TABLE OF CONTENTS

Page I © 2007 DH Instruments, a Fluke Company

T

TA

AB

BL

LE

E

O

OF

F

C

CO

ON

NT

TE

EN

NT

TS

S

TABLE OF CONTENTS...............................................................I

TABLES.................................................................................III

FIGURES................................................................................III

ABOUT THIS MANUAL ..............................................................V

1. INTRODUCTION .................................................................1

1.1 PRODUCT OVERVIEW ...........................................................................................................................1

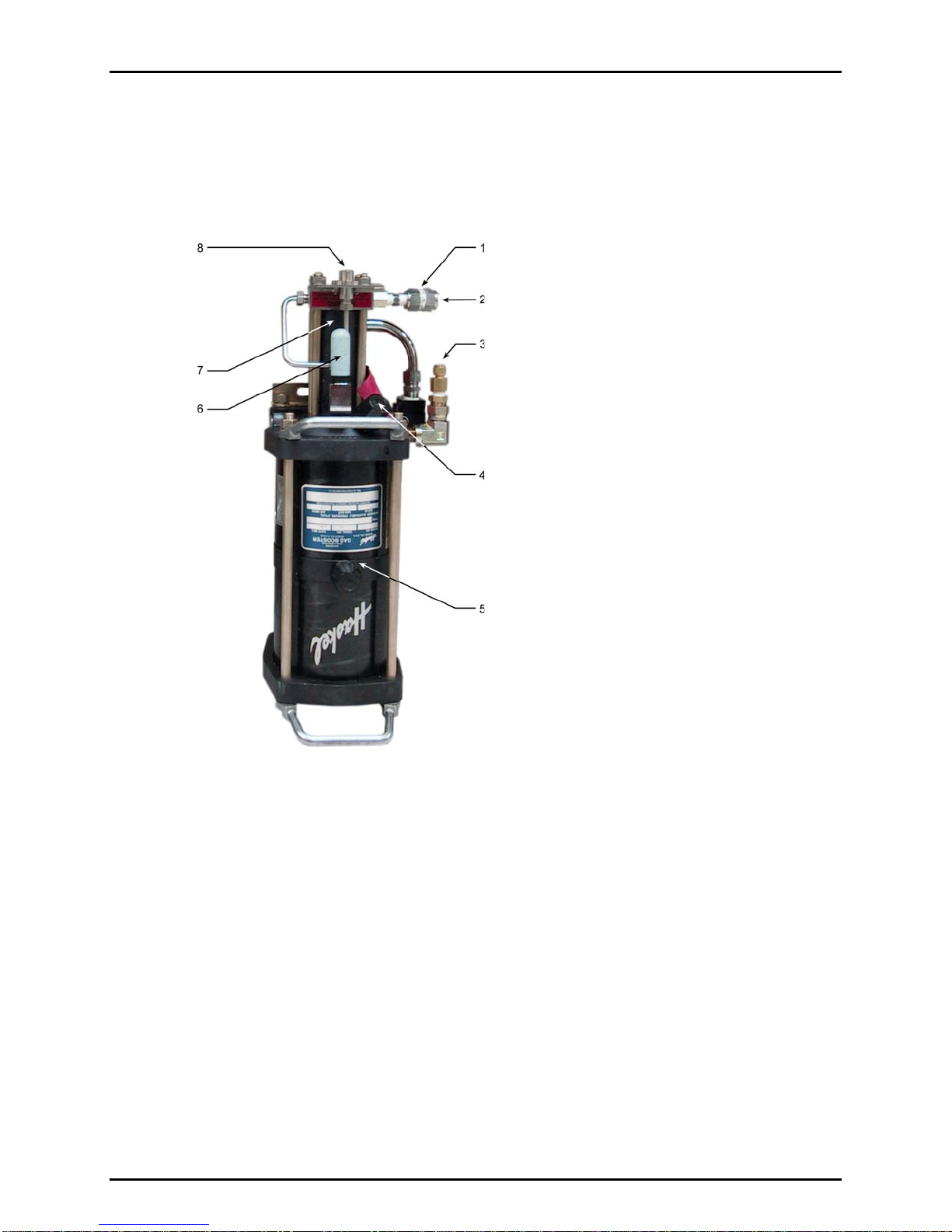

1.2 LOCATION AND DESCRIPTION OF THE COMPONENTS....................................................................2

1.2.1 GAS BOOSTER.............................................................................................................................................2

1.2.2 DRIVE AIR CONTROL KIT............................................................................................................................3

1.3 SPECIFICATIONS ...................................................................................................................................4

2. INSTALLATION ..................................................................5

2.1 UNPACKING AND INSPECTION ............................................................................................................5

2.2 PGC-10000-AF SYSTEM.........................................................................................................................6

2.3 SITE REQUIREMENTS............................................................................................................................7

2.3.1 SITE................................................................................................................................................................7

2.3.2 GAS SUPPLIES.............................................................................................................................................7

2.3.2.1 DRIVE AIR SUPPLY ..................................................................................................................................7

2.3.2.2 HIGH PRESSURE INSTRUMENT GAS.....................................................................................................7

2.4 INSTALLATION AND INITIAL SETUP ....................................................................................................8

2.4.1 GENERAL CONSIDERATIONS.....................................................................................................................8

2.4.2 INSTALLATION .............................................................................................................................................8

2.4.2.1 BOOSTER INSTALLATION .......................................................................................................................9

2.4.2.2 DRIVE AIR CONTROL KIT INSTALLATION..............................................................................................9

2.4.2.3 BOOSTER HIGH PRESSURE INSTRUMENT GAS SUPPLY CONNECTION........................................10

2.4.2.4 BOOSTER HIGH PRESSURE OUTPUT CONNECTION........................................................................10

2.5 INITIAL START UP................................................................................................................................12

3. OPERATION..................................................................... 13

3.1 GENERAL OPERATING PRINCIPLE AND INFORMATION.................................................................13

3.2 OPERATION..........................................................................................................................................14

3.2.1 SETTING THE BOOSTER OUTPUT PRESSURE ......................................................................................14

3.2.2 TURNING THE BOOSTER ON AND OFF...................................................................................................15

4. MAINTENANCE AND ADJUSTMENTS .................................. 17

4.1 MAINTENANCE.....................................................................................................................................17

4.2 ILLUSTRATED PARTS BREAKDOWN.................................................................................................17