R.M. Young 32500 User manual

MODEL 32500

ELECTRONICCOMPASS

REV K080703

MANUALPN 32500-90

R. M. YOUNG COMPANY

2801 AERO PARK DRIVE, TRAVERSE CITY, MICHIGAN 49686, USA

TEL: (231) 946-3980 FAX: (231) 946-4772

Page1

MODEL 32500

ELECTRONICCOMPASS

SPECIFICATIONS*

Compass:

Resolution: 0.5 degrees

Accuracy: ±2 degrees (rms)

Wind Speed Input:

Sensor Type: AC Frequency Generator

Sensitivity: 50mVp-pminimum

Range: 0-2000 Hz

Wind Direction Input:

Sensor Type: Potentiometer

Range: 0-5000mV = 0 to 355 degrees

Excitation: 5000mV (limited to 5 mA)

Voltage Inputs (Auxiliary Sensor Inputs):

VIN1and VIN2 0-1000mV

VIN3and VIN4 0-5000mV

Voltage Outputs:

OUT1 0-5000mV 0-100 m/s wind speed

OUT2 0-5000mV 0-360° true wind dir

(Uses compass meas-

urement to produce

true wind direction.)

Serial Output: Full duplex RS-232,

Half duplex RS-485 (25 mS switchover)

1200, 2400, 4800, and 9600 baud

8 data, 1 stop, no parity

Operating Temp: -50°C to 50°C

Power: 11 to 30 VDC, 40 mA

Mounting: 1 inch IPS (1.34 inch actual diameter)

Size: 4.75” (12cm) H

0.87” (7.3cm) W

2.12” (5.3cm) D *Specificationssubjecttochange

1.0INTRODUCTION

TheModel32500ELECTRONICCOMPASSmeasuresmagnetic

heading and incorporates auxiliary inputs to measure signals from

YOUNG sensors. Wind speed and direction sensors, temperature

and humidity sensors, barometers and other meteorological

instruments can connect directly to 32500 inputs. Two specialized

wind sensor inputs and four general purpose voltage inputs convert

measurements to high-resolution numerical values. Wind direction

input may be combined with compass readings to obtain true

direction.

Measurements are converted to RS-232 or RS-485 serial formats or

calibrated voltage outputs. Both continuous and polled outputs are

available. When polled, up to 16 units can be networked together. For

marine applications the 32500 produces standard NMEA output

sentences. Voltage output for wind speed and direction is available

when the 32500 is connected to a YOUNG wind sensor.

1.1INSTALLATION

The 32500 is supplied in a weather-resistant enclosure with a

mounting adapter that fits 1 inch IPS pipe (1.34 inch nominal

diameter). When used with the YOUNG Wind Monitor, the mounting

adapter engages the Wind Monitor orientation notch. Refer to the

WIRING DIAGRAM for electrical connection details and jumper

settings. Place jumpers to select desired output format. Once

installed, the compass must be calibrated to correct for local

magnetic distortions caused by nearby structures. To calibrate the

compass, follow the procedure outlined below.

1.2SETUP

Operating mode may be set with simple jumpers or customized with

software commands via serial connection. Settings are retained when

power is removed.

1.2.1 COMPASS CALIBRATION

1. Remove cover from compass. Press and hold CALIBRATE button

for 5 seconds. The CALIBRATE indicator will begin to blink. Refer

to WIRING DIAGRAM to locate CALIBRATE button.

2. Slowly rotate vehicle on which compass is mounted. Steer vehicle

in a tight circle and make TWO complete revolutions. Each

revolution should take at least one minute. THE COMPASS MUST

REMAIN LEVEL DURING CALIBRATION.

3. After two complete revolutions, press and hold CALIBRATE button

until indicator stops blinking. Calibration is now complete.

Calibration parameters are retained when power is removed.

4. Replace cover. Use this procedure to recalibrate compass at any

time.

1.2.2 AUXILIARY INPUTS

The 32500 has two special inputs for wind speed and direction and

four auxiliary voltage input channels for connection to other

meteorological instruments like temperature and humidity sensors,

and barometers. For best performance, the sensors should be

installed within 3m (10ft.) of the 32500. Measurements from the

auxiliary input channels are converted to numerical values (0-4000

Full Scale) and sent in the selected serial output string.

For VIN1 and VIN2 full scale input is 1.00 VDC, therefore:

Serial output value = input millivolts x 4

For VIN3 and VIN4 full scale input is 5.00 VDC, therefore:

Serial output value = input millivolts x 0.8

Refer to serial output format drawing and wiring diagram.

1.2.3JUMPERS

W1 JUMPERS The two W1 jumpers determine serial output format.

The two jumper positions are designated A and B. Four possible

jumper configurations and associated output format are listed

below. The first three configurations set the 32500 output to a

popular format without further intervention. The last configuration,

SOFTWARE MODE, allows output format and other operating

parameters to be set via a software Command menu. Refer to the

WIRING DIAGRAM for jumper locations. Refer to the SERIAL

FORMAT DIAGRAM for details regarding serial output format.

The SERIAL COMMUNICATION section provides details about

SOFTWARE MODE.

JUMPERS SERIAL OUTPUT FORMAT

NONE WS WD1 V1 V2 V3 V4 COMPASS WD2

A RMYT for connection to YOUNG Wind Tracker

B NMEA sentences

A & B SOFTWAREMODE

The first 3 format selections override any software commands

given in the above SOFTWARE MODE. See page 4 for detailed

SERIAL OUTPUT FORMAT information.

W2 JUMPERS The W2 jumper pattern sets the output connection

type. Only one connection type may be used at one time. Refer

to the WIRING DIAGRAM drawing for jumper location and

connection details.

Page2

JUMPERS OUTPUTTYPE

VOUT Calibrated output for wind speed and direction.

0-5000mV = 0-100 m/s

0-5000mV = 0-360 degrees

232 RS-232 full duplex serial input/output

485 RS-485 half duplex serial input/output

1.2.4 SERIAL COMMUNICATION

Both RS-232 and RS-485 connections are available. The RS-232

type is the simplest to use and features full-duplex operation.

Transmission distances of up to 30M (100ft.) using RS-232 are ac-

ceptable. The RS-485 option is a good choice in electrically noisy

environments, in cases where the units must be networked, or in

NMEA marine applications where the differential RS-485 signal lev-

els are required.

The RS-485 connection is half-duplex meaning the unit cannot

transmit and receive at the same time. Internal hardware and soft-

ware automatically manage the transition from transmit to receive

as needed. However, when using RS-485, be sure that any exter-

nally connected devices are also capable of managing the transition

for itself. YOUNG RS-485/232 converter modules incorporate this

capability. Transmission distances up to 70km (4mi.) using RS-485

are possible.

Three of the W1 jumper configurations set predetermined serial out-

put formats without further setup or intervention. When W1 jumpers

are set for SOFTWARE MODE, operating parameters may be set via

the Command menu using a simple serial communications program

such as the popular HyperTerm or ProComm.

1.2.5 COMMANDS

To access the Command menu, with W1 jumpers set to

SOFTWARE MODE, send three ESC (ASCII 27) characters to

the 32500 in quick succession via the serial connection. The

32500 replies by sending the Command menu with these

options:

COMMANDS

-----------------------

B) BAUD

C) CALIBRATE VOLTAGE

D) DAMPING

F) FORMAT

R) RATE

S) STATUS

X) EXIT TO OPERATE MODE

NOTE: The RATE menu item does not appear when the output for-

mat is RMYT. In that case the rate is preset.

BAUD sets the serial communications baud rate.

NOTE: Selecting output formats NMEA or RMYT via W1 jumpers

or the FORMAT menu item may change the baud rate without

user intervention. Also, your serial communications program must

always be set to the same baud rate as the 32500 or it will be un-

able to communicate.

BAUD RATE

----------

A) 1200

B) 2400

C) 4800

D) 9600

X) EXIT

CALIBRATE VOLTAGE is used to calibrate voltage inputs and ex-

ternal devices connected to the voltage outputs. This command

should be used only by qualified technicians.

To calibrate the voltage inputs, apply full scale reference voltage

to an input and select the menu item associated with that input.

The standard full scale input for VIN1 and VIN2 is 1.000 VDC. For

VIN3 and VIN4 the full scale input is 5.000 VDC.

Whatever voltage appears on the input when the menu item is

selected will be recorded internally as the full scale value and

used to scale all measurements on that input channel when the

32500isin OPERATEmode.IMPROPER CALIBRATIONWILLRE-

SULTINERRONEOUSMEASUREMENTS.

Use menu items E and F to calibrate externally connected de-

vices such as data loggers and chart recorders. To use items E

and F, jumper W2 must be set for voltage outputs. See W2

JUMPERSfor additionaldetails.

OPTIONS A THRU D FOR

QUALIFIED TECHNICIAN ONLY!

IMPROPER USE CAUSES ERRONEOUS

CALIBRATION DATA TO BE STORED.

CALIBRATE VOLTAGE

-----------------

A) VIN1 FS

B) VIN2 FS

C) VIN3 FS

D) VIN4 FS

E) VOUT ZERO

F) VOUT FS

X) EXIT

DAMPING sets the amount of averaging to use on compass mea-

surements. When DAMPING is set to NONE or FAST, compass

readings change quickly. When set to SLOW, the readings

change more gradually and are often easier to interpret.

COMPASS DAMPING

-----------------

N) NONE

F) FAST

S) SLOW

X) EXIT

FORMAT selects the serial output format. Formats RMYT and

NMEA will automatically change the baud rate. See the SERIAL

FORMAT DIAGRAM for details.

OUTPUT FORMAT

------------------------------------------------------------

A) RMYT

B) RMY POLLED

C) NMEA (KNOTS DEGREES(TRUE))

D) NMEA (KNOTS DEGREES(TRUE) TEMP RH BARO)

E) SPEED DIR(CORRECTED) V1 V2 V3 V4 COMPASS DIR(UNCORRECTED)

F) COMPASS DIAGNOSTICS

X) EXIT

When RMY POLLED is selected, a prompt appears for entering a

single character ‘address’:

ENTER SINGLE CHAR POLL ADDR [0-9, A-Z, a-z] : a

This is the address character that must be used when polling the

32500 for data. By using unique addresses, up to 16 units may be

networked on the same RS-485 connections.

RATE sets the output rate. The RATE menu item does not appear

when the output format is RMYT since, for that format , the output

is fixed at 15 Hz. The 0.1 Hz output means that an output ap-

pears once every 10 seconds.

OUTPUT RATE

-----------

A) 15 HZ

B) 2 HZ

C) 0.1 HZ

X) EXIT

STATUS reports firmware version and other parameters. These

values are used only by qualified technicians to asses the state

of the 32500. A typical STATUS report appears below.

STATUS

YOUNG 32500 ELECTRONIC COMPASS v1.22

------------------------------------

Page3

VIN1 FS: 3716

VIN2 FS: 3715

VIN3 FS: 4094

VIN4 FS: 4095

FORMAT: RMY POLLED

POLL ADDR: a

OUTPUT RATE: 15 HZ

BAUD: 9600

OFFSET X,Y,RATIO: -251, 75, 847

COMPASS DAMPING: SLOW

WATCHDOG TIMER: ENABLED

1.2.6POLLEDMEASUREMENTS

When the serial output format is RMY POLLED, the 32500 sends

data only when it receives a polling command that contains the

unique address of the unit being polled. The command for polling is:

Ma!

where a = address character.

See the SERIAL FORMAT DIAGRAM for details on the data sent

from the 32500 when polled.

1.3 MAINTENANCE

Like all quality measuring instruments, the 32500 Electronic Com-

pass should be periodically recalibrated. The recalibration period de-

pends on the application but once per year is typical. The unit may

be sent to the factory or your distributor for recalibration. A copy of

the calibration procedure is available to qualified technicians.

In order to compensate for local magnetic conditions, the compass

calibration can take place only at the site where it is installed. If the

installation is changed, the compass must be recalibrated for

the new conditions. In addition to changing the actual installation,

local conditions may also change by the introduction of iron masses

or electrical machinery and thus warrant recalibration.

1.4 WARRANTY

This product is warranted to be free of defects in materials and con-

struction for a period of 12 months from date of initial purchase. Li-

ability is limited to repair or replacement of defective item. A copy of

the warranty policy may be obtained from R. M. Young Company.

CE COMPLIANCE

This product has been tested and shown to comply with European

CE requirements for the EMC Directive. Please note that shielded

cable must be used.

Declaration of Conformity

Application of Council Directives: 89/336/EEC

Standards to which Conformity is Declared:

EN 50081-1

EN 55022 (CISPR 22 class A)

EN 50082-1 (IEC 801-2, 3, 4)

Manufacturer's Name and Address: R. M. Young Company

Traverse City, MI, 49686, USA

Importer's Name and Address: See Shipper or Invoice

Type of Equipment: Meteorological Instruments

Model Number / Year of Manufacture: 32400/32500/2000

I, the undersigned, hereby declare that the equipment

specified conforms to the above Directives and Standards.

Date / Place: Traverse City, Michigan, USA September 1, 2000

David Poinsett

R & D Manager, R. M. Young Company

Other manuals for 32500

3

Table of contents

Other R.M. Young Compass manuals

Popular Compass manuals by other brands

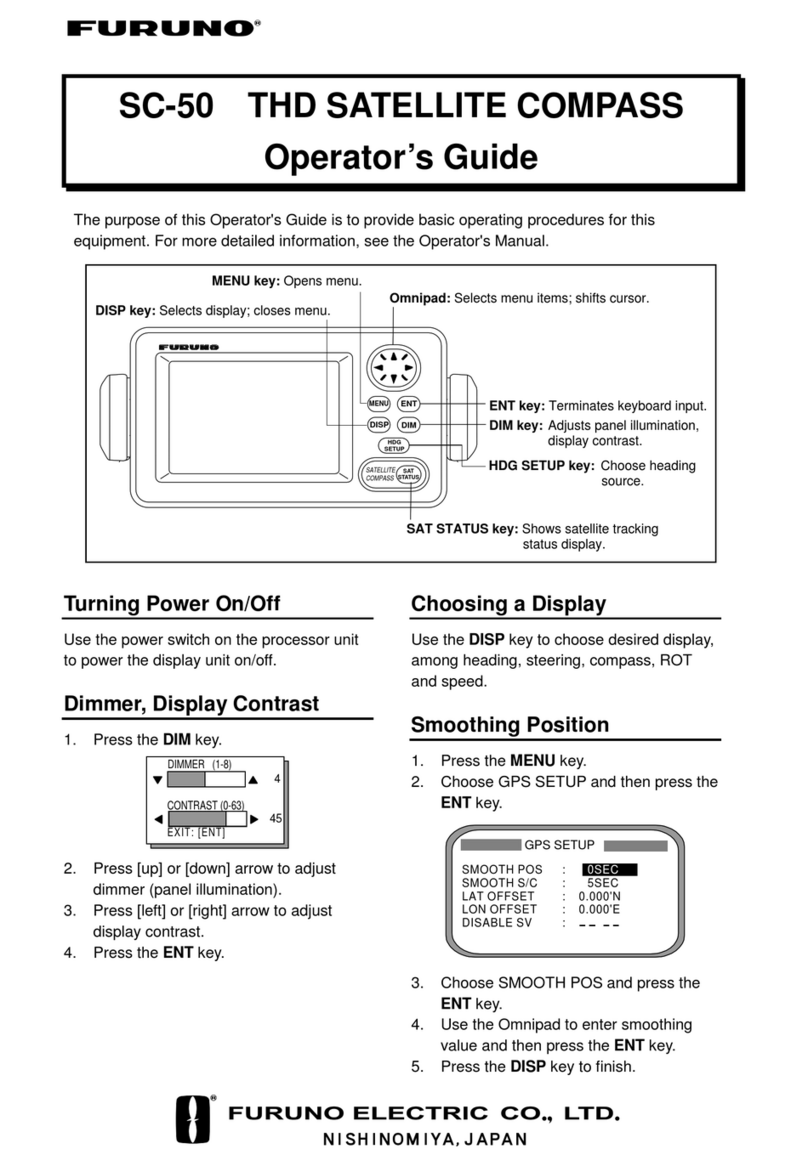

Furuno

Furuno Sc 50 Operator's guide

B&G Network

B&G Network Network System user manual

Riviera

Riviera ARTICA 2 3/4 user manual

SIRS Navigation

SIRS Navigation KCA0101C COMPONENT MAINTENANCE MANUAL WITH ILLUSTRATED PARTS LIST

Raymarine

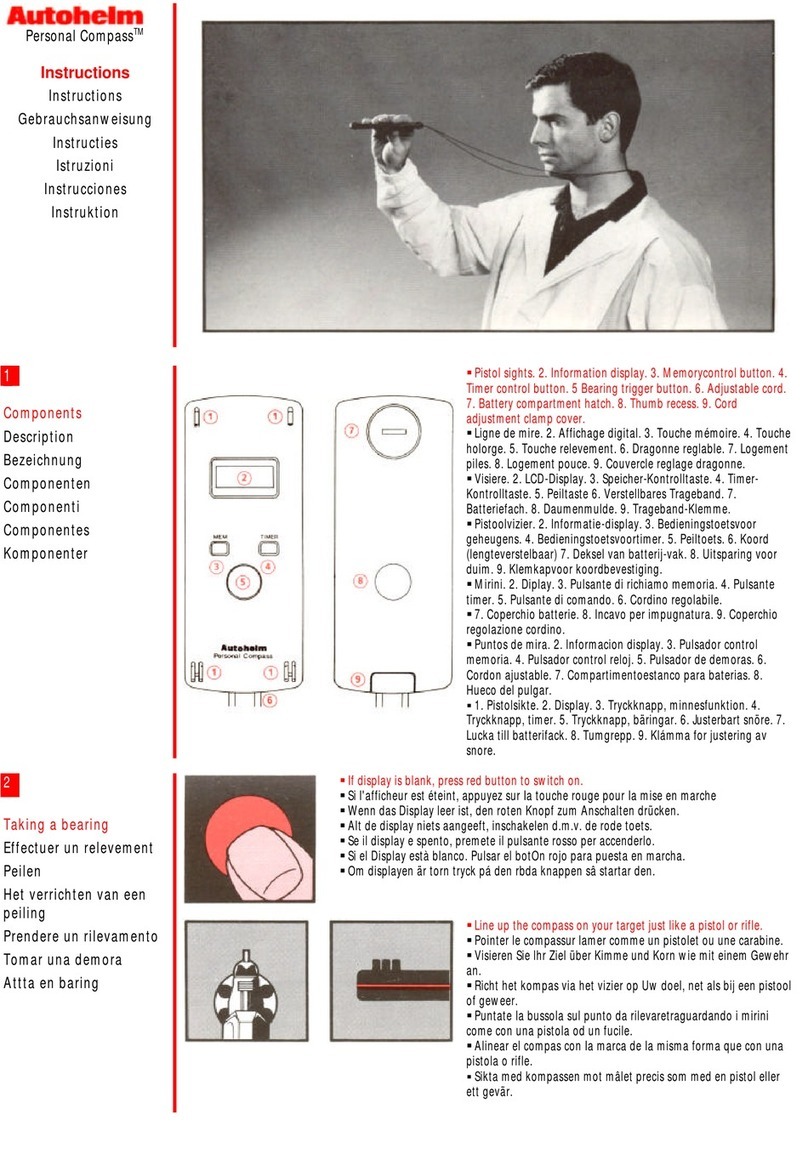

Raymarine Compass user guide

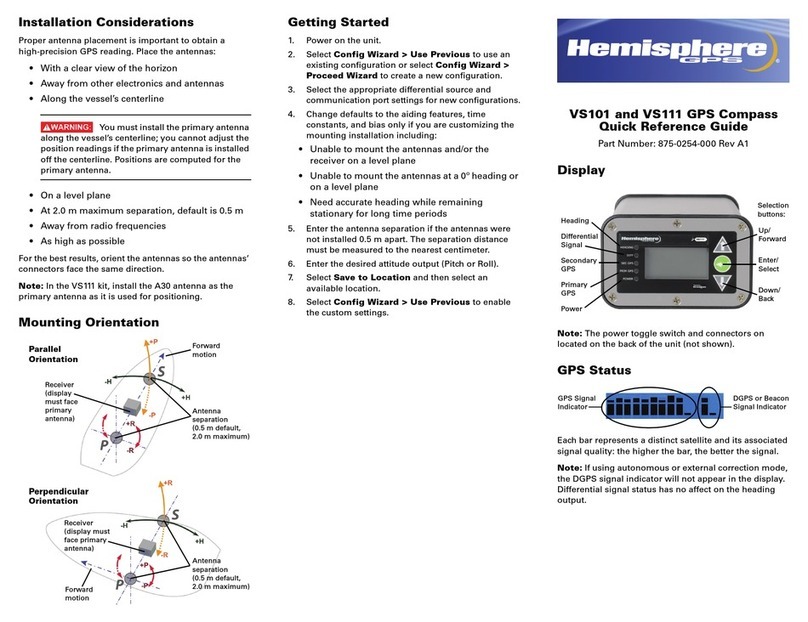

Hemisphere GPS

Hemisphere GPS VS101 Quick reference guide