

Audible

Signal Horn

Battery Indicator Light

Visual LCD Signal Strength Display Shoulder Strap Clips

Gain Knob

Wand Plug Port Quick Change Battery

Compartment

Benchtop Rubber Feet

14

Setup

and

Free

Air

Test

for

the

ptr

STEP 1. If desired, attach the supplied strap to the two “D” rings on each side of

the receiver to allow the receiver to be hung over the shoulder for ease of carrying.

STEP 2. Plug the Wand into the lower right side female audio receptacle on the

front of the PTR. To later release the wand, press the tab with the word “PUSH”

down until the connector is released.

STEP 3. Place the wand parallel to the transmitter.

STEP 4. To test for proper operation of the transmitter and receiver, begin by

placing the transmitter on the ground approximately 10 – 15 ft (3.05 m – 4.6 m)

from the wand. With the receiver switched on, turn the wand until it parallels the

transmitter and be sure that it is horizontal. Increase the receiver gain until you

hear the transmitter signal beep while verifying that you see the visual indicator

moving with the pulses. Begin moving away from the transmitter laterally while

keeping the wand steady, horizontal and parallel to the transmitter. The analog

meter movement will begin to decrease with distance. Begin to increase the gain

slowly as you walk away, ensuring that you continue to receive signal from the

transmitter. Continue walking away as you turn the gain slowly up to maximum

(10). Continue walking away until you loose the signal. This point represents the

maximum free air transmit distance for this transmitter.

NOTE: As you turn the gain above 5, you will begin to notice more false

signaling created by movement of the wand. You should also note that due

to the nature of the type of signal the receiver senses, items such as, keys,

pocket knives, tools, large metal belt buckles, or other metallic items can cause

disturbances in the earth’s electromagnetic field, and create false signals.

Other possible sources of false signals are electronic wristwatches, electronic

vehicle ignition systems, and two way portable radios.

15

before

launching

the

transmitter

A short period of working with the units in the shop prior to using the equipment

in the field is highly recommended.

After the batteries have been installed in the transmitter and before the pig

has been launched, turn the transmitter on and verify that you can pick up the

transmitter. Move away approximately 5 to 10 ft (1.5 m to 3.04 m). Place the

wand parallel to the pipe and turn the gain to 5 or 6. Verify that you still receive

the pulse. Again, note that you should not set the “Gain” higher than necessary

in order to pick up the signal as that will make the possibility of false triggering

much more likely. Conversely, if the “Gain” is set too low, you may not be able

to detect passage of the pig. If you cannot receive the transmitter signal by

adjusting the gain, replace the batteries in the transmitter and receiver.

launching

and

tracking

Prior to actual launch, and after the above described testing, place the wand

parallel and directly above the pipe on the ground, some distance down from

the launcher. Set the receiver gain to approximately 5 to 6. This will provide a

positive indication that the pig has actually left the launcher when the launch

process begins.

Repeat this process at prescribed intervals along the pig run and monitor the

pig movement past these checkpoints to verify the pig’s progress.

By using two receivers you can “leapfrog” one over the other to track the

passage. This process is highly recommended. Minimize the distance between

the “leapfrog” positions in order to minimize the possible distance that will

have to be walked to locate a stuck pig.

16

pinpointing

a

stuck

pig

Pinpointing the location of the transmitter located in a stuck pig is a

relatively simple operation. Move to the last leapfrogging location where

you know the pig passed. At this point hold the wand horizontally and

begin to slowly walk the line listening for the steady pulsing beep of the

transmitter. Please note that you must be sure where the pipe is when you

are attempting to walk the line. Lateral distance from the center of the pipe

will greatly decrease the possibility of picking up the signal. Drawings do

not always represent the actual position of the pipe. Nor can you assume

you know that the pipe goes in a straight line between two points. Use

a pipe locator to ensure you know the pipe location. If you cannot use

a locator, begin walking the line using sweeping “S” curves over the

approximate location of the line. This should enhance your possibility of

actually passing over the line. If too many stray or false signals are picked

up caused by bouncing or movement of the wand or spurious signals turn

the gain down.

Upon picking up the signal, continue walking towards the transmitter while

watching the analog sweep meter. When the meter movement begins to

decrease, move backward until you see the approximate maximum signal

strength. Turn the wand vertical over the pipe. Slowly move the wand over

the approximate area of maximum signal strength. The signal strength will

increase and then fall to zero as well as the audible signal will disappear

(in other words “NULL”) and then start to rise again. Move the wand back

and forth until you center over the “NULL”. You should now be standing

directly over the transmitter.

17

18

pig

tracker

Sensor

(pts)

When the need for noting the passage of a pig becomes a little less

temporary, (e.g.; manpower or distance prevents leap frogging) then SPY®

offers a line of stationary Pig Tracking Sensors (PTS). We offer the standard

PTS for use with electromagnetic transmitters and our model PTS-M for

use with magnet equipped pigs.

The PTS system requires NO HOLE to be drilled in the pipe. This non-

invasive system allows for lower installation costs and significantly reduces

the overall cost of the monitoring point. It also offers safer monitoring. This

feature also makes the PTS more desirable than invasive systems from a

pollution prevention standpoint.

The PTS systems must be mounted directly onto the pipe in order to pick

up the signal of the transmitter or magnet. Care should be taken to allow

sufficient distance between the sensor and the launcher/ receiver so that

the pig can travel completely past the sensor.

NOTE: The PTS is a passage indicator, not a presence indicator.

Power Module*Sensor Module*Indicator Module*

Reset Button

Passage

Indicator

Window

*Explosion-proof Class I, Division 1, Groups B, C, & D certified enclosures.

19

Mounting can be permanent or temporary and can be accomplished by using

pipe straps or clamps. Units can be installed along the line as often as needed.

The systems are provided in explosion-proof Class I, Division 1, Groups B, C, &

D certified enclosures. The enclosures come complete with an “O” ring seal,

which makes the housing NEMA 4X/7. Three quarter inch hubs are provided on

each enclosure for conduit connection into your SCADA or recording system.

When supplied by the factory as an assembly, proper explosion proof fittings are

used and manufacturer specified procedures are followed to connect the units in

order to maintain their rating. Make sure that you follow proper wiring and conduit

procedures as specified by the appropriate authority for wiring in hazardous areas

if you wish to connect your monitoring systems to the PTS system.

pts

specifications

MODEL PTR

Enclosure Enclosure Class 1, Division 1,

Groups B, C & D Blind modules

Power Input Either 129 Volts AC or ±3VDC (Sensor

Module) and 18 Volts DC for Indicator**

Power Output Normal Open non-latching Dry

Contacts rated at 1A at 250 Volts AC

Transmit Speed PTS Passage Indicator NOT a

Presence Indicator

Display Type Visual

Unit Weight (lb) 9.4

Unit Dimensions (L x W x H) 26” x 26” x 4.75”

Factory Warranty 12 Month

Domestic & International CE Compliant

Standards

**Other types of power supply inputs can be used, but must be specified on order entry

to allow for modifications to be made to the modules.

20

pts

individual

modules

PTS SENSOR. The Sensor Unit can be powered

using 120 Volts AC input or by ±3VDC input from the

PTSB module. The sensor picks up the presence of

the Pig Tracker Transmitter signal and then activates

a set of normally open dry contacts with a maximum

rating of 1A @ 250 Volts DC. These contacts will

remain engaged as long as the signal is present. They will open within two

seconds of the absence of the signal.

PTS INDICATOR MODULE. The PTSI indicator is

powered by the PTSB module or by the 120 Volt AC

being supplied to an AC powered PTS module. The

indicator for noting pig passage is a 2 inch orange

disc. This disc is orange on one side and black on the

other. When the PTS notes a Pig Transmitter signal

by closing the contacts in the PTS, that actuates the

indicator to flip from Black to Orange. The indicator is visible by means of a

viewing window in the cover of the unit. This unit must be reset after each

passage of a pig by the means of an external magnetic button.

PTSB BATTERY POWER MODULE. The battery

module can supply ±3VDC Volts DC for powering

the Sensor and 18 volts DC for powering the PTSI

indicator module. This module can also be configured

to supply backup power for a 120-Volt AC powered

version of the PTS Sensor.

This manual suits for next models

6

Table of contents

Other SPY Measuring Instrument manuals