FM Calefaccion ST Pizza Series User manual

Instruction Manual

Electric Ovens

Models:

STZ 133/233/433/633

ATTENTION: Please, read these instructions before using this unit.

3

Mod. B4600Humid

CONTENTS

1. CE CERTIFICATION 4

2. WARRANTY 5

3. GENERAL AND SAFETY STANDARDS 6

4. SAFETY INSTRUCTIONS, TRANSPORT AND MAINTENANCE 8

4.1 Unpackaging 8

4.2 Transport 8

4.3 Preliminary operations 9

4.4 Placing the unit 9

5. STARTING UP THE UNIT 11

5.1 Electrical connection 11

6. DISPLAY USE INSTRUCTIONS 14

6.1 First start 14

6.1.1 Control panel 14

6.2 Use for cooking 15

6.2.1 Starting to cook 15

6.2.2 Turning off 15

6.3 Cleaning 16

6.4 Maintenance 16

7. MOST FREQUENT DOUBTS 17

4

Mod. B4600Humid

1. CE Certification__________________________________________

DECLARATION OF CONFORMITY

Council Directive(s) to which conformity is declared:

DC 2014/35/EU + DC 2014/30/EU + DC 2011/65/EU

Application of the Standards:

EN 60335-1:2012 / EN 60335-2-42:2003 + Corr:2007 + A1:2008 + A11:2012 /

EN 55014-1:2006 + A1:2009 + A2:2011 / EN 55014-2:1997 + A1:2001 + A2:2008 / EN 61000-3-2

:2006 + A1:2009 + A2:2009 / EN 61000-3-3 :2008

Manufacturer:

FM CALEFACCIÓN S.L.

CIF: B-14343594

Manufacturer´s addres:

CTRA. de Rute km.2.700, C.P.:14900, Lucena

Cordoba, España

Type of equipment:

HORNO / OVEN

Marca / Trade:

FM CALEFACCIÓN

Model:

STZ 133/233/433/633

We, the undersigned, hereby declare under our sole responsibility that the specified equipment is in

conformity with the above Directive(s) and Standard(s)

Place:

Lucena

Signature: B-14785315

Date:

01/10/2019

5

Mod. B4600Humid

2. Warranty

The warranty period is 12 months from the date of purchase of the unit.

The warranty does not cover damages to the glass, lamps, door seals, damage to the insulating material or damage

caused by improper installation or maintenance, lack of maintenance, improper repair or misuse.

To process the repair of a unit under warranty or for any other query, please contact your distributor and refer to

the following description table.

Distributor:

Unit model:

Serial number:

Name:

Date of the request:

Fault description:

Address:

Contact phone number:

Working hours:

Warning: improper adjustment, installation, service or maintenance of the unit may lead to damages to

the goods or persons. For this reason, please, read this manual thoroughly before starting the unit.

6

Mod. B4600Humid

3. General and safety standards

Safety standards and responsibility for installing and maintaining

Read this manual thoroughly before starting the unit and keep it for further consultation. If you need technical

support, contact an authorised technical service.

Installation, starting and maintenance of the oven shall be carried out by qualified technicians in accordance with

the scale and technical characteristics specified by the manufacturer. Likewise, observe the current legislation on

safety with regard to installations and occupational safety in force in the country of use.

Check that the unit is unplugged from the power supply before installing or maintaining.

Before installing the unit, check that installations are in accordance with the current legislation in the country of

use and refer to the indications on the data plate.

Do not manipulate or disconnect the unit safety devices. This will invalidate the warranty.

Damages, injuries or fatal accidents could be produced due to the non-observance of the manufacturer’s

indications.

If the oven is installed on supports or overlaying parts, use the ones supplied by FM only and follow the assembly

instructions inside the packaging.

Non-original spare parts do not ensure the correct operation of the unit and will imply the loss of the warranty.

The over must be only used by duly-trained technicians.

The oven data plate provides the necessary technical information for repair or maintenance. Therefore, avoid

removing, damaging or modifying it.

Failure to comply with these safety standards will release FM from any responsibility and the warranty will

become null and void.

Safety standards for use

Please, read this manual thoroughly before starting the unit and keep it for further consultation. If you need

technical support, contact an authorised technical service.

If the unit is not used for a long time, all connections must be interrupted (power supply and water).

The oven must only and exclusively be used for the purpose it was designed, it is to say, for cooking products

such as fresh or frozen bread, pastries and all types of gastronomic products. Any use other than that mentioned

may damage the unit.

Do not put products with a high alcohol concentration into the oven.

The outside and inside surfaces of the oven should be cleaned frequently to ensure hygiene and proper

performance. Do not use abrasive or flammable products, which may damage the unit, to clean those surfaces

7

Mod. B4600Humid

Usage and cleaning different from what is recommended by the manufacturer and with non-authorised products

may damage the unit and the user.

The use of an anti-lime filter at the water supply inlet is recommended. Otherwise, some oven components may

be damaged. Faults caused by lime or water sediment are not included in the warranty.

Failure to comply with these safety standards will release FM from any responsibility and the warranty will

become null and void.

Maximum loads according to the size of the units

CAPACITY

MAXIMUM LOAD

1 x Ø350

5 kg

2 x Ø350

10 kg

4 x Ø330

18 kg

6 x Ø330

25 kg

Never exceed the maximum load capacity to avoid damaging the unit. Failure to comply with these maximum

loading values will release FM from any responsibility and the warranty will become null and void.

Risk of burns

Read these warnings carefully and follow its indications when the oven is working or not completely cooled

down.

Only touch the unit control elements and the door opening handle. Avoid touching any other external elements

of the oven as they may reach temperatures over 60ºC.

Wear thermal mittens or similar to move or handle containers or trays inside the cooking chamber.

Open the oven door slowly and be careful with high temperature vapours coming out from the cooking chamber.

Risk of fire

If you do not clean the unit properly and as often as needed, greases and food leftovers will be accumulated in

the cooking chamber and then, become inflamed.

Only use the products recommended by the manufacturer. Using other products may damage the unit and

invalidate the warranty.

Only use home-use cleaning products and a soft damp cloth to clean the outside coating. Do not use corrosive or

irritating substances.

8

Mod. B4600Humid

4. Safety instructions, transport and maintenance

4.1 Unpackaging

Visible damages: When receiving the material, enter a detailed description of the break in the PDA or in the

delivery note.

General comments such as “damaged packaging” or “damage can be seen”, etc. will not be accepted. Clear

photographs showing the damaged good and packaging must be provided.

Hidden damages: When receiving the material and within 24 hours after reception, once the hidden damage has

been checked, photographs showing the damaged good and its corresponding packaging must be provided. The transport

agency label must be clearly visible. Photographs showing the content only and exclusively will not be accepted.

In either case, transport incidences should be reported to FM Industrial to manage the replacement of the

machine.

If visible damages are detected when receiving the packaged machine, indicate “hits to the oven” at the time of

the delivery, take photos of the damages and transport agency label on the packaging. Please, contact FM Industrial

immediately.

If apparently package is in good conditions, and damages are detected when unpacking, place the original

packaging again on the machine, take pictures of the packaging and transport agency label on the packaging. Next, unpack

again and take photos of damages to the machine. Please, contact FM Industrial immediately.

4.2 Transport

Before transporting the unit to its installation site, make sure that:

- Fits through the door

- The floor withstands its weight

Transport should only and exclusively be carried out by mechanical means, such as a pallet jack, and always on a pallet.

9

Mod. B4600Humid

4.3 Preliminary operations

Remove the protection film from the unit. Clean the adhesive residues with an appropriate solvent. Never use

abrasive or acid products or tools that may damage the surface.

If your unit is fitted with a core probe kit, remember to remove its silicon protection cap. Otherwise, it could be

melted and damage the probe.

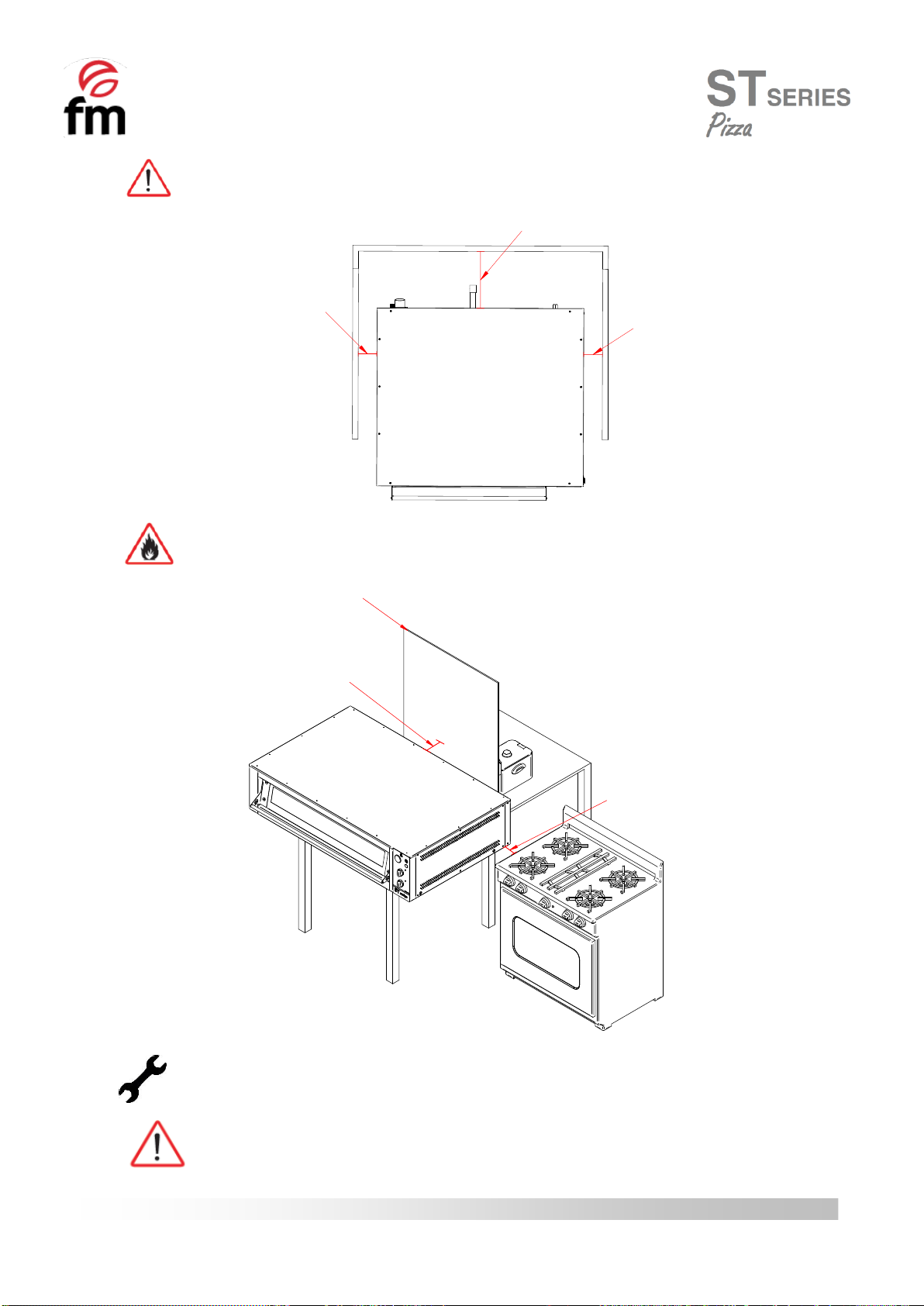

4.4 Placing the unit

Place the oven in the selected workplace and keep a safe distance as indicated below. Check that the unit has

sufficient cold air inlets through the ventilation registers ensuring correct operation. Otherwise, the unit may overheat,

and some components may be destroyed.

- If the oven is installed on an auxiliary support, it must be fixed to it.

- The facilities must be conditioned and meet the regulations in force with regard to safety in installations.

- In addition, the unit must be protected from atmospheric agents.

- The ambient temperature may range between 5ºC and 35ºC maximum for correct operation of the unit.

- Humidity in the facilities should never exceed 70%.

We recommend leaving a 120 mm gap for repair and if there are heat sources or combustible elements, that

safety distance must be 700 mm minimum. We also recommend ensuring good ventilation of the unit to prevent

overheating its components.

10

Mod. B4600Humid

Example of placing the unit without nearby heat sources.

Min.120mm

Min.120mm

Min.120mm

Placing the unit next to heat sources.

Panel aislanteignífugo

Insulatingpanel

Min.100mm

Min.700mm

We recommend leaving a free working space of around 500 mm for maintenance operations.

This unit is not suitable for built-in installations.

11

Mod. B4600Humid

5. Starting up the unit

Remember that any fault or breakage resulting from improper installation or starting up, will make the

warranty become null and void.

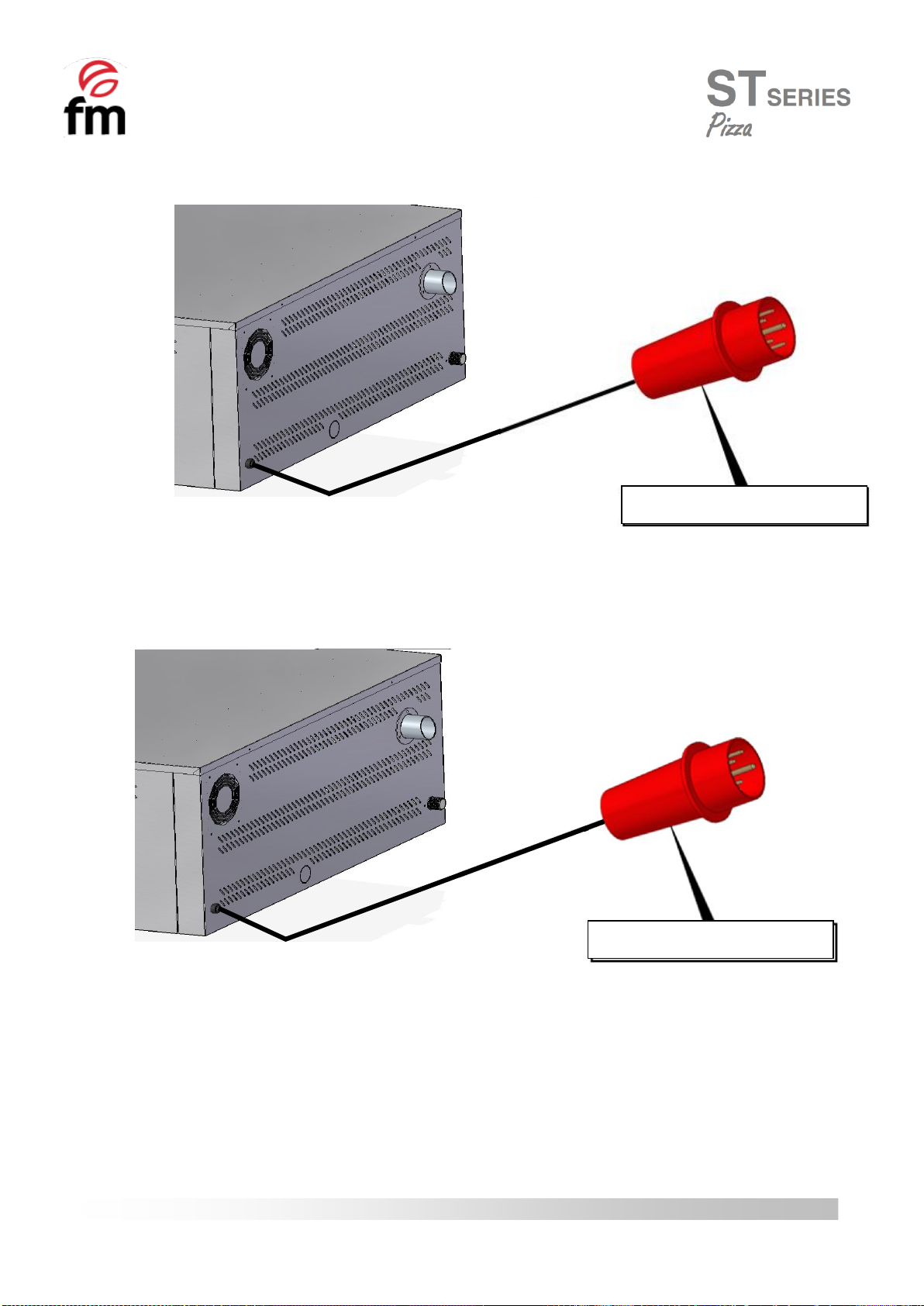

5.1 Electrical connection

Before connecting the unit to the power supply, check that the electrical grid characteristics match those

described in the technical characteristics of each unit. The electrical installation must be performed by authorised

technicians and meet the regulations in force.

Preferably, the electrical connection should be performed by mounting and electrical outlet (NOT INCLUDED) of

appropriate type and capacity for the maximum current absorbed by the oven phases. If not possible, it could be directly

connected to the circuit breaker on the electrical control board.

Next, the types of recommended electrical connections are described:

THREE PHASE 400V

Three phase connection 400V directly connected to a circuit breaker

CIRCUIT BREAKER

12

Mod. B4600Humid

In order to prevent damages from unintentional reset of the cutting thermal device, this unit should not be fed

by an external control device, such as a timer, or be connected to a circuit whose supply is regularly interrupted.

An own power supply line protected by an adequately-sized circuit breaker switch and a fixed supply connection

is recommended to connect the units.

Observe the colour code of cables. Inappropriate connection may damage the unit.

THREE PHASE 230V

Three phase connection 230V connected to a three-phase power

socket type CETAC.

Three-phase connection 400V connected to a three-phase power socket

type CETAC.

MATERIAL NOT SUPPLIED

MATERIAL NOT SUPPLIED

13

Mod. B4600Humid

COLOUR CODE

PHASES

Grey (L1)

Black (L2)

Brown (L3)

NEUTRAL

Blue (N)

GROUNDING

Yellow / Green

5.2 Vapour exhaust from the cooking chamber

Exhaust gases may be wet and reach high temperatures. Therefore, do not use tubes made of materials not

ensuring absolute thermal stability up to 250 ºC to channel exhaust gases.

A condenser enabling the condensation of vapours and exhaust of those vapours into a drainage may be adapted

to treat cooking vapours.

Important: Do not channel the vapour exhaust from the cooking chamber more than 50 centimeters due to risk of

condensation. This pipeline should be vertical and as straight as possible.

14

Mod. B4600Humid

6. Display use instructions__________

Attention! Please, read these instructions thoroughly before starting the device. Store it for future reference and,

if needed, contact an authorised centre.

This machine is designed to be used for cooking fresh or frozen dough as well as bakery and pastry products, fresh

or frozen, being the range of temperature regulation 50-400 ºC.

6.1 First start

Remove the external protection film. If there are adhesive residues, use an appropriate solvent and then, rinse

with a damp cloth.

Certain components of the oven (cooking surfaces, refractory materials, steel sheets…) need preheating. It is

important that this preheating is performed gradually in order to avoid distortions and damage in the machine.

RECOMMENDATION: heat up the oven in a six-hours process (1st HOUR: 0-100 ºC; 2nd HOUR: 100-150 ºC; 3rd HOUR

200 ºC; 4th HOUR 250 ºC; 5th HOUR: 300 ºc; 6th HOUR: 350 º C).

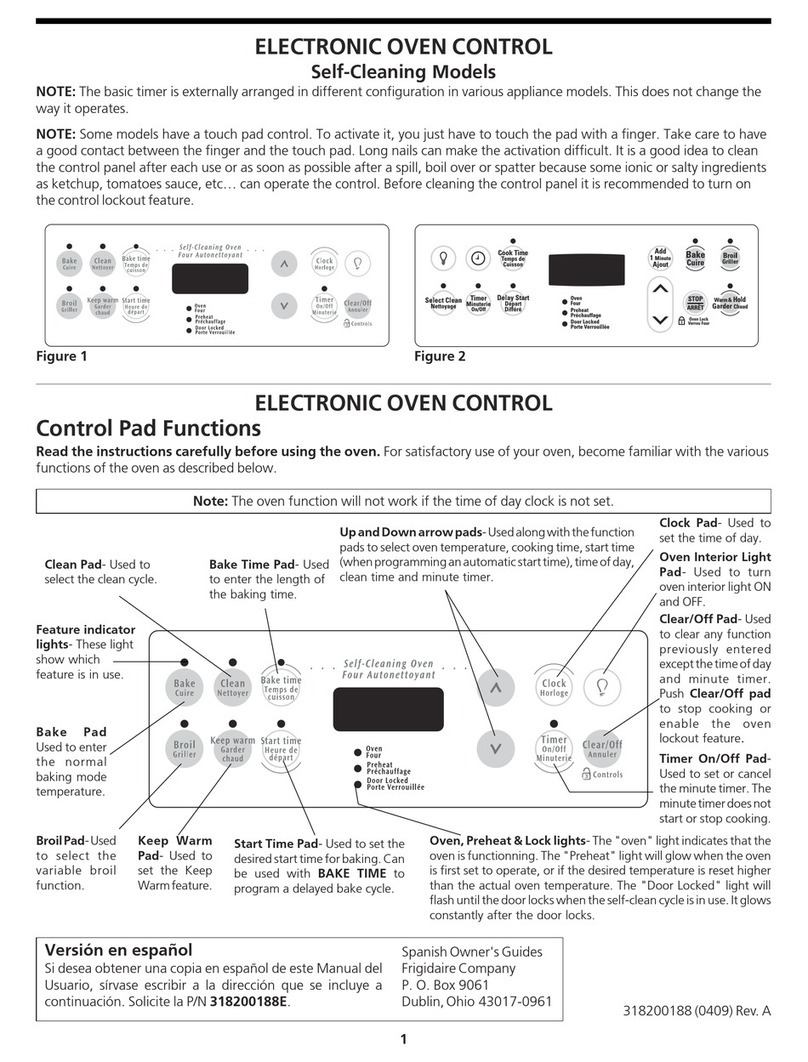

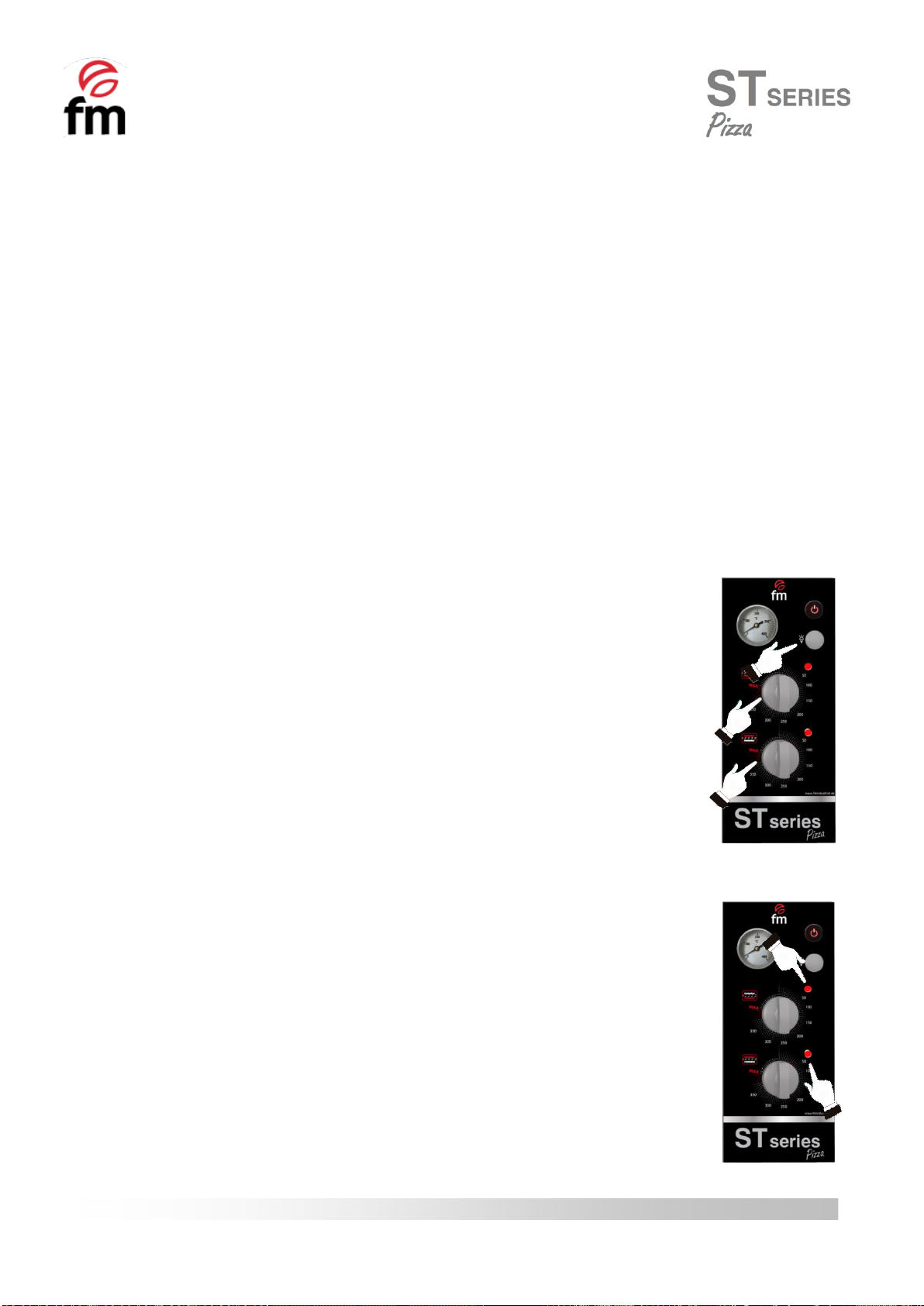

6.1.1 Control panel

No.

Description

Models

1

ON/OFF button

HP 433/633

2

Inner light switch

HP 433/633

3

Led ceiling temperature

HP 133/233/433/633

4

Led floor temperature

HP 133/233/433/633

5

Ceiling temperature regulation knob

HP 133/233/433/633

6

Floor temperature regulation knob

HP 133/233/433/633

7

Analogue thermometer

HP 433/633

1

2

3

3

4

4

5

5

6

6

7

15

Mod. B4600Humid

6.2 Use for cooking

Remove the external protection film. If there are adhesive residues, use an appropriate solvent and then, rinse

with a damp cloth

Important warnings:

Prevent children from having access to manipulating the machine.

The machine must be manipulated and installed by qualified staff.

In case of repair, only original spares should be used.

The machine must not be cleaned with abrasive products that may damage its surfaces.

Never use a jet of water after its use.

Always before a maintenance or cleaning intervention takes place, unplug electric supply and wait until it is

cool.

During its use, external parts may reach high temperatures, therefore, the use of thermal gloves is highly

recommended.

Do not hit the refractory base nor yield it to intense temperature gaps.

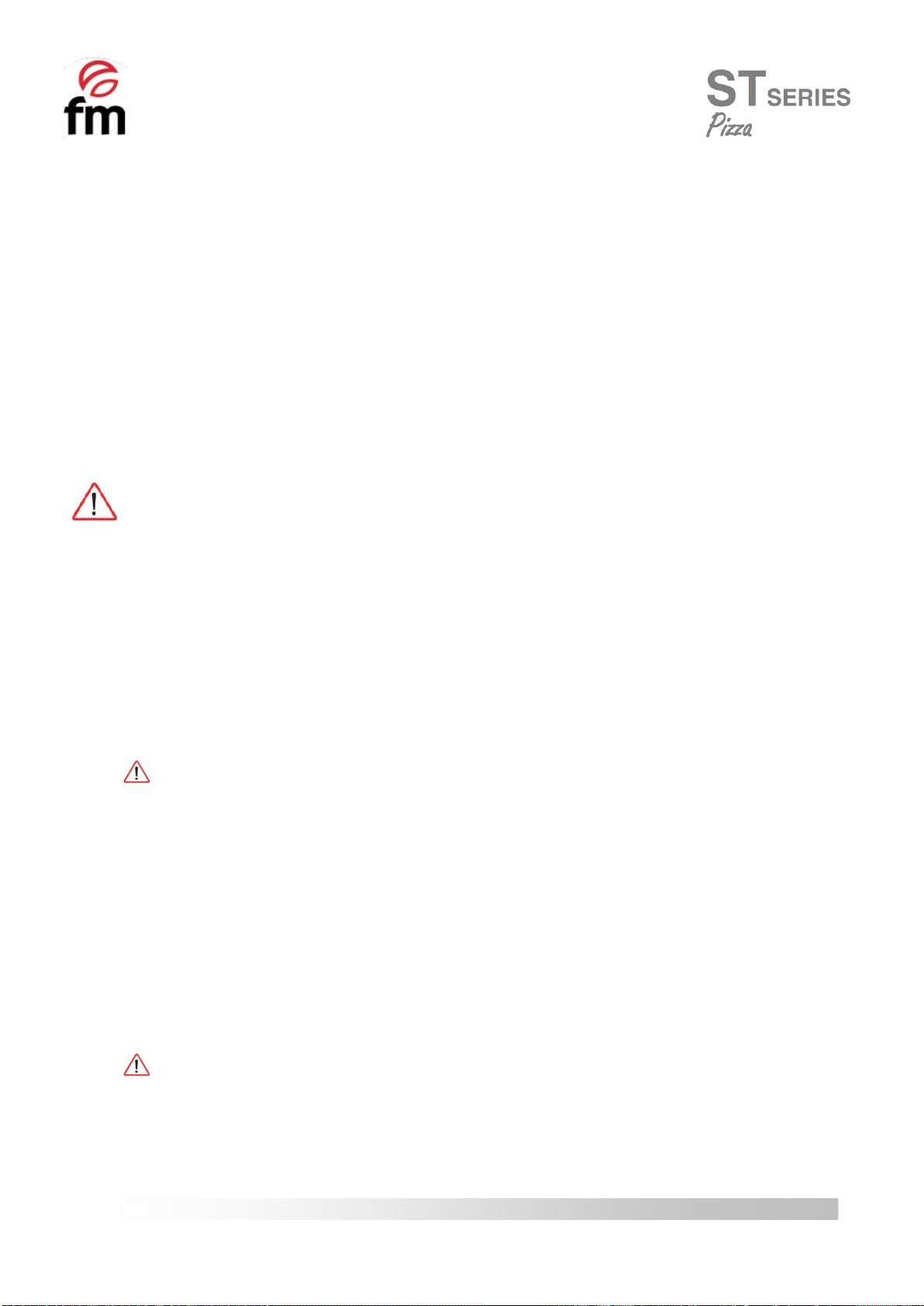

6.2.1 Starting to cook

First, push the ON/OFF button (1) and set floor (2) and ceiling (3) tempereratures using

the regulation knobs.

Bear in mind that these kind of ovens have a refractory floor, consequently, the time

spend in reaching the desired temperatura may be higher than in a standard oven.

6.2.2 Turning off

Once the oven is not working, adjust the regulation knobs to zero and check that both

LED used to indicate the activation of the heating elements turn off. For long storage

periods it is recommended to disconnect the main circuit breaker in the electrical box.

PRECALENTAMIENTO

1

3

1

2

16

Mod. B4600Humid

6.3 Cleaning

After finishing, it is necessary to clean the cooking base and all internal parts that have touched the food with the

goal of preventing food rests from degradation and the consequent contamination of future cookings.

Cleaning must be performed with the oven unplugged and at room temperatura.

To clean the refractory surface, a brush can be used to remove rests from cooking. If any of them are stuck to it,

remove them using a spatula. Never use any kind of liquid and, above all, any detergent, since the refractory material is

porous and a rinse that guarantees a complete removal of any substance is not possible. Neither should excessively

abrasive materials since the refractory material is fragile and may be damaged.

Cleaning of glass must be perform in cool conditions, since, even though that this kind of glass resists high

temperatures, it is especially sensitive to temperature gaps, which may lead to its fracture.

¡ATTENTION! Neve allow that waters contacts the glass until it reaches room temperatura.

6.4 Maintenance

Daily maintenance

Remove any rest of baking or soot in the chamber.

To clean the refactory stone, use a plastic scrapper. If it is extremely dirty, adjust to the maximum temperature

and leave the oven heating for half an hour. Next, and once it has cooled down, use the plastic scrapper again

Never brush the Stone excessively hard and use water or another non-abrasive liquid for it.

To clean the interior of the oven, use a wet rag, avoiding touching the heating elements.

Clean the exterior of the machine with a rag and a specific cleaning product for stainless Steel. Clean, if possible,

repecting the direction of steel brushing.

Clean the glass of the door using a wet cloth and water or a glass cleaning product. Next, dry it using a clean rag.

Annual maintenance

Remove the refractory stones and vacuum the cooking rests or soot in the cooking chamber.

Please, proceed carefully and, if necessary, mark the stones to reinstall them in exactly the same position

once the cleaning process has come to an end.

17

Mod. B4600Humid

7. Most frequent doubts________________________ ____

Down below there is cause-problem-solution chart with the more frequent issues.

Chart 2

PROBLEM

CAUSE

SOLUTION

The machine does not start

No voltage from the supply

Check supply voltage

Improper connection

Check connection

ON/OFF button does not work

Contact a technical service

The machine does not heat

up properly

Upper thermostat is faulty

Contact a technical service

Lower thermostat is faulty

Contact a technical service

Heating elements out of service

Contact a technical service

Chamber light continuously

off

Chamber light switch does not work

Contact a technical service

Loose light bulb

Revisar casquillo y apretar lámpara

Burnt out light bulb

Replace light bulb

This manual suits for next models

4

Table of contents

Other FM Calefaccion Oven manuals