Flying Thingz The Gull Instructions for use

Flying Thingz

“The Gull”

Kit# FT3007

A Sport Scale

Flying Bird

Made In The USA!

About This Construction Manual

This booklet divides the construction into sub-assemblies; wing, fuselage, etc. Please read each section carefully before starting on that particular sub-

assembly. There is a complete description of all parts under “Kit Contents” Please check to make sure your kit is complete. We are human, and occasionally

miss something! If you have trouble identifying a part, or are missing something, please contact us and we can help.

During the construction process the steps will outline what part to use. We have used actual pictures instead of unclear or often inaccurate illustrations to

assist in the building process. This manual was intended for English users, and all measurements are made in standard units. (Inch, foot, etc.)

Customer Service

Should you experience a problem building or flying this kit, we recommend you see your dealer first. If you are unable to solve the problem, feel free to call or

write:

Flying Thingz

P.O. Box 19183

Spokane, WA 99219

support@flyingthingz.com or online at www.flyingthingz.com

This product is sold with exclusion of all warrantee, expressed or implied, statutory or otherwise. Pilot assumes all risk.

Pilot assumes all risk in building and operating this model. Refer to and abide by AMA rules at www.modelaviation.com for regulations on Radio

Control Models.

Page 2

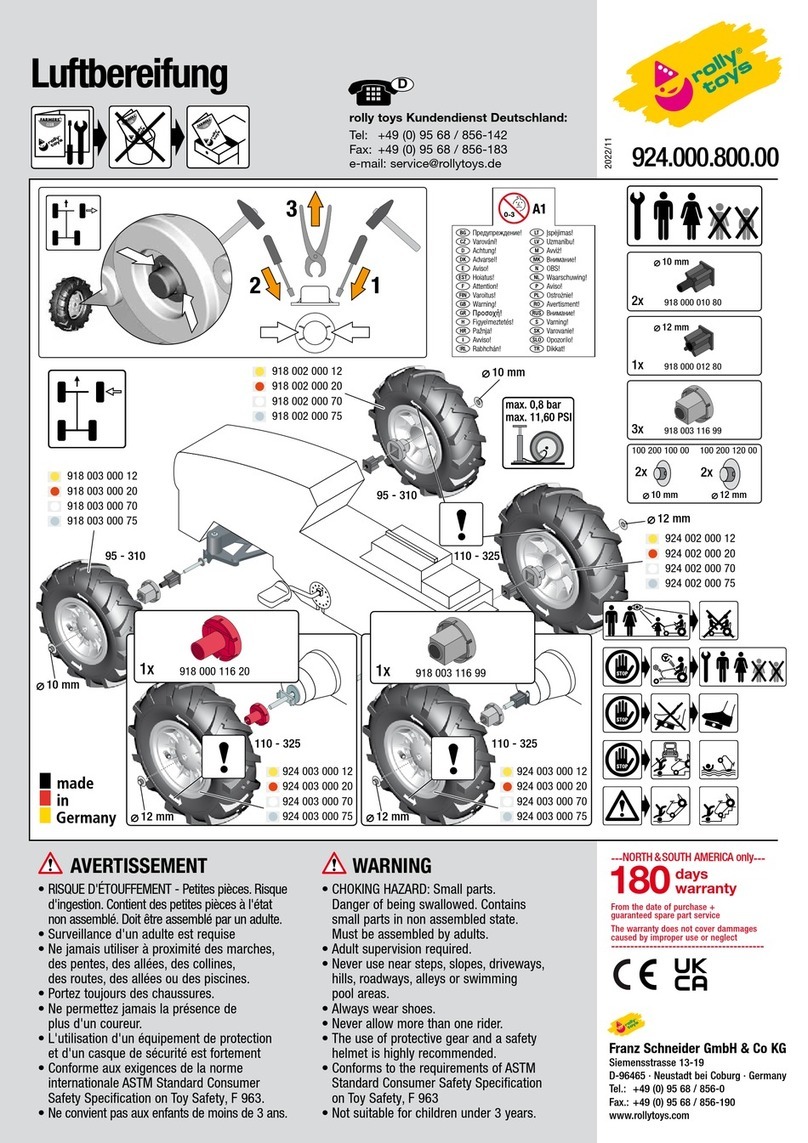

Kit Contents

Part No. QTY. Dimensions Description

1654 2 CNC Cut ply Wing mounting disks

1654 1 1/8” x 3” x 18” Balsa sheet Balsa aileron facing sides

1661 1 CNC Cut Foam Sea Gull body

1655 1 1/16” x 4” x 3” ply Head spar and wing mounting reinforcement

1656 2 CNC Cut Foam Inner wing panels

1657 2 CNC Cut Foam Middle wing panels

1658 2 CNC Cut Foam Outer wing panels

1659 2 1/2” x 2” x 3” Balsa Block Wing tips

1660 3 3/8” x ½” Balsa Balsa Leading edge

1661 1 Glass Cloth Body Glassing

1662 1 Paper Instruction Manual

1663 1 1/32” Balsa Wing skin set

Additional items you will need to build a flyable R/C Gull

This is a list of parts used on the Sea Gull prototype. Consult your hobby shop

for these additional items.

□2 med. DuBro control

horns □White, Black, Yellow

paint

□2- 2-56 threaded

Pushrods □Clear Packing Tape

□foam rubber □2 Ch radio with

elevon mixing and

micro servos.

Page 3

Tools and materials you will need

□Masking tape □#80; #120; #400 sand paper □Steel straight edge

□Sanding blocks □Hobby Knife and extra blades □Scissors

□Razor saw □Pencil and Pen □Needle nose pliers/cutters

□Epoxy and resin glue □Assorted screwdrivers □Paper towels

□Alphaic Resin glue (white glue □Wax paper

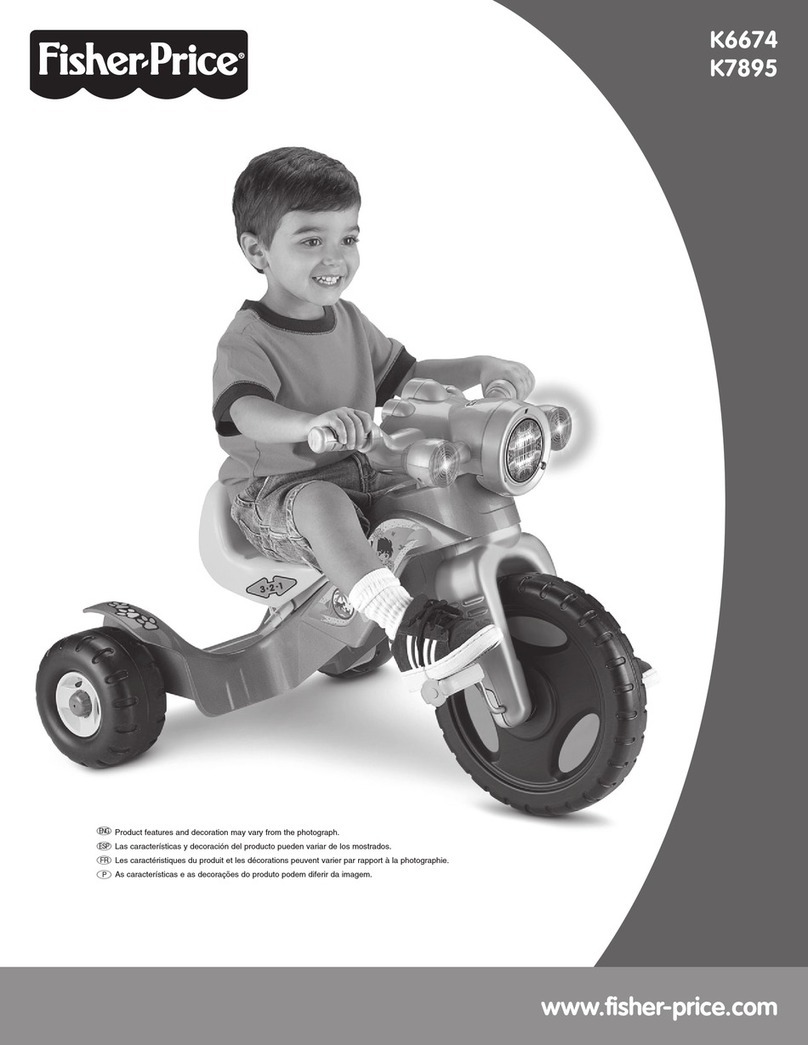

Flight: The main goal for this model is esthetics, but the flight is still very realistic and calm. In the air, realism is very surprising,

some present during first test flights thought it was a prank... The usual comments are: Is that expensive? Did you build it?

Where is the radio? I think that they realized it was not a joke when It flew straight at me, and then turned away from the

slope like all the other sailplanes. (The loops give it away too)

Some photographs of the bird:

Have Fun!!

Page 4

Body Construction:

1.You will start by separating the

foam beds from the body. Leave the

wing cut out in for sanding.

2. Cut through the center of the

beak with a razor saw to allow for

the 4” head spar. This spar will keep

the birds beak from snapping off on

landings

3.Insert the 1/16” ply “head spar”

into place. Trace the outline of the

foam onto the wood with a pen, and

then cut the beak and head out. Use

a bit of white glue or epoxy for

setting this in place.

4.Left is the fuselage after

sandpapering. Use rough grit at first,

and then smooth it out to end up

with a final finish that is smooth for a

light layer of fiberglass. If you need

to fill dings, use lightweight filler,

then re-sand.

5.After you have sanded to

perfection, use the glass cloth to

finish the fuselage. Start at the top

and spread the epoxy out. There

should be no dripping wet spots.

After top is cured, do the bottom,

overlapping the tops edges. Lightly

sand smooth for painting.

Wing Construction: 6.Use 3M Super 77 Spray

adhesive on the top of the foam

core and also on the wing skin. A

light but thorough coat will do. Let it

dry for at least 10 minutes. Use the

wing saddle for alignment and roll

the skin TE to LE onto the wing

core. Leave a ¼” overlap at the TE.

7.Use the same technique for the

bottom side of the inner panel.

Care should be made to keep

wrinkles and warps out of the thin

sheeting.

8.Use a sanding block to bring the

sheeting flush with the foam core.

Leave the extra balsa on the TE for

now. Be very careful NOT to

change the angle of the dihedral at

the root and tip of the core.

Page 5

9.Tape another set of 12” skins

together for the top and bottom of

the outer panel. Lay both of the

panels on the balsa and cut the

skin in half for each side.

10. Use the same procedure as

the inner panel to sheet the outer

panel. Make sure to leave the extra

balsa at the TE. Note that there is

washout in the outer panel and

care should be taken not to untwist

this during the sheeting process.

11. Use the core beds to align

and apply the top sheeting. This

will maintain the correct wing twist.

Trim away the extra balsa and

sand the sheeting flush with the

cores.

12. Cut 2 sections of sheeting for

the middle wing cores. Tape them

together as before. Use the same

procedure to glue the sheeting to

the cores.

13. Sand the excess balsa down

to the cores. Again, make sure not

to change the angles of the wing tip

and root joints.

14. Now join the outer wing to the

middle wing. This is a 0 deg joint

so simply lay the sections on your

building board and epoxy together.

Align the LE’s and the TE should

be flat on the table. Make sure to

coat both joints good. Use 5 Min

epoxy and tape in place until cured.

15. Flip the wing over so the

dihedral angle is rising up off your

building table. Tape the wing

section securely to the table with

the TE flat along it’s length.

16. Use the foam angle brace to

prop up the inner wing to the outer

section. Check the joint and make

sure you have a good flat mating

surface. Lightly sand to correct any

difference. The Wing is upside

down in this picture…. Remember

we are building a gull wing, so

double check the angle before you

glue. Use 5 min epoxy and tape

securely till cured.

Page 6

17. You should now have a

completed wing half that looks like

the picture. Use a straight edge to

trim the balsa TE to meet at each

panel. LIGHTLY sand the sheeting

for covering, but remember it is

very thin, so do not sand through!

18. The LE balsa needs to be

applied as shown as it adds

tremendous strength to the wing

joints. Epoxy the first panels LE to

the cores. Now sand it to match the

LE angle of the second panel.

19. Epoxy the second LE on the

middle panel, overlapping the first

panels LE. Now sand the LE to

match the angle of the outer panel.

20. Finally epoxy the outer panels

LE to overlap the middle. Sand all

of the LE’s to the airfoils contour.

Use discretion to the final LE

shape. A sharp LE will yield higher

speeds and better penetration, but

will stall abruptly. A more blunt,

round LE will stall gently, but not be

as fast.

21. Glue the balsa block wing tips

in place then sand to match the

shape of the wing.

22. Cut Ailerons out of the TE of

the outer 2 panels. The Ailerons

should be 1.5” at the root and taper

to .75” at the tip.

23. Remove 1/8” of material from

the face of the aileron and TE and

then face with 1/8” balsa for

hinging.

24. Use a sharpened ¼” brass

tube to cut a servo lead hole from

the root to the tip of the inner

panel. It should be located in the

center, at the thickest part of the

wing. Do this to both panels.

25. Use a sharp x-acto blade to

cut a servo bay at the end of the

INNER wing panel. The bay should

be placed over the servo tube hole

you just cut. The bay should be

sized to hold the servo flush and

tight against the foam.

26. Cut a notch on the BOTTOM

of the wing at the center section for

access to the servo wires after

wing joining.

27. Place the two wing alignment

blocks to

p

ro

p

the win

g

into

j

oinin

g

Page 7

position. The TE of both wings

should be resting in the same

position. Check the mating surface

of the two panels to see if it is

aligned. Sand if necessary to get a

good joint.

28. Use epoxy to join the center

section. Hold it firmly in position

until cured.

Final Preparations

29. Carve out a cavity in the

foam body under the wing to place

your battery and receiver. Keep

everything as far forward as

possible. Choose a place for

mounting your switch, or remove

the wing to connect power when

flying.

30. Cover the wings in white and

grey Econocoat or Ultracoat Lite,

and then paint the gull body entirely

white with acrylic paint. The result

looks good, and the finish is also

very light. The birds marking are

then applied: Grey wing tops, white

wing bottoms with black wing tips.

The beak is painted in yellow with

plastic model paint. The eyes can

be painted or glued on using the

pictures below, or purchased at a

craft store. The Gull should be

finished to weigh about 470g.

Attention to the wei

g

ht durin

g

the

Radio Set Up

31. 2 channels are all that is

required, but you will need mixing

because it is elevon control. Refer

to your radio on how to set this up.

You will want 1.00” of travel to start

with, and the elevons will need to be

in raised upward about 3 deg.

32. If you have advanced radio

features, set up aileron differential.

You should set it so that the “down”

aileron in a turn moves about 50%

of the “up” ailerons travel. This will

help yaw the plane in the direction

of the turn.

Flying

33. The model should be

balanced before making any test

flights! Balance the bird by placing

your fingers under the wing at the

first gull panel. The plane should

balance slightly (1/4”) forward of the

highest point of the wing. This is

essentially a flying wing, so the

balance point is important. Start a

bit in front of the point and do test

glides in tall grass. If the model

wants to dive, move the CG back, if

it quickly climbs, add more weight to

the nose. The desired result is a

gradual glide with no pitch changes.

Ex

p

eriment with different settin

g

Page 8

and trim changes on the elevons to

get the flight “feel” that you want. An

aft CG will be extremely pitch

sensitive. Add weight to the nose if

it is twitchy.

Hints:

This plane has no rudder, so if you

are flying in strong wings and desire

more “tracking” add a clear lexan

rudder to the tail of the bird.

Remember to send your

pictures!!

This manual suits for next models

1

Table of contents

Other Flying Thingz Toy manuals

Popular Toy manuals by other brands

wiking

wiking Control87 077426 operating instructions

Auhagen

Auhagen 12 215 Assembly manual

Fisher-Price

Fisher-Price BARBIE Sport Mobile 74558 Owner's manual & assembly instructions

H-KING

H-KING FLYCAT manual

Toys for life

Toys for life SENSIDISC instructions

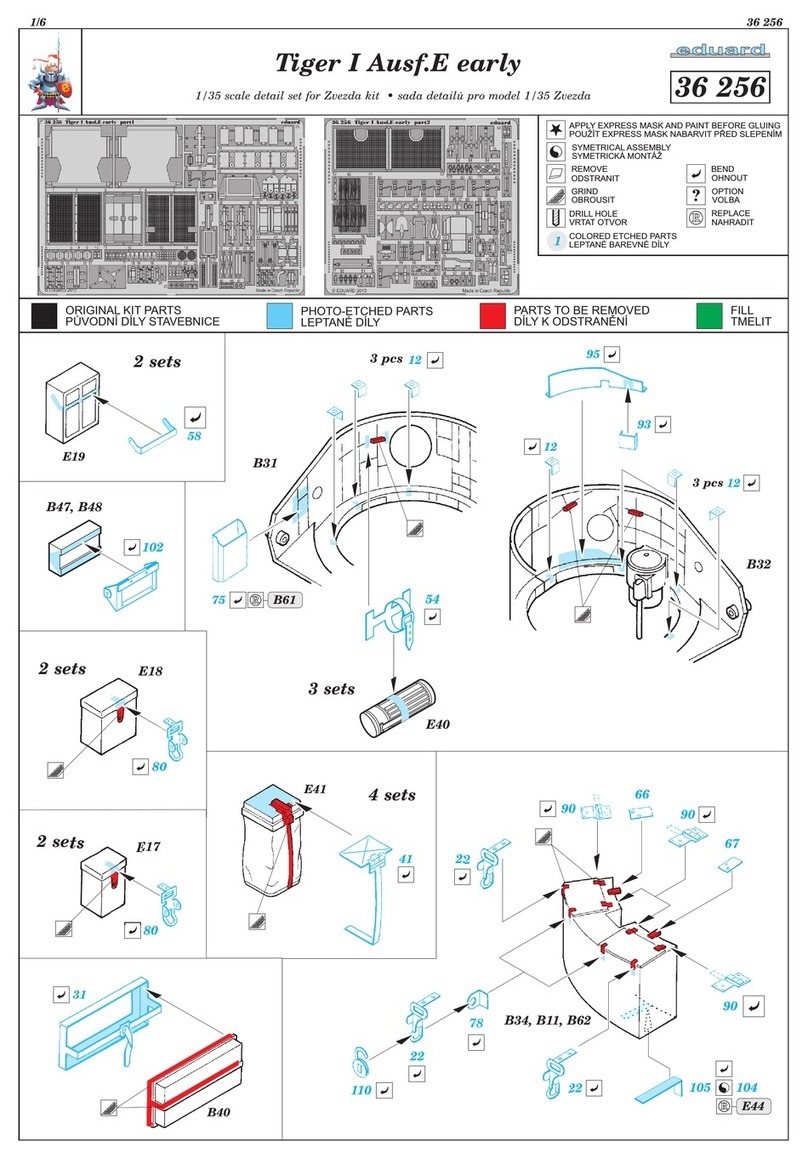

Eduard

Eduard Tiger I Ausf.E early quick start guide

Black Horse

Black Horse bravo 3d instruction manual

Pichler

Pichler Amethyst II manual

Hasbro

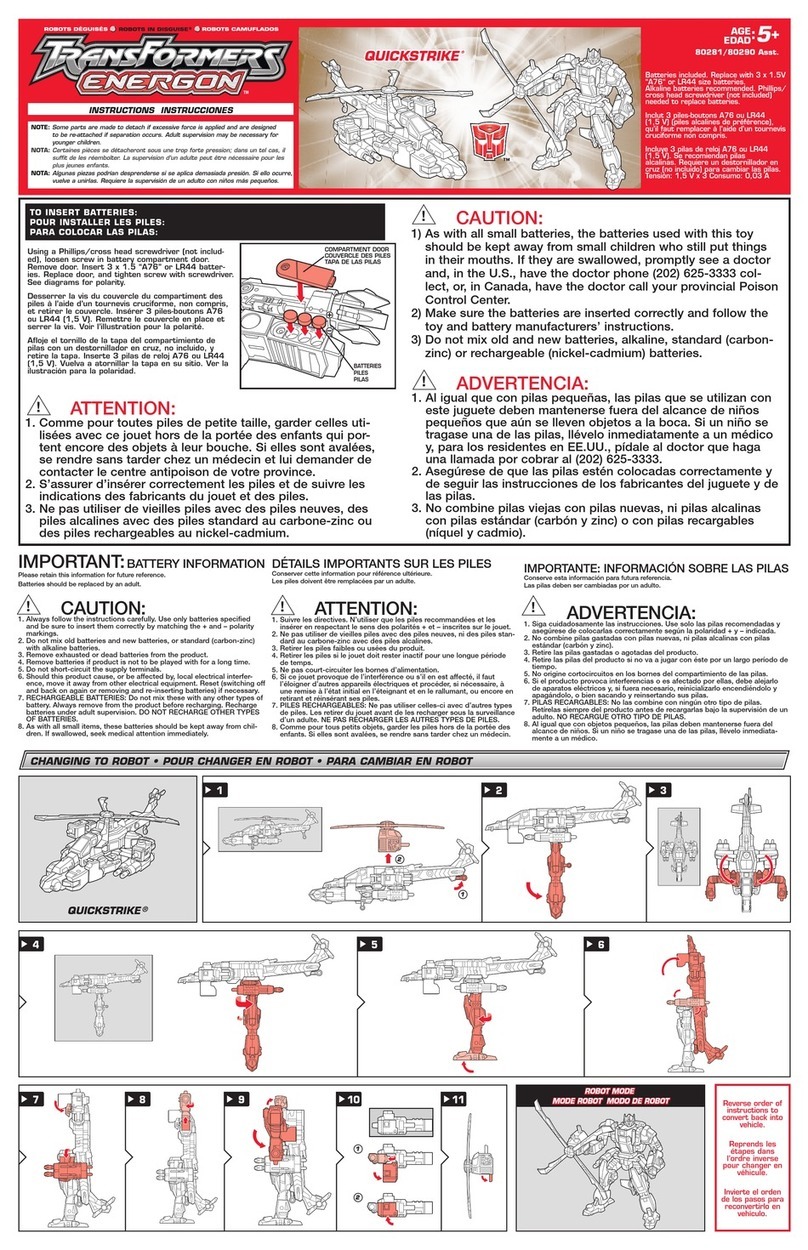

Hasbro TransFormers Energon Quickstrike instructions

roundhouse

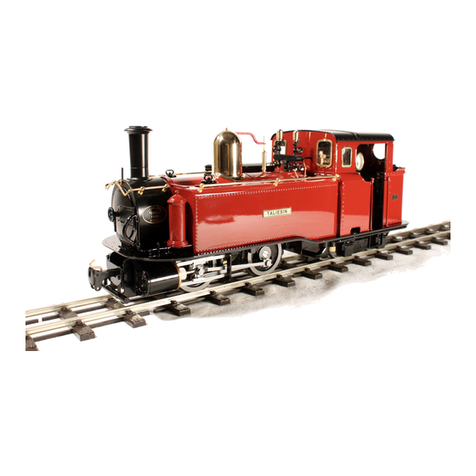

roundhouse TALIESIN Owner's handbook

Airigami

Airigami PAPIER AVION Boeing 737-200 quick start guide

Little Tikes

Little Tikes TotSports T-Ball Set quick guide