POINTS TO REMEMBER ______________________________________________________

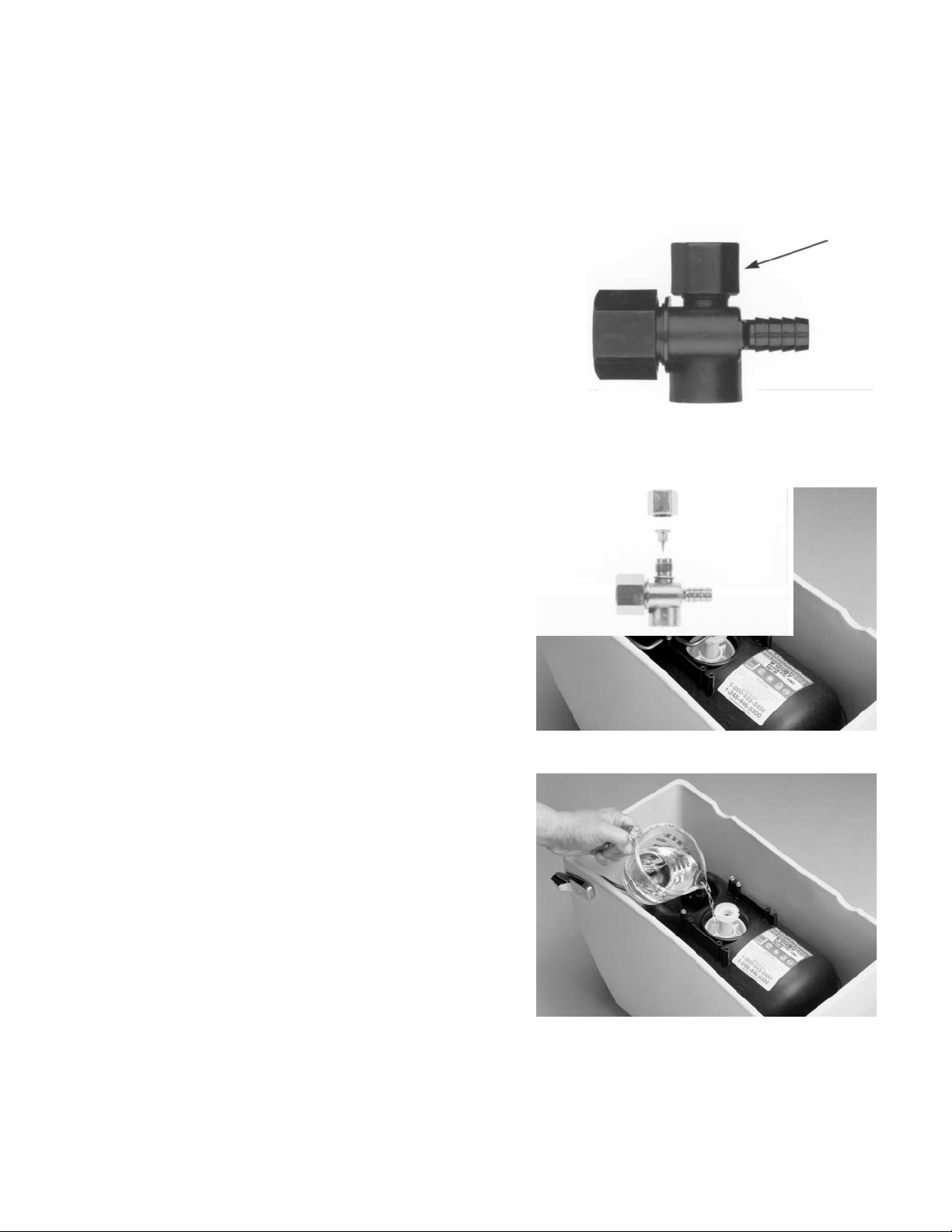

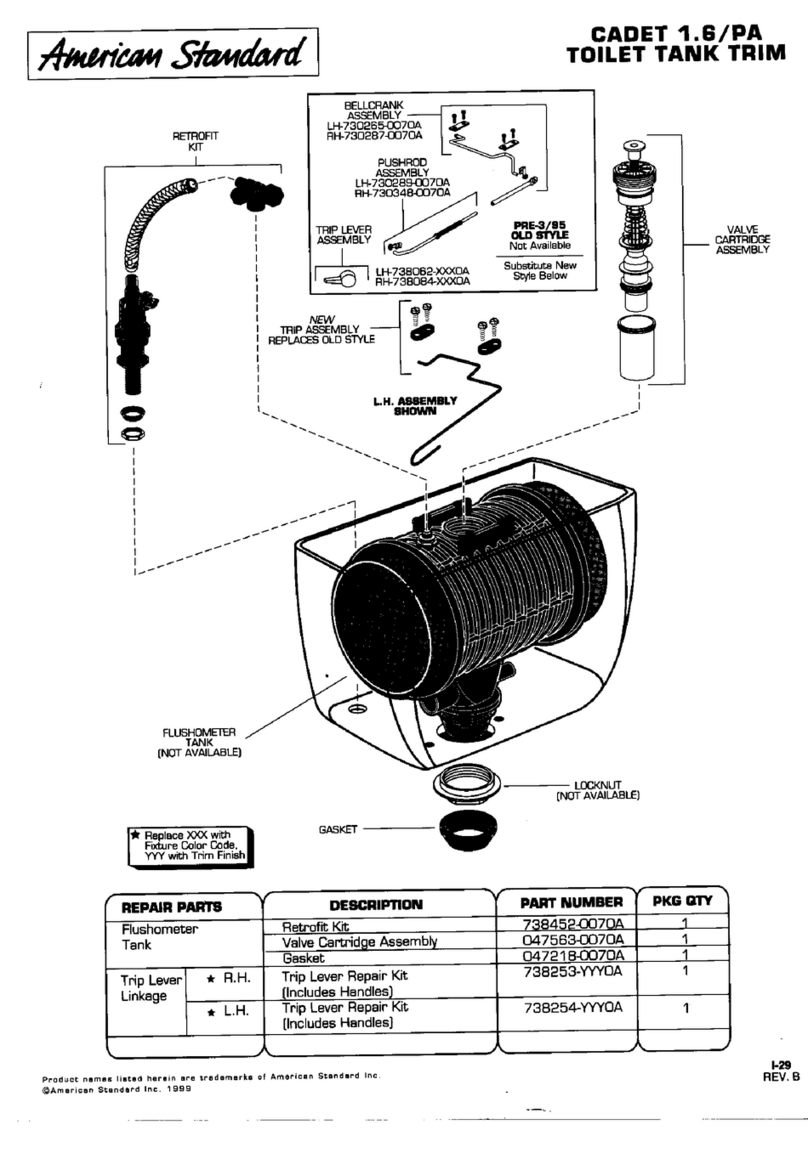

• When servicing any component, the water supply should be turned OFF and the Actuator tripped to relieve

the pressure in the Vessel.

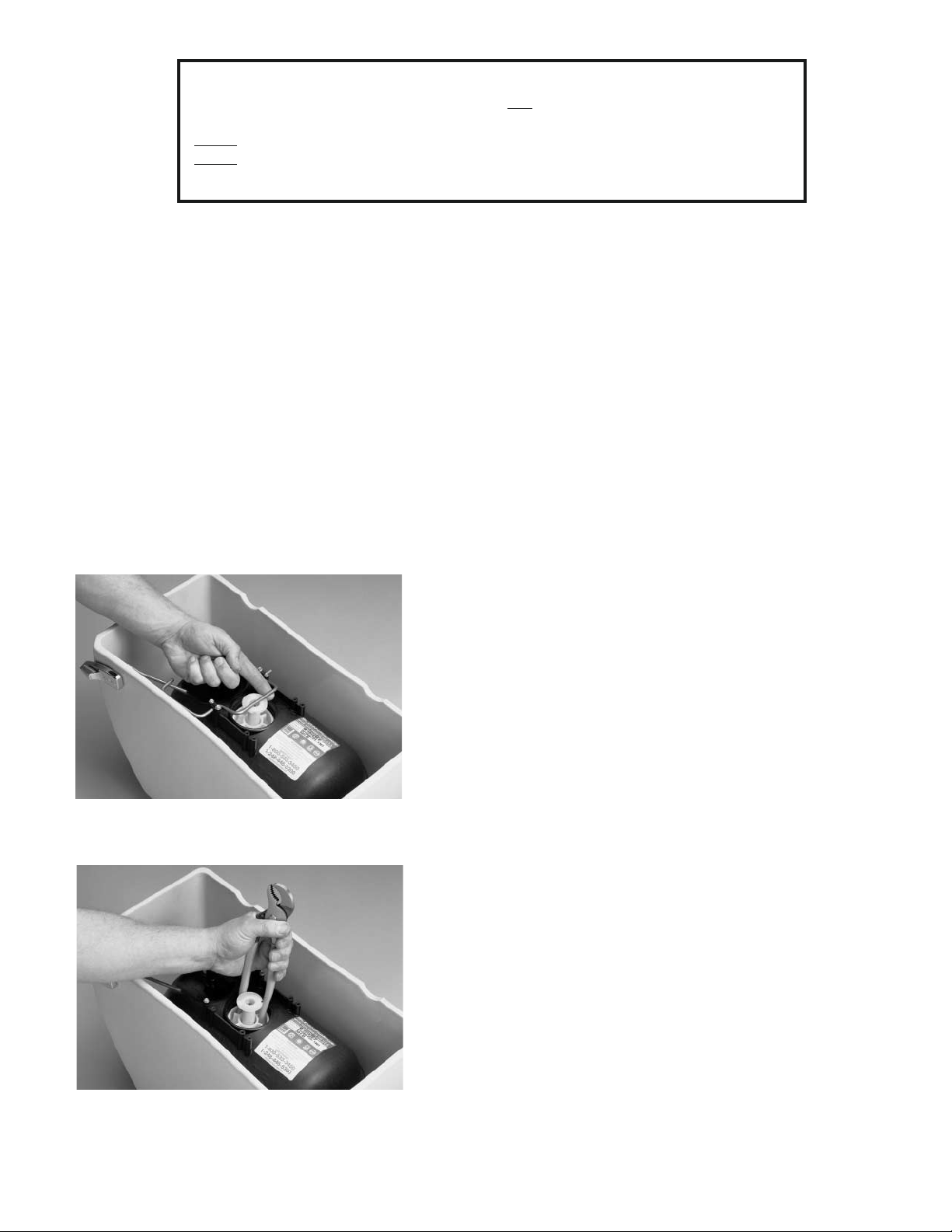

• The Flush Valve Cartridge Assembly can be removed by inserting the handles of a pair of pliers into the top

of the Cartridge and turning counter-clockwise.

• It is normal for less than an inch of water to remain in the bottom of the outside China Tank. The FLUSHMATE

System will automatically recirculate this water with each flush to eliminate any stagnant condition.

•NEVER use any chemicals or corrosive household cleaners on FLUSHMATE ®Products.

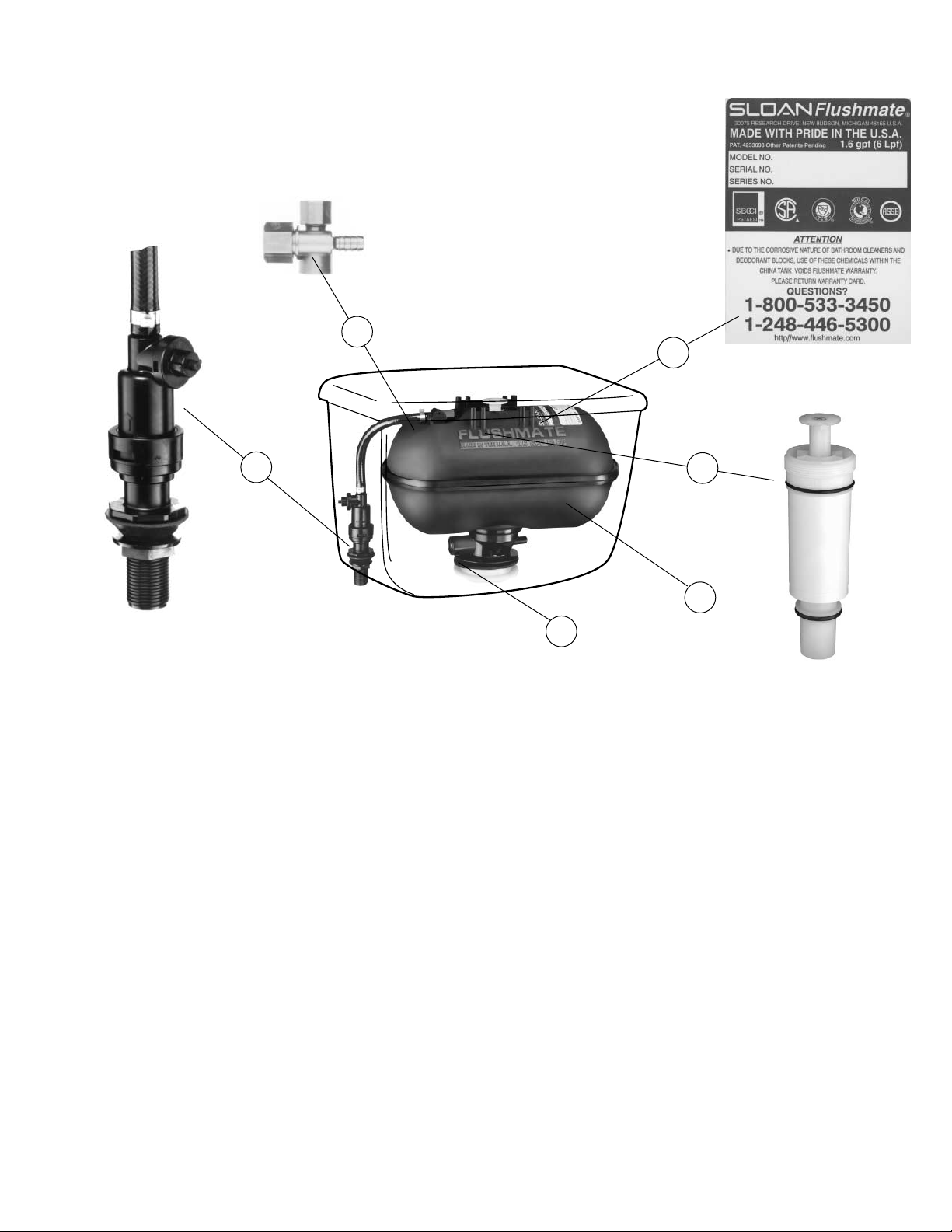

The Sloan FLUSHMATE ®Flushometer-Tank System has been engineered to provide reliable performance year after year. However, if

servicing is ever required, it is recommended that you follow the instructions included in this brochure. If you would like additional

information or require technical assistance, write to us or call us at the address or telephone number below.

ATTENTION OWNER

THIS IS YOUR WARRANTY REGISTRATION

Sloan FLUSHMATE ®(the “Company”), warrants the FLUSHMATE ®flushometer tank operating system (the “unit”), to be free of defects

in material and workmanship for a period of five (5) years from the date of installation and the Company promises to replace any part

of this product that proves, upon our inspection and within five years from date of installation, to be defective in material or

workmanship. All labor and transportation costs or charges incidental to warranty service are to be borne by the purchaser-user.

This warranty is subject to the following:

Specific Conditions to Warranty

A Warranty Registration card has been fully completed and mailed by the purchaser (the “user”) to the Company within thirty (30) days

of the date of installation.

The unit has been subject to proper installation, operation and maintenance as outlined in the installation instructions that were supplied

with the unit. Note carefully that this warranty is voided if the unit is installed and operated subject to water supply line pressures greater

than 125 psi (static) or less than 20 psi (static).

Service and repairs may only be performed by authorized representatives of the Company or by others upon specific approval by the

Company. Unauthorized repairs or alterations shall specifically void the warranty.

Use of chemical disinfectants or corrosive household cleaners on FLUSHMATE ®products will void this warranty.

Proof of purchase is required.

Exclusions

IN NO EVENT SHALL THE COMPANY BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES, FOR DAMAGES RESULTING

FROM IMPROPER INSTALLATION, OR FOR DAMAGES CAUSED BY NEGLECT, ABUSE OR ALTERATION. ALL IMPLIED WARRANTIES,

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE ARE LIMITED TO A

PERIOD OF FIVE (5) YEARS FROM DATE OF INSTALLATION.

Some states do not allow limitations on the duration of an implied warranty and some states do not allow exclusions or limitations

regarding incidental or consequential damages, so the above limitations may not apply to you. This warranty gives you specific legal

rights and you may have other rights which vary from state to state.

No person is authorized to change, add to, or create any warranty or obligation other than that set forth herein.

To obtain warranty service contact Consumer Services toll free 1-800-533-3450 (Outside North America, Call 248-446-5300) or

write to us at:

FLUSHMATE ®

A DIVISION OF SLOAN VALVE CO.

30075 Research Drive

New Hudson, MI 48165 U.S.A.

800-533-3450 • 248-446-5300

http://www.flushmate.com

Installation Date ________________________________________________________________________________________

Serial Number __________________________________________________________________________________________

FLU6025 05/00