Flowplant 115 Series User manual

115 Series 200 / 300 Series 315 Series 400 Series Mk4 Lightpack

EQUIPMENT • PARTS & ACCESSORIES • SERVICING • TRAINING

Operator’s Quick Reference

Safety Guide

Vanpacks

Part No 061874

Focussed on Your Jetting Needs

Flowplant has been creating innovative, high pressure drain and sewer

cleaning equipment for over 40 years, selling thousands of high quality and

reliable machines throughout the UK and exporting to over 50 countries

around the world.

Through our nationwide network of service and distribution centres, we offer

a complete range of keenly priced drain jetters and accessories that get the

job done, are affordable within your budget and will continue to operate

efficiently and cost effectively for many years.

2.0 Scope of Supply

3.0 Health & Safety

4.0 Technical Specification

5.0 Controls

6.0 Operation Maintenance

03

04 - 07

08 - 09

10 - 14

15 - 18

7.0 Fault Finding

8.0 Appendix

Declaration of Conformity

Service History

19 - 20

21

22 - 23

This Operator’s Quick Reference Safety Guide is intended to allow operators to quickly become familiar with the

essential controls and safety requirements of Flowplant jetters. It does not replace the full operation and maintenance

manual which should be read and which contains additional operation and safety information.

Contents

Throughout this manual various warnings are given with this icon.

Where shown, failure to follow the instruction can result in serious injury or even death.

!Please pay particular attention to these recommendations

1.0 Introduction

Flowplant drain jetters have been designed to the highest standards so that they will work safely and reliably for many

years. It is important that you take time to read the information provided in this guide so that you understand how to

make the most of the jetter and how to use it safely. Flowplant jetters are powerful pieces of industrial equipment and

should only be operated by competent users who understand that serious injury or death can occur through misuse.

The jetters described in this Operator’s Quick Reference Safety Guide are intended to be used for high pressure

water jetting in drain and sewer systems from 50mm up to 450mm diameter.

They will remove soft blockages, tree roots and hard scale, liquefying fats and restoring drain flow by blasting high

pressure water through a drain nozzle connected to the end of a high pressure hose. Some models can be fitted with

jump jets kits to increase the effective cleaning distance.

Flowplant jetters use diesel or petrol engines to power a high pressure water pump up to 350 bar (5,000 psi) / 60 l/min

(13 gpm). Van pack jetters are installed semi permanently into the back of a suitable panel van and they are fitted with a

water tank up to 780 litre (180 gallons) capacity.

Additional accessories can be purchased from Flowplant, such as: floor cleaners, jetting guns and jet pumps which

extend the range of work that can be carried out with the jetter. Separate details are available on request.

03

2.0 Scope of Supply

3.1 Safety Notes

●Operating procedures throughout this manual must

be adhered to. In the case of conflicting or

ambiguous instructions, reference must be made

to a Site Manager or Safety Officer before

commencing work.

●Any person operating, working with, or passing

near the jetter must wear the necessary Personal

Protective Equipment (PPE).

●The Site Management should make available to

operators or persons working with the jetter the

appropriate technical documentation and should

ensure such persons read and understand the

documentation prior to commencing their duties.

●Special tools should be used where

recommended.

●Prior to any maintenance or repair work being

carried out the jetter must be shut down,

de-pressurised and equipment isolated.

●Any maintenance requirements in this manual

should be adhered to as minimum maintenance

requirements. Maintenance records should be up

to date at all times.

●Guards which are located within the jetter must be

fitted and must not be loosened or removed whilst

the jetter is operational. Should it be necessary to

remove any guard for access, it must be re-fitted

and secured before start up.

3.2 Use of High Pressure Equipment

●All persons using high pressure jetting equipment

should be fully conversant with relevant operating

instructions, safety notes and Codes of Practice.

●Operators must be competent in all aspects of jetter

use.

●All high pressure water jetting operations should be

under the control of a fully trained supervisor, who will

be aware of the potential hazards to operators and

passers-by

●Warning notices, ‘DANGER - HIGH PRESSURE

JETTING’ should be displayed at all possible access

points to the jetting area. Notices are available from

Flowplant Group Ltd.

●Before starting the jetter, ensure that you, and

anyone else who may be in control at any time, are

fully aware of its controls and their function.

●It is especially important that everyone knows how to

stop the jetter in case of an emergency.

●Ensure that all the pre-operational checks have been

completed, and that any necessary actions have been

taken.

●Do not operate the jetter near any persons or

animals.

Throughout this manual various warnings are given with this icon.

Where shown, failure to follow the instruction can result in serious injury or

even death.

High pressure jetting can be extremely dangerous if it is not properly controlled by

fully trained personnel

3.0 Health & Safety

3.0 Health & Safety

3.3 Potential Hazards and Misuse of High Pressure Equipment

05

●Never use a jetter that isn’t regularly serviced

according to the manufacturer’s recommendations.

●When a jetter is used to clean drains & sewers that

are contaminated with a hazardous substance it is

possible these may be entrained in the resulting

aerosol and inhaled by operators. Consider using

respiratory protection.

●Do not spray flammable liquids - there is

a risk of explosion.

●Ensure the correct fuel is used on all

occasions or there is a risk of explosion.

●Never start the jetter when frozen. Operating a

jetter whilst frozen could cause high speed ice

bullets to be ejected from the jetter hose on

machine start up.

●Never start jetting a drain, sewer or pipe unless the

jet nozzle is safely inside the drain and pointing in

the direction that you intend it to travel.

●When drain jetting a drain, sewer or pipe with an

inside diameter that is not small enough to prevent

the hose from turning back on itself, a drain jet

extension (a piece of straight rigid tube equivalent

to the pipe diameter) should be fitted between the

end of the hose and the nozzle.

●Always use a safety leader hose at the beginning

of the main jetting hose to alert operators when the

jet nozzle is nearing the manhole entrance.

●Always consider the use of a tiger tail hose feed

guide to protect the jetting hose from abrasion and

prevent premature failure.

●Be aware that high pressure hoses can generate

static electricity which may need to be controlled

when working in hazardous areas.

●Never direct a high pressure water

jet at electric power lines or electrical

equipment as serious injury or death

from electrocution could occur.

●When jetting drains or sewers if there is a danger

to the general public from hoses laying across

public walkways they must be covered in such a way

as to protect against injury from hose failure and

tripping hazards.

●Before starting work check and ensure the drain jets

have no blocked holes or nozzles as this may cause

the pumping system to over pressurise which could

result in burst disc failure or bursting the jetting hose.

●Never attempt to unblock a fully choked drain or pipe

before considering the consequence of releasing the

blockage and having a plan to deal with it. E.g.

flooding, material ejection, drain nozzle ejection.

●Never attempt to clean drains or pipes in one pass

because this could lead to debris build up behind

the jet nozzle causing a pressure build up in the

drainage system. Be aware that a pressure build up

in the drain or pipe could cause the jet nozzle to be

ejected at speed back towards the operator.

●Never enter the manhole to either place the jet

nozzle into or extract it from the drain entrance

unless the required confined space regulations have

been met.

●Never work in a manhole with a radio remote control

transmitter that is not classified for use in such

areas.

●Never use the hydraulic hose reel facility as a winch

to retract a jetting hose that has become stuck in the

drain or pipe. Damage to the hose could be caused

that will make subsequent hose failure more likely.

●Never allow jetting hoses to become kinked and

always remove from service any jetting hose with an

outer cover that has worn through to the reinforcing

braid.

●Never use the high pressure jetting hose for any

purpose other than sewer, drain or pipe cleaning,

e.g. winching vehicles or other plant.

●Never use jetting nozzles and/or accessories that

have not been calibrated for the jetting machine

pump performance as this could cause rapid over

pressurisation catching operators unaware.

3.0 Health & Safety

●Never attempt to clean a drain or pipe with a

nozzle that has more forward force than rear force.

It could be ejected back toward the operator

causing injury.

●Never attempt to clean a drain or pipe with a chain

flail type jet that has unequal chain lengths as this

could lead to severe vibration and high pressure

hose failure.

●When using a venturi jet pump to remove fluid from

a flooded manhole never place your fingers into

the pump inlet as they could be trapped by the

vacuum and cause injury.

●When using a venturi jet pump to remove fluid from

a flooded manhole always secure the free end of

the pump hose securely and ensure adequate

drainage is in place to deal with high volumes of

pumped water.

●Never use a dry shut type foot control valve on a

jetter that does not have a pressure unloader valve

as this could result in burst disc failure or bursting

the jetting hose.

●Never use a dry shut type jetting gun valve on a

jetter that does not have a pressure unloader valve

as this could result in burst disc failure or bursting

the jetting hose.

●When using a dry shut type system be aware that

high pressure can be retained in the jetting hose

even after the machine has been shut down.

Always discharge pressure in a safe manner after

machine shut down.

●Never point the gun at anyone as injury from high

pressure water will occur if the jet stream comes

into contact with body parts.

●Never work on a slippery surface because the

reaction force of the jetting gun could cause you to

become unstable and lose your footing.

●Never work from a ladder as the reaction force of

the jetting gun could cause the ladder to fall

backwards from the working area causing possible

injury.

●Never work from scaffolding unless it is designed,

erected and managed by competent persons and it

is adequately secured to prevent it being pushed

over by jetting gun reaction forces.

●When using the jetting gun to clean hard surfaces

be aware that splash back could contain hard debris

travelling at speed.

●When using the jetting gun to clean contaminated

surfaces be aware that splash back could contain

dangerous contaminants.

●Never use the jetting gun to clean a surface that

could be damage or penetrated by the water

pressure unless that is the desired effect.

●Always ensure that an adequate area is cordoned

off around the working zone so that flying debris

and contamination cannot injure passers by.

●Be aware that the use of water jetting guns fitted with

oscillating or rotating heads tend to produce higher

hand arm vibration levels than simple fixed head jets.

●When using a jetting gun or nozzle to clean at floor

level wear suitable protective foot wear.

●Never use a high pressure jetting gun to

clean down PPE whilst you or others are

still wearing it as serious injury and death

could result.

●Never use a high pressure jetting gun to

wash or cool down livestock as serious

injury and death could result.

●Drainage systems may carry bacteria and

micro-organisms which can cause severe illness or

death. Avoid exposing eyes, nose, mouth, ears,

hands, cuts or abrasions to waste water or faecal

matter during drain cleaning operations. After

working around drainage systems help protect

yourself by always washing hands, arms and other

areas of the body with hot, soapy water and, if

necessary, flush mucous membranes with clean

water. Disinfect soiled equipment by washing

surfaces with a hot soapy wash using a strong

detergent.

3.3 Potential Hazards and Misuse of High Pressure Equipment

3.0 Health & Safety

All persons using high pressure water jetting equipment

should use all necessary PPE suitable for the task being

carried out. This includes, but is not limited to:

●Ear protection

●Eye protection: a helmet with chin guard and visor

is recommended

●Hand protection

●Waterproof clothing

●Safety boots with toe protection

Please note: A site specific risk assessment must

be completed to analyse which PPE must be worn.

3.5 Hoses

The following checks must be made before use:

●High pressure jetting hoses must be checked

along their entire length at the start of each shift to

ensure that they are free from external damage.

Hoses with exposed or broken reinforcing braid or

damaged couplings and fittings may fail without

warning and must be replaced immediately.

●Before use check end fittings and couplings for

damage to threads, sealing faces and rounding of

connection nuts. Only use the correct size spanner

to tighten the hose fitting. Stilsons or adjustable

spanner type tools with serrated teeth must not be

used.

●Hoses that have been used MUST NOT be

re-ended under any circumstances - see ISO

4413:2010 section 5.4.6.5.1

●If water appears from the hose, coupling

or connector, often first sighted as a fine

mist, then the hose is damaged and could

burst or a joint is loose or defective.

STOP THE JETTER IMMEDIATELY!

No attempt should be made to adjust any

hose, coupling or connector whilst that part

of the system is under pressure.

●Pressure relief valves should be checked for

functionality and certified by the manufacturer or

their authorised representative at least every 6

months.

●Pressure discs (burst discs) should be replaced at

least every 6 months to ensure continued safe

operation and only manufacturer’s original

replacements should be used.

●Under no circumstance should a foreign object be

used in place of a manufacturer’s pressure disc

(burst disc).

3.7 Carbon Monoxide Poisoning

●Ensure the van cab is fully vented after using the

jetter.

●The operator should have rear and side doors open

when operating the machine.

●It is advisable to carry a carbon monoxide monitor in

the rear or the vehicle and the cab of the vehicle as

an early warning of any gas build up.

●Ensure that any exhaust emissions are not in the

vicinity of any air intakes as suffocation could occur.

!

3.4 Personal Protective Equipment (PPE) 3.6 Pressure Safety Devices

The vehicle & jetter use an engine that

could cause build-up of carbon

monoxide gases in the vehicle storage

area or cab.

07

115 Series 200 Series 300 Series

Pressure 200 bar / 3000 psi 200 bar / 3000 psi 200 bar / 3000 psi

Flow 36 l/min / 8 gpm 41 l/min / 9 gpm 50 l/min / 11 gpm

Pump Hawk XLTI Interpump HP22 Speck NP25

Engine Honda GX690 Lombardini LDW1003 Lombardini LDW1404

Engine Power 16 kW / 22hp 18 kW / 24 hp 26 kW / 35hp

Engine Cooling Air Cooled Water Cooled Water Cooled

Run Time Meter Engine Monitor Engine Monitor Engine Monitor

Fuel Type Petrol Diesel Diesel

Fuel Capacity 20 litres 20 litres 20 litres

Standard Tank Capacity 325 litres 270 litres (400 litre option) 270 litres (400 litre option)

Hose Type 3/8” 60m (200 ft) 1/2” 90m (300 ft) 1/2” 90m (300 ft)

Hose Reel Pivoting Fixed Fixed

Hose Reel Control Manual Hydraulic Hydraulic

Hose Feed N/A

Inlet Hose Reel 1/2” 50m (170 ft) 3/4” 25m (85 ft) 3/4” 25m (85 ft)

Standard Drain Jets

Drain Jet Extension

Safety Leader Hose

Radio Remote

Jump Jet Kit N/A

Anti Freeze Kit

Dry Weight (kg) * 270 465 495

Max Weight (kg) * 600 735 765

Dimensions (L x W x H) m 1.14 x 1.20 x 1.12 1.25 x 1.20 x 1.36 1.25 x 1.20 x 1.44

???

x3

x3

x3

Included

3 Included

Optional

x3

?

4.0 Technical Specifications

*All weights & dimensions are approximate

315 Series 400 Series Lightpack

Pressure 200 bar / 3000 psi 200 bar / 3000 psi 200 bar / 3000 psi

Flow 50 l/min / 11 gpm 60 l/min / 13 gpm 55 l/min / 12 gpm

Pump Speck NP25 Hawk HFR Harben ‘P’ Type

Engine Lombardini LDW1404 Lombardini LDW2204 Yanmar 4TNV-88

Engine Power 26 kW / 35 hp 36 kW / 48 hp 33 kW / 44 hp

Engine Cooling Water Cooled Water Cooled Water Cooled

Run Time Meter Engine Monitor Engine Monitor Engine Monitor

Fuel Type Diesel Diesel Diesel

Fuel Capacity 20 litres 30 litres 30 litres

Standard Tank Capacity 270 litres (400 litre option) 390 litres (780 litre option) 390 litres (780 litre option)

Hose Type 1/2” 90m (300 ft) 1/2” 90m (300 ft) 1/2” 90m (300 ft)

Hose Reel Fixed Fixed Fixed

Hose Reel Control Hydraulic Hydraulic Hydraulic

Hose Feed

Inlet Hose Reel 3/4” 25m (85 ft) 3/4” 25m (85 ft) 3/4” 25m (85 ft)

Standard Drain Jets

Drain Jet Extension

Safety Leader Hose

Radio Remote

Jump Jet Kit

Anti Freeze Kit

Dry Weight (kg) * 495 634 630

Max Weight (kg) * 765 1024 1020

Dimensions (L x W x H) 1.25 x 1.20 x 1.21 1.70 x 1.00 x 1.54 1.70 x 1.00 x 1.54

???

x3

x3

x3

Included

3 Included

Optional

x3

?

4.0 Technical Specifications

09

*All weights & dimensions are approximate

5.0 Controls

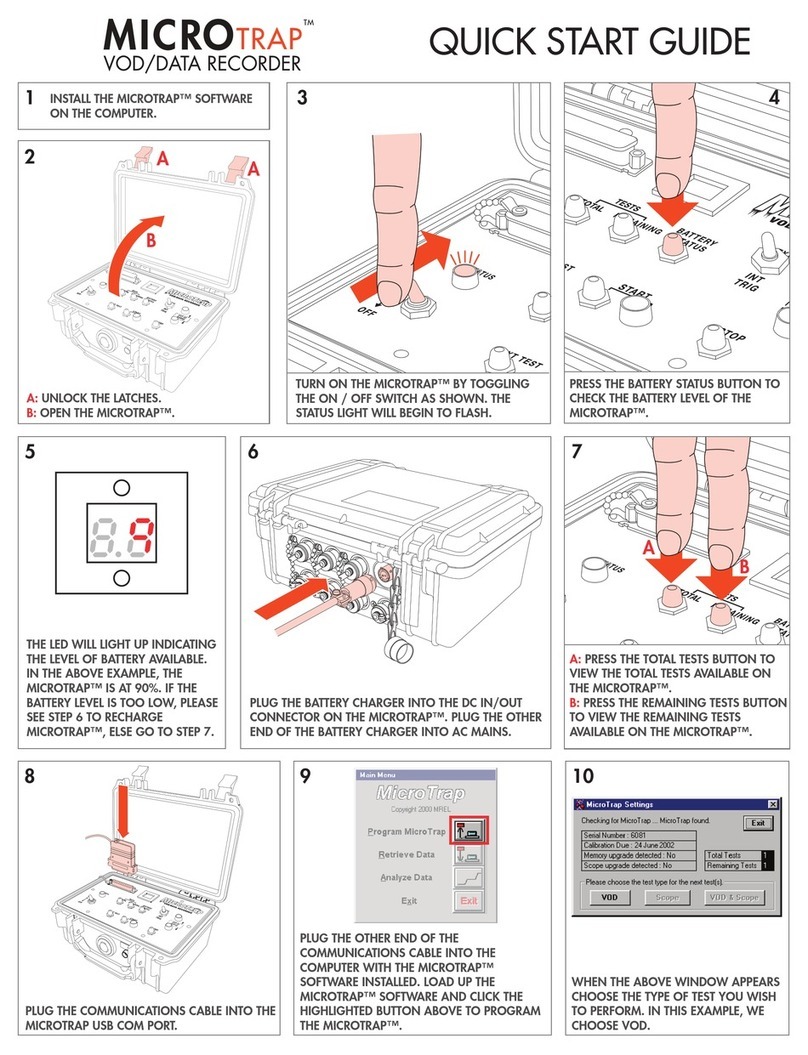

5.1 115 Series *

1 Petrol tank 9 Inlet water filter

2 Antifreeze tank 10 Antifreeze valve

3 Water tank 11 High pressure hose reel

4 Inlet hose reel 12 High pressure selector valve

5 Throttle & choke 13 Tank drain

6 Engine controller 14 Tank overflow

7 Emergency stop 15 Pressure control valve

8 Pressure gauge

*Manual controlled version shown here

11

12

3

4

5

6

7

8

9

10

12

13

14

15

5.0 Controls

5.2 200/300 Series *

1 Diesel tank 9 Inlet water filter

2 Antifreeze tank 10 Antifreeze valve

3 Water tank 11 High pressure hose reel

4 Inlet hose reel 12 High pressure diverter valve

5 Radio control unit 13 Tank drain

6 Engine controller 14 Tank overflow

7 Jump jet 15 Hydraulic tank

8 Pressure gauge 16 Hose reel control lever

*Radio controlled version shown here

16

5

4

3

6

7

1

2

8

9

10

13

11

14

15

12

11

5.0 Controls

5.3 315 Series *

1 Diesel tank 7 Jump jet

2 Antifreeze tank 8 Hose feed guide

3 Hose reel control lever 9 Antifreeze valve

4 Inlet hose reel 10 High pressure hose reel

5 Radio control unit 11 Tank overflow

6 Engine controller 12 Tank drain

*Radio controlled version shown here

1

2

3

4

5

6

7

8

9

11

12

10

5.0 Controls

5.4 400 Series *

*Radio controlled version shown here

13

1 Diesel tank 9 Inlet water filter

2 Antifreeze tank 10 High pressure hose reel

3 Water tank 11 High pressure diverter valve

4 Inlet hose reel 12 Tank drain

5 Radio control unit 13 Tank overflow

6 Engine controller 14 Pump

7 Hose reel control lever 15 Engine oil drain

8 Pressure gauge

10

1

3

2

4

5

6

7

8

9

11

12

13

14

15

5.0 Controls

5.5 Lightpack *

*Radio controlled version shown here

1 Diesel tank 9 Inlet water filter

2 Antifreeze tank 10 Pump

3 Water tank 11 High pressure hose reel

4 Inlet hose reel 12 High pressure diverter valve

5 Radio control unit 13 Tank drain

6 Engine controller 14 Tank overflow

7 Jump jet 15 Hose reel control lever

8 Pressure gauge 16 Engine oil drain

1

10

2

3

4

5

6

7

8

9

11

12

13

14

15

16

6.0 Operations

For a detailed operation guide specific to your jetter please refer to the digital manual included on the USB device

supplied with your jetter.

6.1 Daily Checks

Carry out all daily checks before you operate the jetter:

●Pump oil level

●Gearbox oil level

●Water filter cleanliness

●Engine oil level

●Fuel level

●All jets are clean and free from debris

●All jetting hoses are free from damage and

abrasion

If the jetter has been in operation for more than 100 hours,

other routine maintenance checks may need to be carried

out. For a more comprehensive guide to routine

maintenance, refer to Section 6.10.

6.2 Hydraulic Hose Reel (Optional)

The hydraulic control lever has three positions:

●In

●Out

●Freewheel (push lever fully back)

In ‘freewheel’ mode you can rotate the reel without

hydraulic power. The speed of the hydraulic motor can be

controlled with the black knob on the lever.

It is important to take note of the following points when

operating the reel:

●Never wind the hose onto the reel when it is not

pressurised. An unpressurised hose will wind

very tightly around the reel and cause the drum to

crush.

●If the hose becomes trapped in a drain you must

stop winding the reel immediately, stop jetting and

wind the hose manually. Failure to stop can result

in the hose crushing the drum, and/or the hose

being permanently damaged.

●If the hose has been wound on too tightly it must

be completely unwound and then rewound loosely

on the reel.

6.3 Pre-Start Procedure

●Park the vehicle safely on a level surface with the

engine switched off, the vehicle left in gear and with

the hand brake applied.

●Connect the inlet reel to a mains water supply and

fill the jetter tank. When full, the water will flow

through the tank overflow pipe.

●Push the hydraulic control lever (optional) to the

‘free wheel’ position and feed off enough high

pressure hose to reach the work area. Return

control lever to centre position.

●Check the emergency stop is in the out position

●Check the high pressure valve is in the OFF

position (manual machines only)

3

6.4 Starting the Engine (Manual Jetter)

If your machine is fitted with a radio remote control go to

section 6.5

●Turn the ignition key to the first position to energise.

●Once the glow plug light has switched off, or, after

approximately 5 seconds on a diesel engine, turn

the key to the second position to start the engine.

●If the jetter is fitted with a petrol engine, and you are

starting from cold, you will need to pull out the

choke while starting. Push it back in after the engine

has run for approximately 5 seconds.

●If there are any warning lights on

the engine controller switch off the

engine and consult the engine manual

supplied with your jetter. Only use a

machine with manual controls where

your risk assessment has shown that

it is safe to do so!

15

6.0 Operations

6.5 Starting the Engine (Radio Controlled

Jetter)

When operating the jetter using a radio handset it will be

necessary to “pair” the radio handset with the jetter before

the engine can be started.

●Check the E-Stop on the radio handset is released

and the handset is powered on.

●Select Remote on the jetter radio control panel.

●Turn the ignition key to the first position to

energise.

●To pair the radio handset to the jetter, hold down

buttons 7 & 8 for about 2 seconds. You should

hear a beep once the radio handset is paired and

the green handset light will flash.

Please Note: Pairing should take place within 15

seconds of switching the ignition on or else the

process will time out.

●Once the glow plug light has switched off, or, after

approximately 5 seconds on a diesel engine, turn

the key to the second position to start the engine.

●If the jetter is fitted with a petrol engine, and you

are starting from cold, you will need to pull out the

choke while starting. Push it back in after the

engine has run for approximately 5 seconds.

●You can now control the engine revs with buttons

1 & 2, and the high pressure water ON or OFF with

buttons 3 and 4.

●To stop the machine in an emergency whilst using

the radio handset, push the E-stop on the bottom

of the handset.

Please Note: The radio handset pairing procedure

will need to be repeated each time the handset or

engine ignition are switched off.

6.6 Operating the Jetter

.

An emergency shutdown can be initiated at any time by

switching off the engine with the key or pressing the

E-Stop button!

●With the engine running and high pressure water

OFF fit a nozzle to the end of the hose and tighten it

securely.

●Check the nozzle is inserted about 2m into the drain

before turning the high pressure water ON.

●Once inserted, switch the high pressure water ON

(on manual jetters) or press the water ON button on

the radio handset.

●To increase the engine speed, rotate the throttle

anticlockwise (on manual jetters) or press the

‘speed up’ button on the radio handset.

●To shut down the jetter decrease the engine speed

and switch the high pressure water OFF (on manual

jetters) or press the water OFF on the radio handset.

Please Note: It is possible to use radio control

machines in ‘local’ mode by selecting ‘local’ on the

machine radio control panel and using the local

control buttons appropriately.

6.7 Using a Pressure Control Valve

If the jetter has been fitted with a pressure control valve you

can adjust the jetting pressure independently of the engine

revs.

Please Note: To avoid stalling it is advisable to run

the engine at a minimum of 1/2 full speed.

●Before starting, check the pressure control valve is

wound out to avoid any sudden pressure increase.

●Start the jetter as described in Sections 6.4 /6.5.

●With high pressure water ON, wind in the pressure

control valve to increase the pressure.

●To shut down the jetter decrease the engine speed

and switch the high pressure water OFF (on manual

jetters) or press the water OFF on the radio handset.

Unwind the pressure control valve.

!

!

!

!

6.0 Operations

17

6.8 Using a Gun

6.8.1 Dump Style Gun

A dump style gun has two barrels. When the trigger is

pulled, water comes from the main barrel, through a jet, at

high pressure. When it is released the water is dumped

safely through a secondary barrel at low pressure.

6.8.2 Dry Shut Gun

A dry shut gun must only be used when an unloader valve

is fitted to the jetter. When the gun trigger is released the

water is diverted through the unloader valve and back to

the jetter tank.

If you do not have an unloader valve fitted when using a

dry shut gun you will cause serious damage to your jetter,

as well as possible serious or fatal injury to the operator.

When working with a gun always consider using a safety

shroud to provide the operator with greater protection in

the event of a burst hose.

Please Note: After turning off the jetter always

point the gun at the ground and pull the gun trigger

to safely release any trapped pressure.

6.9 Frost Precautions

Attempting to use a frozen jetting machine can

lead to ice pellets being ejected from the hose at

high speed with risk of serious injury or death!

It is recommended that during cold periods in the weather

you run antifreeze throughout your jetter including the main

jetting hose. If you suspect your jetter has frozen then you

should not attempt to start it. This can cause serious

damage to your equipment resulting in costly repairs.

Flowplant jetters can be fitted with an antifreeze kit as an

optional extra.

To antifreeze the machine:

●Drain the water tank

●Check your antifreeze tank is full with a 50/50

antifreeze mix

●Wind off a few meters of hose and remove any jet or

other accessory from the end

●Turn the antifreeze valve into the ‘Antifreeze’

position. This will close off the main tank and

instead feed the pump from the antifreeze tank

●Start the jetter and immediately switch to pressure

ON (on manual jetters) or press the ‘water on’ button

on the radio panel.

Please Note: If you allow the jetter to run on

dump all of the antifreeze will be diverted to the

main tank and will be wasted.

●Pointing the hose towards the ground and running

the engine at low speed, flush all the fresh water out

of the hose

●As soon as the antifreeze mix comes from the hose

switch off the jetter ignition.

To de-antifreeze the machine:

●Fill the water tank

●Move the antifreeze valve to the ‘run’ or ‘main tank’

(depending on jetter) position

●Put the end of the main jetting hose into the

antifreeze tank

●Start the jetter and fill the antifreeze tank

Please Note: Start the jetter and immediately switch

to pressure ON (on manual jetters) or press the

‘water on’ button on the radio panel.

●Switch to pressure OFF (on manual jetters) or press

the “water off” button on the radio panel when the

antifreeze tank is full.

●Switch off the jetter ignition.

Please Note: Regularly check the antifreeze

strength during cold weather periods.

Please Note: Flowplant suggests the use of

propylene glycol type antifreeze because it is less

damaging to the environment. Under no

circumstances should any antifreeze mix be

disposed of into the sewer system or be allowed to

enter any water courses.

!

!

!

!

!

6.0 Operations

6.10 Routine Maintenance

We recommend that maintenance be carried out by a recommended service agent. Maintenance should only be carried

out with the engine turned off and when cold.

Frequency Action

Daily ●Check inlet water filter element

●Check engine oil level on dip stick

●Visual check for hose damage/water leaks

●Check emergency stop button operation

Weekly / 24 Hours ●Visually inspect van pack for security, checking for any loose, damaged or missing

parts

●Check air filter cleanliness

●Check engine fuel filter for contamination

3 Monthly / 50 Hours ●First service contact Flowplant

●Replace pump oil (only required for first service only)

6 Monthly / 100 Hours ●Inspect tanks and fittings for leaks

●Tighten any loose joints

●Check condition of 12 volt start battery

●Grease battery terminals for protection

Yearly / 200 Hours ●Intermediate service of engine, gearbox and pump required (contact Flowplant)

●Closely inspect the structural integrity of the framework for signs of stress and

cracking

●Carry out detailed inspection of pipes, hoses and fittings

●Check unloader valve operation

2 Yearly / 400 Hours ●Major service of engine, gearbox and pump required (contact Flowplant)

●Check wiring terminals/connections and continuity of electrical earth

7.0 Fault Finding

19

7.1 Engine Faults

Problem Possible Cause Recommended Action

Engine shutdown Low oil pressure Check and replace switch if faulty

Check oil pressure, if pressure is low refer to

engine handbook

Coolant temperature Check and replace switch if faulty

Check water temperature in radiator, if very hot

refer to engine handbook

Emergency stop in Twist to release

Low engine charge Check alternator belt tension

Check terminals on alternator

Check engine idle speed, reset if necessary

Refer to engine handbook

7.2 System Faults

Problem Possible Cause Recommended Action

Low system pressure

Worn or incorrect size of

cutting nozzle

Replace the old jetting nozzle with a new one

Engine speed slow Adjust to correct speed

Leaks from hose, pipes and connections Check the connections for tightness, replace if

needed

Blocked inlet filter Clean or replace element

Inlet hose too long Shorten hose length

Loss of water through dump line of selector

valve or gun when high pressure selected

Check seats and seals

Loss of water through dump line of remote

control kit, if fitted

Check seats and seals

High system pressure

Blocked nozzle, selector valve or gun Clean the items and flush out the delivery line

Incorrect nozzle size Replace the nozzle

Incorrect hose bore size Replace the hose

Engine speed high Adjust to correct speed

Crushed delivery hose Replace if necessary

Two gun choke left in gun when operating

as single gun unit

Replace with standard choke

Low water level

Blocked or dirty pre-filters Clean or replace elements

Faulty ball valve assembly Replace if necessary

Wrong seat in ball valve assembly Replace the seat if necessary

Low inlet pressure Increase pressure

Problem Possible Cause Recommended Action

Pump not running

evenly (refer to pump

manual)

Air in water Water bleed pump

Air in crankcase oil Oil bleed pump

Worn drive coupling Replace flexible elements and examine coupling

Faulty inlet or delivery valve Check valve condition

Valve nut over tightened Check tightness of inlet & delivery nut

Burst disc failure or

safety relief valve

operating (also refer

to high system

pressure problem)

Incorrect burst disc Replace with correct disc

Incorrect valve setting Check certificate/setting

Faulty valve Repair or replace if required

Faulty or fatigued burst disc Replace with new disc

7.0 Fault Finding

7.2 System Faults (continued)

7.3 Useful Links

●www.flowplant.com

●www.lombardini.co.uk

●www.yanmar.com

●www.engines.honda.com

●www.speck.co.uk

●www.interpump.co.uk

●www.waterjetting.org.uk

This manual suits for next models

5

Table of contents

Popular Other manuals by other brands

BW Broadcast

BW Broadcast DSPXmini-FM Operational manual

FAAC

FAAC 620 SR Series user guide

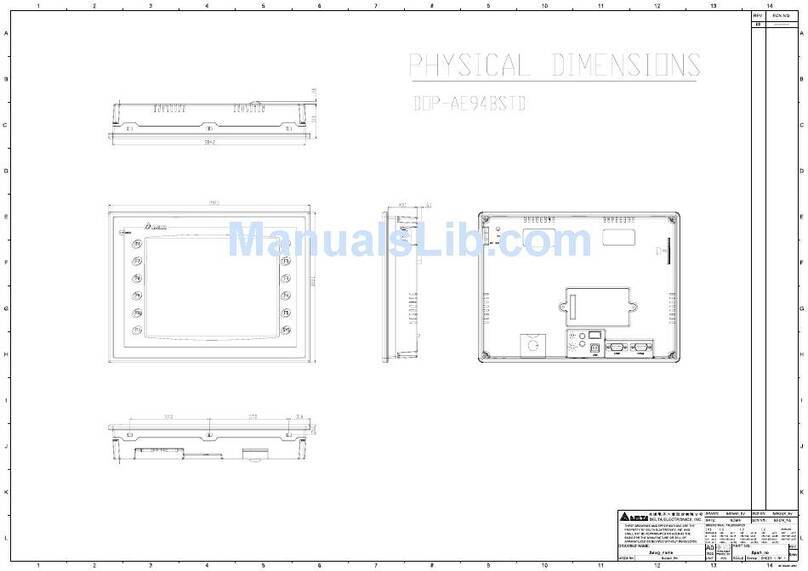

Delta Electronics

Delta Electronics AE94BSTD Specifications

LAMBORGHINI

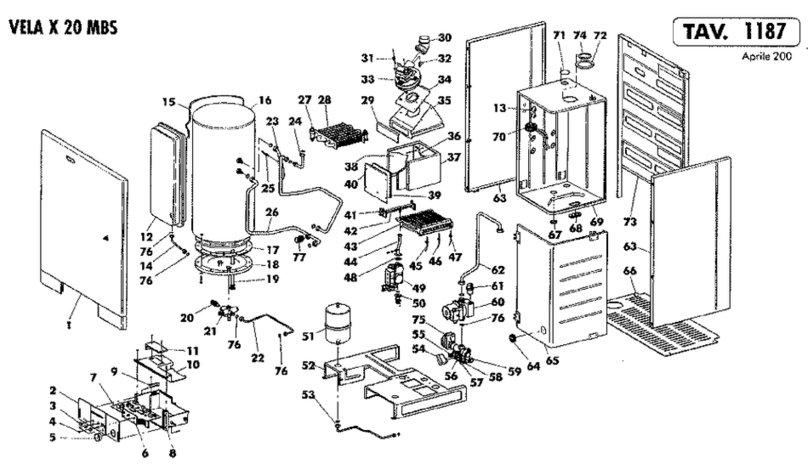

LAMBORGHINI VELA X 20 MBS - SCHEMA manual

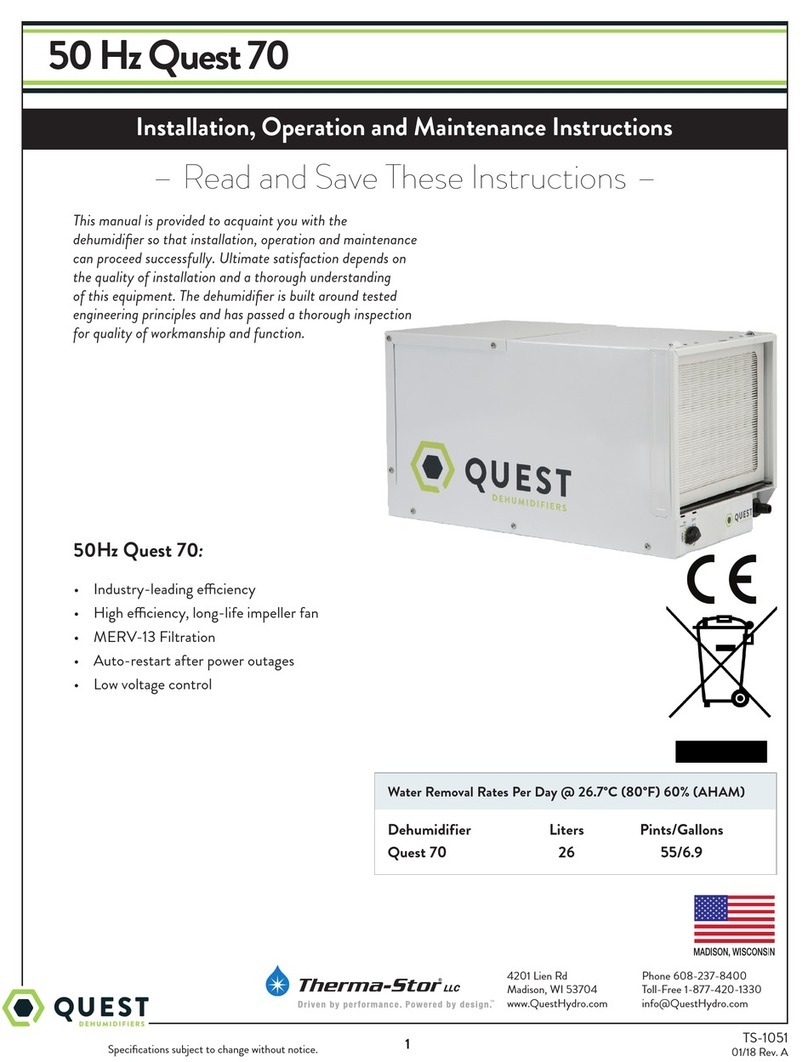

Quest Engineering

Quest Engineering 70 Installation, operation and maintenance instructions

kincrome

kincrome K7745 Operation manual