Fluigent LineUp Series User manual

USER’S

MANUAL

LINEUPTM SERIES

Push-PullPush-Pull

QUICK START GUIDE

LineUp Flow EZTM

Pressure controller

LineUpTM Push-Pull

Pressure controller

Aria is a perfusion system which automates perfusion or timed

injection protocols. It allows for the sequential delivery of up to 10

different solutions at the desired ow rate into a microuidic chip,

perfusion chamber or petri dish.

The quick start guide is a forward to the LineUpTM Series user's manual

3

QUICK START GUIDE

1Supplied (inlet) pressure from pump or compressed air supply

2Power supply to the Flow EZTM / Push-Pull pressure controller

3Regulated (outlet) pressure from pressure controller to reservoir

4Pressurized reservoir P-CAP

5Microuidic set-up in example a microuidic chip

1

2

4

3

5

1. The TM/ Push-Pull regulates the externally supplied

(inlet) pressuretoauser -denedpressurewith.

2. Thisregulated(outlet)pressure ,

driving the liquid up through the tubing and into the

.

3. Controllingtheoutletpressureallowsoneto

atwhichuidisinjectedintothemicrouidicset up.

4

QUICK START GUIDE

Contained in the package

Flow EZTM or Push-Pull Outlet tubing (OD 4mm)

*OD: Outer diameter

P-CAP Kit or Fluiwell Kit (sold separately)

P-CAP (or Fluiwell) reservoir

Fluiwell: for 15mL or 50mL reservoirs

P-CAP for 2mL, 15mL or 50mL reservoirs

Fluidic tubing

Outer diameter and inner diameter

depending on the Kit

5

Outlet tubing (OD 4mm)

Fluidic tubing

QUICK START GUIDE

LineUpTM supply Kit (sold separately)

Inlet tubing (OD: 6mm)

Power supply (24VDC)

Power supply to Sub-D adaptor

*OD: Outer diameter

6

QUICK START GUIDE

Oncepoweredon,theTMor

Push-Pull willdisplaythe "Inlet

pressure check window",givingthe

attheinlet

(P inlet)andthe

requiredtooperatethepressure

controller (Ptarget).

For example, left shows a 1000 mbar

range Flow EZTM

P target : 1100 mbar

P inlet : 0 mbar

Note : For the 7000 mbar range as

well as negative pressure ranges

Flow EZTM, this window will not appear.

To wall socket

7

Oncepoweredon,theTMor

Push-Pull willdisplaythe "Inlet

pressure check window",givingthe

attheinlet

(P inlet)andthe

requiredtooperatethepressure

controller (Ptarget).

QUICK START GUIDE

The TM or Push-Pull

needs an

supply to operate. This can be

a lab's compressed air supply,

an air compressor, or any

clean(filtered< 10 µm)anddry

compressed air supply.

Different TM ranges

require different supply

pressures(showntotheright).

Note : If one intends to use compressed gas other than air, or if the pressure

supply is out of the pressure range requirements, please contact Fluigent.

Always wear safety protection

when manipulating pressure.

- For positive range,

exceed 8 bar (120 psi)

- For negative range,

connect any positive pressure

Pressure supply

Flow EZTM

range (mbar)

Required pressure

supply (mbar)

7000 7100

2000 2100

1000

1100

345

69

150

25

-25

-800

-69

-345

-800

8

The Push-Pull module works the same way as other TM modules,

except that it can output pressure (above atmospheric pressure)

and (below atmospheric pressure) through the same port.

Note : Depending on the supply pressures, the performance of

the module can vary, especially for the vacuum pressure supply.

When connecting the two supplies, only the positive pressure supply

will be checked on the "Inlet pressure check window". (see page 10)

Push-Pull output (mbar) Required pressure supply (mbar)

1000 1100

-800 -800

QUICK START GUIDE

Positive pressure

supply inlet

Vacuum

supply inlet

Pressure /

Vacuum outlet

Special attention

should be taken to

prevent liquid from

into

the module.

To do so, it needs two inlets: the positive one, uses the standard pressure

supply of the TM, and the negative one, utilizes an additional

connector located at the front between the FLOW UNIT port and the

"unlock" handle.

9

Positive pressure

supply inlet

QUICK START GUIDE

A Push-Pull module can be combined with other

pressure LineUPTM modules the same way as a Flow EZTM

1 bar. If connecting to higher pressure modules, please

consider adding an Adapt module to reduce the

positive pressure supply. (See page 29 for more details)

When using a Push Pull module, care should be taken to

avoid drawing liquid into the system. This can seriously

damage the module. It is advised to use a liquid filter

between the outlet and the reservoir as it reduces the risks.

Note : The Push-Pull can be

used as a regular Flow EZTM with

no vacuum supply connected.

Please, a Push-

Pull module with a

Flow EZTM as it would not work.

10

(A 1000 mbar range Flow EZTM is shown as an example)

Adjust the pressure

from your

pressure source

The P inlet value

is displayed in

red

The P inlet value

is displayed in

green

When connecting the pressure supply, if its value (P inlet) is not set at

the (P target), the Flow EZTM or Push-Pull will continue to

display the "Inlet pressure check window" (with the exception of the 7000

mbar range and the negative ranges which don't have this window)

If the value is displayed in red, please adjust the pressure supply.

When the two values are close enough, the will turn green

and the display on the Flow EZTM or Push-Pull will transition to "Operation

window"

QUICK START GUIDE

11

QUICK START GUIDE

Pause button

Press to bring outlet

pressure to zero

Press again to

recover pressure

Hold to enter sleep

mode

Pmeas

Measurement of

the pressure in the

reservoirs

Product name and

pressure range

Open menu

Unit can be

changed using the

menu

Rotates display

Pcmd

User-dened

pressure command

The pressure sensor inside the Flow EZTM or Push-Pull device

needs to be (see next page).

If the system isn't calibrated, the outlet measured pressure (Pmeas) may

be incorrect.

12

1. Press "Menu"

2. Use the dial (turn and press) to select "Pressure calibrate"

3. Wait a few seconds

4. The calibration is done

Note: Due to the high sensitivity of the internal pressure sensor,

one may observe some small fluctuations of the measured

pressure (Pmeas), even after the calibration is complete.

An example of

Pmeas before

calibration

Calibrating ...

10

1

3

2

4

QUICK START GUIDE

13

QUICK START GUIDE

P-CAP (or Fluiwell)

and reservoir

Microuidic setup

FLOW UNIT (sold separately)

Aria is a perfusion system which automates perfusion or timed

injection protocols. It allows for the sequential delivery of up to 10

different solutions at the desired ow rate into a microuidic chip,

perfusion chamber or petri dish.

One can connect a FLOW UNIT (Fluigent ow sensor) between the

reservoir and the microuidic setup. (See page 22 for more details)

14

TM

QUICK START GUIDE

If one needs to disconnect the power supply (e.g. to move or store the

unit), please make sure the Flow EZTM or Push-Pull is already in sleep

mode before disconnecting the power.

When one has nished using the Flow EZTM or Push-Pull, hold

the "P=0" button in order to put the device into sleep mode.

Thisprocedurewillreleaseallinthe system, preventing

any further pressure from being appliedtoyouruidicset up.

Forafullydetailed,pleaseseepage 32.

1

2

15

The Flow EZTM or Push-Pull is ready to be used,

Simply turn the dial to start.

The user's manual in on the next page:

Allowing one to get the most out of the LineUpTM series devices.

PRODUCT OVERVIEW 18

SETTING UP 21

A faster way to change the pressure 21

Add a FLOW UNIT 22

Flow rate control 24

Inject a volume 25

Flow-related setting 26

Liquid type 27

28

Create a multi-channel conguration 28

Mixing different pressure range 29

LineUpTM Adapt 30

COMPUTER CONNECTION 31

LineUpTM Link 31

SHUTDOWN PROCEDURE 32

ADDITIONAL FEATURES 33

34

WARRANTY TERMS 36

TECHNICAL SUPPORT 37

LINEUPTM SERIES

USER’S MANUAL

18

1FLOW UNIT port to the ow sensor

2Pressure supply transmission used only in multi-channel conguration

3Pressure outlet to reservoir

4Pressure inlet from pump or compressed air supply

3

2

1

PRODUCT OVERVIEW

LineUp Flow EZTM

Pressure controller

4

19

PRODUCT OVERVIEW

LineUp Push-Pull

Pressure controller

1FLOW UNIT port to the ow sensor

2Pressure supply transmission used only in multi-channel conguration

3Pressure outlet to reservoir

4Positive pressure inlet from pump or compressed air supply

5Vacuum inlet from vacuum pump

3

2

1

4

5

20

1Unlock button used only in multi-channel conguration

2P=0 button press once to set pressure to 0, press again to return to original

pressure, hold to put into sleep mode

3Left button press to rotate the display/go back

4Right button press to open the menu/enter

5Power / Data connection provide power supply and data connection

6Power / Data transmission used only in multi-channel conguration

7Dial for local control

1

3

5

2

4

6

7

PRODUCT OVERVIEW

Change pressure command

Navigate in menu

Set/Apply pressure

Command set in menu

Other manuals for LineUp Series

1

This manual suits for next models

2

Table of contents

Other Fluigent Controllers manuals

Popular Controllers manuals by other brands

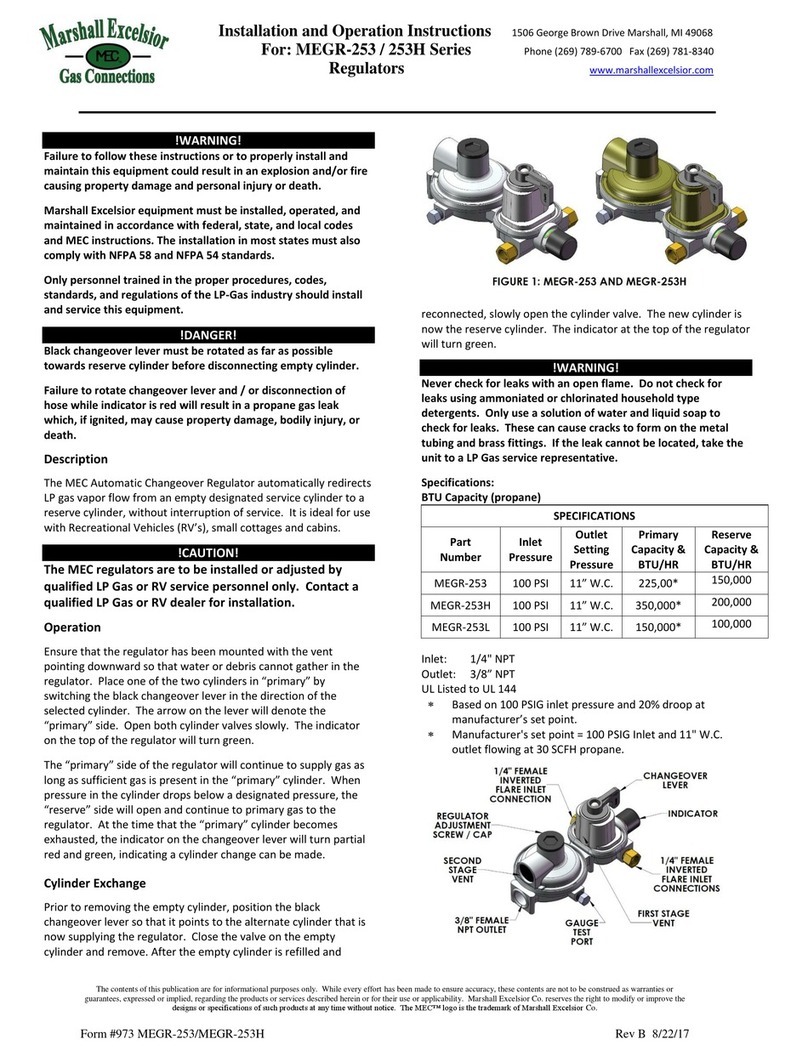

Marshall Excelsior

Marshall Excelsior MEGR-253 Installation and operation instructions

Bender

Bender ICC1324 manual

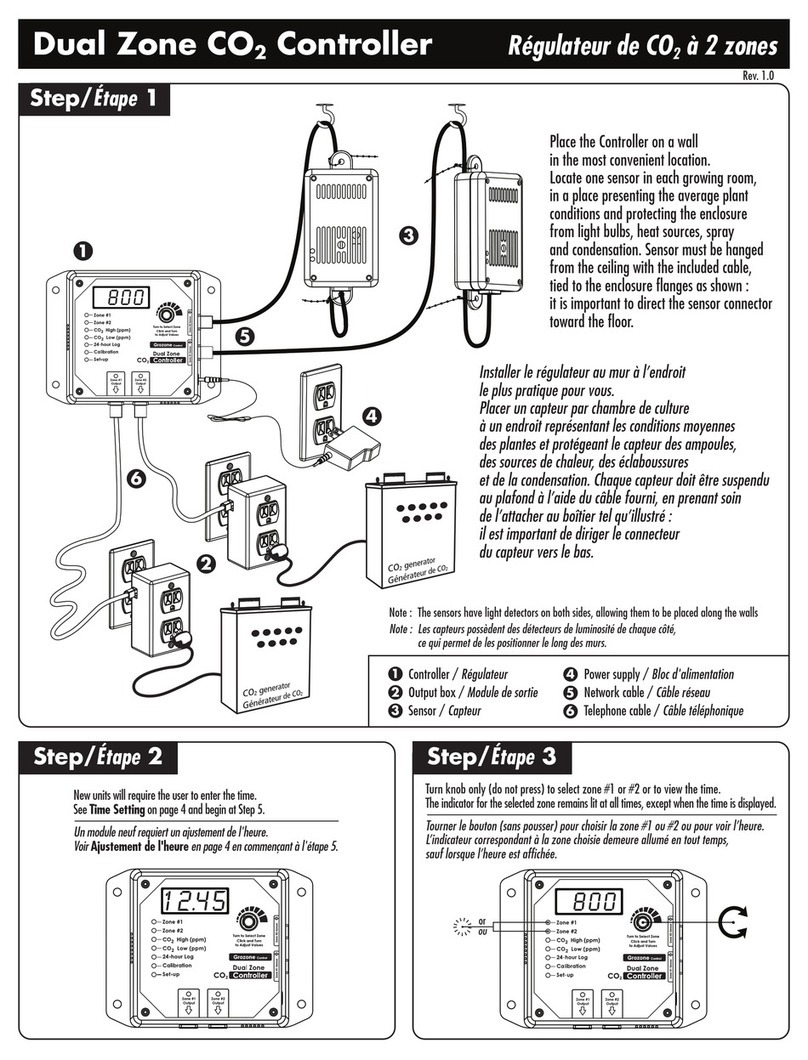

Grozone Control

Grozone Control Dual Zone CO2 Controller manual

Aphex

Aphex Compellor 320A owner's manual

Epever

Epever RC-10 quick guide

Titan Controls

Titan Controls Helios 3 instruction manual