Table of Contents

2 / 44 0870208958_INVEOR_VFD_-0002_PCI_en

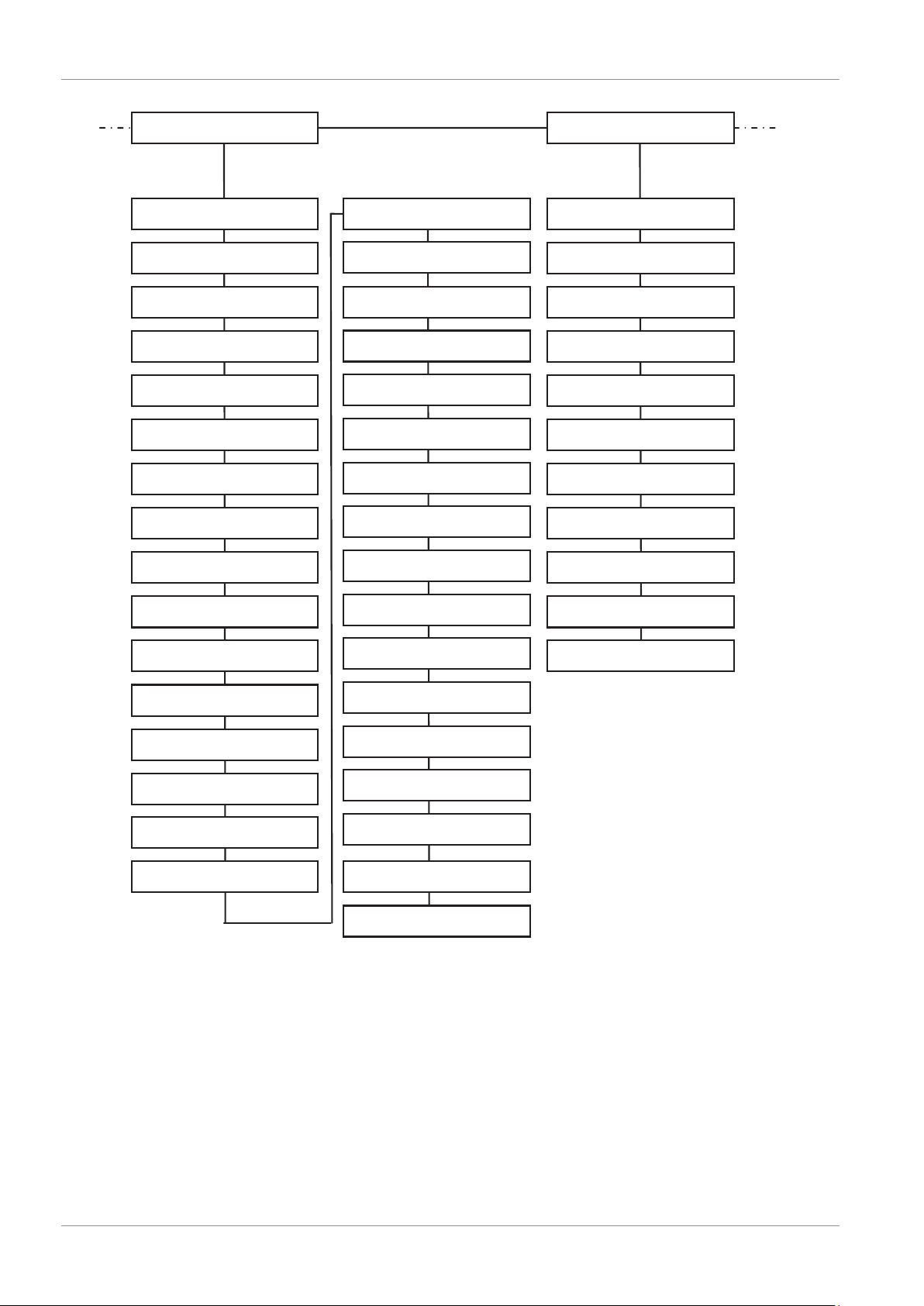

Table of Contents

1 Safety .......................................................................................................................................3

2 Introduction..............................................................................................................................4

3 Product Description ..................................................................................................................5

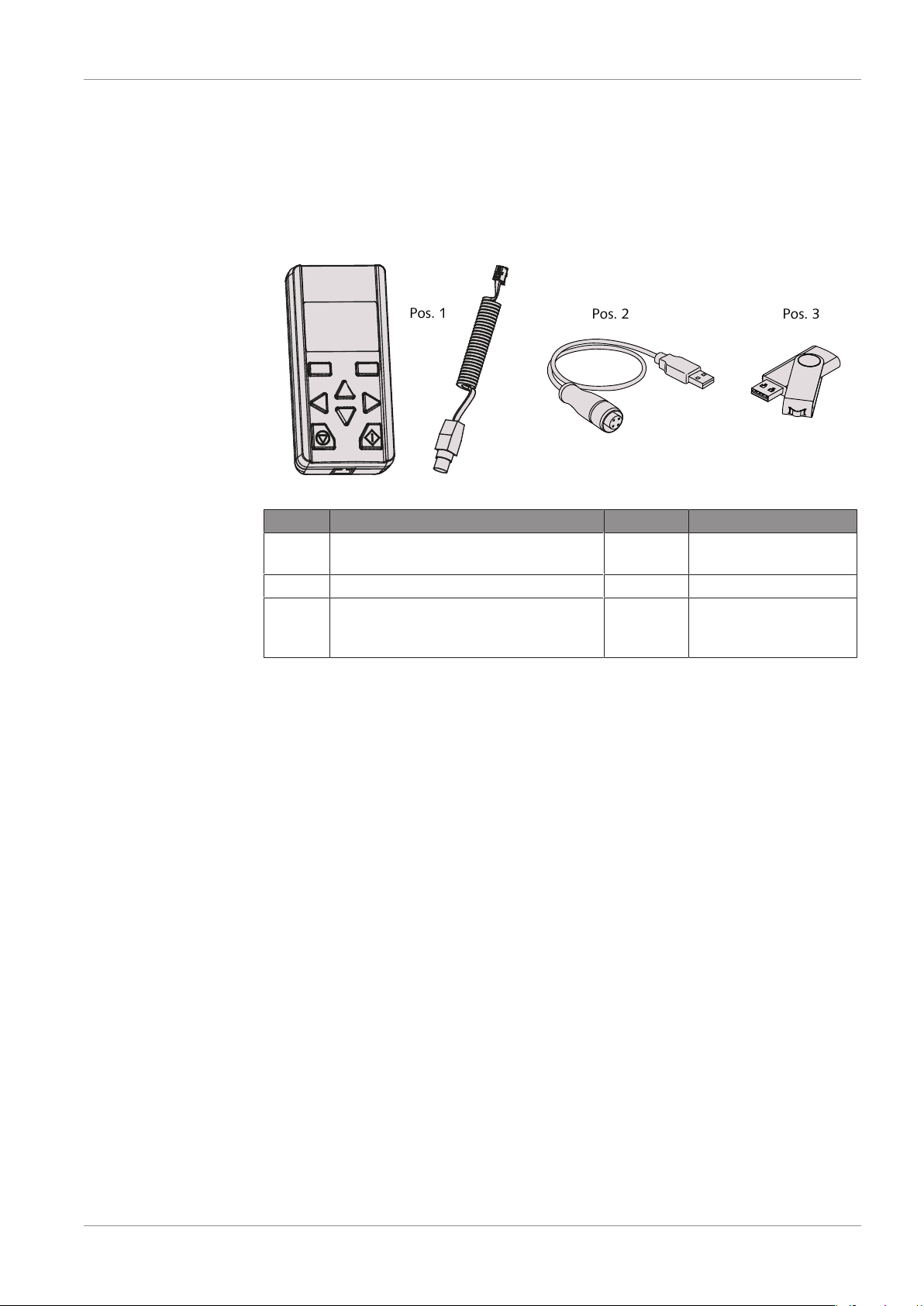

3.1 Scope of Delivery ............................................................................................................. 5

3.2 Application....................................................................................................................... 5

4 Installation................................................................................................................................6

4.1 Remote Control Connection............................................................................................. 6

4.2 PC-Software Installation................................................................................................... 6

5 Commissioning.........................................................................................................................7

5.1 Operate the Remote Control............................................................................................ 7

5.1.1 Key Overview........................................................................................................ 7

5.1.2 Navigation and Input............................................................................................. 7

5.1.3 Menu .................................................................................................................... 8

5.1.4 Parameter Group Menu (Expert Mode) .................................................................9

5.2 Run the Machine.............................................................................................................. 12

6 Custom Parametrisation ...........................................................................................................13

6.1 Disable the Machine......................................................................................................... 14

6.2 Save Parameters............................................................................................................... 15

6.3 Reload Factory Settings .................................................................................................... 17

7 Parameter Description ..............................................................................................................19

7.1 Overview I/O Connections .............................................................................................. 19

7.2 Preventing Electromagnetic Interferences ......................................................................... 21

7.3 NX 0950 A Parameters Set Change Values....................................................................... 22

7.3.1 Description ............................................................................................................ 22

7.3.2 How to know if the machine has two set values ? .................................................22

7.3.3 Parameters not to be changed............................................................................... 22

7.4 Start / Stop Functionality.................................................................................................. 23

7.4.1 Description ............................................................................................................ 23

7.4.2 Parameter’s to Change .......................................................................................... 23

7.5 Fixed Frequency Selection via Digital Inputs ..................................................................... 23

7.5.1 Description ............................................................................................................ 23

7.5.2 Speed Control: 1 Fixed Frequency + Min. Frequency............................................. 24

7.5.3 Speed Control: 3 Fixed Frequency + Min. Frequency............................................. 24

7.5.4 Speed Control: 7 Fixed Frequency + Min. Frequency............................................. 25

7.6 Speed Control via Analogue Input.................................................................................... 26

7.6.1 Description ............................................................................................................ 26

7.6.2 Speed Control via Internal Potentiometer ..............................................................26

7.6.3 Speed Control via Analogue Input 1 ...................................................................... 26

7.6.4 Speed Control via Analogue Input 2 ...................................................................... 29

7.7 PID Process Control.......................................................................................................... 32

7.7.1 Description ............................................................................................................ 32

7.7.2 Change for PID Process Control ............................................................................ 33

7.7.3 Stand-by Function in PID Process Control.............................................................. 35

8 Troubleshooting .......................................................................................................................36

8.1 LED Flash Codes............................................................................................................... 37

8.2 List of Errors ..................................................................................................................... 38