Flying Thingz Flag Ship 40 Instructions for use

Flying Thingz

Flag Ship 40

Kit# FT3012

A Sport Scale

Flying Flag

Made In The USA!

About This Construction Manual

This booklet divides the construction into sub-assemblies; wing, fuselage, etc. Please read each section carefully before starting on that particular sub-

assembly. There is a complete description of all parts under “Kit Contents” Please check to make sure your kit is complete. We are human, and occasionally

miss something! If you have trouble identifying a part, or are missing something, please contact us and we can help.

During the construction process the steps will outline what part to use. We have used actual pictures instead of unclear or often inaccurate illustrations

to assist in the building process. This manual was intended for English users, and all measurements are made in standard units. (Inch, foot, etc.) This

manual was intended to be used alongside of the plans. Please refer to the plans if any step is unclear.

Customer Service

Should you experience a problem building or flying this kit, we recommend you see your dealer first. If you are unable to solve the problem, feel free to

call or write:

Flying Thingz

2075 Grandview St.

Oceanside, CA 92054

This product is sold with exclusion of all warrantees, expressed or implied, statutory or otherwise.

Pilot assumes all risk in building and operating this model. Refer to and abide by AMA rules at www.modelaviation.com for regulations on Radio

Control Models.

© 2002, 2003 Flying Thingz All Rights Reserved.

2

Kit Contents

Part No.

QTY.

Dimensions

Description

9654

2

Laser Cut 1/8” balsa

Balsa fuselage sides

9655

1

½” x 36” balsa triangle

Fuse and bar reinforcement

9658

1

4” x 1/16” x 36” balsa

Bottom fuse sheeting

9660

1

12” x 24” x 1/8” ply

Laser Cut Construction set

9659

1

Laser Cut 1/8” balsa

Fuselage hatch and sheeting

9661

1

¼” x ¼” x 36” balsa

Hatch reinforcement

9662

1

Metal

5/32” Nose Gear

9663

2

Metal

Pre-bent 5/32” Wire Main Gears

9664

1

4-40 bolt

1- hatch mount

9671

1

4-40 blind nuts

1- hatch mount

9691

2

Laser Cut Ply

Control horns

9694

1

1.5# CNC Cut Foam

CNC cut foam wing; elevons

9674

1

Coroplast (corrugated plastic)

Uncle Sam

9675

1

Paper

Full Color Construction manual (Your Reading It )

9684

1

36” x 48” Paper

Full size plan sheet

9690

1

Laser Cut 1/8” balsa

Balsa fuselage sides

© 2002, 2003 Flying Thingz All Rights Reserved.

3

Additional items you will need to build a flyable R/C Mower

This is a list of parts used on the Sky Cutter prototype. Consult your hobby shop or our website at

www.flyingthingz.com for these additional items.

□3- 2 ½” wheels

□Engine-.40-.53 2c or .45-

.72 4c

□4- Pushrods (Nyrods work)

□Motor Mount

□6- 5/32” wheel collars

□8 oz fuel tank

□2’ medium fuel tubing

□Foam rubber

□2” spinner

□Prop-suitable for engine

□Covering material (low

temp)

□4 Ch radio with elevon

mixing

□Fiber Tape

□Clear Packing Tape

Tools and materials you will need

□Instant CA (superglue). Used

to instantly bond parts

□#80; #120; #400 sand paper

□Steel straight edge

□Slow CA (superglue) Used to

bond parts that need to be

moved for alignment

□Hobby Knife and extra blades

□Tack Rag

Note: CA’s come in many grades,

and some are not compatible for

foam, balsa and ply woods.

□Black Sharpie and Pen

□Wire cutters and needle nose

pliers

□Epoxy and resin glue

□Assorted screwdrivers

□Paper towels

□CA Accelerator Used to

accelerate or instantly harden

CA (superglue).

□Building pins

□Scissors

□Alphaic Resin glue (white

glue)

□Razor saw

□Sanding blocks

□Small building square

□Masking tape

□Epoxy or Polyurethane

Paints

© 2002, 2003 Flying Thingz All Rights Reserved.

4

Construction

Fuselage Construction

□Begin by setting the

two fuselage sides

across from each other.

This way you will have a

left and right side.

(Reference the plans as

to which side to glue

the lower wing saddle

to!)

□REMEMBER TO MAKE

2 OPPOSITE SIDES!

Using medium CA, glue

the LASER cut plywood

fuselage sides to the

balsa fuselage sides.

Use the top and the

front of the balsa

fuselage for alignment.

(Again, check the plans

as to what side the ply

wood doublers face!)

□Glue F1 and F2 onto

ONE side of the

fuselage. Use a square

to get them perfectly

vertical. We will join the

other side to these in a

couple minutes.

□Set the fuselage

upside-down, and glue

the other half of the

fuselage side to F1, F2,

and the servo tray.

□Next add the forward

servo tray to it’s

location in front of F2.

© 2002, 2003 Flying Thingz All Rights Reserved.

5

□Now you will add the

forward hatch bolt plate

to the notch in the fuse

side behind F2

□Using the rear servo

tray as a spacer, sheet

the rear of the fuselage

with the small laser cut

1/8” balsa. DO NOT glue

the servo tray at this

time.

□With the fuselage still

UPSIDE DOWN, glue in

the rear servo tray. Use

a 1” block underneath

to support and space

the rear servo tray. (DO

NOT glue the block)

Add a few pieces of

triangle stock on the

bottom to support the

tray.

□Set the1/8” balsa hatch

under the fuselage and

glue your ¼”x¼” stick

hatch support rails

between F1 and F2.

Glue only to the hatch,

DO NOT let glue get on

the fuselage body.

□Glue the 1” x ¼” balsa

rear into the notch in

the fuselage. Sand flush

with fuselage sides.

□Create a tongue for the

rear part of the hatch

with a piece of ¼” x 1”

balsa and a 1/8” ply

scrap. The ¼”x1” balsa

should fit snugly

between the two

fuselage sides.

□Glue on the 1/8” ply

lower fuselage plate

between the wing

saddles.

□Trim the excess hatch

to be flush with the

fuselage and sand

smooth.

© 2002, 2003 Flying Thingz All Rights Reserved.

6

□Using the 1/16”x4”

balsa, sheet the bottom

of the fuselage cross

grain. Sand the edges

flush.

□Add the ½” tri stock to

the back of F-1

□Do a final sanding, and

set aside till later.

Wing Construction

□Sand the entire wing

lightly to remove any

roughness left from the

CNC cutting process.

□Place the center cut out

on the wing next to the

fuse so there is ¾” from

the back of the cut out to

the front of the TE.

□Mark a line on the foam

that matches that of the

rear of the fuse.

□Cut on your line to

make the filler for the aft

wing.

□Place filler in cut out.

There will be a small

overhang at the TE. Cut

this off flush with the TE.

(We do it this way to

account for the loss of

foam from the cutting

process.)

□Sand the foam filler

smooth, and glue into

place. You should have a

nice, even fit. Fill any

gaps with filler.

© 2002, 2003 Flying Thingz All Rights Reserved.

7

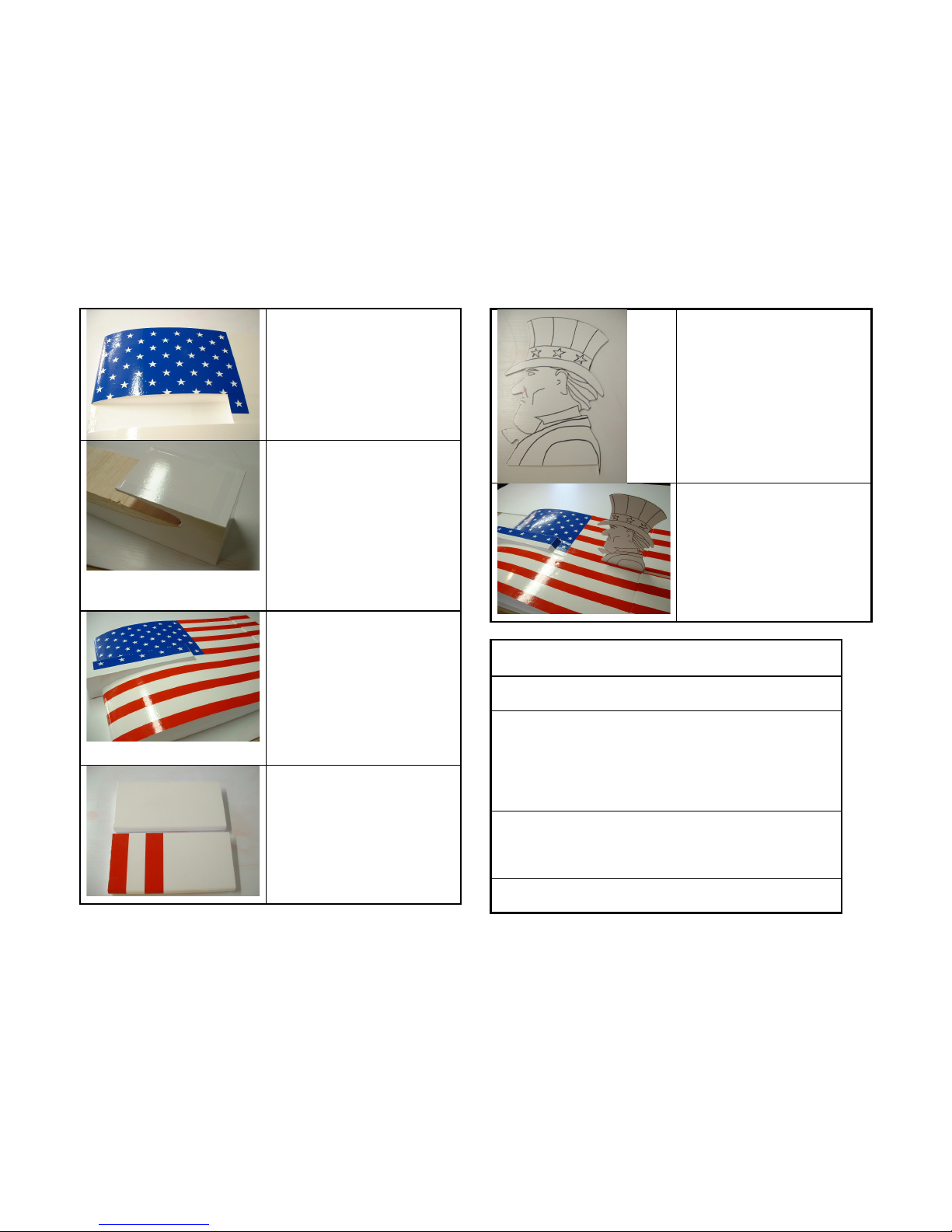

□Mark the center of the

wing at the trailing edge

for Uncle Sam. Use a

square to get it perfect.

This is important!

□Cut a 3/16” wide slot for

Uncle Sam to fit into.

The slot goes all the way

through the wing. A table

saw makes this easy, but

a sharp knife or a Dremel

tool works well also.

□Stack the laser cut gear

blocks in the order

shown to the left.

(Notched block is in

center)

□Use Epoxy to assemble

the layers. Clamp in a

vise until dry. After dry,

sand edges flush, then

use a 5/32 drill bit to

enlarge the gear slot.

□Flip the wing over and

reference the plans for

the locations of the

landing gear blocks.

Trace the outline of the

blocks onto the wing.

Using a Dremel tool or

razor blade, make a

channel that matches

the gear blocks. (MAKE

SURE YOU CUT THE

SLOT ON THE BOTTOM

OF THE WING!)

□Using Epoxy, glue in

the gear blocks. Use

plenty epoxy to get a

good bond! (DO NOT

USE CA’s ON FOAM)

□Sand the gear block

area smooth.

Elevons

□We have already cut

the Elevons from foam,

sand if necessary to

remove cutting residue.

Cut the 24” elevon in

half for each side if the

wing.

© 2002, 2003 Flying Thingz All Rights Reserved.

8

□Use your drill, saw or

Dremel to cut a 2” long

slot for the laser cut

aileron control horn. The

slot is 1” from the end of

the aileron. Wait until

after covering to glue the

plywood control horn

into place.

Make Covering Easier!

We supply a special covering that is super

easy to use, needs no iron, lasts and is fuel

proof. It is also lighter than the other

coverings. We use this on all our planes

and have great results. The Computer cut

covering sets are available for the USA,

JAPAN, and ENGLAND flags. You can

order online at FlyingThingz.com

Covering

Wing:

□Before covering the

foam, spray it with a

light coat of 3-M Super

77 spray adhesive. Let it

sit for 10 minutes! (This

lets the solvents

evaporate so they are

not trapped under the

covering) Cover the wing

bottom first. The seam

will go straight down the

center. Leave the rest to

wrap around the edges.

(HINT: Use a few strips of

fiber reinforced

strapping tape across

the length of the LE for

added durability from

bumps)

□Use the same

technique on the top; go

LE to TE. Fold access

over the tips and trim

center section for a ½”

overlap. Cover the wing

tips last.

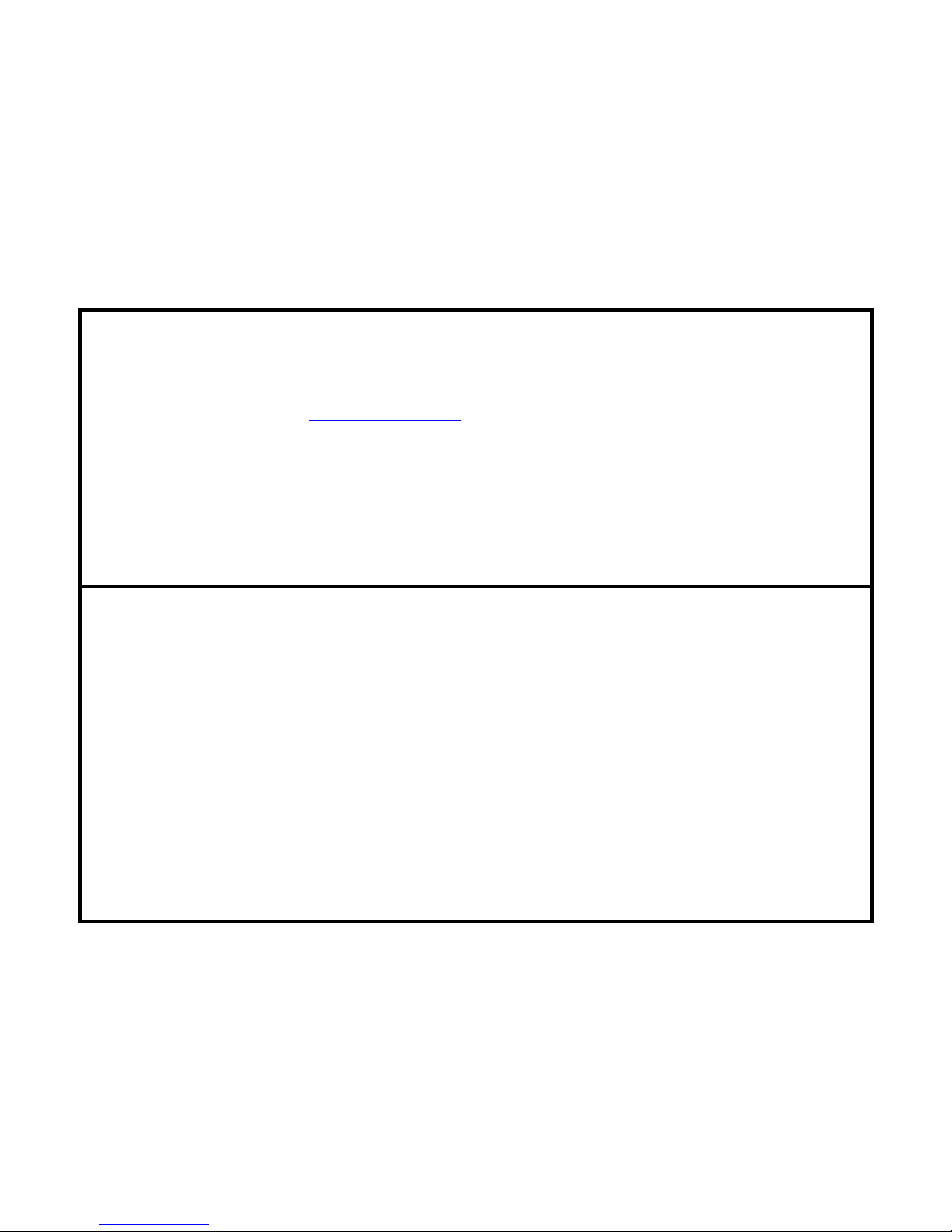

□Carefully position the

blue stars section on the

leading edge of the Right

wing. Use care to push

out any bubbles. A light

misting of water before

applying the blue will help

placement.

© 2002, 2003 Flying Thingz All Rights Reserved.

9

□Carefully trim the blue

along the fuselage cut

out. SAVE THIS PIECE!!!

Set it aside on a piece of

nonstick backing.

□Cover the fuselage with

the white covering. Use a

heat gun to help pull

around the corners for a

smooth finish. When

finished, remove the

covering that will be

hidden in the wing center

section. This will allow for

a good glue joint.

□FIRST slide the fuse

into place and apply the

rest of the stars to the top

of the fuselage. Use blue

covering to fill in the rear

and right side of the

fuselage. LAST apply the

red stripes in the order

shown on the plans.

Elevons:

□Use the same

technique as the wing to

cover the elevons in

white. Align the elevons

on the wing, and then

apply the red strips to

match the wing.

Uncle Sam

□Using the plans as a

drawing reference, give

uncle same his looks

with a black sharpie

marker. Use paint or

some scrap covering for

the stripes on his hat.

□Remove only the

covering on the TOP OF

THE WING over the

Uncle Sam mounting

slot. Using 5 min. epoxy,

glue him in place. Use a

square to keep him

vertical.

Final Assembly

Remove any covering where the fuse and wing

will be glued

Using epoxy, glue the fuse into the wing cradle,

making sure it is in the correct position and

seated both front and back. Use some white

alphaic resin glue to fill in the fuselage and wing

joint. This will keep out the fuel and will dry

clear.

Fit the main gear into place. Secure the landing

gear with the supplied gear straps and screws.

The gear is designed to break the straps before

damaging the wing!

Mount the nose gear to the fire wall. Make sure

to leave enough room for your engine and

© 2002, 2003 Flying Thingz All Rights Reserved.

10

mounts. We like the engine mounts with a gear

hole built in.

Hinge the elevons using packing tape. Put a

layer of 2” tape across the top of the hinge, then

flip over the elevon, and do a layer on the

bottom. Use extra covering material to cover the

hinge if desired. Use epoxy to glue the control

horns into the elevons at this time. (see plans for

diagram)

If you desire the optional air rudder for improved

cross wind handling and aerobatics, cut ONE

SIDE of a flute on Uncle Sam-- at the back of his

neck, extending to the top of the hat. Attach the

rudder to the nose gear servo with a pushrod.

You will need 1 large nylon control horn for this

option. You may also consider adding a 3/16

dowel or carbon rod vertically down through

Uncle Sam for increased stiffness in aerobatic

maneuvers. You can also use string flying wires

to add rigidity.

Add your radio gear to the servo trays. The rear

servo tray has a receiver section to rubber band

to. Run the receiver antenna out the rear of the

plane, and tape down between the elevons. DO

NOT cut the excess wire, let it dangle.

Bolt on your engine to the engine mount before

mounting to set the spacing (if using a 2 piece

mount) Then drill and bolt the engine and mount

to the front of F-1.

Place your fuel tank behind F-1 and run fuel and

vent lines to the engine through F-1

Use threaded end pushrods for your controls.

Connect all surfaces to the servos securely, and

test for free movement. Make sure to use a

sleeve on the outside to eliminate any flexing.

Add your wheels and wheel collars to the main

and nose gear. Make sure that you airplane is

sitting at a slightly nose up attitude on the gear.

This will help the plane rotate for takeoff.

Do a final check over all parts and electronics to

make sure all is correct. And don’t forget to take

a picture now!

Flying

Do the standard range checks, and make sure

your controls are moving in the right directions,

including the nose wheel and throttle. Double

check your CG! Get used to the taxi and show off

your new toy to all those watching! When you

are ready to take off, advance throttle SLOWLY,

you don’t want it to torque around on you. Since

we have no air rudder, if you are in a crosswind,

uses down elevator to keep the nose wheel on

the ground until you are ready to rotate for take

off. When you are up to flying speed, gently ease

off the down, and slowly pull back. It is

responsive, and needs no extra help finding its

home in the clouds! Get used to the way it flies

up high, try a few stalls (it won’t do any thing

crazy) and play around. When it’s time to land,

set up normal, but keep on a little power until

you are over the runway. With its low 1:1 aspect

ratio, it is not the best glider out there. If you find

your self in a power out situation, just keep the

nose down to maintain speed. A little practice up

high will make this kind of incident a snap. You

will find it to be fun to fly and a real crowd

pleaser! Have FUN and be safe!!

Don’t forget to send Pictures

and Comments to us!

© 2002, 2003 Flying Thingz All Rights Reserved.

11

Flying Thingz

2075 Grandview St

Oceanside, CA 92054

Table of contents

Other Flying Thingz Toy manuals

Popular Toy manuals by other brands

Pro Boat

Pro Boat Rockstar 48 PRB09000 owner's manual

V-tech

V-tech Click Box - Xtreme Power user manual

AUTO GYRO

AUTO GYRO MTOsport 2017 Operating handbook

V-tech

V-tech Go Go Smart Wheels Race Car II user manual

V-tech

V-tech Splashtime Submarine Parents' guide

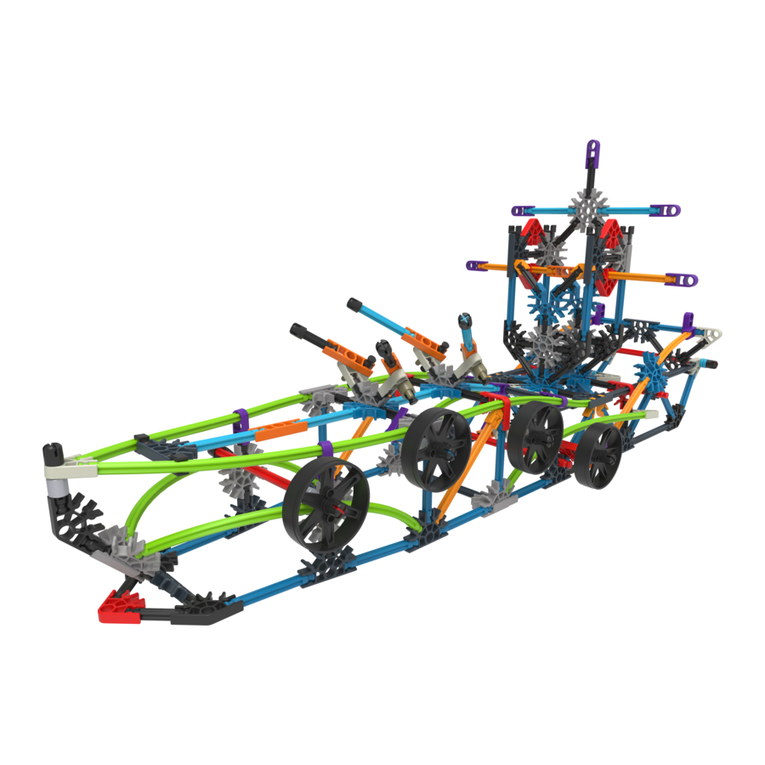

KNEX

KNEX 100 MODEL IMAGINE BUILDING SET manual

V-tech

V-tech Spin Master nickelodeon Paw Patrol Skye to the... instruction manual

OMPHOBBY

OMPHOBBY M2 instruction manual

Lightmybricks

Lightmybricks Light & Sound Kit for LEGO Ghostbusters Ecto-1... installation guide

V-tech

V-tech Secret Safe Magic Notebook instruction manual

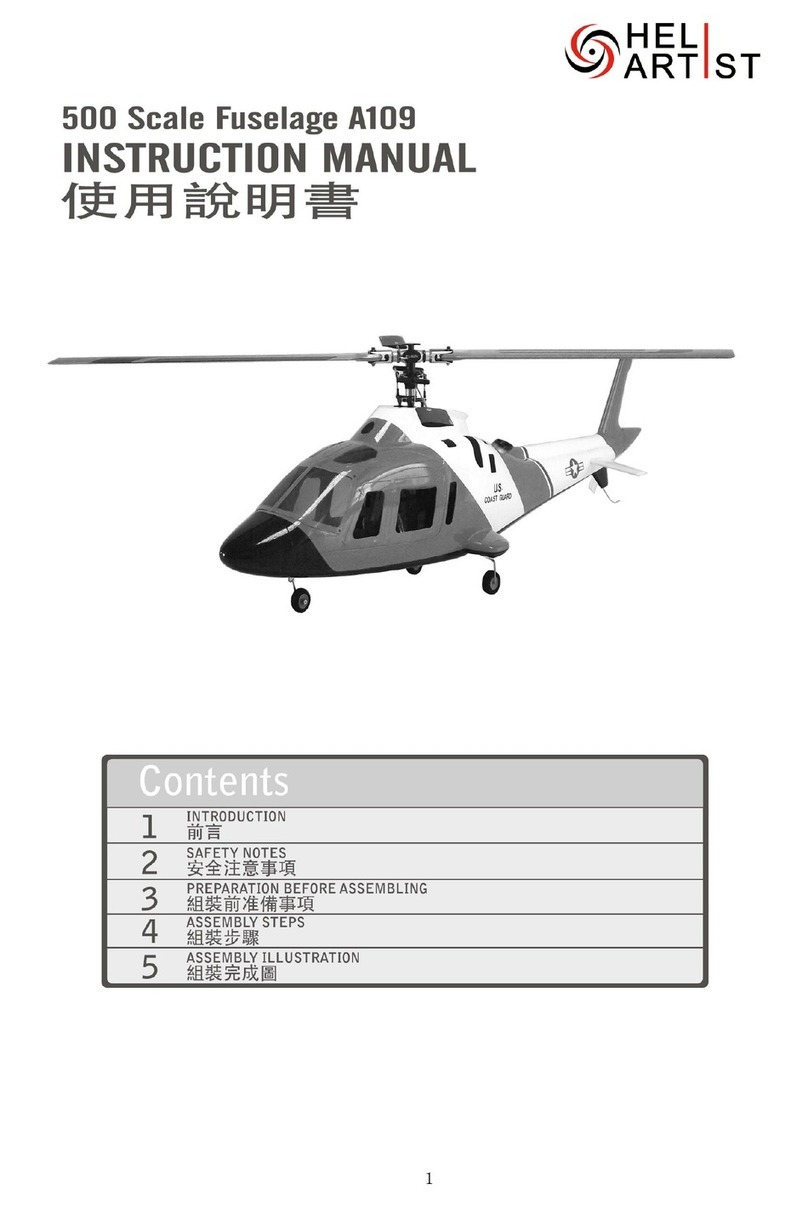

HeliArtist

HeliArtist 500 Scale Fuselage A109 instruction manual

Pro Boat

Pro Boat Pro Boat Miss LLumar owner's manual