Flushmate 501-A Series Application guide

TROUBLESHOOTING _____________________________________________________________

CONDITION: No Flush

Step 1. Check the water pressure (20 psi to 125 psi).

Step 2. Check the Air Inducer for sufficient air draw. Refer to Step 2 of

“Weak or Sluggish Flush”.

Step 3. Review all of Step 3 and Step 4 covered in “Weak or Sluggish Flush”

Condition.

Step 4. Replace the Flush Valve Cartridge. NEVER use lubricant on the “O”

Ring (Arrow - Figure 6).

CONDITION: Relief Valve Discharging

This is a sign that the Lower Supply Group (Number 1 from list of components) is not working properly and should be replaced. Follow

the procedure outlined below:

REPLACE PROCEDURE FOR LOWER SUPPLY:

Step 1. Turn the water supply off. Flush the fixture to relieve pressure

in the Vessel.

Step 2. Disconnect the water supply from the Shank.

Step 3. Unscrew the plastic locknut that holds the Shank to the bottom

of the China Tank.

Step 4. Carefully pull the entire Lower Supply up and out of the Tank.

Step 5. Cut the Hose just above the Barbed Fitting (about 1/4” above

clamp) on the Lower Supply. Discard old Lower Supply.

Step 6. Insert new Lower Supply into Hose and secure with new Hose Clamp.

Step 7. Follow Step 3 above and in reverse to re-connect water and check for leaks.

WINTERIZING___________________________________________________________________

The Sloan FLUSHMATE®, when installed in a summer home, cottage or cabin, can be winterized to allow for periods for non-

use especially when the dwelling is subject to frigid conditions. Follow the procedures outlined below.

NOTE: A sponge, a pail and adjustable channel locks will be useful.

Tank Procedure:

Step 1. Turn off the water supply line valve and remove the Toilet Tank Cover.

Step 2. Push the Actuator on top of the Vessel to flush and discharge the water.

Step 3. Disconnect the supply line coupling nut from the Lower Supply located under the Toilet Tank Housing. NOTE:

A small amount of water will drip out of the Shank. Be prepared to collect it in a bucket or sponge it up. Remove the

Supply Shank and drain the water from the bottom of the china tank into a bucket.

Step 4. Push down on the Actuator one more time, then pull it up momentarily to allow air into the Vessel.

Bowl Procedure:

After flushing out the Vessel, remove the remaining water from the bowl or add from 1 pint to 1 quart of antifreeze

or RV antifreeze to the water remaining in the bowl.

NOTE: Refer to fixture manufacturer’s instructions for procedures to winterize bowl.

POINTS TO REMEMBER ______________________________________________________

•When servicing any component, the water supply should be turned OFF and the Actuator tripped to relieve

the pressure in the Vessel.

•The Flush Valve Cartridge Assembly can be removed by inserting the handles of a pair of pliers into the top

of the Cartridge and turning counter-clockwise.

•It is normal for less than an inch of water to remain in the bottom of the outside China Tank. The FLUSHMATE ®

System will automatically recirculate this water with each flush to eliminate any stagnant condition.

•

NEVER use corrosive disinfectants, bowl cleaners or deodorant blocks on FLUSHMATE

®

Products or in the

china tank.

•Cold water use only.

The Sloan FLUSHMATE ®Flushometer-Tank System has been engineered to provide reliable performance year after year. However, if

servicing is ever required, it is recommended that you follow the instructions included in this brochure. If you would like additional

information or require technical assistance, write or call us at the address or telephone number below.

ATTENTION OWNER

THIS IS YOUR WARRANTY REGISTRATION

Sloan FLUSHMATE (the "Company") warrants the FLUSHMATE®flushometer tank operating system (the "unit") to be free of defects in

material and workmanship for a period of two (2) years from the date of installation and the Company promises to replace any part of

this product that proves, upon our inspection and within two (2) years from date of installation, to be defective in material or

workmanship. All labor and transportation costs or charges incidental to warranty service are to be borne by the purchaser-user.

This warranty is subject to the following:

Specific Conditions to Warranty

A Warranty Registration card has been fully completed and mailed by the purchaser (the “user”) to the Company within thirty (30) days

of the date of installation.

The unit has been subject to proper installation, operation and maintenance as outlined in the installation instructions that were supplied

with the unit. Note carefully that this warranty is voided if the unit is installed and operated subject to water supply line pressures greater

than 125 psi (static) or less than 20 psi (static).

Service and repairs may only be performed by authorized representatives of the Company or by others upon specific approval by the

Company. Unauthorized repairs or alterations shall specifically void the warranty.

Use of chemical disinfectants or corrosive household cleaners on FLUSHMATE®products will void this warranty.

Proof of purchase is required.

Exclusions

IN NO EVENT SHALL THE COMPANY BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES, FOR DAMAGES RESULTING

FROM IMPROPER INSTALLATION, OR FOR DAMAGES CAUSED BY NEGLECT, ABUSE OR ALTERATION. ALL IMPLIED WARRANTIES,

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE ARE LIMITED TO A

PERIOD OF TWO (2) YEARS FROM DATE OF INSTALLATION.

Some states do not allow limitations on the duration of an implied warranty and some states do not allow exclusions or limitations

regarding incidental or consequential damages, so the above limitations may not apply to you. This warranty gives you specific legal

rights and you may have other rights which vary from state to state.

No person is authorized to change, add to, or create any warranty or obligation other than that set forth herein.

To obtain warranty service contact Consumer Services toll free 1-800-533-3450 (outside North America, call 248-446-5300) or

write to us at:

FLUSHMATE®

A DIVISION OF SLOAN VALVE CO.

30075 Research Drive

New Hudson, MI 48165 U.S.A.

800-533-3450 • 248-446-5300

http://www.flushmate.com

Installation Date ________________________________________________________________________________________

Serial Number __________________________________________________________________________________________

©2002 Sloan Flushmate FLU6018.1 0702

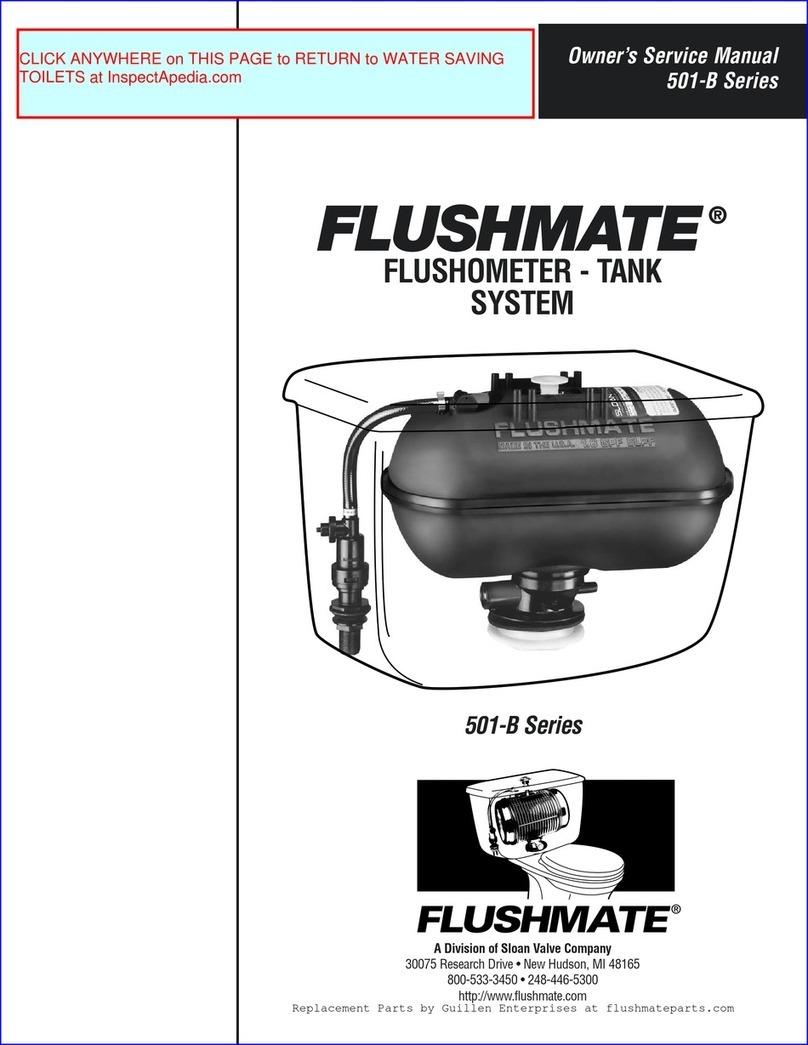

FLUSHMATE®

FLUSHOMETER - TANK

SYSTEM

501-A Series

Owner’s Service Manual

501-A Series

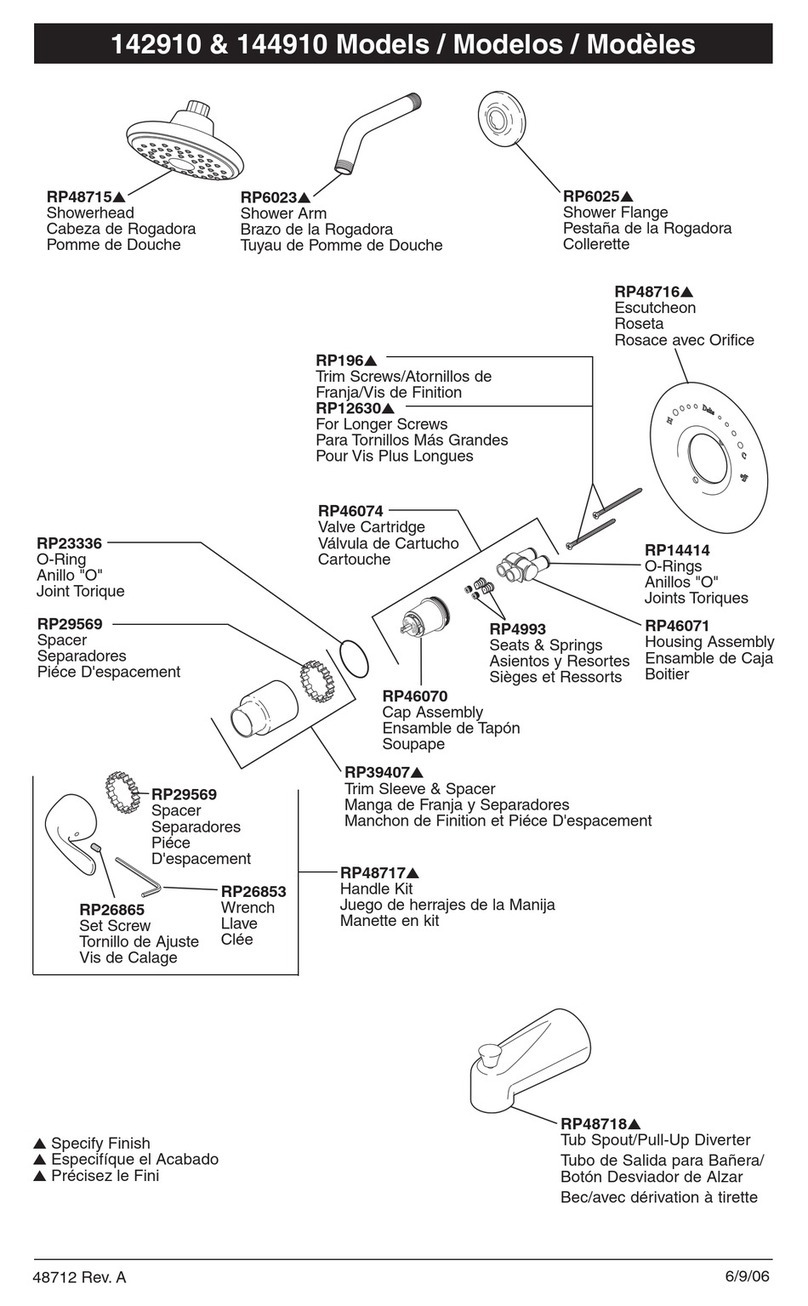

FIGURE 6

FIGURE 7

A Division of Sloan Valve Company

30075 Research Drive • New Hudson, MI 48165

800-533-3450 • 248-446-5300

http://www.flushmate.com

FLUSHMATE ®501-A SERIES_______________________________________________________

INSTALLATION __________________________________________________________________

The Sloan FLUSHMATE ®Flushometer-Tank System Fixture installs in the same manner as other water closets. Please follow the

instructions provided by the fixture manufacturer.

Using the gasket, washer and nuts provided with the fixture, assemble the tank to the bowl. Before connecting the supply to the tank,

be sure the supply line is flushed clean. Do this by running water from the supply stop into a bucket until water flows clear.

After connecting the supply line to the tank, turn on the water again and check for leaks. You may be required to make adjustments to

the actuator for either pushbutton type or trip lever type units. Please follow the instructions provided by the fixture manufacturer.

TROUBLESHOOTING _____________________________________________________________

CONDITION: Water runs on and will not shut off.

A newly installed toilet that does not shut off may be caused by inadequate or low pressure, and is usually the result of an insufficient

water supply flow rate into the FLUSHMATE Vessel. (NOTE: The recommended static pressure range by code is 20 p.s.i. to 125 p.s.i.).

If sufficient supply pressure has been verified and the toilet continues to run, the following steps may be required:

Step 1. Make sure supply stop is fully open.

Step 2. Check the Supply Shank Screen for any obstruction that would

restrict the supply.

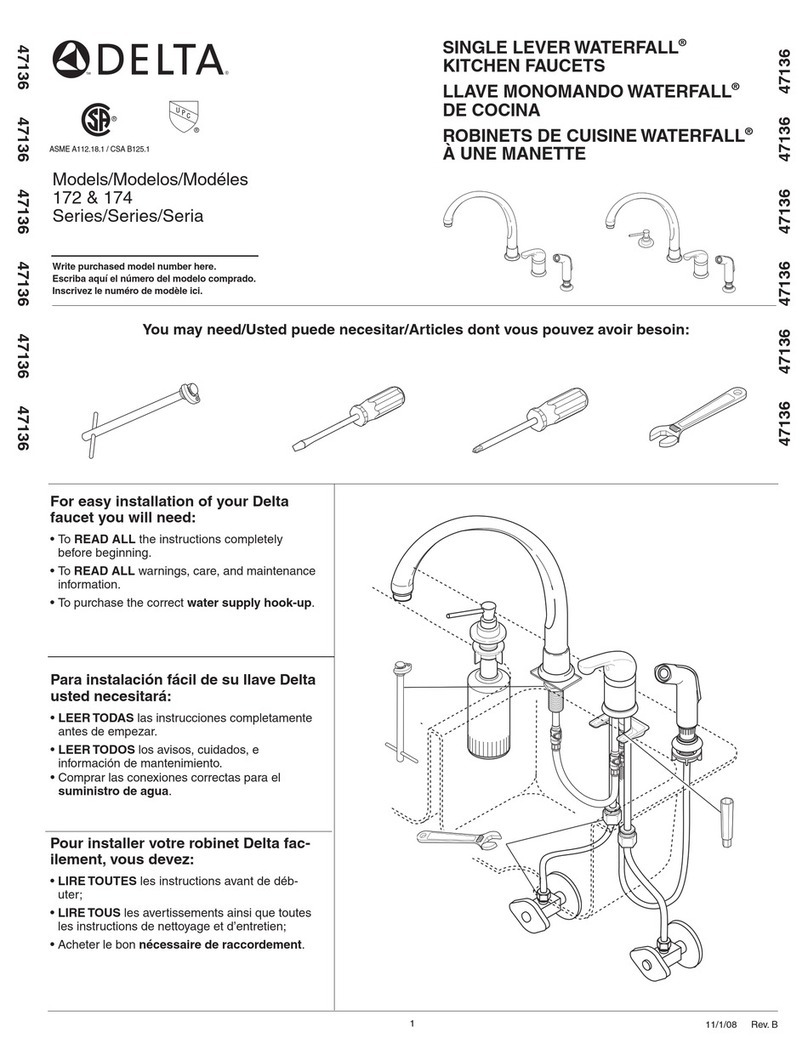

Step 3: Check the Actuator adjustment (see Installation Procedure). The

linkage rod or push button should not interfere with the flush. On

Pushbutton type units, loosen the setscrew on the actuator (See

Number 4F on the component list) and rotate the Actuator up or

down until proper clearance is obtained (1/8”). For trip lever units,

gently lift the actuator rod and observe proper clearance is

maintained (approximately 1/8” gap between rod and actuator). See

Figure 1.

Step 4. Check the Flush Valve Cartridge Assembly for proper installation.

Proceed as follows:

a) Turn off the water supply and flush the toilet.

b) Remove the Flush Valve Cartridge Assembly using pliers’

handles as shown in Figure 2. NOTE: You may be required to

disconnect the Actuator Linkage Rod to remove the Flush Valve

Cartridge Assembly.

c) Inspect the “O” Rings on the Flush Valve Cartridge and the

seating area inside the tank for wear and/or improper seating.

Step 5. Reinstall the Flush Valve Cartridge Assembly.

First, insert the cartridge into vessel and, while gently

pushing down on the Cartridge, turn the Cartridge counter-

clockwise until you hear an audible click, indicating that the

threads are now aligned. Screw Cartridge clockwise into

place until two black threads of the Vessel are showing.

Next, turn on the water and continue to turn cartridge until

the water stops running. Do not over-tighten.

Step 6. If the Tank continues to run on, push down lightly on the Flush Valve Actuator. If the water stops running, it is an indication that

the Flush Valve Cartridge requires tightening (clockwise). If water still runs on while pushing down on the Actuator, the Flush Valve

Cartridge requires loosening (counter-clockwise).

NOTE: Adjust the Flush Valve Cartridge Assembly in quarter- to half-turn increments until the water stops running. Always turn the water

supply off for all adjustments. Flush Valve Cartridge turns the water off.

Step 7. If replacement of the Flush Valve Cartridge is necessary, follow the instructions in Step 5.

TROUBLESHOOTING _____________________________________________________________

CONDITION: Weak or Sluggish Flush.

Step 1. Check the water pressure (20psi - 125psi recommended). If OK,

then check the Flush System by removing the Tank Cover and tripping the

Actuator. While the unit is flushing, gently raise the Actuator. Water should

flow freely and wash away any debris in the supply line and Vessel.

Step 2. Check the Air Inducer for sufficient air draw. The Air Inducer is

designed to draw air during the refill cycle. To test the Air Inducer, place a

small amount of water (2 to 3 drops) in the orifice of the Air Inducer cap

and flush the toilet. If the Air Inducer is functioning properly the water will

be drawn in. If not, it will need to be cleaned and tested again.

TO CLEAN AIR INDUCER: (Figures 3 & 4)

a) Turn off the water supply and trip the Actuator.

b) Unscrew the Air Inducer Cap, clean thoroughly and remove

any obstructions. Reassemble. (Hand tighten ONLY)

c) Turn on water supply. Wait for the Vessel to refill (30 to 60

seconds). Repeat Step 2 above. If the Air Inducer does not

function properly, replace the Upper Supply Assembly.

Step 3. Check the Flush Valve Cartridge for leaks. Turn the water supply off

and drain the Vessel by tripping the Actuator and holding it down until

completely drained. Next, pour a cup of water onto the Cartridge Housing

area as shown in Figure 5. Turn on the water supply. If a leak is detected

(a steady flow of bubbles from the center of the Cartridge Area), the

Cartridge should be replaced.

Step 4. Check Lower Supply. Turn the water off and relieve the Vessel

pressure by flushing the toilet. Remove the supply line connection to the

shank. Remove any obstruction in the supply shank screen. If necessary,

you can use a small brush to gently brush the screen. Reattach the supply

line to the supply shank and observe connections to assure no leakage.

IMPORTANT: If you are still experiencing a weak or sluggish flush after this

point, it is recommended you replace the entire lower supply group.

Step 5. Check the following:

1. water line pressure (20 - 125psi)

2. obstruction in the bowl trapway

3. obstruction in the drain

4. proper drain ventilation

Consult a professional for their recommendations if any of these

conditions exist. If the drain and drain vent are clear, and the flush has not

been improved, replace the Lower Supply Assembly.

List of Components for 501-A Series*:

1. Lower Supply Group w/Hose BL100504

(A) Supply Shank with Screen

(B) Pressure Regulator w/Back Check

(C) Relief Valve

2. Upper Supply Group BU100505

(D) Air Inducer

(E) Vacuum Breaker

3. Name Plate w/Serial Number

4. Flush Valve Cartridge Assembly C-100500

(F) Actuator w/setscrew

5. Vessel

6. Discharge Extension w/Drain

FLUSHMATE®

A Division of Sloan Valve Company

Manufactured under one or more of the following U.S. patents:

3,817,279 3,817,286; 3,817,489; 3,820,171,754; 4,233,698 and

5,802,628. Also covered by various foreign patents (country and

number available upon request) and other patents pending.

The Sloan FLUSHMATE®Flushometer - Tank System provides the highest

performance capability available today in the ULF (Ultra-Low Fixture) category. That

means it consumes less than 1.6 gallons/6 liters of water per flush. It achieves this

remarkable performance by using compressed air inside the tank, which creates a

turbo-charged flushing action for effective bowl cleaning. Compared to other types of

low consumption water closets, FLUSHMATE offers many distinct advantages.

Outstanding FLUSHMATE ®Features:

•Positive Bowl Extraction (No Double Flushing)

•Stronger Flushing Action Improves Drainline Carry &

Leaves Bowl Cleaner

•Large Water Spot for Reduced Housekeeping

•Uses less than 1.6 gallons per flush

•Larger Trapway to Eliminate Stoppages

•No Water Leakage Between Flushes

•Non-Sweating Tank Enclosure

WARNING:

When servicing or replacing components to the FLUSHMATE®Flushometer-Tank

System, make certain that the water supply is turned OFF and the toilet is then flushed to

relieve pressure in the vessel.

NEVER

use lubricants on any of the components unless otherwise noted in this manual.

NEVER use corrosive chemicals or household cleaners on FLUSHMATE products.

NEVER

use corrosive disinfectants, bowl cleaners or deodorant blocks on FLUSHMATE

®

Products or in the china tank.

Note: It is normal for less than one inch of water to remain in the bottom of the china tank.

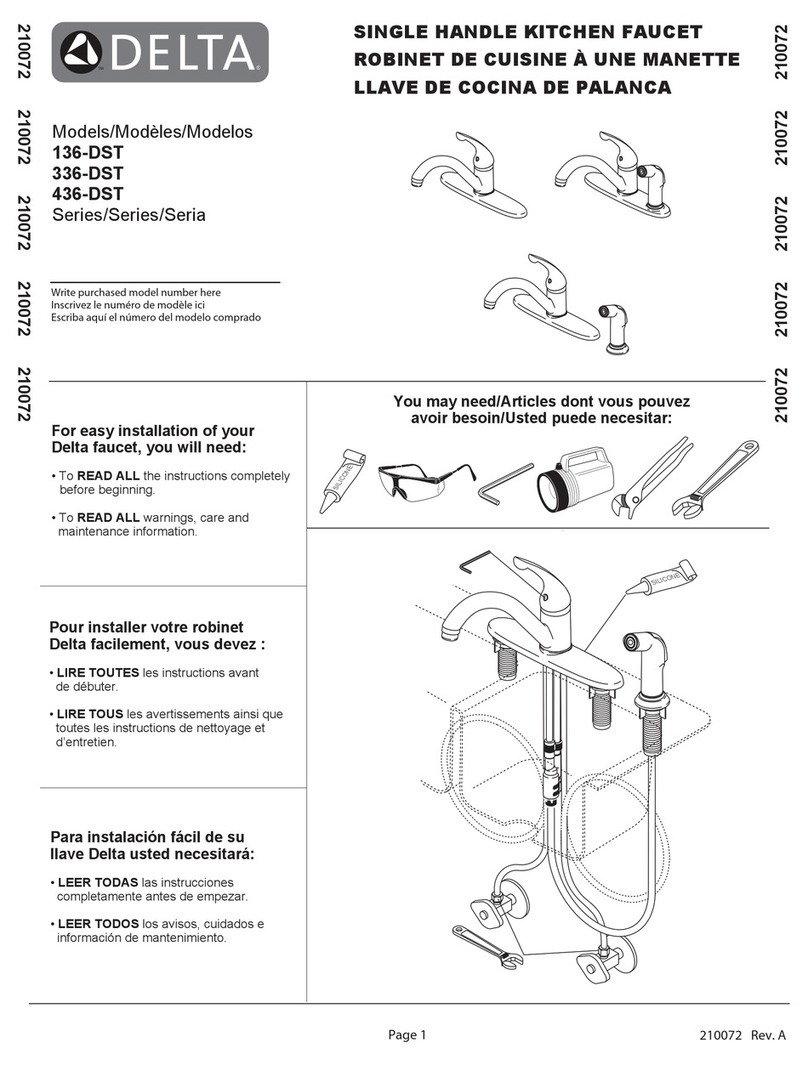

FIGURE 1

(A)

(B)

(C)

(D)

(E)

(F)

1

23

4

5

6

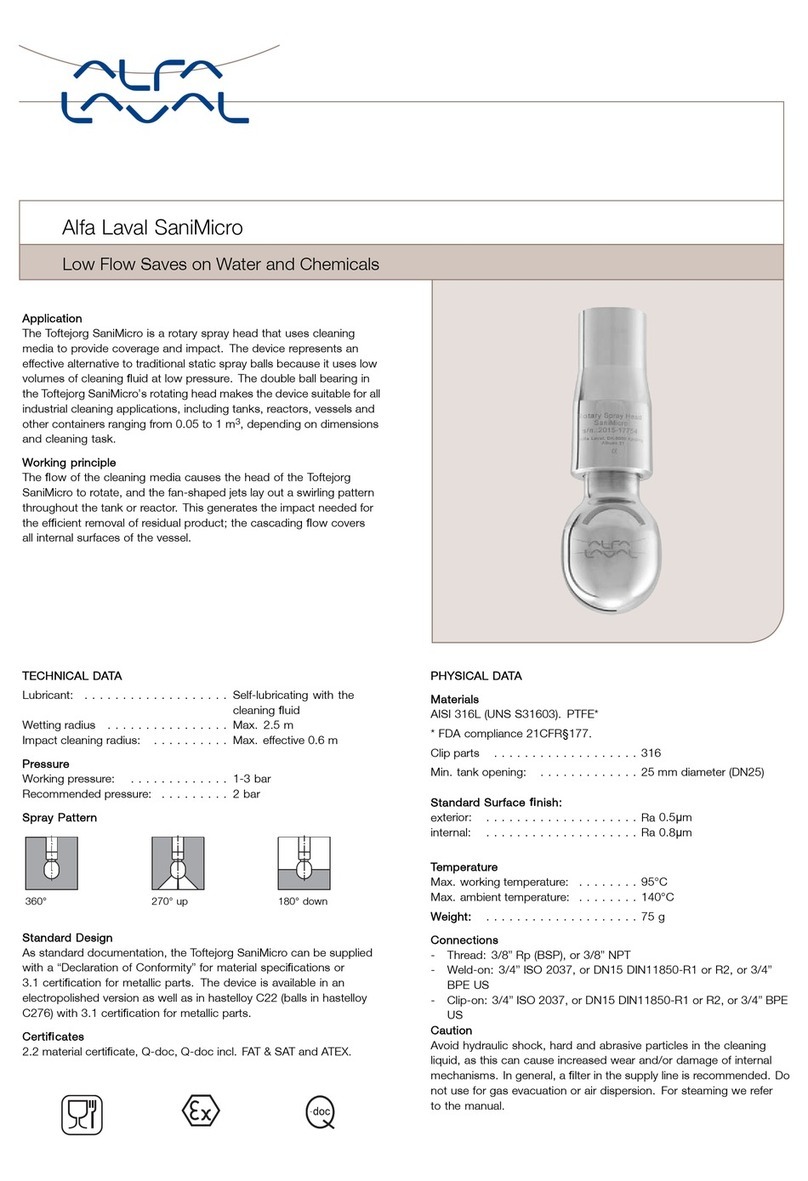

FIGURE 2

FIGURE 3

FIGURE 4

FIGURE 5

Air Inducer Cap

* Components identified may appear different but are a direct replacement for this series.

FLUSHMATE ®501-A SERIES_______________________________________________________

INSTALLATION __________________________________________________________________

The Sloan FLUSHMATE ®Flushometer-Tank System Fixture installs in the same manner as other water closets. Please follow the

instructions provided by the fixture manufacturer.

Using the gasket, washer and nuts provided with the fixture, assemble the tank to the bowl. Before connecting the supply to the tank,

be sure the supply line is flushed clean. Do this by running water from the supply stop into a bucket until water flows clear.

After connecting the supply line to the tank, turn on the water again and check for leaks. You may be required to make adjustments to

the actuator for either pushbutton type or trip lever type units. Please follow the instructions provided by the fixture manufacturer.

TROUBLESHOOTING _____________________________________________________________

CONDITION: Water runs on and will not shut off.

A newly installed toilet that does not shut off may be caused by inadequate or low pressure, and is usually the result of an insufficient

water supply flow rate into the FLUSHMATE Vessel. (NOTE: The recommended static pressure range by code is 20 p.s.i. to 125 p.s.i.).

If sufficient supply pressure has been verified and the toilet continues to run, the following steps may be required:

Step 1. Make sure supply stop is fully open.

Step 2. Check the Supply Shank Screen for any obstruction that would

restrict the supply.

Step 3: Check the Actuator adjustment (see Installation Procedure). The

linkage rod or push button should not interfere with the flush. On

Pushbutton type units, loosen the setscrew on the actuator (See

Number 4F on the component list) and rotate the Actuator up or

down until proper clearance is obtained (1/8”). For trip lever units,

gently lift the actuator rod and observe proper clearance is

maintained (approximately 1/8” gap between rod and actuator). See

Figure 1.

Step 4. Check the Flush Valve Cartridge Assembly for proper installation.

Proceed as follows:

a) Turn off the water supply and flush the toilet.

b) Remove the Flush Valve Cartridge Assembly using pliers’

handles as shown in Figure 2. NOTE: You may be required to

disconnect the Actuator Linkage Rod to remove the Flush Valve

Cartridge Assembly.

c) Inspect the “O” Rings on the Flush Valve Cartridge and the

seating area inside the tank for wear and/or improper seating.

Step 5. Reinstall the Flush Valve Cartridge Assembly.

First, insert the cartridge into vessel and, while gently

pushing down on the Cartridge, turn the Cartridge counter-

clockwise until you hear an audible click, indicating that the

threads are now aligned. Screw Cartridge clockwise into

place until two black threads of the Vessel are showing.

Next, turn on the water and continue to turn cartridge until

the water stops running. Do not over-tighten.

Step 6. If the Tank continues to run on, push down lightly on the Flush Valve Actuator. If the water stops running, it is an indication that

the Flush Valve Cartridge requires tightening (clockwise). If water still runs on while pushing down on the Actuator, the Flush Valve

Cartridge requires loosening (counter-clockwise).

NOTE: Adjust the Flush Valve Cartridge Assembly in quarter- to half-turn increments until the water stops running. Always turn the water

supply off for all adjustments. Flush Valve Cartridge turns the water off.

Step 7. If replacement of the Flush Valve Cartridge is necessary, follow the instructions in Step 5.

TROUBLESHOOTING _____________________________________________________________

CONDITION: Weak or Sluggish Flush.

Step 1. Check the water pressure (20psi - 125psi recommended). If OK,

then check the Flush System by removing the Tank Cover and tripping the

Actuator. While the unit is flushing, gently raise the Actuator. Water should

flow freely and wash away any debris in the supply line and Vessel.

Step 2. Check the Air Inducer for sufficient air draw. The Air Inducer is

designed to draw air during the refill cycle. To test the Air Inducer, place a

small amount of water (2 to 3 drops) in the orifice of the Air Inducer cap

and flush the toilet. If the Air Inducer is functioning properly the water will

be drawn in. If not, it will need to be cleaned and tested again.

TO CLEAN AIR INDUCER: (Figures 3 & 4)

a) Turn off the water supply and trip the Actuator.

b) Unscrew the Air Inducer Cap, clean thoroughly and remove

any obstructions. Reassemble. (Hand tighten ONLY)

c) Turn on water supply. Wait for the Vessel to refill (30 to 60

seconds). Repeat Step 2 above. If the Air Inducer does not

function properly, replace the Upper Supply Assembly.

Step 3. Check the Flush Valve Cartridge for leaks. Turn the water supply off

and drain the Vessel by tripping the Actuator and holding it down until

completely drained. Next, pour a cup of water onto the Cartridge Housing

area as shown in Figure 5. Turn on the water supply. If a leak is detected

(a steady flow of bubbles from the center of the Cartridge Area), the

Cartridge should be replaced.

Step 4. Check Lower Supply. Turn the water off and relieve the Vessel

pressure by flushing the toilet. Remove the supply line connection to the

shank. Remove any obstruction in the supply shank screen. If necessary,

you can use a small brush to gently brush the screen. Reattach the supply

line to the supply shank and observe connections to assure no leakage.

IMPORTANT: If you are still experiencing a weak or sluggish flush after this

point, it is recommended you replace the entire lower supply group.

Step 5. Check the following:

1. water line pressure (20 - 125psi)

2. obstruction in the bowl trapway

3. obstruction in the drain

4. proper drain ventilation

Consult a professional for their recommendations if any of these

conditions exist. If the drain and drain vent are clear, and the flush has not

been improved, replace the Lower Supply Assembly.

List of Components for 501-A Series*:

1. Lower Supply Group w/Hose BL100504

(A) Supply Shank with Screen

(B) Pressure Regulator w/Back Check

(C) Relief Valve

2. Upper Supply Group BU100505

(D) Air Inducer

(E) Vacuum Breaker

3. Name Plate w/Serial Number

4. Flush Valve Cartridge Assembly C-100500

(F) Actuator w/setscrew

5. Vessel

6. Discharge Extension w/Drain

FLUSHMATE®

A Division of Sloan Valve Company

Manufactured under one or more of the following U.S. patents:

3,817,279 3,817,286; 3,817,489; 3,820,171,754; 4,233,698 and

5,802,628. Also covered by various foreign patents (country and

number available upon request) and other patents pending.

The Sloan FLUSHMATE®Flushometer - Tank System provides the highest

performance capability available today in the ULF (Ultra-Low Fixture) category. That

means it consumes less than 1.6 gallons/6 liters of water per flush. It achieves this

remarkable performance by using compressed air inside the tank, which creates a

turbo-charged flushing action for effective bowl cleaning. Compared to other types of

low consumption water closets, FLUSHMATE offers many distinct advantages.

Outstanding FLUSHMATE ®Features:

•Positive Bowl Extraction (No Double Flushing)

•Stronger Flushing Action Improves Drainline Carry &

Leaves Bowl Cleaner

•Large Water Spot for Reduced Housekeeping

•Uses less than 1.6 gallons per flush

•Larger Trapway to Eliminate Stoppages

•No Water Leakage Between Flushes

•Non-Sweating Tank Enclosure

WARNING:

When servicing or replacing components to the FLUSHMATE®Flushometer-Tank

System, make certain that the water supply is turned OFF and the toilet is then flushed to

relieve pressure in the vessel.

NEVER

use lubricants on any of the components unless otherwise noted in this manual.

NEVER use corrosive chemicals or household cleaners on FLUSHMATE products.

NEVER

use corrosive disinfectants, bowl cleaners or deodorant blocks on FLUSHMATE

®

Products or in the china tank.

Note: It is normal for less than one inch of water to remain in the bottom of the china tank.

FIGURE 1

(A)

(B)

(C)

(D)

(E)

(F)

1

23

4

5

6

FIGURE 2

FIGURE 3

FIGURE 4

FIGURE 5

Air Inducer Cap

* Components identified may appear different but are a direct replacement for this series.

FLUSHMATE ®501-A SERIES_______________________________________________________

INSTALLATION __________________________________________________________________

The Sloan FLUSHMATE ®Flushometer-Tank System Fixture installs in the same manner as other water closets. Please follow the

instructions provided by the fixture manufacturer.

Using the gasket, washer and nuts provided with the fixture, assemble the tank to the bowl. Before connecting the supply to the tank,

be sure the supply line is flushed clean. Do this by running water from the supply stop into a bucket until water flows clear.

After connecting the supply line to the tank, turn on the water again and check for leaks. You may be required to make adjustments to

the actuator for either pushbutton type or trip lever type units. Please follow the instructions provided by the fixture manufacturer.

TROUBLESHOOTING _____________________________________________________________

CONDITION: Water runs on and will not shut off.

A newly installed toilet that does not shut off may be caused by inadequate or low pressure, and is usually the result of an insufficient

water supply flow rate into the FLUSHMATE Vessel. (NOTE: The recommended static pressure range by code is 20 p.s.i. to 125 p.s.i.).

If sufficient supply pressure has been verified and the toilet continues to run, the following steps may be required:

Step 1. Make sure supply stop is fully open.

Step 2. Check the Supply Shank Screen for any obstruction that would

restrict the supply.

Step 3: Check the Actuator adjustment (see Installation Procedure). The

linkage rod or push button should not interfere with the flush. On

Pushbutton type units, loosen the setscrew on the actuator (See

Number 4F on the component list) and rotate the Actuator up or

down until proper clearance is obtained (1/8”). For trip lever units,

gently lift the actuator rod and observe proper clearance is

maintained (approximately 1/8” gap between rod and actuator). See

Figure 1.

Step 4. Check the Flush Valve Cartridge Assembly for proper installation.

Proceed as follows:

a) Turn off the water supply and flush the toilet.

b) Remove the Flush Valve Cartridge Assembly using pliers’

handles as shown in Figure 2. NOTE: You may be required to

disconnect the Actuator Linkage Rod to remove the Flush Valve

Cartridge Assembly.

c) Inspect the “O” Rings on the Flush Valve Cartridge and the

seating area inside the tank for wear and/or improper seating.

Step 5. Reinstall the Flush Valve Cartridge Assembly.

First, insert the cartridge into vessel and, while gently

pushing down on the Cartridge, turn the Cartridge counter-

clockwise until you hear an audible click, indicating that the

threads are now aligned. Screw Cartridge clockwise into

place until two black threads of the Vessel are showing.

Next, turn on the water and continue to turn cartridge until

the water stops running. Do not over-tighten.

Step 6. If the Tank continues to run on, push down lightly on the Flush Valve Actuator. If the water stops running, it is an indication that

the Flush Valve Cartridge requires tightening (clockwise). If water still runs on while pushing down on the Actuator, the Flush Valve

Cartridge requires loosening (counter-clockwise).

NOTE: Adjust the Flush Valve Cartridge Assembly in quarter- to half-turn increments until the water stops running. Always turn the water

supply off for all adjustments. Flush Valve Cartridge turns the water off.

Step 7. If replacement of the Flush Valve Cartridge is necessary, follow the instructions in Step 5.

TROUBLESHOOTING _____________________________________________________________

CONDITION: Weak or Sluggish Flush.

Step 1. Check the water pressure (20psi - 125psi recommended). If OK,

then check the Flush System by removing the Tank Cover and tripping the

Actuator. While the unit is flushing, gently raise the Actuator. Water should

flow freely and wash away any debris in the supply line and Vessel.

Step 2. Check the Air Inducer for sufficient air draw. The Air Inducer is

designed to draw air during the refill cycle. To test the Air Inducer, place a

small amount of water (2 to 3 drops) in the orifice of the Air Inducer cap

and flush the toilet. If the Air Inducer is functioning properly the water will

be drawn in. If not, it will need to be cleaned and tested again.

TO CLEAN AIR INDUCER: (Figures 3 & 4)

a) Turn off the water supply and trip the Actuator.

b) Unscrew the Air Inducer Cap, clean thoroughly and remove

any obstructions. Reassemble. (Hand tighten ONLY)

c) Turn on water supply. Wait for the Vessel to refill (30 to 60

seconds). Repeat Step 2 above. If the Air Inducer does not

function properly, replace the Upper Supply Assembly.

Step 3. Check the Flush Valve Cartridge for leaks. Turn the water supply off

and drain the Vessel by tripping the Actuator and holding it down until

completely drained. Next, pour a cup of water onto the Cartridge Housing

area as shown in Figure 5. Turn on the water supply. If a leak is detected

(a steady flow of bubbles from the center of the Cartridge Area), the

Cartridge should be replaced.

Step 4. Check Lower Supply. Turn the water off and relieve the Vessel

pressure by flushing the toilet. Remove the supply line connection to the

shank. Remove any obstruction in the supply shank screen. If necessary,

you can use a small brush to gently brush the screen. Reattach the supply

line to the supply shank and observe connections to assure no leakage.

IMPORTANT: If you are still experiencing a weak or sluggish flush after this

point, it is recommended you replace the entire lower supply group.

Step 5. Check the following:

1. water line pressure (20 - 125psi)

2. obstruction in the bowl trapway

3. obstruction in the drain

4. proper drain ventilation

Consult a professional for their recommendations if any of these

conditions exist. If the drain and drain vent are clear, and the flush has not

been improved, replace the Lower Supply Assembly.

List of Components for 501-A Series*:

1. Lower Supply Group w/Hose BL100504

(A) Supply Shank with Screen

(B) Pressure Regulator w/Back Check

(C) Relief Valve

2. Upper Supply Group BU100505

(D) Air Inducer

(E) Vacuum Breaker

3. Name Plate w/Serial Number

4. Flush Valve Cartridge Assembly C-100500

(F) Actuator w/setscrew

5. Vessel

6. Discharge Extension w/Drain

FLUSHMATE®

A Division of Sloan Valve Company

Manufactured under one or more of the following U.S. patents:

3,817,279 3,817,286; 3,817,489; 3,820,171,754; 4,233,698 and

5,802,628. Also covered by various foreign patents (country and

number available upon request) and other patents pending.

The Sloan FLUSHMATE®Flushometer - Tank System provides the highest

performance capability available today in the ULF (Ultra-Low Fixture) category. That

means it consumes less than 1.6 gallons/6 liters of water per flush. It achieves this

remarkable performance by using compressed air inside the tank, which creates a

turbo-charged flushing action for effective bowl cleaning. Compared to other types of

low consumption water closets, FLUSHMATE offers many distinct advantages.

Outstanding FLUSHMATE ®Features:

•Positive Bowl Extraction (No Double Flushing)

•Stronger Flushing Action Improves Drainline Carry &

Leaves Bowl Cleaner

•Large Water Spot for Reduced Housekeeping

•Uses less than 1.6 gallons per flush

•Larger Trapway to Eliminate Stoppages

•No Water Leakage Between Flushes

•Non-Sweating Tank Enclosure

WARNING:

When servicing or replacing components to the FLUSHMATE®Flushometer-Tank

System, make certain that the water supply is turned OFF and the toilet is then flushed to

relieve pressure in the vessel.

NEVER

use lubricants on any of the components unless otherwise noted in this manual.

NEVER use corrosive chemicals or household cleaners on FLUSHMATE products.

NEVER

use corrosive disinfectants, bowl cleaners or deodorant blocks on FLUSHMATE

®

Products or in the china tank.

Note: It is normal for less than one inch of water to remain in the bottom of the china tank.

FIGURE 1

(A)

(B)

(C)

(D)

(E)

(F)

1

23

4

5

6

FIGURE 2

FIGURE 3

FIGURE 4

FIGURE 5

Air Inducer Cap

* Components identified may appear different but are a direct replacement for this series.

TROUBLESHOOTING _____________________________________________________________

CONDITION: No Flush

Step 1. Check the water pressure (20 psi to 125 psi).

Step 2. Check the Air Inducer for sufficient air draw. Refer to Step 2 of

“Weak or Sluggish Flush”.

Step 3. Review all of Step 3 and Step 4 covered in “Weak or Sluggish Flush”

Condition.

Step 4. Replace the Flush Valve Cartridge. NEVER use lubricant on the “O”

Ring (Arrow - Figure 6).

CONDITION: Relief Valve Discharging

This is a sign that the Lower Supply Group (Number 1 from list of components) is not working properly and should be replaced. Follow

the procedure outlined below:

REPLACE PROCEDURE FOR LOWER SUPPLY:

Step 1. Turn the water supply off. Flush the fixture to relieve pressure

in the Vessel.

Step 2. Disconnect the water supply from the Shank.

Step 3. Unscrew the plastic locknut that holds the Shank to the bottom

of the China Tank.

Step 4. Carefully pull the entire Lower Supply up and out of the Tank.

Step 5. Cut the Hose just above the Barbed Fitting (about 1/4” above

clamp) on the Lower Supply. Discard old Lower Supply.

Step 6. Insert new Lower Supply into Hose and secure with new Hose Clamp.

Step 7. Follow Step 3 above and in reverse to re-connect water and check for leaks.

WINTERIZING___________________________________________________________________

The Sloan FLUSHMATE®, when installed in a summer home, cottage or cabin, can be winterized to allow for periods for non-

use especially when the dwelling is subject to frigid conditions. Follow the procedures outlined below.

NOTE: A sponge, a pail and adjustable channel locks will be useful.

Tank Procedure:

Step 1. Turn off the water supply line valve and remove the Toilet Tank Cover.

Step 2. Push the Actuator on top of the Vessel to flush and discharge the water.

Step 3. Disconnect the supply line coupling nut from the Lower Supply located under the Toilet Tank Housing. NOTE:

A small amount of water will drip out of the Shank. Be prepared to collect it in a bucket or sponge it up. Remove the

Supply Shank and drain the water from the bottom of the china tank into a bucket.

Step 4. Push down on the Actuator one more time, then pull it up momentarily to allow air into the Vessel.

Bowl Procedure:

After flushing out the Vessel, remove the remaining water from the bowl or add from 1 pint to 1 quart of antifreeze

or RV antifreeze to the water remaining in the bowl.

NOTE: Refer to fixture manufacturer’s instructions for procedures to winterize bowl.

POINTS TO REMEMBER ______________________________________________________

•When servicing any component, the water supply should be turned OFF and the Actuator tripped to relieve

the pressure in the Vessel.

•The Flush Valve Cartridge Assembly can be removed by inserting the handles of a pair of pliers into the top

of the Cartridge and turning counter-clockwise.

•It is normal for less than an inch of water to remain in the bottom of the outside China Tank. The FLUSHMATE ®

System will automatically recirculate this water with each flush to eliminate any stagnant condition.

•

NEVER use corrosive disinfectants, bowl cleaners or deodorant blocks on FLUSHMATE

®

Products or in the

china tank.

•Cold water use only.

The Sloan FLUSHMATE ®Flushometer-Tank System has been engineered to provide reliable performance year after year. However, if

servicing is ever required, it is recommended that you follow the instructions included in this brochure. If you would like additional

information or require technical assistance, write or call us at the address or telephone number below.

ATTENTION OWNER

THIS IS YOUR WARRANTY REGISTRATION

Sloan FLUSHMATE (the "Company") warrants the FLUSHMATE®flushometer tank operating system (the "unit") to be free of defects in

material and workmanship for a period of two (2) years from the date of installation and the Company promises to replace any part of

this product that proves, upon our inspection and within two (2) years from date of installation, to be defective in material or

workmanship. All labor and transportation costs or charges incidental to warranty service are to be borne by the purchaser-user.

This warranty is subject to the following:

Specific Conditions to Warranty

A Warranty Registration card has been fully completed and mailed by the purchaser (the “user”) to the Company within thirty (30) days

of the date of installation.

The unit has been subject to proper installation, operation and maintenance as outlined in the installation instructions that were supplied

with the unit. Note carefully that this warranty is voided if the unit is installed and operated subject to water supply line pressures greater

than 125 psi (static) or less than 20 psi (static).

Service and repairs may only be performed by authorized representatives of the Company or by others upon specific approval by the

Company. Unauthorized repairs or alterations shall specifically void the warranty.

Use of chemical disinfectants or corrosive household cleaners on FLUSHMATE®products will void this warranty.

Proof of purchase is required.

Exclusions

IN NO EVENT SHALL THE COMPANY BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES, FOR DAMAGES RESULTING

FROM IMPROPER INSTALLATION, OR FOR DAMAGES CAUSED BY NEGLECT, ABUSE OR ALTERATION. ALL IMPLIED WARRANTIES,

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE ARE LIMITED TO A

PERIOD OF TWO (2) YEARS FROM DATE OF INSTALLATION.

Some states do not allow limitations on the duration of an implied warranty and some states do not allow exclusions or limitations

regarding incidental or consequential damages, so the above limitations may not apply to you. This warranty gives you specific legal

rights and you may have other rights which vary from state to state.

No person is authorized to change, add to, or create any warranty or obligation other than that set forth herein.

To obtain warranty service contact Consumer Services toll free 1-800-533-3450 (outside North America, call 248-446-5300) or

write to us at:

FLUSHMATE®

A DIVISION OF SLOAN VALVE CO.

30075 Research Drive

New Hudson, MI 48165 U.S.A.

800-533-3450 • 248-446-5300

http://www.flushmate.com

Installation Date ________________________________________________________________________________________

Serial Number __________________________________________________________________________________________

©2002 Sloan Flushmate FLU6018.1 0702

FLUSHMATE®

FLUSHOMETER - TANK

SYSTEM

501-A Series

Owner’s Service Manual

501-A Series

FIGURE 6

FIGURE 7

A Division of Sloan Valve Company

30075 Research Drive • New Hudson, MI 48165

800-533-3450 • 248-446-5300

http://www.flushmate.com

TROUBLESHOOTING _____________________________________________________________

CONDITION: No Flush

Step 1. Check the water pressure (20 psi to 125 psi).

Step 2. Check the Air Inducer for sufficient air draw. Refer to Step 2 of

“Weak or Sluggish Flush”.

Step 3. Review all of Step 3 and Step 4 covered in “Weak or Sluggish Flush”

Condition.

Step 4. Replace the Flush Valve Cartridge. NEVER use lubricant on the “O”

Ring (Arrow - Figure 6).

CONDITION: Relief Valve Discharging

This is a sign that the Lower Supply Group (Number 1 from list of components) is not working properly and should be replaced. Follow

the procedure outlined below:

REPLACE PROCEDURE FOR LOWER SUPPLY:

Step 1. Turn the water supply off. Flush the fixture to relieve pressure

in the Vessel.

Step 2. Disconnect the water supply from the Shank.

Step 3. Unscrew the plastic locknut that holds the Shank to the bottom

of the China Tank.

Step 4. Carefully pull the entire Lower Supply up and out of the Tank.

Step 5. Cut the Hose just above the Barbed Fitting (about 1/4” above

clamp) on the Lower Supply. Discard old Lower Supply.

Step 6. Insert new Lower Supply into Hose and secure with new Hose Clamp.

Step 7. Follow Step 3 above and in reverse to re-connect water and check for leaks.

WINTERIZING___________________________________________________________________

The Sloan FLUSHMATE®, when installed in a summer home, cottage or cabin, can be winterized to allow for periods for non-

use especially when the dwelling is subject to frigid conditions. Follow the procedures outlined below.

NOTE: A sponge, a pail and adjustable channel locks will be useful.

Tank Procedure:

Step 1. Turn off the water supply line valve and remove the Toilet Tank Cover.

Step 2. Push the Actuator on top of the Vessel to flush and discharge the water.

Step 3. Disconnect the supply line coupling nut from the Lower Supply located under the Toilet Tank Housing. NOTE:

A small amount of water will drip out of the Shank. Be prepared to collect it in a bucket or sponge it up. Remove the

Supply Shank and drain the water from the bottom of the china tank into a bucket.

Step 4. Push down on the Actuator one more time, then pull it up momentarily to allow air into the Vessel.

Bowl Procedure:

After flushing out the Vessel, remove the remaining water from the bowl or add from 1 pint to 1 quart of antifreeze

or RV antifreeze to the water remaining in the bowl.

NOTE: Refer to fixture manufacturer’s instructions for procedures to winterize bowl.

POINTS TO REMEMBER ______________________________________________________

•When servicing any component, the water supply should be turned OFF and the Actuator tripped to relieve

the pressure in the Vessel.

•The Flush Valve Cartridge Assembly can be removed by inserting the handles of a pair of pliers into the top

of the Cartridge and turning counter-clockwise.

•It is normal for less than an inch of water to remain in the bottom of the outside China Tank. The FLUSHMATE ®

System will automatically recirculate this water with each flush to eliminate any stagnant condition.

•

NEVER use corrosive disinfectants, bowl cleaners or deodorant blocks on FLUSHMATE

®

Products or in the

china tank.

•Cold water use only.

The Sloan FLUSHMATE ®Flushometer-Tank System has been engineered to provide reliable performance year after year. However, if

servicing is ever required, it is recommended that you follow the instructions included in this brochure. If you would like additional

information or require technical assistance, write or call us at the address or telephone number below.

ATTENTION OWNER

THIS IS YOUR WARRANTY REGISTRATION

Sloan FLUSHMATE (the "Company") warrants the FLUSHMATE®flushometer tank operating system (the "unit") to be free of defects in

material and workmanship for a period of two (2) years from the date of installation and the Company promises to replace any part of

this product that proves, upon our inspection and within two (2) years from date of installation, to be defective in material or

workmanship. All labor and transportation costs or charges incidental to warranty service are to be borne by the purchaser-user.

This warranty is subject to the following:

Specific Conditions to Warranty

A Warranty Registration card has been fully completed and mailed by the purchaser (the “user”) to the Company within thirty (30) days

of the date of installation.

The unit has been subject to proper installation, operation and maintenance as outlined in the installation instructions that were supplied

with the unit. Note carefully that this warranty is voided if the unit is installed and operated subject to water supply line pressures greater

than 125 psi (static) or less than 20 psi (static).

Service and repairs may only be performed by authorized representatives of the Company or by others upon specific approval by the

Company. Unauthorized repairs or alterations shall specifically void the warranty.

Use of chemical disinfectants or corrosive household cleaners on FLUSHMATE®products will void this warranty.

Proof of purchase is required.

Exclusions

IN NO EVENT SHALL THE COMPANY BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES, FOR DAMAGES RESULTING

FROM IMPROPER INSTALLATION, OR FOR DAMAGES CAUSED BY NEGLECT, ABUSE OR ALTERATION. ALL IMPLIED WARRANTIES,

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE ARE LIMITED TO A

PERIOD OF TWO (2) YEARS FROM DATE OF INSTALLATION.

Some states do not allow limitations on the duration of an implied warranty and some states do not allow exclusions or limitations

regarding incidental or consequential damages, so the above limitations may not apply to you. This warranty gives you specific legal

rights and you may have other rights which vary from state to state.

No person is authorized to change, add to, or create any warranty or obligation other than that set forth herein.

To obtain warranty service contact Consumer Services toll free 1-800-533-3450 (outside North America, call 248-446-5300) or

write to us at:

FLUSHMATE®

A DIVISION OF SLOAN VALVE CO.

30075 Research Drive

New Hudson, MI 48165 U.S.A.

800-533-3450 • 248-446-5300

http://www.flushmate.com

Installation Date ________________________________________________________________________________________

Serial Number __________________________________________________________________________________________

©2002 Sloan Flushmate FLU6018.1 0702

FLUSHMATE®

FLUSHOMETER - TANK

SYSTEM

501-A Series

Owner’s Service Manual

501-A Series

FIGURE 6

FIGURE 7

A Division of Sloan Valve Company

30075 Research Drive • New Hudson, MI 48165

800-533-3450 • 248-446-5300

http://www.flushmate.com

Other Flushmate Plumbing Product manuals