Flymaster M1 User manual

M1 USER MANUAL

Document version:1.3

2014 FLYMASTER Avionics Ltd.

R. Comendador Rainho, 192 - Apartado 118

3701-910 S. João da Madeira

Portugal

Tel: + 351 256 880 568

Fax: + 351 256 880 551

All rights reserved. Except as expressly provided herein, no part of this manual may be

reproduced, copied, transmitted, disseminated, downloaded or stored in any storage medium, for

any purpose without the express prior written consent of FLYMASTER Avionics Lda. herein

FLYMASTER avionics. FLYMASTER Avionics hereby grants permission to download a copy

of this manual onto a hard drive or other electronic storage medium to be viewed and to print

a copy of this manual or of any revision hereto, provided that such electronic or printed copy

of this manual must contain the complete text of this copyright notice and provided further

that any unauthorized commercial distribution of this manual or any revision hereto is strictly

prohibited. Information in this document is subject to change without notice. FLYMASTER

Avionics reserves the right to change or improve its products and to make changes in the content

without obligation to notify any person or organization of such changes or improvements.

Visit the FLYMASTER Avionics website (www.flymaster-avionics.com) for current updates and

supplemental information concerning the use and operation of this and other FLYMASTER

Avionics products.

Contents

1 Introduction 4

2 Getting Started 4

2.1 Charging the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 M1 Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Switching M1 On and Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Flight Data 6

4 Settings 7

4.1 Units Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2 Temp. Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3 Stroke Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.4 Fuel Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.4.1 Tank Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.4.2 Sensor Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.4.3 TankEmpty .................................. 9

4.4.4 Average Fuel Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.4.5 Set Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.5 Reset Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.6 Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 Fuel Sensor Installation Procedure 10

5.1 Fuel Sensor Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.2 Fuel Sensor .Cutting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.2.1 Deciding Sensor Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.2.2 Cutting the Metallic Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2.3 Sensor Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 15

6 Tank calibration 17

7 Settings 19

7.1 Units Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.2 Temp. Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.3 Stroke Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.4 Fuel Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.4.1 Tank Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.4.2 Sensor Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3

7.4.3 Tank Empty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.4.4 Average Fuel Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.4.5 Set Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.5 Reset Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.6 Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1. Introduction

Thank you for choosing FLYMASTER M1. If you have any questions or comments regard-

ing the use of our instruments you can visit our website or contact our Support Department

(support@flymaster-avionics.com). This manual covers Firmware versions up to 1.33. If have a

more recent version of firmware some of the features may not be covered.

2. Getting Started

Fully charge battery before using FLYMASTER M1 for the first time. The battery may be

charged by either connecting the M1 USB connector to the wall socket charger or USB cable.

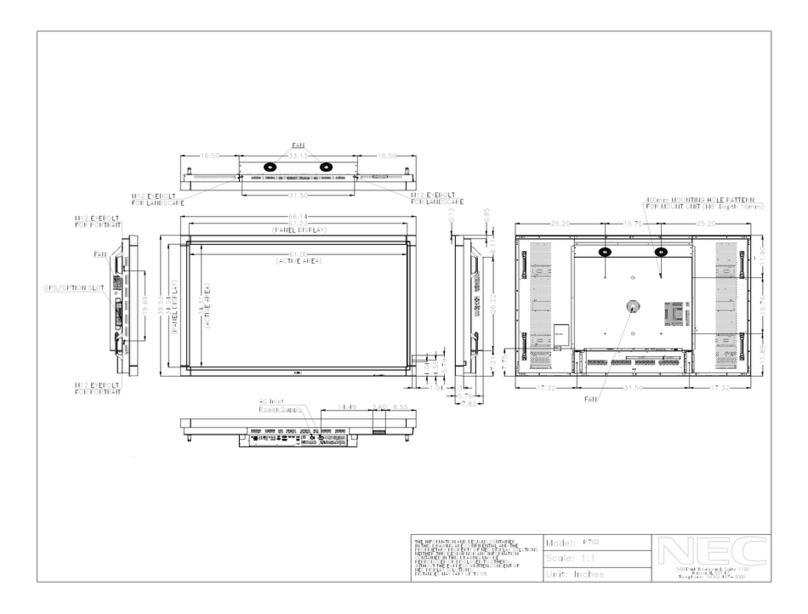

M1 connector can be found on the left side of the M1 (see Figure 1).

Figure 1: Battery charger connection

2.1 Charging the Battery

The charging process is automatic. The end of the charging process is indicated by the screen

message “Charging Complete”. Usually, completely charging the M1 battery takes approximately

7 hours.

M1 uses a Lithium-ion polymer battery, which is not prone to “memory effect”. Therefore the

5

battery does not need to be totally discharged before recharging. In fact, in order to avoid

battery degradation total battery discharge should be avoided.

2.2 M1 Keys

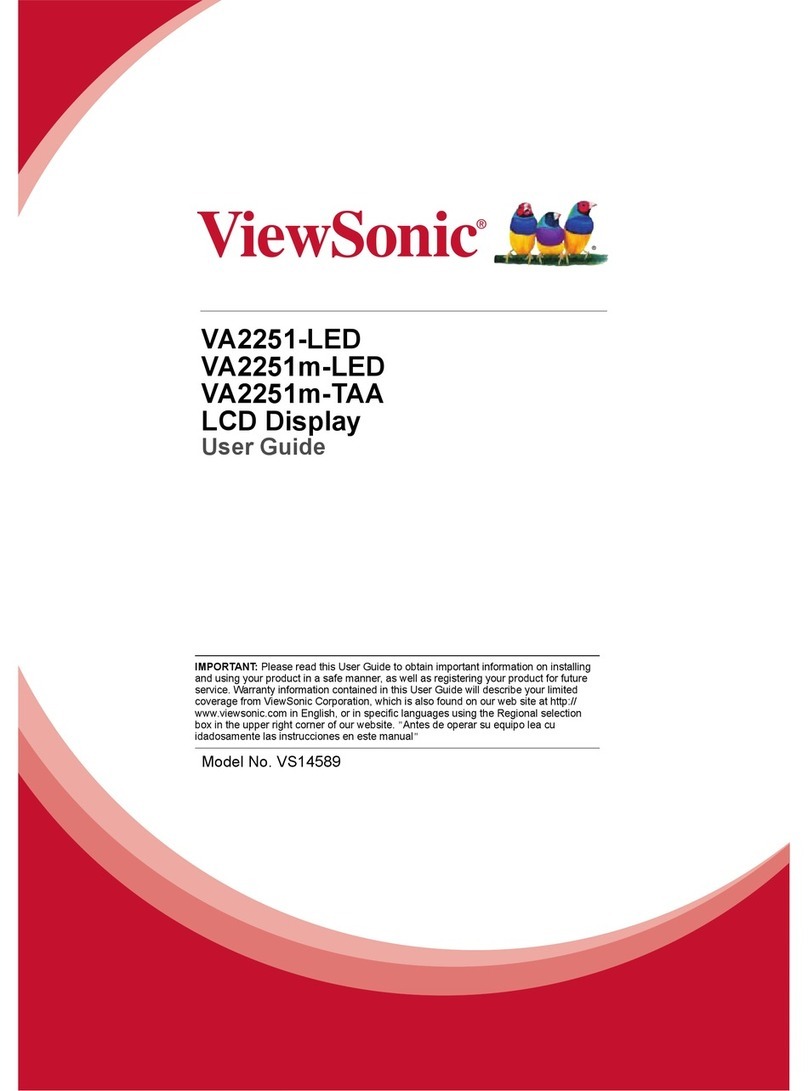

Figure 2: M1 Keys

Three keys are used to interact with M1 (see Figure 2). Depending the context each key can

have more than one function. Key functions are indicated by a symbol, or word. The available

functions are indicated in Table 1.

Table 1 – Key Functions

KEYS Function

Flight Mode Menu Mode

S1 Change Line 1 Data. Change Menu Option (left option).

Decrements parameter values.

S2 Turn On. Change to Menu Mode. Confirm Actions.

S3 Change Line 2 Data. Change Menu Option (Right option).

Increments parameter values.

2.3 Switching M1 On and Off

To switch on the M1, briefly push the S2 key. This will display the start up screen showing the

M1 serial number, firmware version and a 10 second countdown. Pushing S3 before the end of

6

the countdown will initiate the M1. To switch off the M1 , activate menu mode by pushing the

S2 (menu) key. Using keys S3, or S4, chose “Shutdown” menu option. Finally, push the S2

(Enter) Key to confirm. 3. Flight Data

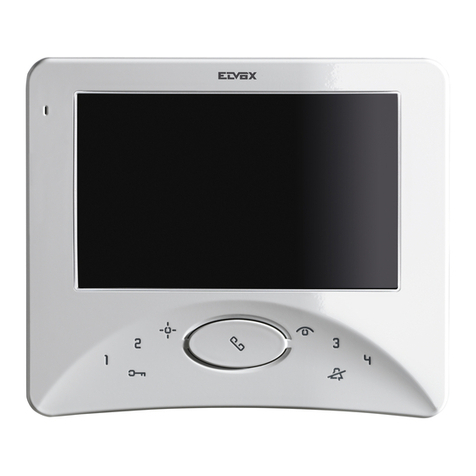

The M1 screen has two 16 character lines. Each one can show a certain type of information.

Changing upper line data can be done by pressing S1 key, while S3 key will change the lower

line data. Each time one of these keys is pressed information changes according with the scheme

shown in Figure 3.

Figure 3: M1 available Information

The meaning of each data field is the following:

Table 1: Data fields Description

Data Field Description

Temperature External probe temperature in oC or oF (see section 7.1). (maxi-

mum temperature is 250oC/482oF).

Date Date in the format Year:Month:Day. Data can be adjusted using

menu (see section 7.6).

Time Time in the format Hour:Minute:Second. Time can be adjusted

using menu (see section 7.6).

7

Data Field Description

Fuel (level) Indicates the tank fuel level. The fuel level can be in centil-

itres,Gallons(Uk or Us) or percentage, according with the “fuel

units” settings (see section ). The fuel level is calculated by mea-

suring the fuel column, therefore its’ accuracy depends on tank

calibration and inclination. To correctly calibrate the tank refer

to the “Tank Calibration“ section.

C.A.F.C. Current Average Flight Consumption - Indicates the average con-

sumption since last user change. The average consumption is up-

dated periodically once rpm is greater than zero. The Average

Consumption value can be changed by the user in the “Fuel Set-

tings” menu (see section 7.4.4).

R.F.T. Remaining Fuel/Flight Time - Gives the remaining fuel time in

the format Hour:Minute. This time is calculated considering the

tank level and average fuel consumption.

T.A.F.C. Total Average Flight Consumption - Indicates the Total average

fuel consumption made, considering all the flights.

TOTAL Shows the total flight time since last timer reset. Timer reset can

be done trough Reset Counter menu option (see section ).

FLIGHT Indicates current flight time. The timer is started once rpm is

detected.

BATTERY Indicates the remaining battery level in percentage. M1 uses a

Lithium-ion polymer battery, which is not prone to “memory ef-

fect”, Therefore the battery does not need to be totally discharged

before recharging. In fact, in order to avoid battery degradation

total battery discharge should be avoided.

RPM Motor angular speed in Revolutions Per Minute. The motor RPM

is determined using an electromagnetic sensor which detects the

supply spark plug current. Depending on the motor type, in or-

der to have the correct value of RPM the number of spark plug

ignitions detected must be multiplied by a certain factor. This

multiplication factor may be adjusted by the user on the configu-

ration menu (see section 7.3).

4. Settings

Settings menu allows the configuration of several M1 parameters. To access the different items

on the Settings menu you can use the LEFT(S1) and RIGHT(S3) keys. Pushing the ENTER

(S2) enter the selected function.

8

Figure 4: M1 Settings

A short description of each option can be seen in Table .

Table 2: Menu Item Description

Menu Item Description

Shutdown Switches off the M1

Units Settings Allows the user to change the M1 inter-

face units

Temp. Settings Change the number of Temperature

Sensors

Stroke Number Configuration of the type of Motor

Fuel Settings Allows the adjustment of several pa-

rameters, and procedures related with

the fuel level measurement and sensor

Reset Counter Allows the user to reset the total flight

time counter.

Date and Time This menu option allows the user to set

the clock and calendar

Exit Main Menu Returns to Main screen

4.1 Units Settings

The "Units Settings" menu option allows the user to change the M1 interface units. In this

Settings the user can change the Temperature Sensor , and the Fuel Units.

9

4.2 Temp. Settings

The "Temp. Settings"’ menu option allows the user to define the Temperature Sensors used. At

this moment the user can choose if one or two CHT sensors are used.

4.3 Stroke Number

The motor rotation is determinate using an electromagnetic sensor which detects the supply

spark plug current.

Depending on the motor type, in order to have the correct value of R.P.M. the number of spark

plug ignitions detected must be multiplied by a certain factor. This multiplying factor can be

changed by the user trough this option.

The current version of firmware allows three settings, specifically 1 spark per 1 revolution, 2

spark per 1 revolution and 1 spark per 2 revolution.

4.4 Fuel Settings

The “Fuel Settings” submenu allows the adjustment of several parameters, and procedures related

with the fuel level measurement and sensor. The available options in this submenu are described

in the following sections.

4.4.1 Tank Calibration

The available fuel on tank is calculated from the measure of the fuel height on tank. Depending

on tank configuration, the same fuel height can give different fuel quantity. In order to get a

more accurate value , is need to calibrate the thank. This calibration procedure establishes a

relation between fuel height and fuel quantity. The calibration procedure is explained in section

6.

4.4.2 Sensor Calibration

The fuel sensor supplied with M1 is factory calibrated. However, the sensor length can be cut

to size . Cutting the fuel sensor length involves several tasks being the last one the Sensor

Calibration. This menu option allows fuel sensor calibration after being cut. The calibration

procedure is necessary in order the M1 recognize the new length. The procedure is explained in

section 5.

4.4.3 Tank Empty

The tank calibration procedure is made in certain conditions which can be different from that

on flight day. This option allows the definition of a new empty set point. In order to define the

new empty point the following procedure should be done: 1. Completely empty the fuel tank; 2.

Choose “Tank Empty” option and follow the instructions on screen.

4.4.4 Average Fuel Consumption

The average consumption is calculated during flight, dividing periodically the value of consumed

fuel by the elapsed time. This calculation is repeated indefinitely when the rotation is greater

than 0 and the fuel level can be determinate. The Average Fuel Consumption is shown in Litres

10

per Hour (L/H). This menu option allows the user to change the Average Fuel Consumption

value. Since values need to be calculated using averages, these need some time to be obtained,

therefore the user can manually insert a reference value so that other calculations that depend

on this value can be immediately carried out.

4.4.5 Set Sensor

The M1 automatic detects if a fuel sensor is connected, but if the user is using the M1 without

the fuel sensor, or want to turn it off in the current flight, in the "Set Sensor" option the user

can set the Sensor Off or On.

4.5 Reset Counter

The M1 includes two flight time counters. One indicates the current flight time, and the other

indicates the total flight time since the last reset. Both timers are automatically started when

RPM is detected, and stopped when RPM is zero. However, whilst the flight time counter is

initiated whenever the flight starts, the total flight time counter accumulates the total of all

flights. The “Reset Counter” menu option allows the user to reset the total flight time counter.

The total flight time counter is useful to control the number of motor working hours in order to

schedule preventive maintenance tasks.

4.6 Date and Time

The M1 has a internal clock, and calendar, which are responsible for time parameters. The

“Date and Time” menu option allows the user to set the clock and calendar. After “Date and

Time” menu option selected the date and time will appears on the screen. To change the data

and Values can be set using S1 and S3 key. Confirming one value will allow changing the next

one.

5. Fuel Sensor Installation

Procedure

Caution: The fuel sensor installation is a delicate, and potentially dangerous, process, which

should only be carried out by skilled technicians. The sensor is fuel certified, but the incorrect

installation, or use, may have serious consequences.

11

Figure 5: Fuel Sensor Installation Example

5.1 Fuel Sensor Position

Considering the height measured by the sensor is proportional to the length of the immersed part,

the fuel sensor should be vertically installed (see Figure 6 a)). However, an inclined position is

possible provided that sealing is guaranteed (see Figure 6 b)).

Figure 6: Installation position

In order to grant the measure accuracy the sensor tube should not have any obstacle closer

than 10 mm (see Figure 7)). Special care should be taken with the distance to the tank bottom.

If required the sensor length can be reduced trough the procedure defined in section 5.2 Fuel

Sensor .Cutting Procedure.Otherwise, the installation continues with tank calibration according

section 5.4 Tank calibration.

12

5.2 Fuel Sensor .Cutting Procedure

The fuel sensor supplied with M1 has a default length. If required the sensor can be shortened.

The first step for shortening the fuel sensor is to decide the correct length of the metallic tube

which will be inserted in the tank.

5.2.1 Deciding Sensor Length

In order to determine the sensor length it is necessary to consider the following points:

•The minimum sensor length is 200 mm.

•A minimum distance of 10 mm should be maintained between the sensor metallic tube and

any other surface, including the tank walls.

Figure 7: Critical Sensor Measures

Taking into account the previous points the length can be easily calculated. For a vertical

installation the length corresponds to the value L of Figure 8.

13

Figure 8: Sensor length

5.2.2 Cutting the Metallic Tube

The sensor cut should be made using an adequate tool (eg. Pipe Cutter; fine toothed hacksaw).

Figure 9: Cutting the Sensor

After cutting the metallic, outer, and inner tube carefully remove the remaining jagged edges

using adequate tool.

14

Figure 10: Sensor after being cut

The sensor has a small hole on the bottom. This hole is necessary to allow fuel entry. (see

Figure 11).

Figure 11: Sensor hole

If cutting the sensor leads to the elimination of the hole a new one should be made using 4

mm drill.

After all the above procedures were done all the surfaces must be cleaned and specially without

filings. The cutting procedure is terminated with the insertion of the special PTFE terminator

supplied with the sensor (see Figure 12).

The main objective of this terminator is to avoid the contact between the centre aluminium rod

and the outer tube. Furthermore, the distance between the rod and the outer tube should be

keep constant along all sensor length.

Attention: Contact between the centre aluminium rod and the outer tube alters

significantly the measures.

Figure 12: End Plug placement

After introducing the end plug, the outer tube should be slightly, and symmetrically, smashed

15

in order to ensure that the plug will not getting out (see Figure 13)

Figure 13: Finishing the tube

After cutting the sensor it is necessary to calibrate it according to the next procedure.

5.2.3 Sensor Calibration Procedure

Sensor calibration allows the M1 to recognize the new probe length after the cutting process.

The calibration process should be made after install the sensor on the tank. However, it can also

be made before the installation using an adequate fuel recipient. Before start the calibration

process assure that you have enough fuel to totally immerse the probe. You should also guaranty

that M1 is charged. Then do the following Steps:

1- With M1 off connect the fuel sensor.

The thank should be empty and the sen-

sor not in contact with fuel.

2- Turn on the M1, enter the MENU and

select the "Fuel Settings" option

3-The fuel sensor by default is off, to en-

able the fuel sensor choose the option "Set

Sensor", select "YES" and press enter to

confirm, and return to Fuel Settings Menu

16

3-Choose the "Calib. Sensor" option

4- The M1 ask you to confirm the sensor

calibration process. By default the flashing

option is "No", so you should choose "Yes"

to proceed.

5- The M1 will ask you to confirm that

sensor is dry (i.e. not in contact with the

fuel). You should choose "Yes".

6- A message "Wait..." appears on the dis-

play while the M1 acquire the empty tank

state. The acquisition takes approximately

3 seconds.

7- After 3 seconds have elapsed ,the M1

will inform you fill the tank to full capacity

, making sure the sensor is fully immersed.

8- When the tank is completely full ,and

the value shown on the screen is stable,

confirm the value using S2 key.

17

9- A message "Wait..." appears on the dis-

play while the M1 acquire the full tank

state. The acquisition takes approximately

6 seconds.

10- If the calibration was successful than

the message "Sensor Calibrated" appears

on the screen, otherwise an error message

will be shown. Despite the message you

should press a key in order to continue.

6. Tank calibration

The available fuel is calculated from the measure of the fuel height on tank. Depending on tank

configuration, the same fuel height can give different fuel quantities. In order the right calculation

can be made a calibration procedure is necessary. This calibration procedure establishes a relation

between fuel height, and fuel quantity. The calibration process is based on a simple idea. After

asking for a standard measure definition, the M1 keeps asking the user to spill measures on

the tank until it is full. For each added measure the corresponding height is saved. Later the

fuel quantity can be calculated by interpolation. The calibration process requires one M1 and a

calibrated fuel sensor correctly installed. If enough fuel is available to completely fill the tank

,follow the next steps:

1- 1- Start with an empty tank, and the

fuel sensor correctly connected to the M1.

2- Turn on the M1, enter the MENU and

select the "Fuel Settings" option

18

3- Within the Fuel Settings menu select

"Calibrate Tank" option.

4- The first step is the definition of the

standard measure. By default the standard

measure is 100 cl. In this step user can al-

ter the standard measure value, or skip the

alteration and maintain the previews defi-

nition.

5- The standard measure value can vary

between 5cl and 200cl. Value can be al-

tered using keys S1 and S3 and confirmed

using S2 Key.

6- Depending on the first value measured

by the sensor the M1 can ask the user to

confirm if tank is really empty. In case

"No" is selected the calibration process is

aborted.

7- In this step M1 waits for a fuel quan-

tity, equal to the "standard measure" value,

be added in the tank. For example, if the

standard measure value is 100 cl, then 100

cl of fuel should be added in the tank. Af-

ter putting the fuel on tank it is important

to wait for the stabilization of the fuel be-

fore selecting "Done" option.

8- After a measure being added the M1

asks the user if tank is full. If "No" is se-

lected the process returns to point 7, oth-

erwise, all values are saved in memory and

calibrations ends.

19

9-.If the calibration was successful than the

message "Tank Calibrated" appears on the

screen, otherwise an error message will be

shown.

Note: Smaller "standard measure" values allow more accurate fuel level calculation, particu-

larly in tanks with irregular shapes. However, the chosen value should cause fuel height variations

greater than 1 centimetre. The maximum number of measures is 30. Once the calibration is

done M1 can calculate data as: fuel level; average fuel consumption; remaining flight time.

20

Table of contents