MOLBLOC/MOLBOX™ LOW MASS FLOW CALIBRATION SYSTEM AFMETCAL

CONFIGURATIONS

INSTALLATION AND OPERATION MANUAL SUPPLEMENT

Page 1 ©2000-2008 DH Instruments, a Fluke Company

Introduction

system overview

An AFMETCAL configuration molbloc/molbox mass flow calibration system is made up of standard

molbloc/molbox system components plus a special hardware kit. The kit includes this manual and

several hardware items to provide pressure regulation and interconnections to devices under test (DUTs).

These hardware items are selected to allow calibration of flow devices as defined by AFMETCAL,

specifically, gas flow meters with 1/4 in. tube (Swage) or AN4 type fittings used at various pressures

ranging from zero to 50 psig. The system’s maximum calibrated flow rate is 40 slm.

There are two different AFMETCAL configurations. One is the basic configuration. The other is the

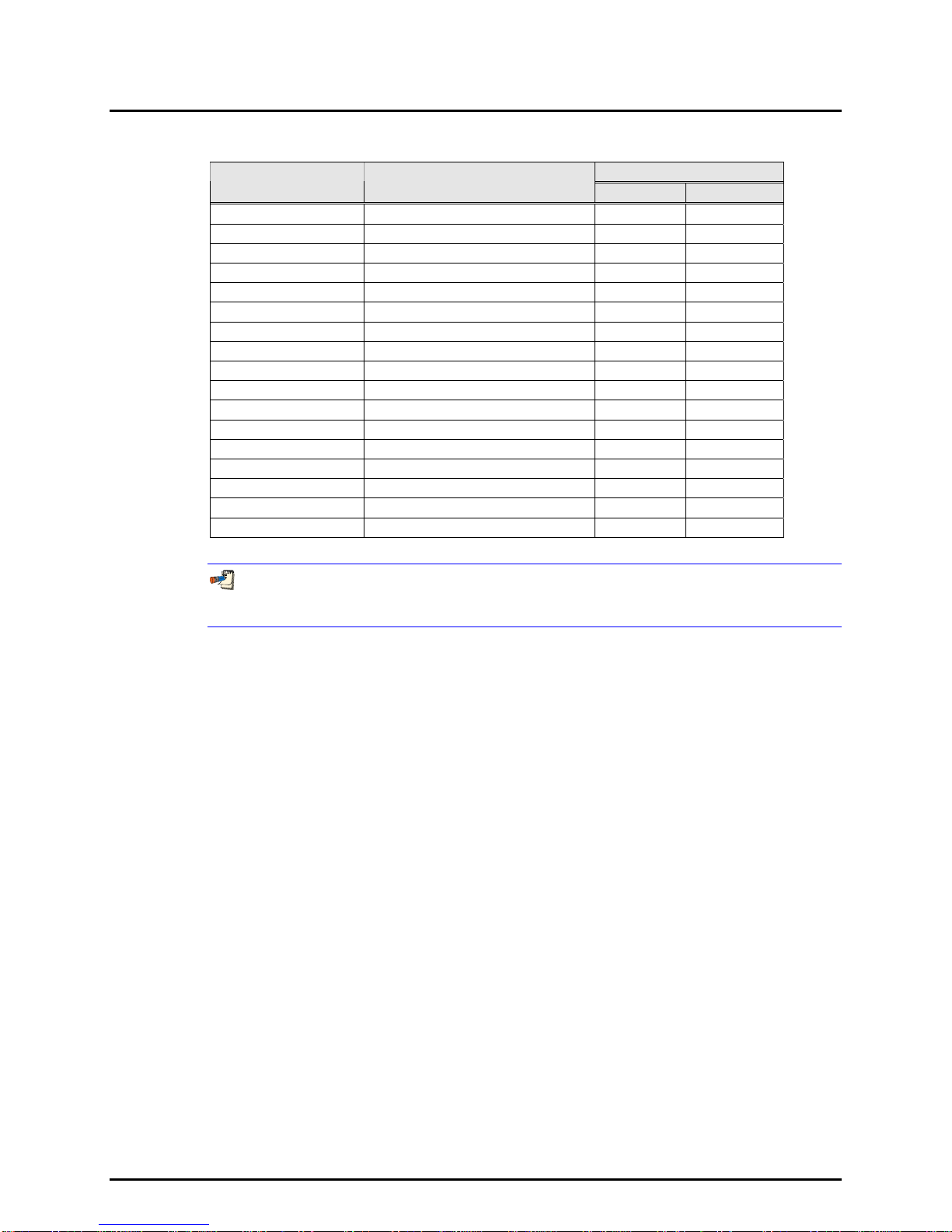

calibration exchange system. Their differences are summarized below in Section 1.1.1. Table 1 lists the

specific components included in each configuration.

the two system configurations

BASIC AFMETCAL CONFIGURATION

The basic configuration includes a molbox, molstics and five molblocs to handle flows up to 40 slm. COMPASS for molbox software,

metering valve kits and the AFMETCAL Configuration Kit are also included in the basic configuration. This is the system

configuration which will be in regular use in the PMEL labs, and is specifically defined by NSN 6680-01-466-2062.

CALIBRATION EXCHANGE SYSTEM

This system is intended for delivery to AFMETCAL for temporary use at the various PMELs while each PMEL’s system is being

serviced or recalibrated. The exchange system is identical to the basic configuration above with two exceptions:

•The exchange system is delivered with CalTool software instead of COMPASS software to provide AFMETCAL with the

ability to recalibrate molblocs.

•Two custom shipping containers are included to facilitate the shipping of the exchange and PMEL systems back and forth for

recalibration.