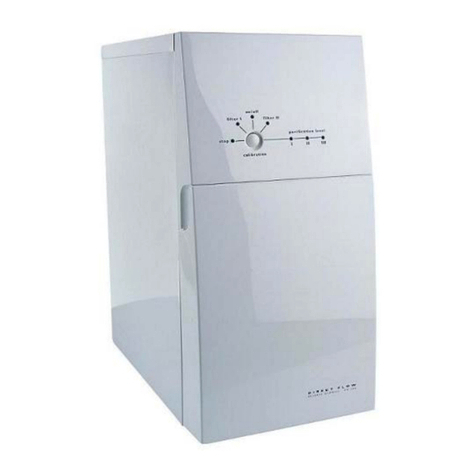

Fluidart Pinnacle User manual

OWNER’S MANUAL

Pinnacle

Filter

by Fluidart®

Congratulations on making the smartchoice!

Fluidart Technologies filtration systems are designed

with the pond owner in mind. Our filtration systems

are unparalleled in quality, performance, ease of

operation, and maintenance. We are certain that you

will have many years of happy KOI keeping with our

system.

Contact us at info@fluidart.com or phone 1-888-499-3852

or 405-843-9060

Fluidart Technologies

Bead Filter

Owners Manual

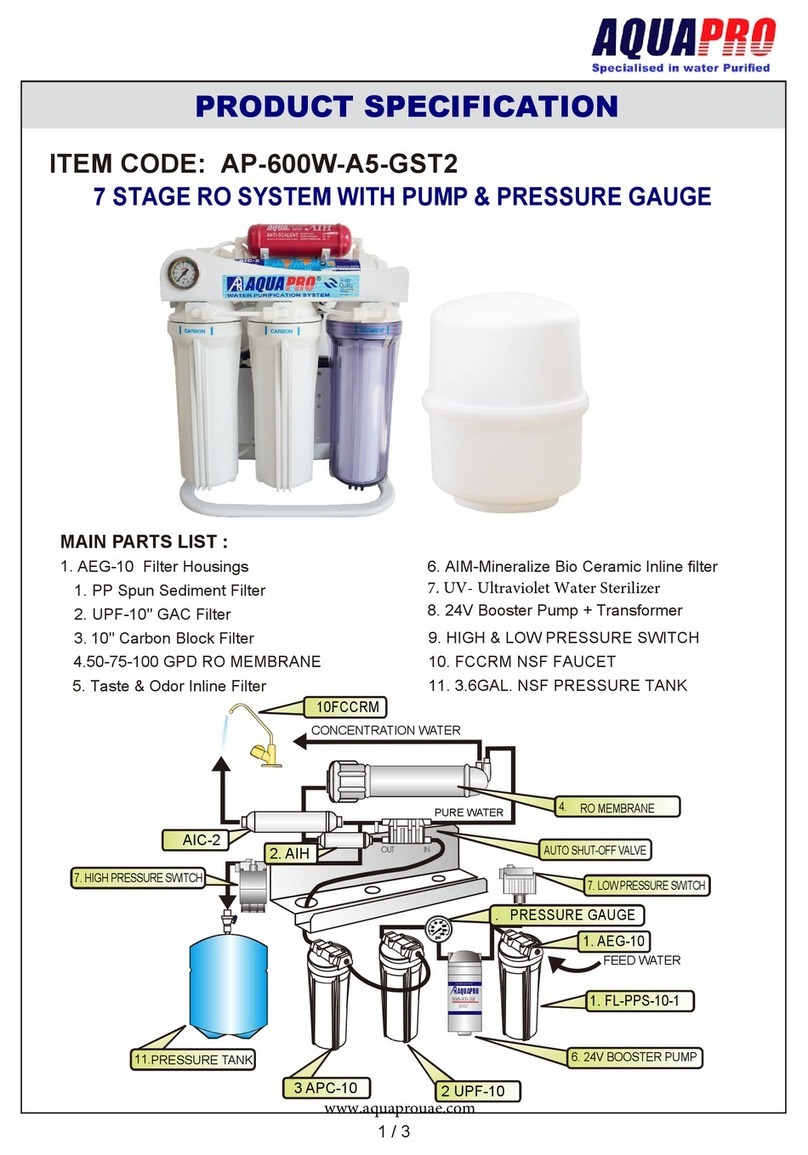

Challenger Internals

Laterals

Bead Pack

Sludge Drain

Multiport

Valve

Spinner And

Backwash

Laterals

Drain Plug

Pump

Filter

Vortex

Tank

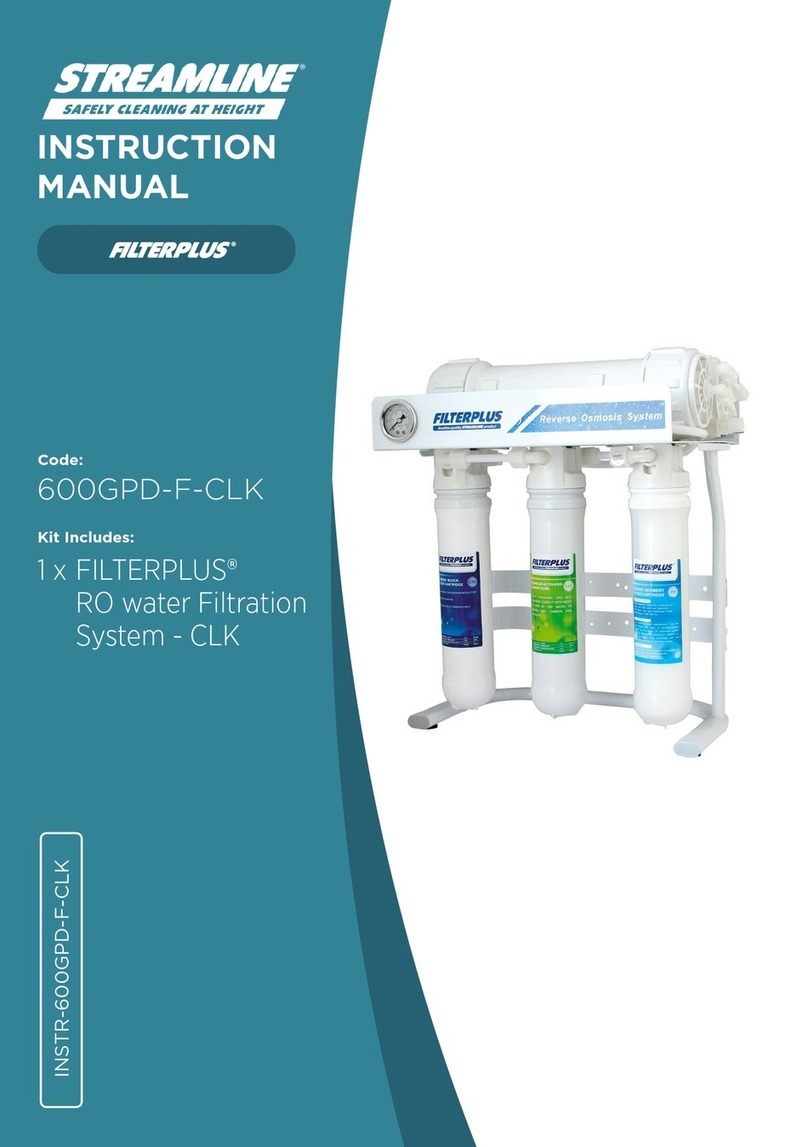

Suggested installation of

Fluidart Filtration System

Swing check valve installed below water

level in an easily accessed location will

make keeping the pump and Turbovortex

primed much more easy.

Swing check

valve

Introduction to Bead Filtration

How long have bead filters been in use?

Bead filters have been around since the mid-70's and got their start

In the food fish industry. Bead filters have been tested at various universities

around the country, including Louisiana State University and Langston

University in Oklahoma. In these tests, bead filters out performed

other filtration systems, when considering both biofiltration and clarification.

What is the theory behind bead filter operation?

Bead filters accomplishtwo goals, one being water polishing (solids capture) and the other being

biofiltration. Other filtration systems accomplish these goals, but are muchlarger and more difficult to

clean. The advantage of the bead filter is that it

provides a home for beneficial bacteria with high surface area for a large colony

per cubic foot and fine particulate straining all within the same vessel. The other

big advantage the bead filters have over other types of filters is that they are much

easier to clean. This makes the hobby of KOI or pond keeping much more

enjoyable, with less work involved in maintaining a healthy environment for the

fish.

How does a bead filter perform Mechanical Filtration?

Mechanicalfiltration or clarification is the process of removing suspended solids

from water. Suspended solids in arecirculating system are generally smallparticles

of undigested food, bacteria, andalgae. These solids tend to reduce the clarity of

water and cause problems in consuming tremendous amounts of oxygen, also needed

by our beloved fish. Bead filters remove solids fromwater by different mechanisms.

Physical straining is probably the most dominant mechanismremoving larger

particles (>50 microns). Finer particles (<20 microns) are removed at a lower rate

by a process called bioabsorption. The particles are capturedby bacterial biofilm

on the surface ofthe bead. Studies show that bead filters capture 100% of particles

>50 microns and48% of particles in the 5-10 micron range per pass. The more

passes the more solids captured.

**Important**in order for the bead filter to perform FINE micronstraining it

MUST be fully colonized with bacteria. Depending on the temperature this can

take up to 4-6 weeks, at temps. above 60-65 degrees F.

How does a bead filter perform Biofiltration?

Biofiltration depends on the establishment of a colony of bacteria on the surface of

the beads large enoughto convert dissolved toxic nitrogenous waste to harmless

compounds. When the bacteria are given the proper environment, they grow in a

thin biofilm on the surface of each bead. Each cubic foot of beads contain about

600,000 beads. This is one of the secrets of the beadfilters success--high surface

area per cubic foot for a large bacterial colony per cubic foot of filter media. The

two most commontypes of bacteria are, Nitrosomonas which is responsible for the

break down of ammonia in the system. The next is Nitrobacter, which is responsible

for the breakdown ofnitrite into relatively harmless nitrate.

**Important** in order for the bead filter to perform Biofiltration the beads

must be colonized with alarge enough colony to handle the load of dissolved

ammonia presented to it. This may take up to 4-6 weeks at temps. above 60-65

degrees. Until the colony has grown large enough, the pond owner MUST be

responsible for monitoring the levels of ammonia and nitrites in the pond water and

taking appropriate measures to correct dangerously high levels.

How do you size a bead filter?

When we start talking bead filter size, usually the first thing said is "I have a ___

gallon pond. What size filter do I need?" This just gets the conversationrolling.

The next question should be, "How many fish do you plan to keep in the pond?".

Fish have to eat and what it really boils downto is how many pounds of food is the

pond keeper going to feed per day. The larger the fish load and the more food that

will be fed, the larger the filter needs to be. A good rule of thumb when dealing

with bead filters is this: 1cu. ft. of beads will handle the solids capture and

nitrificationof up to one lb. of foodper day. 100lbs offish fed at 1% body weight

or 50lbs of fish fedat 2% body weight. This is feeding 35% protein food. Water

quality and clarity can be achieved by adjusting feeding rates and/or stocking

densities.

What pump do I use with my filter?

Almost any out of pond pump will work witha FLUIDART FILTER. 2 speed

pumps have proven to be favorites among many bead filter owners. 2 speed pumps

have the versatility of running onlow for normalfiltration and saving energy

dollars, while using high for backwashing. High is also great to have when you are

having friends over andyou want your waterfallto really roar!

Pinnacle Filter

Installation Instructions

1. Remove the filter fromthe box and locate the plastic bag containing the top cap

and open wrench.

2. Inspect the internals for any shipping damage. You will note that there are

plastic zip lock bands on the internals to hold them in place during shipping.

Cut and discard these as they are not needed.

3. Position the filter at the site of installation. Be sure that this is a level site with

full access to all sides of the filter, as you will need to use the sludge drain on a

regular basis and may eventually need to use the tank drain valve. We also

recommend that the filter be installed on a pad of some type to prevent settling.

4. Attach the multiport valves. Be sure that the "O" rings of the valve are properly

positioned. ** Important ** Hand tighten the unions, do not use a wrench as

you may over tighten the union and crack the outer ring.

5. Make pipe connections. The pressure (pump) line, returnline, and the waste line

connections are clearly labeled on the valve. **Important** Installa swing check

valve on the suction line from the pond to the pump. Install this below water

level and you will have much less trouble priming your pump. See ideal

installation diagram at the front of the manual. We also recommend that the

Wastewater is plumbed away from the site to prevent settling from moist

ground.

6. Fill the tank about one half full of water. Now pour the beads into the tank from

the top opening. When all the beads have beenplaced in the tank, screw the top

cap into place and tighten with the wrench provided.

7. Set the multiport valve to the filter position and open the air relief valve at the top

of the filter. Turn onthe pump and when water sprays out the air relief valve,

close it. Your filter is now operational.

8. Insert the section of PVC pipe that came with the filter into the upper union of

the spring check valve for the blower attachment. Glue this union. Then slide the

blower down onto the pipe and secure with setscrew. (Do Not Glue). When you

turn on the blower, the spring check valve will open, allowing pressurized air to

enter the filter tank for bead agitation. Only one multiport will come with a

blower attachment and can be attached to either set of bulkhead fittings.

* Special note * When lubricating connections, gaskets, or valves, use only silicone

based lubricants. Do Not use petroleum-based lubricants. Magic lube works well

and can be obtained at most pool and spa stores.

Pinnacle Filter

Operating Instructions

Now that your filter is installed and running there are a few simple things that you need to

know and understand.

FILTER MATURATION

This has been stated earlier, but is very important. It takes 4-6 weeks of operation at

temperatures above 60-65 degrees F. before there is a large enough colony of bacteria to

handle the bioconversion of ammonia and fine particulate straining. During this transition

period, the pond owner must watch the ammonia and nitrite levels in the pond. If they

become dangerously high, steps should be taken to correct the problem, such as a water

change. Also during this period fine particulate straining will not be fully mature and you

may notice your water being less polished than you would like. Both of the above issues will

improve with time and the growth of the bacterial colony. This will occur with any type of

bead filter used.

ULTRAVIOLET LIGHT STERILIZERS

Bead filters will remove suspended particles down to 5-10 microns in size.

However, some algae particles are smaller than 5 microns and will not be removed by the

beads. These tiny algae cells will give the water a green cast and affect the clarity of the

water. If the pond owner wants crystal clear swimming pool clarity, then a UV-light is

needed. UV-lights will also remove many harmful bacteria and decrease the suspended

bacterial counts in the water. We recommend the use of UV-lights for the above reasons.

BACKWASH INSTRUCTIONS

When you first start up your filter, we recommend that you let it run for two weeks before

you perform your first backwash. After that, once a week during the warm season should

be all that is needed. During the winter months backwashing can be reduced to as little as

once every 2-3 weeks. To perform a backwash, do the following:

Pre-Backwash Instructions

1. Open Sludge Drain for 15-20 seconds with Pump ON, then close drain.

2. Turn Pump OFF.

3. Turn Multiport to Backwash position.

4. Turn Pump ON for 10-15 seconds.

5. Turn Pump OFF.

Backwash Instructions

1. Move Multiport to Rinse position.

2. Turn the blower on for 1-2 minutes.*

3. Open Air Relief valve.

4. Turn Pump ON for 10-15 seconds.

5. Turn Pump OFF.

6. Move Multiport to Backwash position.

7. Turn Pump on until water runs clear.

8. Turn Pump OFF.

9. Repeat Steps 1-8 as needed.**

* While the blower is agitating the beads you should be able to hear the beads hitting the

inside of the tank. It should sound like individual beads ad not clumps. Running the

blower longer than 1-2 minutes at a time can cause overheating and damage the blower.

Note: Never run blower and pump at the same time.

** To achieve a thorough backwashing, you may need to repeat steps 1-8 several

times.Note: Be aware that large fluctuations in water temperatures from replacing too

much water too quickly can cause stress and/or death in fish.

Post Backwash Instructions

1. Move Multiport to Rinse position.

2. Turn Pump ON.

3. Open Sludge Drain until water runs clear.

4. Turn Pump OFF.

5. Move Multiport to Filter position.

6. Turn the Pump ON.

7. Add Dechlorinator to Pond as needed.

WATER MISER SLUDGE DRAIN.

The Water Miser Sludge drain allows a low volume backwash if water is expensive, in short

supply, or you have a low volume pond. To use your Water Miser Sludge drain, do the

following:

1. Turn off your pump and move the Multiport valve to the rinse position.

2. Turn on the blower and allow it to run for 2-3 minutes. Now open the Water

Miser Sludge drain valve with the blower running. You will notice water

being forced out of the sludge drain. Allow the blower to evacuate all the

water from the tank.

3. Now turn off the blower, close the sludge drain valve, and open the air release

valve at the top of the filter. With the multiport valve still in the rinse

position turn on the pump. You will be filling the tank with water at this point

and you will notice air rushing out of the air release valve at the top of the

tank. Whenwater exits the air release valve then the tank is full. Now turn

off the pump.

4. The tank is again filled with water. Now repeat steps #2 and 3 above. This

will agitate the beads and force the dirty water out of the tank. You can

repeat this step as many times as you would like. You are using only the

volume of the tank minus the volume of the beads to wash the beads each

time. This will use much less water than a hydraulic backwash.

5. When you are done with the above steps, fill the tank as above and do a rinse

on the beads. Run the water until clear and then go back to filter mode. You

are done and save many gallons of water.

*Note* If you leave your filter unbackwashed for two or more weeks, it is a

good idea to perform an extra long blower treatment on the beads.

*Word of Caution* If you leave you filter unbackwashed for extended periods of

time, and you live in an area with relatively soft water, you may want to buffer

your pond water. The bacteria in the filter can consume enough alkalinity in the

waterto cause a dangerous pH drop. Total alkalinity should be kept above

80ppm to avoid these potentially dangerous shifts. To increase alkalinity, add

sodium bicarbonate, do a water change, or add a commercially prepared pH

Buffer.

INTERNAL INSPECTION

We recommend that twice a season you inspect the output laterals, backwash

laterals, and the condition of the beads.

1. Backwash your filter then turn off the pumps and leave the valve in

the backwash position. Also open the sludge drain valve and the drain

plug at base of the filter.

2. Open the air release valve at the top of the filter. You will notice air

rushing into the filter. This represents water draining out of the filter.

3. When air stops being sucked into the filter, most of the water has

drainedout of the filter. Using the Hexagonal wrench that came with

the filterunscrew the top cap and remove.

4. Now inspect the beads. Do they look clean after the backwash? Are

thereareas of caked beads? If you find areas of dirty beads or caked

beads, you may need to adjust the length of time that you use the

blower, or increase the backwash time, or possibly the backwashing

frequency. If you find caked beads, now is the time to break them

apart. Using your hand or a stick, stir the beads and break up any

clumps that you might find.

5. Wipe any beads stuck to the output laterals off and inspect them.

Make sure that they clear of any obstructions. If there is material

inside the laterals, they can be unscrewed and removed. A baby bottle

brushcleaner works well for removing internally trapped solids.

Replace whendone.

6. Next, inspect the backwash laterals. They will need to be removed.

This can be done by pushing the output laterals at the top of the filter

to the side and reaching down in the filter and unscrewing the union

that holds the backwash lateral in place. When loose inspect them for

debris. Clean if needed then replace when done.

7. Replace the top cap using the wrench and make sure that it is secure.

Pay attention to the position of the air release valve so that it is

pointed in the direction you wish.

8. When the top cap is back on, with the air release valve open, move

the filter valve to the Filter position and turn on the pumps. When

water comes out of the air release valve, close the valve and

perform another backwash and rinse cycle before going back to

filtration. Now your done.

MEDICATING YOUR POND

Sometime during your career as a pondkeeper you may need to medicate

your pond with chemicals that will harm the bacterial colonies on the filter

media. To insure that they are not damaged follow these simple steps:

1. Do a good backwash on thefilter then turn off the pumps.

2. Move the valve to the "recirculate position". This will cause the

waterto bypass the filter while your treating your pond. Turn your

pumps back on.

3. Open the sludge drain at the bottom of the filter and then the air

release valve at the top of the filter. Water will start draining out of

the filter without loss of any beads. The bead pack will now be

surrounded with air instead of water. This will prevent any bacterial

loss from lack of oxygen. The beads will stay moist for several days.

4. When the medication period is over, close the sludge drain, but leave

the air release valve open. Turn off the pumps and move the handle

to the filter position. Now turn on the pumps. You will notice air

"whistling" out of the air release valve as the tank refills with water.

When watersprays out of the air release valve turn off the pumps. Do

a quick backwash and rinse, then go to filter mode.

*Note* Depending on the chemicals used, it is advisable to do a 50%

water change before starting the filter back up. Check with your dealer.

WINTERIZING YOUR FILTER

If you live in an area where you experience hard freezing, you may decide to

shut your filter down for the winter. Do the following:

1. Do a good backwash of the filter. Move the multiport valve to the "winter"

position.

2. Turn off your pumps and open the drain plugs on the pump strainer basket.

3. If you have a Turbovortex on your system, open the drain plug at the base of

the filter and open the priming cap, to drain water from the tank. Loosen all

connections so that any remaining water can drain out.

4. Open the drain plug at the base of the filter and then the air release valve at

the top of the filter. Water will drain out of the filter, but no beads will be lost.

5. Loosen all connections and drain exposed pipes, so that no water will be

trapped. This is especially important for your UV lights!

In the Spring:

1. Tighten all the connections that you loosened in the Fall.

2. Close the drain plug on the Turbovortex and the pump strainer basket. Fill

the Turbovortex half full of water. Replace the Bio-Balls and replace the lid

being careful to not over-tighten the lock ring. Prime the Turbovortex and

the pump strainer basket. When full close.

3. Move the multiport valve to the filter position and open the air release valve

at the top of the filter and close the sludge drain. Turn on the pumps. When

water comes out of the air release valve at the top of the filter, shut it and

turn off the pumps. Now do a good backwash and rinse before going to

the filter mode.

*Note* The bacterial colony on the beads in the filter will take some time to get

back up to full capacity. During the first few weeks of operation in the spring, it

is a good idea for the pond owner to do frequent checks of the ammonia and

nitrite levels.

Trouble Shooting

Decrease in water flow

1. If you notice that your waterflow is decreasing the most likely cause is that

the filter needsto be backwashed. The bead filter is designed totrap solids

and does it very well. When fully loaded with solids, the filter may restrict

flow. Perform a backwash and rinse.

2. If after backwashing the filter the water flow is still low, next check the

strainer basket on the pump. Be sure that it is clean and replace.

3. If you have a TURBOVORTEX on your system. Perform a backwash.

Pay attention to the amount of water flow available while backwashing the

TURBOVORTEX. This water is coming straight from the pond. If there is

little flow, then you have a supply problem, meaning that the bottom drain,

return line, or the skimmer is in need of cleaning. If these are clean and clear

then check the impellers on the pump to make sure that there are not any

objects trapped that would decrease their rpm. Ifthere is plenty of flow

while backwashingthe TURBOVORTEX, then the flow restriction is after

the pump.

4. If flow is still low after backwashing the TURBOVORTEX and there was

plenty of flow through thepump, then youneed to inspect the internalsof

the filter.

Check to see if the laterals are clear of obstruction and that the beads are not

caked into large clumps. When the bead pack gets "gelled" they are hard to

break apart with backwashing and doing ablower treatment. They may

need to be manually broken apart. When the beadsare gelled they tend to

cause "Channeling,” which means that the bead pack is totally clogged and

water will follow paths of little resistance through or around the bead pack.

When channeling is occurring you will notice that after backwashing the

filter quickly clogs and flow slows in intervals that used to take 1-2 weeks,

now flow slows in 2-3 days. Follow the directions in theinternal inspection

section of the filter operation section of the manual.

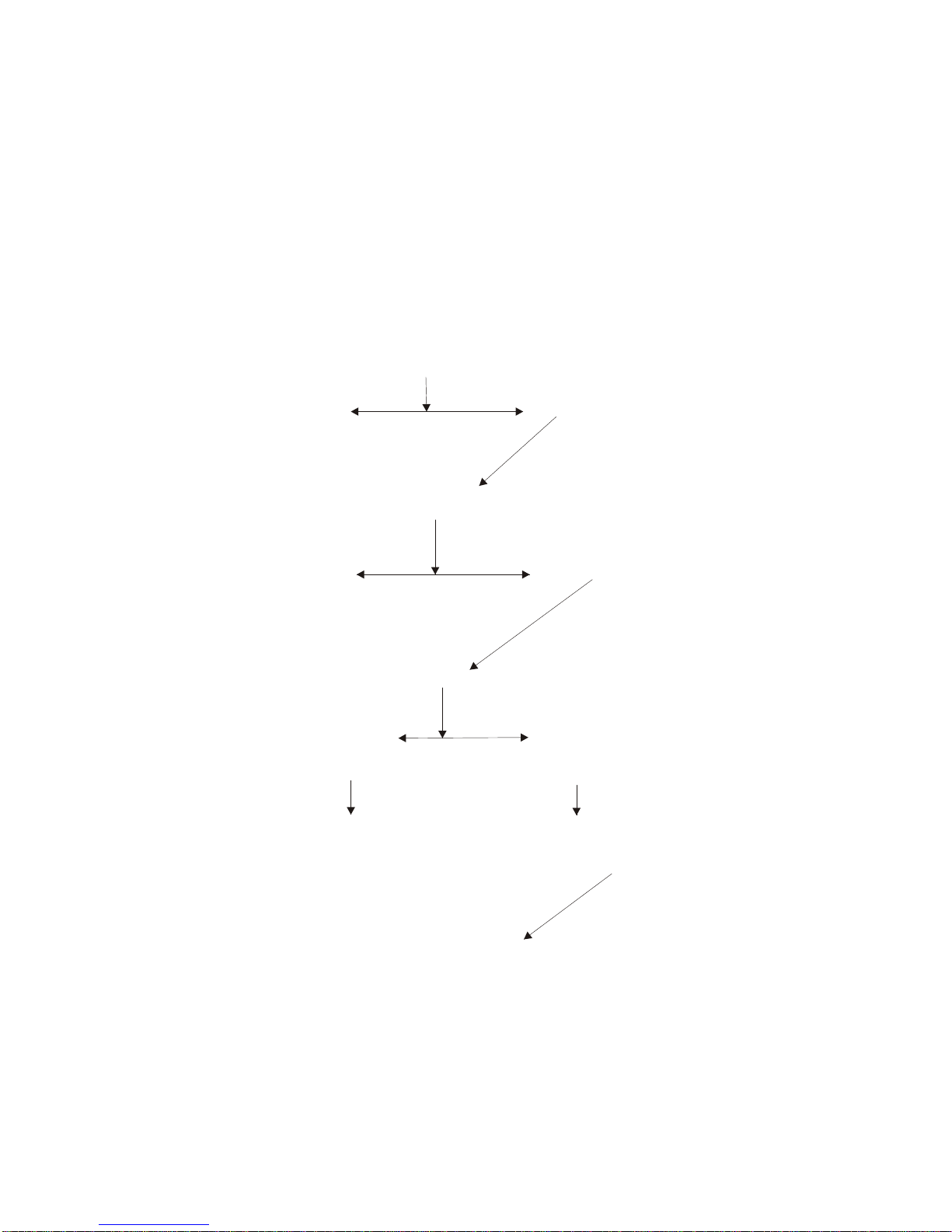

Trouble Shooting

Decrease in Water Flow

Backwash

Normal Flow Flow Still Low

ProblemSolved

Clean Pump

Strainer Basket

Dirty-Cleaned Clean -Flow Still Low

Normal Flow

ProblemSolved

Backwash the TURBOVORTEX

Good Flow through Low Flow through pump

pump while backwashing. while backwashing.

Flow still low Flow still low

Flow restriction after pump Flow restriction before the pump.

-inspect the internals of the -check bottom drain, return

filter and condition of the line, skimmer, and pump

beads. impeller.

Flow Still Low

Call Us -1-888-499-3852

5. If you follow the above steps and yourflow is still low, PLEASE, call us at

1-888-499-3852

6. See the following page fora quick flow chart of the above directions

Trouble Shooting

Decrease in water Clarity

1. If your filter hasa mature bacterial colony, which could take up to 4-6

weeks at temps. above 60-65 degrees F., and your water quality and clarity

have been good then decreases, the first thing to do is a good backwash and

rinse. Spend an extra amount of time with the bloweragitation of the beads.

2. If you clarity does not improve orimproves then decreasesquickly, open

the filter and inspect the internalcondition of the laterals and the beads. If

the beads are gelled and channeling is occurring, then the water will bypass

most of the bead pack and no mechanical filtration will occur. Manually

break up the beadsand make sure the laterals are clear of obstruction.

3. If your water clarity does not improve, and you have UV-lights on the

system, checkto see if the bulbsare stillworking. Dependingon the bulb,

some UV-light bulbs will only have killing powerfor sixmonths of continuous

run. Others will last for a year or more. Check to see when they were last

changed and replace if needed. They should be changed at least once a

season.

4. If your clarity does not improve, check the water flow out of the system.

The entire pond watervolume should be turned overthrough the filter

system at least 3-4 times per day. If turn overtime is slowthen the amount

of solids that the filter can capture will decrease. Check to make sure that

there are no flow restrictions. Follow the low flow trouble-shooting chart.

Also make sure that your pump islarge enough to move the amount of water

needed for enough turn oversthrough the filter.

5. If after following the above suggestions and the clarity is still off, PLEASE

call us at 1-888-499-3852 or your dealer.

Trouble Shooting

Decrease in Water Clarity

Backwash

Water Clarity Water Still

Improves Cloudy

ProblemSolved

Open Filter-

Clean laterals, Stir Beads

Backwash and rinse

Water Clarity Water Still

Improves Cloudy

ProblemSolved

Check UV Lights

Replaced Bulb Lights Okay

Water Clarity Water Still Cloudy

Improves

ProblemSolved

Check Water Flow

See Decrease Flow Chart Flow Normal

Flow Improves andClarity Water Still Cloudy

ProblemSolved

Call Us at 1-888-499-3852

Trouble Shooting

High Ammonia and Nitrite with previously stable state

If your pond hasbeen up and running at warm temperatures (60-70 F) for

six or more weeks and your ammonia and nitrite levels have been previously

controlled, but you experience a spike in the ammonia level try the following:

1. Perform an extra long blower treatment on the bead pack and an extra

long backwash. If the bead pack becomestotally clogged with solids, the

available surfacearea for bioconversion drops significantly. Backwashing

will open up the active surfacearea and bioconversion will resume.

2. If after backwashing the ammonia levels are stillhigh, open the filter.

Check the laterals to make sure they are clear, stir the beads to break up

any gelled areas and then backwash.

3. If ammonia levelsare still high, consider how much food is being fed to

the fish. One cubic foot of mature beads can handle around one pound of

35% protein food per day. Check to see how many cubic feet of beads are in

your filterand compare that with howmuch food yourfeeding.

4. If ammonia levelsare still high, check the flow rate through the filter.

The entire volume of the pond should be turned overthrough the filter 3-4

times per day. If the flow isdown for some reason, bioconversion of

ammonia will alsoslow. If you find the flow is in fact down, follow the

troubleshooting flow chart for correcting low flows.

5. If all the above are found to be in good condition, consider the fish load on

the pond. This actually also relates to the above discussion about amount of

food fed. If you have a heavily stocked pond you willalso be feeding more to

the fish and thus adding more nitrogen to the pond waterthat will have to be

bioconverted. Again, consider your filtersize and what your asking it to do.

6. If the ammonia levels are still high, call us at 1-888-499-3852

Trouble Shooting

High Ammonia and Nitrite-- Previously Stable

Backwash Filter

Decrease Ammonia Ammonia Still High

ProblemSolved

Open Filter

Check Laterals and

Stir Beads then Backwash

Decrease Ammonia Ammonia Still High

ProblemSolved

Check Amount of Food Fed

-1lb. Food/cubic foot beads

Too Much Food Food Amount Okay

Amount Reduced

Ammonia Decreased

ProblemSolved

Check Water Flow

See Decrease Flow Chart Normal Flow

Flow Down-Solution Found Ammonia High

Ammonia Decreases

ProblemSolved

Too Many Fish or

Too Many Big Fish?

Pond Over Stocked Pond Not OverStocked

Numbers reduced Ammonia Still High

Ammonia Decreases

ProblemSolved

Call us at 1-888-499-3852

Table of contents

Popular Water Filtration System manuals by other brands

Watts

Watts E-Treat ETREATWCS Installation, operation and maintenance manual

Dometic

Dometic RO400 User instructions

deconta

deconta C 25 L operating instructions

Astral Pool

Astral Pool Combo 27413 Instruction and operation manual

AQUA EL

AQUA EL DEKOR Operation manual

Aqua Guard

Aqua Guard Invisipure user manual