User’s

Manual

2-9-32, Naka-cho Musashino-shi, Tokyo 180-8750 Japan

Phone: +81-422-52-7179 Facsimile: +81-422-52-6793

http://www.yokogawa.com/ns/juxta/im/

You can download the latest manuals from the following website:

1

CAUTIONARY NOTES FOR SAFE USE OF THE PRODUCT

This User’s Manual should be carefully read before installing and operating the product. Please keep

this User’s Manual for future reference.

The related manuals and general specications are shown in the table below.

Doc. Name Doc. Number

Model MVHK Limit Alarm for DC Input (Userʼs Manual) IM 77J04H31-01E (This manual)

Model MVHK Limit Alarm for DC Input (General Specications) GS 77J04H31-01E

User’s manuals in the above table are essential parts of the product; keep it in a safe place for future

reference.

This manual is intended for the following personnel;

• Engineers responsible for installation, wiring, and maintenance of the equipment.

• Personnel responsible for normal daily operation of the equipment.

The following symbol is used on the product and in this manual to ensure safe usage.

WARNING

Calls attention to actions or conditions that could cause serious or fatal injury to the

user, and indicates precautions that should be taken to prevent such occurrences.

The following symbols are used only in this manual.

CAUTION

Calls attention to actions or conditions that could cause injury to the user or damage

to the instrument or property and indicates precautions that should be taken to prevent

such occurrences.

CHECKING THE PRODUCT SPECIFICATIONS AND THE CONTENTS

OF THE PACKAGE

(1) Checking the Model and Product Specications

Check that the model and specications indicated on the nameplate attached to the side face

of the main unit are as ordered. (In checking the model and sux codes, refer to the main

specications listed on the last page of this manual.)

(2) Packaged Items

Check that the package contains the following items.

• MVHK: 1

• Tag number label: 1 sheet

• Range label: 1 sheet

• Spacer: 1 (used for DIN rail mounting)

• Receiving resistor: 1 (supplied when the input signal code “A,” optional specication code

“/R100” or “/R250” is specied)

• Monitor output terminal connector: 1 (supplied when monitor output code 6, A, P is specied)

• User’s manual (this manual: IM 77J04H31-01E): 1

GENERAL

This plug-in type Limit Alarm for DC input receives DC current or DC voltage signal. It is equipped

with Active color PV display (PV display color changing function).

MODEL AND SUFFIX CODES

Model Sux codes Description

MVHK -[] 0 [] -[] [] [] 0 /[][] Limit Alarm for DC Input

Type

-0 General use type

-1 JK12 type (The terminal assignment is same as that of

Yokogawa’s JK12 and MHKW.)

-2 Fail output type

0Always 0

Power Supply 324 V DC±10%

6100-240 V AC/DC (Operating range: 85 to 264 V)

Input Signal

-6 1 to 5 V DC

-A 4 to 20 mA DC (with 250 Ω receiving resistor)

-U DC voltage or DC current signal

-Z Custom order

Output Signal

1Alarm output (transfer contact [1a1b] ), 2 points

2Alarm output (NO contact), 4 points

3Alarm output 2points, Fail output 1point

Monitor Output

61 to 5 V DC

A4 to 20 mA DC

PCommunication function (RS-485)

NNo monitor output

0Always 0

Optional Specication

/SN No socket (with socket if not specied)

/R100 With 100 Ω receiving resistor

/R250 With 250 Ω receiving resistor

/C0 Coating

/FB Fuse bypass

/F1 Alarm 1: NO, Alarm 2: NO, Fail output: NO

/F2 Alarm 1: NC, Alarm 2: NO, Fail output: NO

/F3 Alarm 1: NO, Alarm 2: NC, Fail output: NO

/F4 Alarm 1: NC, Alarm 2: NC, Fail output: NO

/F5 Alarm 1: NO, Alarm 2: NO, Fail output: NC

/F6 Alarm 1: NC, Alarm 2: NO, Fail output: NC

/F7 Alarm 1: NO, Alarm 2: NC, Fail output: NC

/F8 Alarm 1: NC, Alarm 2: NC, Fail output: NC

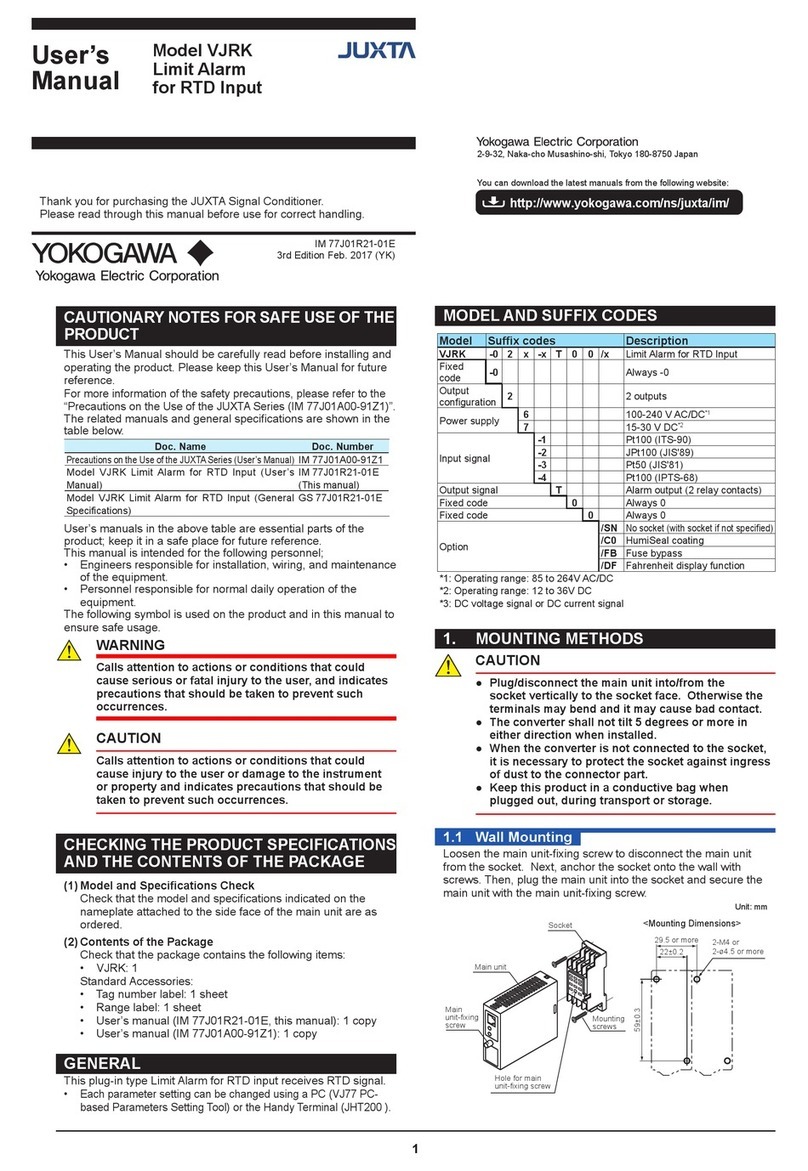

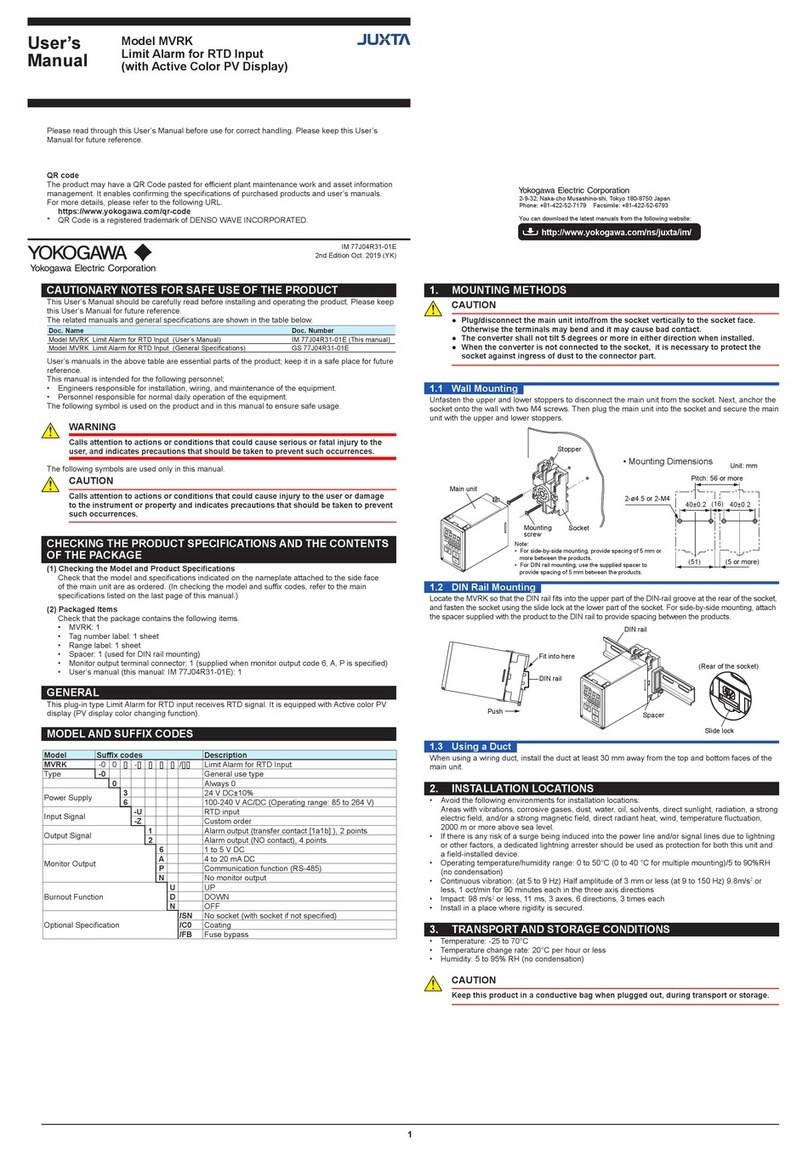

1. MOUNTING METHODS

CAUTION

●Plug/disconnect the main unit into/from the socket vertically to the socket face.

Otherwise the terminals may bend and it may cause bad contact.

●The converter shall not tilt 5 degrees or more in either direction when installed.

●When the converter is not connected to the socket, it is necessary to protect the

socket against ingress of dust to the connector part.

1.1 Wall Mounting

Unfasten the upper and lower stoppers to disconnect the main unit from the socket. Next, anchor the

socket onto the wall with two M4 screws. Then plug the main unit into the socket and secure the main

unit with the upper and lower stoppers.

(51)

40±0.2 (16) 40±0.2

Pitch: 56 or more

(5 or more)

2-ø4.5 or 2-M4

• Mounting Dimensions Unit: mm

Socket

Stopper

Main unit

Mounting

screw

Note:

• For side-by-side mounting, provide spacing of 5 mm or

more between the products.

• For DIN rail mounting, use the supplied spacer to

provide spacing of 5 mm between the products.

1.2 DIN Rail Mounting

Locate the MVHK so that the DIN rail ts into the upper part of the DIN-rail groove at the rear of the socket,

and fasten the socket using the slide lock at the lower part of the socket. For side-by-side mounting, attach

the spacer supplied with the product to the DIN rail to provide spacing between the products.

Slide lock

Spacer

DIN rail

DIN rail

Fit into here

Push

(Rear of the socket)

1.3 Using a Duct

When using a wiring duct, install the duct at least 30 mm away from the top and bottom faces of the

main unit.

2. INSTALLATION LOCATIONS

• Avoid the following environments for installation locations:

Areas with vibrations, corrosive gases, dust, water, oil, solvents, direct sunlight, radiation, a strong

electric eld, and/or a strong magnetic eld, direct radiant heat, wind, temperature uctuation,

2000 m or more above sea level.

• If there is any risk of a surge being induced into the power line and/or signal lines due to lightning

or other factors, a dedicated lightning arrester should be used as protection for both this unit and

a eld-installed device.

• Operating temperature/humidity range: 0 to 50°C (0 to 40 °C for multiple mounting)/5 to 90%RH

(no condensation)

• Continuous vibration *: (at 5 to 9 Hz) Half amplitude of 3 mm or less (at 9 to 150 Hz) 9.8m/s2or

less, 1 oct/min for 90 minutes each in the three axis directions

• Impact *: 98 m/s2 or less, 11 ms, 3 axes, 6 directions, 3 times each

• Install in a place where rigidity is secured.

*: Type code 2 is an environment without vibration and impact.

3. TRANSPORT AND STORAGE CONDITIONS

• Temperature: -25 to 70°C

• Temperature change rate: 20°C per hour or less

• Humidity: 5 to 95% RH (no condensation)

CAUTION

Keep this product in a conductive bag when plugged out, during transport or storage.

Model MVHK

Limit Alarm for DC Input

(with Active Color PV Display)

IM 77J04H31-01E

4th Edition Oct. 2019 (YK)

Please read through this User’s Manual before use for correct handling. Please keep this User’s

Manual for future reference.

QR code

The product may have a QR Code pasted for ecient plant maintenance work and asset information

management. It enables conrming the specications of purchased products and user’s manuals.

For more details, please refer to the following URL.

https://www.yokogawa.com/qr-code

* QR Code is a registered trademark of DENSO WAVE INCORPORATED.