SAFETY PRECAUTIONS

Step Two

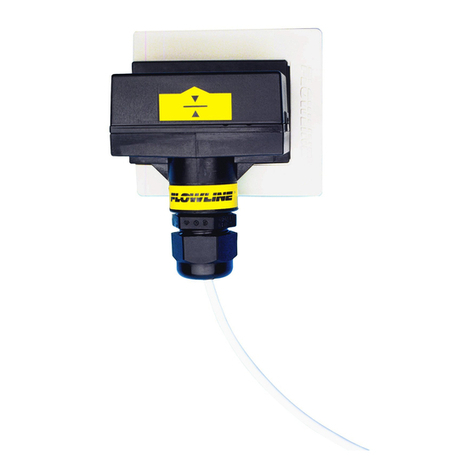

About this Manual:

PLEASEREADTHEENTIREMANUALPRIORTOINSTALL-

INGORUSINGTHISPRODUCT.Thismanualincludesinforma-

tionon all modelsof Intrusive RFCapacitance level switchesfrom

Flowline, LP10 series. Please refer to the part number located on

the switch label to verify the exact model which you have pur-

chased.

User’s Responsibility for Safety:

Flowline manufactures a wide range of liquid level sensors and

technologies. While each of these sensors is designed to operate in

awidevarietyofapplications,itistheuser’sresponsibilitytoselect

a sensor model that is appropriate for the application, install it

properly, perform tests of the installed system, and maintain all

components. The failure to do so could result in property damage

or serious injury.

Proper Installation and Handling:

Use a proper sealant with all installations. Never overtighten the

sensor within the fitting, beyond a maximum of 80 inch-pounds

torque. Always check for leaks prior to system start-up. Do not

install the LP10 series sensor within 6" of any metal.

Material Compatibility:

The LP10 series sensor is available in two different wetted materi-

als. Models LP10-1___ are made of Polypropylene (PP). Models

LP10-2___ are made of Perfluoroalkoxy, also known by the trade

name Teflon, (PFA). Make sure that the model you have selected

is compatible with the application liquid. To determine the chemi-

cal compatibility between the sensor and its application liquids,

refertoanindustryreferencesuchastheCompassCorrosionGuide

(available from Compass Publications, phone 619-589-9636).

Wiring and Electrical:

The supply voltage used to power the LP10 series sensor should

never exceed a maximum of 36 volts DC. Electrical wiring of the

sensor should be performed in accordance with all applicable

national, state, and local codes.

Flammable,ExplosiveandHazardousApplications:

Only the LP10-___0 series switch is rated for use in hazardous

locations. Refer to the certificate of Compliance for all applicable

intrinsically safe ratings and entity parameters for the LP10-___0.

Refer to the National Electric Code (NEC) for all applicable

installation requirements in hazardous locations. DO NOT USE

THE LP10-___2, LP10-___3 or LP10-___5 GENERAL PUR-

POSE SWITCH IN HAZARDOUS LOCATIONS.

WARNING

DonotinstalltheLP10levelswitchonametallictank,

or within 6" of any metallic object. Metal will ad-

verselyaffect thedielectric sensitivityof thesensor.

ThemaximumcurrentdrawontheFETswitchis100mA.

Flowline’sLP10seriessensorsarenotrecommended

forusewithelectrically charged applicationliquids.

For the most reliable operation, the liquid being

measured will need to be electrically grounded.

INTRODUCTION

Step Three

About Intrusive RF Capacitance Technology:

Flowline’sLP10seriesgeneratesa300kHzpulse-waveradiofrequency

signal from the capacitance electrode located in the sensing tip of each

sensor. When liquid comes into contact with the sensing tip, the

capacitance as measured by the sensor changes based on the dielectric

constant of the liquid. Flowline’s sophisticated electronics convert the

capacitance value into a simple two-wire, 4 or 20 mA, a three-wire FET

switchoutputwhichindicateswhetherthesensoriswetordryora4-wire

NO or NC 1A relay output. In the dry state, the sensor delivers a two

wire,5mAsignal output.Inthe wetstate,the sensordeliversa twowire,

19 mA signal output.

The sensor’s operation may vary based on the dielectric properties of

variousapplicationliquids. TheLP10series sensorisfactory-calibrated

to be used with liquids with a dielectric value between 20 and 80. For

example, if the application liquid is acetal (with a dielectric constant of

about 3.6), the sensor (as factory calibrated) will not detect its presence

when it is wet. However, if the application liquid is glycol (with a

dielectric constant of about 35) the sensor will reliably detect its

presence when wet.

Warning: Do not install the LP10 series sensor within 6 inches of any

metallic object. Metal will adversely affect the dielectric sensitivity of

the sensor.

Flowline’s LP10 series sensors are not recommended for use with

electricallycharged application liquids.Formost reliable operation,the

liquid being measured may need to be electrically grounded.

Acetone 21

Acetoaldehyde 22.2

Acetyl methyl hexyl

ketone 28

Alcohol 16 to 31

Ammonia 15 to 25

Acetic acid 4.1 to 6.2

Butyl chloride 9.6

Barium chloride 9 to 11

Benzene 2.3

Benzine 2.3

Barium nitrate 5.6

Bromine 3.1

Chlorobenzene 4.7 to 6

Chlorotoluene 4.7

Chloroform 4.5 to 5.0

Chlorine, liquid 2.0

Carbon tetrachloride 2.2

Cyan 2.6

Cyclohexane methanol3.7

D.I. Water 20

Ethyl toluene 2.2

Ethyl alcohol 23

Ethylene glycol 37

Ethylene oxide 14

N-butyl formate 2.4

Nitrobenzene 26 to 35

Nitrotoluene 25

Naphthalene 2.3 to 2.5

Oils, vegetable 2.5 to 3.5

Oils, mineral 2.3 to 2.4

Oils, petroleum 1.8 to 2.2

Oleic acid 2.5

Propane, liquid 1.8 to 1.9

Potassium nitrate5.0 to 5.9

Potassium chloride 5.0

Stearic acid 2.3

Toluene 2.4

Trichloroethylene 3.4

Trichloroacetic acid 4.5

Terephthalic acid1.5 to 1.7

Thinner 3.7

Urea 3.5

Vinyl chloride 2.8 to 6

Vinyl alcohol 1.8 to 2.0

Water, 20°C80

Water, 100°C48

Ethylene dichloride

11 to 17

Ethylene chloride 10.5

Ethyl acetate 6.4

Ethyl salicylate 8.6

Ethyl stearate 2.9

Ethyl silicote 4.1

Formic acid 59

Ferric oleate 2.6

Freon 2.2

Glycerine 47

Glycol 30

Glycol nitrite 27

Gasoline 2 to 2.2

Hydrochloric acid 4.6

Isobutyric acid 2.7

Isobutyl methyl ketone 13

Jet fuel 1.7

Lead carbonate 18

Lead nitrate 38

Methyl salicylate 9.0

Methanol 33

Methyl alcohol 33 to 38

Margarine, liquid2.8 to 3.2

Methyl acetate 7.3

Table of Common Dielectric Constants

NOTE: Liquids with a dielectric constant less than 20 will not be

detected by an LP10 series sensor, as factory calibrated.