Fluidwell F1-A-PD-OS Series User manual

F1xx-A-PD-OS

INDICATORS WITH ANALOG SENSOR INPUT

WITH HIGH / LOW ALARMS

ADDENDUM / INSTALLATION GUIDE

FOR MODELS F113-A, F170-A AND F173-A

FOR TYPE PD-OS:

- 4 MECHANICAL RELAY OUTPUTS

F-Series - Field mounted indicators for safe and hazardous areas.

More info: www.fluidwell.com/fseries.

FW_F1xxAOS_v1702_03_EN (addendum).docx

Page 2

SAFETY INSTRUCTIONS

▪Any responsibility is lapsed if the instructions and procedures as described in this

manual are not followed.

▪LIFE SUPPORT APPLICATIONS: The F1xx-A is not designed for use in life support

appliances, devices, or systems where malfunction of the product can reasonably be

expected to result in a personal injury. Customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify the

manufacturer and supplier for any damages resulting from such improper use or sale.

▪Electro static discharge does inflict irreparable damage to electronics! Before installing

or opening the unit, the installer has to discharge himself by touching a well-grounded

object.

▪This unit must be installed in accordance with the EMC guidelines (Electro Magnetic

Compatibility).

▪Do connect a proper grounding to the metal enclosure as indicated if the F1xx-A has an

incoming power line which carries a 115-230V AC. The Protective Earth (PE) wire may

never be disconnected or removed.

▪Intrinsic safe applications: follow the instructions as mentioned in Chapter 5 and consult

“Fluidwell F1..-..-XI - Documentation for Intrinsic safety”.

DISPOSAL OF ELECTRONIC WASTE

•The WEEE Directive requires the recycling of disposed electrical and electronic equipment in the

European Union. When the WEEE Directive does not apply to your region, we support its policy

and ask you to be aware on how to dispose of this product.

•The crossed out wheelie bin symbol as illustrated and found on our products tells that this

product shall not be disposed of into the general waste system or into a landfill.

•At the end of its life, equipment shall be disposed of according to the local regulations regarding

waste of the electrical and the electronic equipment.

•Please contact your local dealer, national distributor or the manufacturer’s Technical helpdesk for

information on the product disposal.

SAFETY RULES AND PRECAUTIONARY MEASURES

▪The manufacturer accepts no responsibility whatsoever if the following safety rules and

precautions instructions and the procedures as described in this manual are not followed.

▪Modifications of the F1xx-A implemented without preceding written consent from the

manufacturer, will result in the immediate termination of product liability and warranty period.

▪Mounting, electrical installation, start-up and maintenance of this device may only be carried out

by trained persons authorized by the operator of the facility. Persons must read and understand

this manual before carrying out its instructions.

▪This device may only be operated by persons who are authorized and trained by the operator of

the facility. All instructions in this manual are to be observed.

▪Check the mains voltage and information on the manufacturer's plate before installing the unit.

▪Check all connections, settings and technical specifications of the various peripheral devices

with the F1xx-A supplied.

▪Open the enclosure only if all leads are free of potential.

▪Never touch the electronic components (ESD sensitivity).

▪Never expose the system to heavier conditions than allowed according the classification of the

enclosure (see manufacture's plate and chapter 4).

▪If the operator detects errors or dangers, or disagrees with the safety precautions taken, then

inform the owner or principal responsible.

▪The local labor and safety laws and regulations must be adhered to.

FW_F1xxAOS_v1702_03_EN (addendum).docx

Page 3

ABOUT THE MANUAL

This manual is an addendum to the standard user manual ‘FW_F1xx-A_vxxxx_xx_EN’that is also

supplied with the F1xx-A-PD-OS flow rate monitor / totalizer and is suitable for the Level

indicators / monitors, models F170-A and F173-A and the Flowrate / Totalizer indicator / monitor,

model F113-A..

This addendum describes the terminal connections and configurations that are specific for type

PD-OS (4 mechanical relay outputs) and replaces chapter 4 of the standard user manual.

For all other types of supply (PM, PF, PD, PX) in combination with types OA, OT and OR, please

consult chapter 4 of the standard user manual ‘FW_F1xx-A_vxxxx_xx_EN’for your model. For

additional information, please contact your supplier.

A hazardous situation may occur if the F1xx-A is not used for the purpose it was designed for

or is used incorrectly. Please carefully note the information in this manual indicated by the

pictograms:

A "warning !" indicates actions or procedures which, if not performed correctly, may lead to

personal injury, a safety hazard or damage of the F1xx-A or connected instruments.

A "caution !" indicates actions or procedures which, if not performed correctly, may lead to

personal injury or incorrect functioning of the F1xx-A or connected instruments.

A "note !" indicates actions or procedures which, if not performed correctly, may indirectly

affect operation or may lead to an instrument response which is not planned.

WARRANTY AND TECHNICAL SUPPORT

For warranty and technical support for your Fluidwell products,

visit our internet site www.fluidwell.com or contact us at support@fluidwell.com.

Hardware version : 03.01.xx

Software version : 03.04.xx (F113-A) and 03.05.xx (F17x-A)

Manual : FW_F1xxAOS_v1702_03_EN (addendum).docx

© Copyright 2019 : Fluidwell B.V. - the Netherlands

Information in this manual is subject to change without prior notice. The

manufacturer is not responsible for mistakes in this material or for incidental

damage caused as a direct or indirect result of the delivery, performance or

use of this material.

© All rights reserved. No parts of this publication may be reproduced or used

in any form or by any means without written permission of your supplier.

FW_F1xxAOS_v1702_03_EN (addendum).docx

Page 4

CONTENTS MANUAL

Safety instructions ..............................................................................................................................2

Disposal of electronic waste...............................................................................................................2

Safety rules and precautionary measures..........................................................................................2

About the manual................................................................................................................................ 3

Warranty and technical support..........................................................................................................3

Contents manual.................................................................................................................................3

4. Installation..............................................................................................................................5

4.1. General directions..................................................................................................... 5

4.2. Installation / surrounding conditions.......................................................................... 5

4.3. Dimensions- Enclosure.............................................................................................6

4.4. Installing the hardware..............................................................................................8

4.4.1. General installation guidelines.................................................................................. 8

4.4.2. Aluminum enclosure - Field mounted .......................................................................9

4.4.3. Aluminum enclosure - Panel mounted......................................................................9

4.4.4. Plastic (GRP) enclosure..........................................................................................10

4.4.5. Sensor supply .........................................................................................................10

4.4.6. Terminal connectors ...............................................................................................11

FW_F1xxAOS_v1702_03_EN (addendum).docx

Page 5

4. INSTALLATION

4.1. General directions

•Mounting, electrical installation, start-up and maintenance of this device may only be

carried out by trained persons authorized by the operator of the facility. Persons must

read and understand this manual before carrying out its instructions.

•This device may only be operated by persons who are authorized and trained by the

operator of the facility. All instructions in this manual are to be observed.

•Make sure, the measuring system is correctly wired up according to the wiring diagrams.

Protection against accidental contact is no longer assured when the housing cover is

removed or the panel cabinet has been opened (danger from electrical shock). The

housing may only be opened by trained persons authorized by the operator of the facility.

•Take careful notice of the "Safety rules, instructions and precautionary measures" at the

front of this manual.

4.2. INSTALLATION / SURROUNDING CONDITIONS

Take the relevant IP classification of the

enclosure into account (see identification plate).

Even an enclosure rated for IP67 / TYPE 4(X)

should NEVER be exposed to strongly varying

(weather) conditions.

When panel-mounted, the front panel of the

F1xx-A is rated for IP65 / TYPE 4(X)!

When used in very cold surroundings or varying

climatic conditions, inside the instrument case,

take the necessary precautions against moisture.

Mount the F1xx-A onto a solid structure to avoid

vibrations.

FW_F1xxAOS_v1702_03_EN (addendum).docx

Page 6

4.3. DIMENSIONS- ENCLOSURE

Fig. 1: Aluminum enclosures - Dimensions

75 mm (2.95")

130 mm (5.12") 112 mm (4.40")

120mm(4.72”)

M20 x 1,5

PG9 PG9

30mm 30mm

M20 x 1,5

M16 x 1,5 M16 x 1,5

30mm 30mm

M20 x 1,5

M20 x 1,5 M20 x 1,5

25mm 25mm

1/2"NPT

0.9”

3x 1/2"NPT

0.12" 0.12"

HA

HM

HN

HO

HP

HT

HU

6 x M12

12mm 12mm

24mm24mm

36mm

36mm

14mm17mm

115 mm (4.53”)

HB

29.1 mm (1.15”)

31 mm

(1.22”)

HZ

4x M20 x 1,5

15 15

HV

2323

16

mm

1/2"NPT 1/2"NPT

25mm 25mm

22,5mm

HL

22,5mm22,5mm22,5mm22,5mm

0.9”

15

60mm(2.36”)

98mm(3.86”)

FW_F1xxAOS_v1702_03_EN (addendum).docx

Page 7

Fig. 2: GRP enclosures - Dimensions

75 mm (2.95")

130 mm (5.12") 112 mm (4.40")

60 mm (2.36")

120 mm (4.72")

HD

HK

HK back box:

(flat bottom)

HE

HF

HG

HH

D=12mm

12mm 12mm

24mm24mm

36mm

36mm

14mm 17mm

22,5mm

30mm 30mm

D=16mm

D=20mm

0.9"

D=22mm (0.866")

22,5mm

25mm 25mm

D=20mm D=20mm

D=16mm

HC

75 mm (2.95") 118 mm (4.65”)

104 mm (4.09”)

HJ

0.9”

0.12” 0.12”

3x D=22mm (0.866”)

115 mm (4.53”)

98 mm (3.86”)

29.1 mm (1.15”)

31 mm

(1.22”)

FW_F1xxAOS_v1702_03_EN (addendum).docx

Page 8

4.4. INSTALLING THE HARDWARE

•Electro static discharge does inflict irreparable damage to electronics! Before installing or

opening the F1xx-A , the installer has to discharge himself by touching a well-grounded

object.

•Do ground the aluminum enclosure properly as indicated. It is the responsibility of the

installer to install, connect and test the Protective Earth connections in accordance with

the (inter)national Rules and Regulations.

•This chapter shows general information regarding the electrical installation of the F1xx-A.

Chapter 5 gives additional specific information regarding Intrinsic safe installation and

overrules the information given in this chapter.

•When installed in an aluminum enclosure and a potentially explosive atmosphere

requiring apparatus of equipment protection level Ga and Da, the unit must be installed

such that, even in the event of rare incidents, an ignition source due to impact or friction

sparks between the enclosure and iron/steel is excluded.

4.4.1. GENERAL INSTALLATION GUIDELINES

•In the F1xx-A , different types of bonding and earthing are used. The common (ground) is mostly

used for termination of the wire shields and the Protective Earth (PE) is used for electrical safety.

•The F1xx-A that came with a power module type PM; 110V-230V AC or type PD/PF with an

option OR (the relays can handle 110V-230V AC) shall be connected to the Protective Earth (PE)

stud which is installed in the metal back panel. The metal front panel is connected to the

Protective Earth by the mounting screws and serrated washers.

•For V AC applications, the terminal 00 shall not be connected to avoid earth loops.

For V DC applications, the terminal 00 shall be connected to the common (do NOT use for PE).

•The wire screens (shield) are meant to prevent electromagnetic interference and shall be,

galvanic isolated, connected to the common ground terminals that belong to the specific sensor

connection. The wire screens shall be terminated at one side to prevent wire loops. Inside of the

Fluidwell unit, the different common ground terminals are connected to each other. It is advised,

as illustrated, to terminate the wire screens in the vicinity of the sensor and to insulated the wire

screen with a shrink tube at the Fluidwell unit side.

•The wire screens (shield) are meant to prevent electromagnetic interference and shall be,

galvanic isolated, connected to the common ground terminals that belong to the specific sensor

connection. The wire screens shall be terminated at one side to prevent wire loops. Inside of the

Fluidwell unit, the different common ground terminals are connected to each other. It is advised,

as illustrated, to terminate the wire screens in the vicinity of the sensor and to insulated the wire

screen with a shrink tube at the Fluidwell unit side.

•Separate cable glands with effective IP67 / TYPE 4(X) seals for all wires.

•Unused cable entries: ensure that you fit IP67 / TYPE 4(X) plugs to maintain rating.

•A reliable ground connection for both the sensor, and if applicable, for the metal enclosure

(above).

•An effective screened cable for the input signal, and grounding of its screen to the “┴ “ terminal or

at the sensor itself, whichever is appropriate to the application.

Field mounted

Panel mounted

FW_F1xxAOS_v1702_03_EN (addendum).docx

Page 9

4.4.2. ALUMINUM ENCLOSURE - FIELD MOUNTED

Risk of damage to equipment!

Do not use the terminal 00 to connect the protective earth wire, the 00 and the common

ground terminals are internally connected. Be careful, to prevent damage to equipment when

you connect different power supplies (sensor, PLC, etc.). Inside the Fluidwell display, the

common grounds are internally connected to each other.

The PE connection

The PE connection is made with the PE stud

inside the back panel and the 4 mounting

screws that attach the cover to the back panel.

Type PM (110-230V AC)

The PE connection in the

metal back panel is made

with a serrated washer, a

terminal, a washer and a

screw.

The PE connection to the

metal cover is made with the

serrated washers and the

mounting screws.

Type OR (8-24V AC)

Type OR (8-30V DC)

4.4.3. ALUMINUM ENCLOSURE - PANEL MOUNTED

The PE connection

The PE connection is made with one of the

mounting screws that attaches the front panel

to the panel.

Type PM (110-230V AC)

The PE connection to the

metal cover is made with the

serrated washers and the

mounting screws.

The PE connection to the

panel is made with the

washer, the nut, the

terminal, the washer and a

lock nut.

Type OR (8-24V AC)

Type OR (8-30V DC)

FW_F1xxAOS_v1702_03_EN (addendum).docx

Page 10

4.4.4. PLASTIC (GRP) ENCLOSURE

The PE connection

The F1xx-A in a GRP enclosure meets the

requirements of class 2 (double insulated).

Therefore the incoming PE wire is terminated

with an insulating end cap.

Type PM (110-230V AC)

Type OR (8-24V AC)

Type OR (8-30V DC)

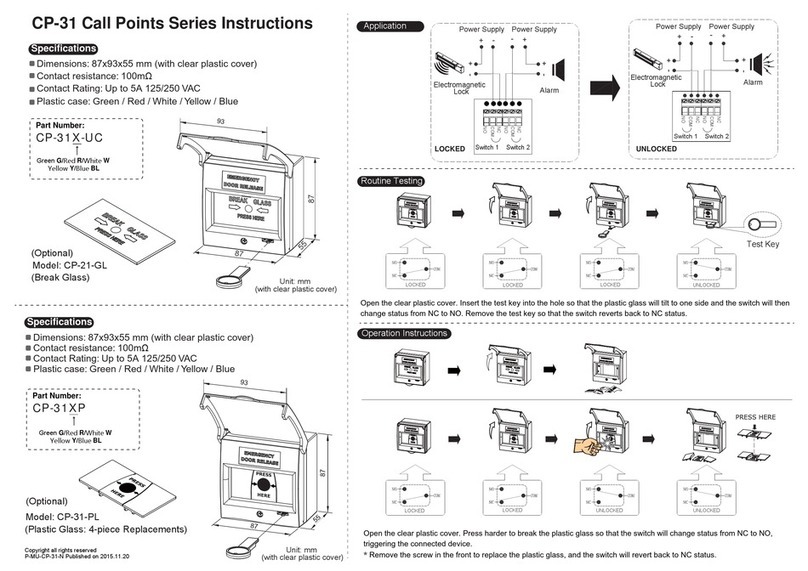

4.4.5. SENSOR SUPPLY

Option PD: Sensor supply: 8.2V, 12V or 24 V:

With this option, a real power supply for the sensor is available. The sensor can be powered with

8.2, 12 or 24 V DC (max. 50mA@24V). The voltage is selected by the two switches inside the

enclosure.

First, remove the terminal strip(s) after which the internal plastic cover can be removed. The

switches are located in the top left corner (option PD) as indicated:

Switch positions

SENSOR A

VOLTAGE SELECTION

SWITCH 1

VOLTAGE

SWITCH 3

SWITCH 4

VOLTAGE

INT

3.2 V DC

on

on

8.2 V DC

EXT

switch 3+4

off

on

12 V DC

on

off

12 V DC

off

off

23 V DC

Fig. 3: switch position voltage selection (option PD and PD-OS).

Function switch 1: Keep this switch in the EXT position at all times so the external sensor

supply is available from terminal 5. The 3.2V DC supply voltage does not

have enough power to supply a 4-20mA analog sensor.

Function switch 3+4: The combination of these switches determines the voltage that will be

available from terminal 5, as indicated in the table..

on

off

43

1INT EXT

1 INT EXT

on

off

PD-OS

FW_F1xxAOS_v1702_03_EN (addendum).docx

Page 11

4.4.6. TERMINAL CONNECTORS

The following paragraphs describe the terminal connections and configurations that are

specific for type PD-OS (4 mechanical relay outputs).

For all other types of supply (PM, PF, PD, PX) in combination with types OA, OT and OR,

please consult the standard user manual ‘FW_F1xx-A_vxxxx_xx_EN’.

The following terminal connectors are available:

Fig. 4: Overview of terminal connectors - Standard configuration F17x-P-OS

Terminal GND- 01- 02; power supply - only available with option PD:

OPTION

SENSOR SUPPLY

Terminal

backlight

GND

01

02

PD

24V AC

8.2, 12, 24V max 50mA

AC

AC

◊

PD

24V DC

8.2, 12, 24V max 50mA

L-

L+

◊

Note PD

do not use a AC autotransformer (Spartrafo) without a galvanic isolation.

◊=option

Terminal 03-05; Sensor input:

The F1xx-A-OS requires a (0)4-20mA sensor signal which will be processed 4 times a second with a

14 bits accuracy. The input is not isolated.

INTERNAL EXTERNAL

(0)4 - 20mA signal input

4

Common ground unit

SIGNAL

3GND shielding

58.1 - 12 - 23V

-

+

max.25mA

Terminal 06-07; Unused

Caution:

Do not connect wires to these terminals; they are not in use for daily operation of the F1xx-A-OS.

The onboard electronics hardwired to these terminals, should not be exposed to field wiring or

“foreign voltages”.

FW_F1xxAOS_v1702_03_EN (addendum).docx

Page 12

Terminal 08-09: Analog output (passive):

A passive 4-20mA signal proportional to the flowrate for model F113-A or level, height or percentage

for model F170A (see setup 72) and model F173-A (see setup 82) is available as standard. When a

power supply is connected but the output is disabled, a 3.5mA signal will be generated.

Max. driving capacity 1000 Ohm. This output does loop power the unit as well but is NOT able to

power the mechanical relays !!

Terminal 10-11; relay output R1:

This output is an alarm or pulse output according setup 81 (F113-A, F170-A) / setup 91 (F173-A).

Terminal 12-13; relay output R2:

This output is an alarm or pulse output according setup 82 (F113-A, F170-A) / setup 92 (F173-A).

Terminal 14-15; relay output R3:

This output is an alarm or pulse output according setup 83 (F113-A, F170-A) / setup 93 (F173-A).

Terminal 16-17; relay output R4:

This output is an alarm or pulse output according setup 84 (F113-A, F170-A) / setup 94 (F173-A).

FW_F1xxAOS_v1702_03_EN (addendum).docx

Page 13

Terminal 26-31: type CB / CH / CI / CT - communication RS232 / RS485 / TTL (option)

▪Full serial communications and computer control in accordance with RS232 (length of cable

max. 15 meters) or RS485 (length of cable max. 1200 meters) is possible.

▪Read the Modbus communication protocol and Appendix C.

Fig. 11: Overview terminal connectors communication option.

When using the RS232 communication option, terminal 27 is used for supplying the interface.

Please connect the DTR (or the RTS) signal of the interface to this terminal and set it active (+12V).

If no active signal is available it is possible to connect a separate supply between terminals 26

and 27 with a voltage between 8V and 24V.

26 27 29

RS485 - 2-wire

28

A B+ 30 31

Y

26 27 Z

29

RS485 - 4-wire

28

A B+ 26 27 29

RS232

28

RXD TXD

30 31 30 31

DTR

+12V

INTERNAL

EXTERNAL

Mechanic relay output - R1, R2, R3, R4

10

11

R1

R1

12

13

R2

maximum

240V AC - 0.5A

R2

DEVICE

maximum

240V AC - 0.5A

DEVICE

14

15

R3

maximum

240V AC - 0.5A

R3

DEVICE

16

17

R4

maximum

240V AC - 0.5A

R4

DEVICE

FW_F1xxAOS_v1702_03_EN (addendum).docx

Page 14

FW_F1xxAOS_v1702_03_EN (addendum).docx

Page 15

FW_F1xxAOS_v1702_03_EN (addendum).docx

Page 16

Fluidwell B.V.

PO box 6 Voltaweg 23 Website: www.fluidwell.com

5460 AA Veghel 5466 AZ Veghel Find your nearest representative: www.fluidwell.com/representatives

The Netherlands The Netherlands © 2019 Fluidwell B.V. - FW_F1xxAOS_v1702_03_EN (addendum).docx

Other manuals for F1-A-PD-OS Series

1

This manual suits for next models

3

Table of contents

Other Fluidwell Security System manuals