1000C Series

DC Powered Sensor Operated Mixing Faucet

Installaon Instrucons

ISO 9001 Cered

1000C Series

Sensor Operated Faucet

Installaon Instrucons

HYDROTEK INTERNATIONAL, INC.

5055 Forsyth Commerce Rd., Ste 124

Orlando, FL 32807

800.922.9883 (Phone)

866.670.5580 (Fax)

www.hydrotekintl.com

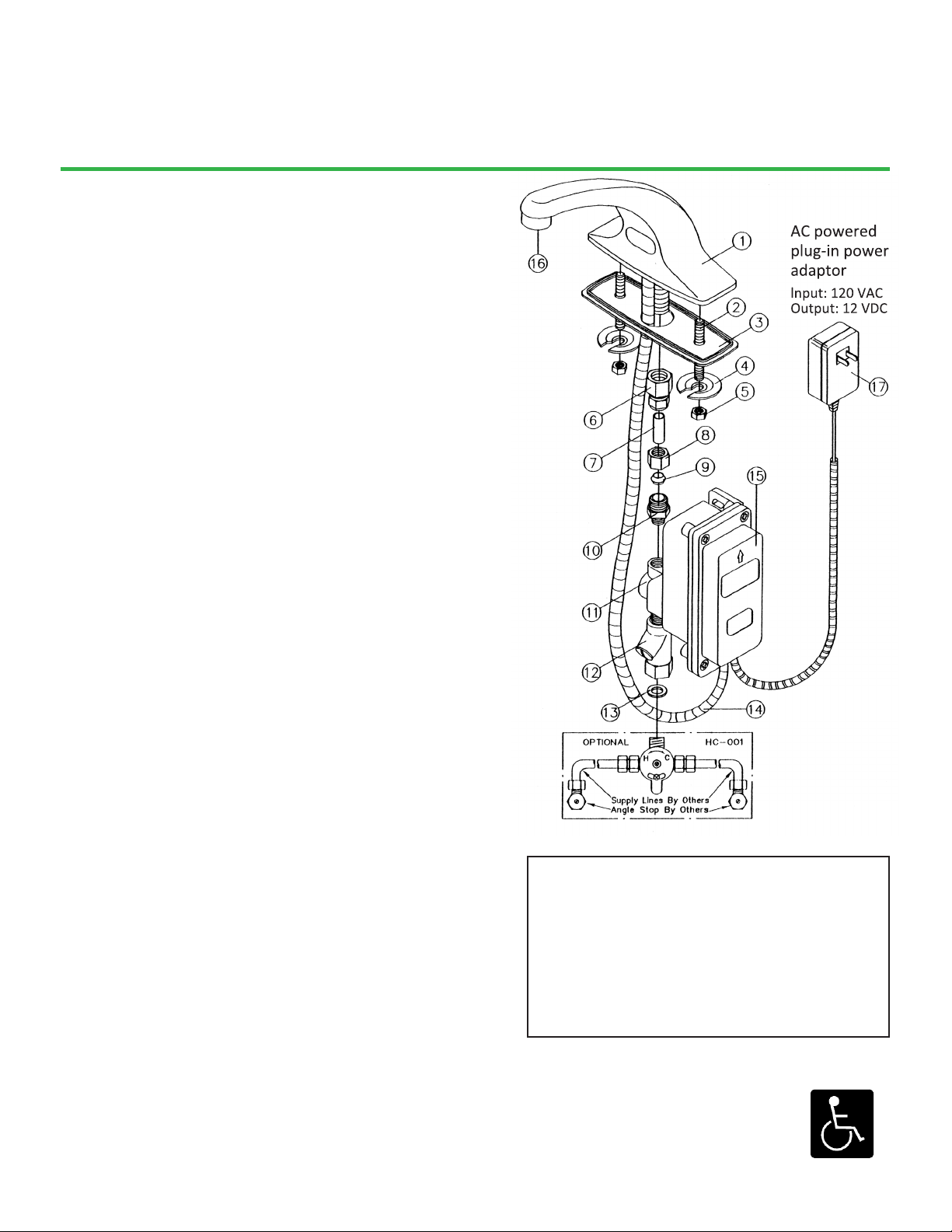

1. Faucet Body

2. Mounng Bolt

3. Mount Gasket

4. Sloed Washer

5. Mounng Nut

6. Compression Adapter

7. Supply Tube

8. Compression Nut

9. Compression ferrule

10. Compression Fing

11. Solenoid Valve

12. In-Line Filter

13. Nylon Washer

14. Sensor Eye Cable

15. Control Box

16. Aerator

17. Power Adapter

1. Prior to installaon, thoroughly ush all water lines and replace

stop washers, if required.

2. To ensure proper operaon, “DRY TEST” the faucet by plugging the

Sensor Eye Cable (14) into the matching connector on the PC board

inside of the Control Box (15).

a. AC Powered: Connect the Power Adapter (17) to the PC board

inside of the Control Box (15), then plug the Power Adapter

into a 120 V AC wall outlet. Place your hand in front of the

sensor eye and listen for a clicking sound. If there is no clicking

sound, call the factory.

b. Baery Powered: Properly install new baeries into the

baery holder and ensure the baery holder is connected to

the PC board. Place your hand in front of the sensor eye and

listen for a clicking sound. If there is no clicking sound, call the

factory.

3. Aer a successful “DRY TEST”, unplug the Sensor Eye Cable (14)

and Power Adapter (17) or baery holder from the PC board.

4. Aach the Compression Adapter (6), Supply Tube (7), and

Mounng Bolts (2) to the inlet on the Faucet Body (1).

5. Install the Mount Gasket (3) onto the Faucet Body and mount the

faucet onto the sink. Apply plumber’s puy to the boom of the

gasket and secure the faucet using the Sloed Washers (4) and

Mounng Nuts (5).

6. Reconnect the Sensor Eye Cable (14) and Power Adapter (17) or

baery holder as described in step #2 making sure the cables going

into the Control Box (15) are seated properly. Reinstall the cover

for the Control Box (15) and ghten the screws to ensure water

resistance. Coil excess cables and secure in a safe, dry area.

7. Aach the Solenoid Valve (11) to the Supply Tube (7) using the

supplied Compression Nut (8), Compression Ferrule (9), and

Compression Fing (10). Insert the Nylon Washer (13) into the

swivel nut loacted on the In-Line Filter (12).

a. Pre-tempered or cold water only: Use a union ng (not

supplied) to connect the supply line (not supplied) from the

supply stop to the In-Line Filter (12).

b. Tempered water: Aach an oponal Hydrotek HC-001 or HC-

003 mixing valveto the In-Line Filter (12). Connect the supply

lines (not supplied) to the mixing valve.

USE TEFLON TAPE FOR ALL CONNECTIONS, NO PIPE DOPE

8. Turn on the water and check for leaks. Plug the Power Adapter

(17) into a 120V AC outlet (for AC Powered). Push the reset buon

on the PC Board. Place hand in front of the sensor eye to acvate

water ow. Remove hands and the water should stop. If not, refer

to the troubleshoong guide.

9. Periodically clean the lter element in the In-Line Filter (12).

10. For minor adjustments, refer to instrucons located inside the

cover of the Control Box (15).

11. IMPORTANT: The stop valve should never be opened to the point

where the water ow exceeds the ow capability of the xture.

The xture must be able to accommodate the connuous water

ow from the faucet in the event of a failure. Should the xture

overow due to water exceeding the capability of the xture and/

or the drain pipe, Hydrotek will not be responsible for any damages.

Parts: