FMI VJCAT42/50S User manual

OWNER’S OPERATION AND INSTALLATION MANUAL

INDOOR WOOD BURNING (V)GCAT42/50(H)A SERIES

INDOOR/OUTDOOR WOOD BURNING (V)JCAT42/50(H,S)

SERIES FIREPLACES WITH INSULATION

PFS

®

USC

ICC-ES #ESR-2542

For more information, visit www.fmiproducts.com

These models meet the EPA Wood Burning Fireplace

Program Phase 2 emission level. NOTE: To ensure proper

replace operation, the catalyst should be replaced at a

minimum of 3 years and a maximum of 5 years.

SAVE THIS BOOK

This book is valuable. In addition to instructing you

on how to install and maintain your appliance, it also

contains information that will enable you to obtain re-

placement parts or accessory items when needed. Keep

it with your other important papers.

This replace is approved for use as a wood burning

replace or for use with a vented gas log approved to

ANS Z21.60 and Z21.84 standards.

This wood burning replace complies with UL127-CAN/

ULC-S610-M87 standard as a FACTORY BUILT FIREPLACE.

FOR CANADA: The authority having jurisdiction (such

as the municipal building department, re department,

etc.) should be contacted before installation to deter-

mine the need to obtain a permit.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

www.fmiproducts.com 125655-01B2

WARNING: Improper installation, adjustment, altera-

tion, service or maintenance can cause injury, property

damage or loss of life. Refer to this manual for assis-

tance or additional information. Consult a qualied

installer or local distributor.

TABLE OF CONTENTS

SAFETY

FOR YOUR SAFETY

• Do not store or use gasoline

or any other ammable vapors

or liquids in the vicinity of this

or any other appliance.

• Due to high temperatures, the

appliance should be located

out of trafc and away from

furniture and draperies.

• Do not place clothing or other

ammable materials on or near

the appliance.

• Never leave children unat-

tended when a re is burning

in the replace.

WARNING: Use solid wood

or processed solid fuel relogs

only. When processed wood fuel

re logs are used, do not poke or

stir the logs while they are burn-

ing. Use only re logs that have

been evaluated for the application

in replace and refer to re log

warnings and caution markings

on packaging prior to use.

This replace is not intended to be

used as a substitute for a furnace

to heat an entire home. Use for

supplemental heat only.

IMPORTANT: Check local codes

before installing this replace.

Before beginning the installation of the

fireplace, read these instructions through

completely.

• ThisFMIPRODUCTS,LLCreplaceandits

components are safe when installed accord-

ingtothisinstallationmanual.Unlessyou

use FMI PRODUCTS, LLC components,

which have been designed and tested for

thereplacesystem,youmaycauseare

hazard.

• TheFMIPRODUCTS,LLCwarrantywill

bevoidedbyandFMIPRODUCTS,LLC

disclaims any responsibility for the follow-

ing actions.

a. Modification of the fireplace, com-

ponents, doors, air inlet system and

damper control.

b. Useofanycomponentpartnotmanu-

facturedor approvedby FMIPROD-

UCTS,LLCincombinationwithaFMI

PRODUCTS,LLCreplacesystem.

Properinstallationisthemostimportantstep

in ensuring safe and continuous operation

of the replace. Consult the local building

codes as to the particular requirements

concerned with the installation of all factory

builtreplaces.

WARNING: Do not install a

replace insert in this box unless

the manufacturer's instructions

with the insert specically state

this replace has been tested for

use with this insert.

Safety .................................................................. 2

Specications ...................................................... 3

FireplaceInstallation............................................ 5

VentingInstallation .............................................. 7

RefractoryPanelInstallation.............................. 12

OptionalGasLineInstallation............................ 13

PureFireInstallation........................................... 14

GlassDoorInstallation ...................................... 15

OperationandMaintenanceGuidelines ............ 16

PureFireEmissionsControlSystem.................. 17

TechnicalService............................................... 19

ReplacementParts............................................ 19

Parts ................................................................. 20

Accessories ....................................................... 24

www.fmiproducts.com

125655-01B 3

SPECIFICATIONS

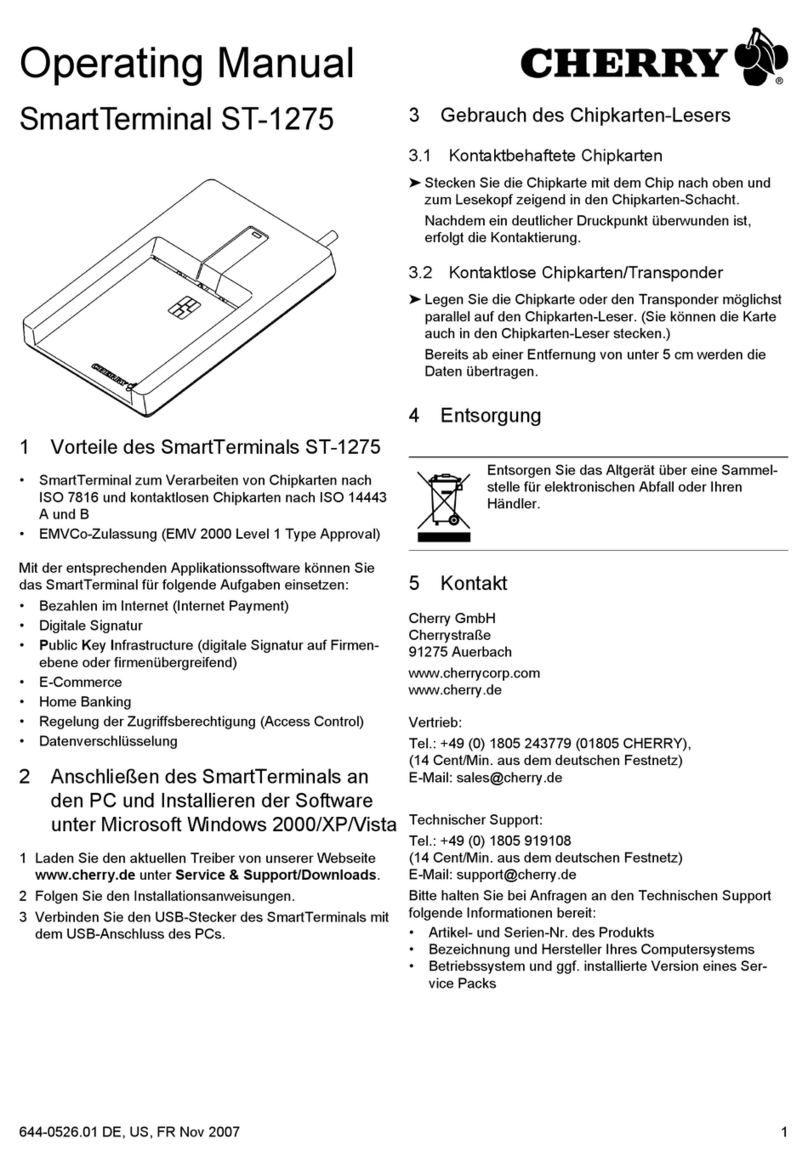

42" MODELS

OUTSIDE AIR

11/2" AIR SPACE

BACK AND SIDES

0" TO

BOTTOM

GAS LINE

KNOCKOUTS

12" EACH SIDE

COMBUSTIBLE

WALL BOARD

NO COMBUSTIBLE

MATERIAL ON FACE

MINIMUM 18" TO

PERPENDICULAR

SIDEWALL

HEARTH EXTENSION

66" X 20"

2" CHIMNEY AIRSPACE

CLEARANCE TO

COMBUSTIBLE MATERIAL

42"

23 1/2"

25 1/8"

22 3/4"

30 1/2"

29"

4 3/8"

15 3/4"

5/8"

17 5/8"

67"

61"

49"

7"

1"

30"

11"

58"

42"

51 1/8"

4 1/2"

3 1/2"

9 1/2"

10 1/2"

81/2"

13"

17"

OUTSIDE

AIR

ACCESS

GAS LINE

ACCESS

42" HEARTH

Figure 1 - 42" Models (V)GCAT42(H)A AND (V)JCAT42(H,S) Series

www.fmiproducts.com 125655-01B4

SPECIFICATIONS Continued

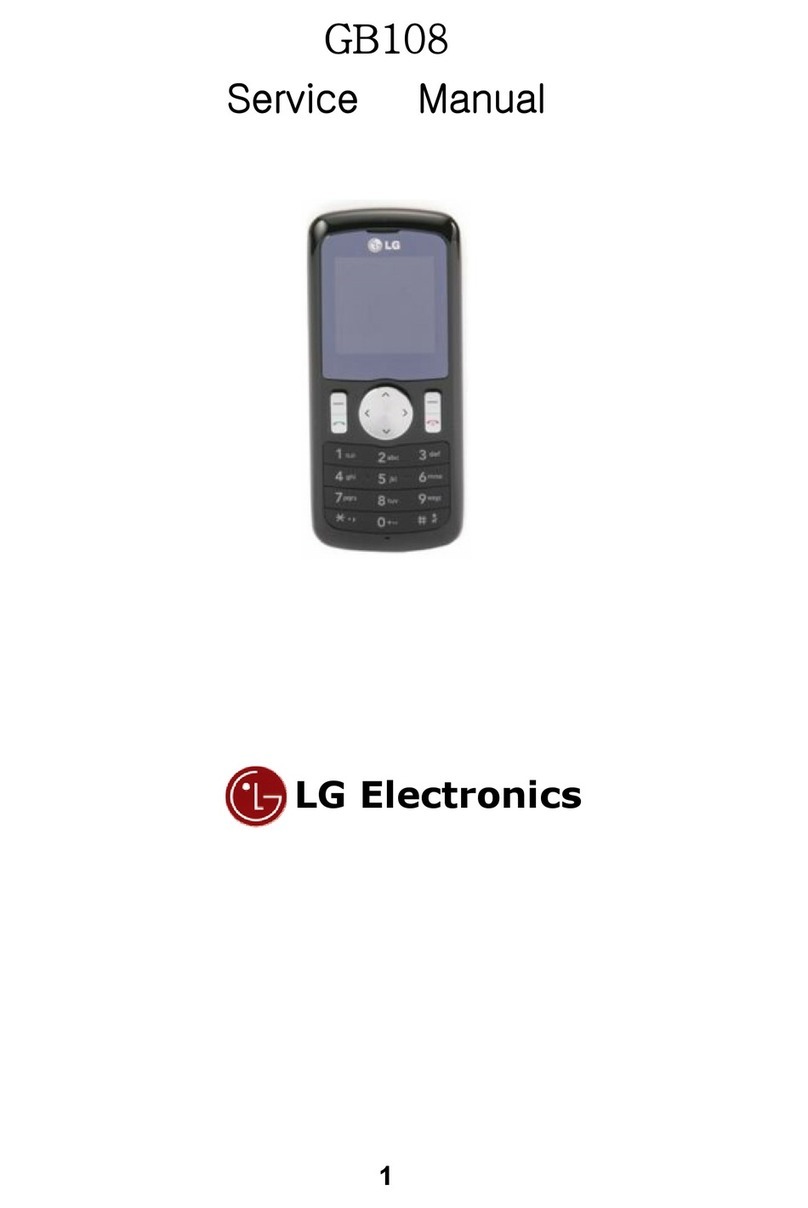

50" MODELS

Figure 2 - 50" Models (V)GCAT50(H)A AND (V)JCAT50(H,S) Series

50"

23 1/4"

33 1/8"

2" CHIMNEY AIRSPA CE

CLEARANCE TO

COMBUSTIBLE MATERIAL

COMBUSTIBLE

WALL BOARD

NO COMBUSTIBLE

MATERIAL ON FACE

0" TO

BOTTOM

OUTSIDE AIR

11/2" AIR SPACE

BACK AND SIDES

GAS LINE

KNOCKOUTS

12" EACH SIDE

MINIMUM 18" TO

PERPENDICULAR

SIDEWALL

HEARTH EXTENSION

74" X 20"

38 1/2"

28 1/2"

43/8"

17 5/8"

19 1/4"

24"

49"

30"

11"

61"

67" 58"

7"

1"

59"

50" 4 1/2"

3 1/2"

9 1/2"

10 1/2"

8 1/2"

13"

17"

GAS LINE

ACCESS

OUTSIDE

AIR

ACCESS

50" HEARTH

www.fmiproducts.com

125655-01B 5

FIREPLACE INSTALLATION

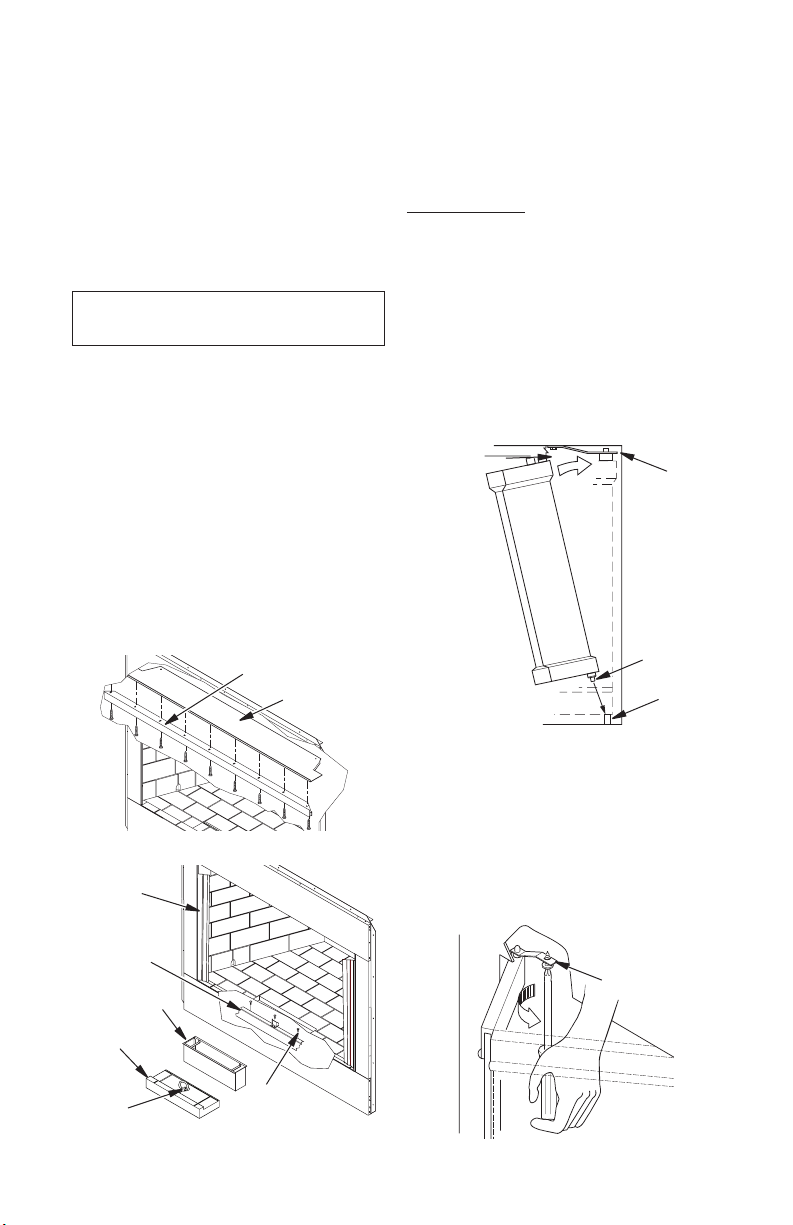

FRAMING

1. Frameopeningforreplaceusingdimen-

sionsshowninFigures3and4.

2. If replace is to be installed directly on

carpeting, tile (other than ceramic) or any

combustible material other than wood

ooring,replacemustbeinstalledupon

a metal or wood panel extending full width

anddepthofreplace.

3. Setreplacedirectlyinfrontofthisopen-

ingandslideunitbackuntilnailinganges

touch side framing.

4. Checklevelofthereplaceandshimwith

sheet metal if necessary.

5. Before securing fireplace to prepared

framing, ember protector (provided) must

be placed between hearth extension (not

supplied) and under bottom front edge of

replacetoprotectagainstglowingembers

fallingthrough.Ifreplaceistobeinstalled

on a raised platform, a Z-type ember pro-

tector (not supplied) must be fabricated to

t your required platform height. Ember

protectorshouldextendunderreplacea

minimum of 1 1/2".Emberprotectorshould

be made of galvanized sheet metal (28

gauge minimum to prevent corrosion.

6. Usingscrewsornails,securereplaceto

framingthroughangeslocatedonsides

ofreplace.

Figure 3 - Framing Dimensions

Figure 4 - Corner Installation

SELECTING LOCATION

To determine the safest and most efcient

locationforthereplace,youmusttakeinto

consideration the following guidelines:

1. Thelocationmustallowforproperclear-

ances(seeFigures5and6).

2. Consider a location where replace will

not be affected by drafts, air conditioning

ducts, windows or doors.

3. A location that avoids cutting of joists or

roof rafters will make installation easier.

4. An outside air kit is available with this

replace(seeOptional Outside Air Kit on

page 7).

MINIMUM CLEARANCE TO

COMBUSTIBLES

Backandsidesofreplace 11/2" min.*

Frontofreplace 48"min.

Floor** 0"min.

Perpendicularwalltoopening 18"min.

Topspacers 0"min.

Mantelclearances

see Mantels, page 7

Chimneyouterpipesurface 2"min.

*Notrequiredatnailinganges

**Seestep2ofFraming

WARNING: Do not pack re-

quired air spaces with insulation

or other materials.

Minimum/Maximum Chimney Height for

Residential Installation

Minimumheightofchimney,measuredfrom

baseofreplacetouegasoutletoftermina-

tion,is16feetforstraightueorauewith

oneelbowset.Maximumdistancebetween

elbowsis6feet.Forsystemswithtwoelbow

sets, minimum height is 22 feet. Maximum

heightofanysystemis50feet.Thismeasure-

mentincludesreplace,chimneysectionsand

height of termination assembly at level of the

uegasoutlet(seeFigure16,page10).

Minimum/Maximum Chimney Height for

Outdoor Installation

Minimumheightofchimney,measuredfrom

baseofreplacetouegasoutletoftermina-

tion, is 9.5 feet (minimum of 4 feet of chimney

pipe sections required for outdoor installation).

71" (50" Models)

100" (50" Models)

65" (42" Models)

92" (42" Models)

86.5" (36" Models)

61" (36" Models)

Maintain 1 1/2"

Clearance

at Sides and

Back of Fireplace

1 1/2" Clearance

Not Required at

Nailing Flanges

30.125"

59" (50" Models)

58.125"

67.125"

51.25" (42" Models)

45.25" (36" Models)

28.250" (36" Models)

www.fmiproducts.com 125655-01B6

Note: For outdoor installations, fireplace

enclosure must allow for adequate drainage

and fresh air ventilation. It is recommended

that a sealed, corrosion resistant catch pan

with provision for drainage be installed under

replace within replace enclosure.

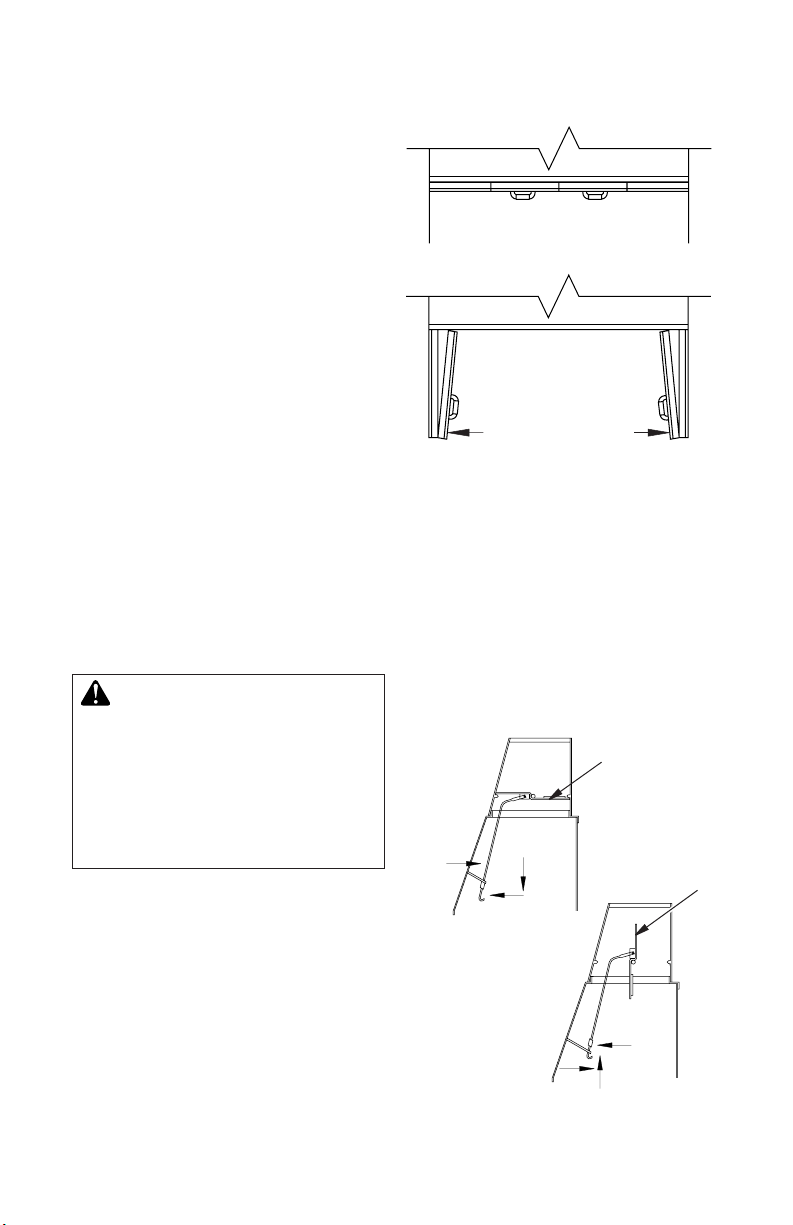

HEARTH EXTENSION

A hearth extension projecting a minimum of

20" in front of and a minimum of 12" beyond

eachsideofreplaceopeningisrequiredto

protectcombustibleoorconstructioninfront

of replace. Fabricate a hearth extension

using a material which meets the following

specications: a layer of noncombustible,

inorganic material having a thermal conduc-

tivityofK=0.84BTUIN/FT,HR.F(orless)at

1"thick.Forexample,ifthematerialselected

hasaKfactorof0.25,suchasglassber,the

following formula would apply:

0.25 x 1.0" = 0.30" thickness required

0.84

Thermalconductivity"K"ofmaterialscanbe

obtained from manufacturer or supplier of

noncombustiblematerial.Ifhearthextension

is to be covered, use noncombustible mate-

rial such as tile, slate, brick, concrete, metal,

glass,marble,stone, etc. Providea means

to prevent hearth extension from shifting and

sealgapbetweenreplaceframeandhearth

extension with a noncombustible material

(seeFigure5).

WARNING: Hearth extension

is to be installed only as shown

in Figure 4.

FIREPLACE INSTALLATION

Continued

Figure 5 - Hearth Extension

SealGap

FireplaceFront

EmberProtector

FireplaceFront

RaisedHearth

FireplaceFront

Elevated

EmberProtector

EmberProtector

SealGap

Hearth

Extension

MANTELS

Amantelmaybeinstalledifdesired(seeFigure

6). Woodwork such as wood trims, mantels

or any other combustible material projecting

from front face must not be placed within 18"

of replace opening. Combustible materials

above 18" and projecting more than 1 1/2" from

replacemustnotbeplacedlessthan21"from

the top opening of the replace (NFPA STD

211,Sec.7-3.3.3).

Mantels or any other combustible material

also may come up to side edge of black metal

faceofreplaceaslongasprojectionsfrom

frontfacefallwithinlimitshowninFigure6.

Figure 6 - Mantel Clearances to

Combustible Material

12 1/4"Ref.

6"

Ref.

21"Min.

18"Min.

11/2"Max.

3" Nom.

33°

Combustible

Material

Safe

Zone for

Projectionof

Combustible

Materials

FireplaceOpening

Upper

Sectionof

Fireplace

FIREBOX

SAFE ZONE

TopViewofFireplace

3"Max.

4.5"

18"Min.to

Perpendicular

SideWall

11.5"

33° Combustible

MaterialMust

NotOverlap

FrontFace

www.fmiproducts.com

125655-01B 7

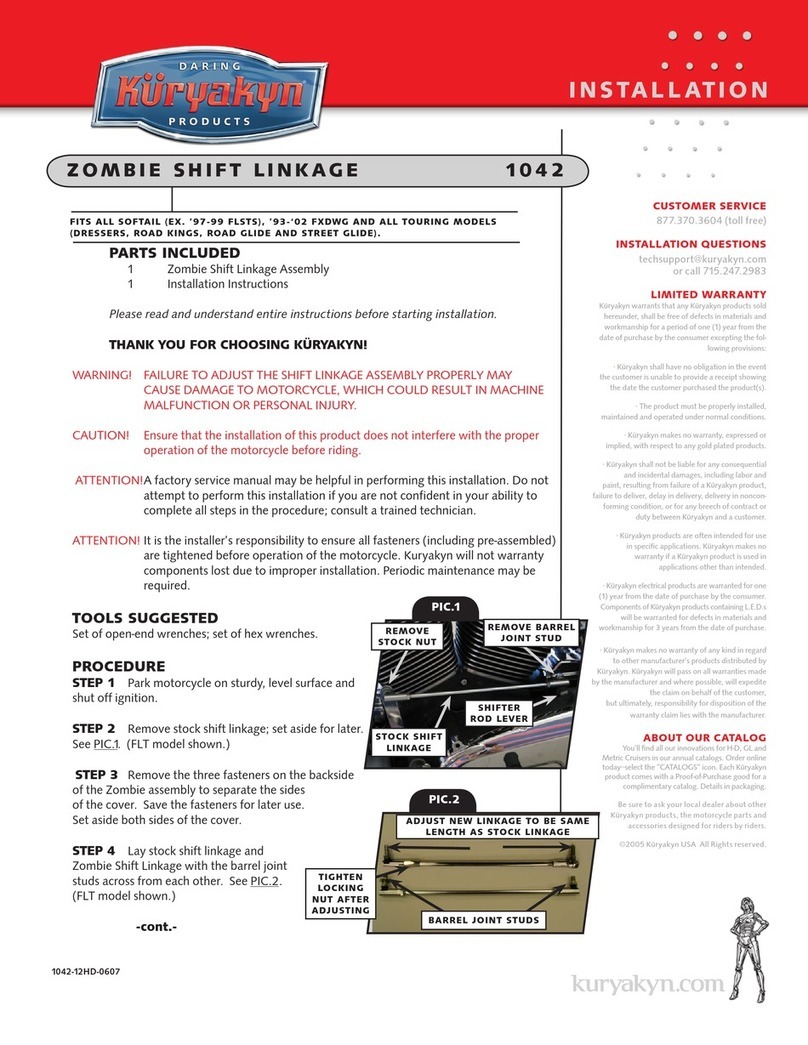

Figure 8 - Lineal Gain

LINEAL GAIN

PART NO. DESCRIPTION GAIN

Georgian Fireplace 66 1/2

"

12-12DM

12-12HT PipeSection 10 5/8

"

18-12DM

18-12HT PipeSection 16 5/8

"

24-12DM

24-12HT PipeSection 23 5/8

"

36-12DM

36-12HT PipeSection 34 5/8

"

48-12DM

48-12HT PipeSection 46 5/8

"

RLT-12D

RLT-12HT RoundTermination 7 3/4

"

*

STL-12D SquareChase-Top

withSlipSection 7

"

to 15

"

*

*Thelinealgainfortheterminationsismea-

suredtotheuegasoutletheight.

Hemmed

End

12 3/8"

Stainless

InnerPipe

15"Galvanized

OuterPipe

ASSEMBLY AND INSTALLATION OF

DOUBLE WALL CHIMNEY SYSTEM

Eachdoublewallchimneysectionconsistsofa

galvanizedouterpipe,astainlesssteelinnerue

pipeandawirespacer.Thepipesectionsmust

be assembled independently as the chimney is

installed. When connecting chimney directly to

thereplace,theinneruepipesectionmust

beinstalled rstwith thelanced sideup.The

outer pipe section can then be installed over

5the uepipe sectionwith thehemmed end

up.Pressdownoneachpipesectionuntilthe

lancessecurelyengagethehemonthereplace

starter.Thewirewillassuretheproperspacing

between the inner and outer pipe sections.

Figure 7 - Outside Air Kit

SecuretoCollarswithMetalTape,

ScrewsorStraps(Min.of1/4"x20"

in size)

AirInlet

Location

MustAllow

ForBushes

orSnow

VentHood

Requiredfor

WallInstallation

AirInlet

Eyebrow

VentedCrawlSpace

(CheckLocalCodes

BeforeInstallingina

VentedCrawlSpace)

CHIMNEY PIPE

TheFMIPRODUCTS,LLCchimneysystem

consists of 12", 18", 24", 36" and 48" snap-

lock, double-wall pipe segments, planned

for maximum adaptability to individual site

requirements. Actual lengths gained after

ttingoverlapsmustbetakenintoconsider-

ation (lineal gain) and are given in the lineal

gainchart(seeFigure8).LinealGainisthe

actual measurable length of a part after two or

morepartsareconnected.ForCanada,use

chimneypartsdesignated"HT".

VENTING INSTALLATION

OPTIONAL OUTSIDE AIR KIT

(MODEL AK4/AK4F)

The installation of an outside air kit should

be performed during the rough framing of

thereplaceduetothenatureofit'slocation.

Outsidecombustionairisaccessedthrough

a vented crawl space (AK4F) or through a

sidewall (AK4).

CAUTION: Combustion air

inlet ducts shall not terminate

in attic space.

The maximum height for the

air vent can not exceed 3 feet

below the ue gas outlet of the

termination.

WARNING: The opening in

the collar around the chimney at

the top of the replace must not

be obstructed. Never use blown

insulation to ll the chimney

enclosure.

www.fmiproducts.com 125655-01B8

VENTING INSTALLATION

Continued

OFFSET

RISE CHIMNEY LENGTH

A B 12" 18" 24" 36" 48"

4 3/8" 16 3/8"

ELBOWSETONLY

9 3/4" 25 1/2"

1

12 3/4" 30 3/4"

1

15" 34 3/4"

1

18" 40"

1 1

21 1/4" 46 1/4"

1

23 3/4" 49 1/4"

1 1

27 3/4" 56 3/4"

1

30" 60 3/4"

1 1

33" 66"

1

36" 71"

1 1

38 1/4" 75"

2

41 1/4" 80 1/4"

1 1 1

45" 86 3/4"

2

46 3/4" 89 1/2"

1 1 1

51" 97"

1 1

53 1/4" 101"

2

56 1/4" 106 1/4"

2

59 1/4"111 1/2"

1 1 1

61 3/4" 115 1/2"

1 2

64 3/4" 120 3/4"

1 2

68 1/4" 127"

2 1

70" 130"

1 1 2

74 1/4" 137 1/2"

1 2 1

76 3/4" 141 1/2"

1 2 1

79 3/4" 146 3/4"

4

OFFSET CHART (22-50 FT. SYSTEM HEIGHT)

Figure 10 - Ceiling Support Pipe

12S-12DM

2"Min.

Straps

Straps

Straps

Straps

DetailA

ReturnElbow

DetailB

AngleFirestop

SeeDetailA

SeeDetailB

Continue to assemble chimney sections as

outlined above, making sure that both the

inner and outer pipe sections are locked to-

gether. When installing double wall snap-lock

chimney together, it is important to assure

the joint between the chimney sections is

locked. Check by pulling chimney upward

afterlocking.Thechimneywillnotcomeapart

Figure 9 - Elbow Offset

B

A

Screws

ifproperlylocked.Itisnotnecessarytoadd

screws to keep the chimney together (excep-

tion,seeFigure9).

USING ELBOW OFFSETS (30E-12DM)

1.

Toachievedesiredoffset,youmayinstall

combinations of 12", 18", 24", 36" and 48"

length of double wall pipe (see offset chart

andFigure9).

2.

Chimney weight above offset rests on

return elbow. Straps must be securely

nailedtoraftersorjoists(seeFigure10,

details A and B).

3. Maximum length of pipe between sup-

ports(return elbowor12S-12DM)is6'

ofanglerun. Maximumoftwo 6'angle

run sections per chimney system (see

Figure11,page9).

4. All pipe connections between the offset

and return must be secured with two

screws on the outer pipe only (see

Figure 9). Do not penetrate the inner

stainless.

www.fmiproducts.com

125655-01B 9

VENTING INSTALLATION

Continued

FIRESTOP SPACERS (FS-10)

Firestop spacers are required at each point

where the chimney penetrates a oor space.

Their purpose is to establish and maintain

the required clearance between the chimney

and the combustible materials. When the pipe

passes through a framed opening into a living

spaceabove,therestopmustbeplacedonto

theceilingfrombelowasshowninFigure12.

They also provide complete separation from

one oor space to another or attic space as

required by most codes. When the double wall

pipe passes through a framed opening into an

atticspace,therestopmustbeplacedintoan

atticoorasshowninFigure13.

Figure 12 - Firestop Spacer with Living

Space Above Ceiling

Figure 13 - Firestop Spacer with Attic

Space Above Ceiling

Existing

Ceiling

Frame

Firestop

Spacer

Screwsor

Staples

(Min.of8)

Firestop

Spacer

ScrewsorStaples

(Min.of8)

PENETRATING ROOF

Tomaintaina2"clearancetothepipeona

roof with a pitch, a rectangular opening must

be cut.

1. Determinecenterpointthroughwhichpipe

will penetrate roof.

2. Determine center point of roof. Pitch is

distance the roof drops over a given span,

usually 12". A 6/12 pitch means that roof

drops 6" for each 12" measured horizon-

tally down from roof rafters.

3. Useroofopeningchart(Figure14,page

10) to determine correct opening length

andashingrequired.

4. Removeshingles around openingmea-

sured.Cutoutthissection.

Existing

Ceiling

Frame

Figure 11 - Typical Offset Terminations

Return

Elbow

Offset

Elbow

Return

Elbow

Offset

Elbow

6'Max.

6'Max.

6'Max.

6'Max.

6'Max.

6'Max.

Return

Elbow

Offset

Elbow

Offset

Elbow

Return

Elbow

A B C

Offset

Elbow

Ceiling

SupportPipe

12S-12DM

Return

Elbow

www.fmiproducts.com 125655-01B10

VENTING INSTALLATION

Continued

Pitch Slope Opening

"A" Max.

Used Flashing

Model No.

Flat 0° 19.5" V6F-10DM

0-6/12 26.6° 22' V6F-10DM

6/12-12/12 45.0° 27" V12F-10DM

5. Add next sections of pipe until end

penetrates roof line. Check to see that

properclearancesaremaintained.Extend

chimney by adding sections of double wall

pipe until pipe is minimum of 30" above

highestpointofroofcutout.Termination

and chimney must extend a minimum of

36" above highest point where it passes

through roof.

19.5" Min. 30" Min.

2" Min.

2" Min.

2" Min.

Opening "A"

Figure 14 - Roof Opening Measurements

NailOnly

Outer

Perimeter

ofFlashing

StormCollar

Flashing

Cone

UnderlapShingles

at Bottom

Overlap

ShinglesTop

andSidesOnly

Figure 15 - Flashing Installation

FLASHING INSTALLATION (V6F-10DM

OR V12F-10DM)

Determine the ashing to be used with the

roofopening chart.Slide ashingover pipe

until base is at against roof. Replace as

many shingles as needed to cover exposed

areaandashingbase.Secureinpositionby

nailingthroughshingles(seeFigure15).DO

NOTNAILTHROUGHFLASHINGCONE.

Storm Collar Installation (SC2-1)

Placestormcollaroverpipeandslidedown

until it is snug against the open edge of the

ashing (see Figure 16).Apply waterproof

caulk around the perimeter of the collar to

provide a proper seal.

Figure 16 - Storm Collar

Chimney

Pipe

Waterproof

Caulk

Storm

Collar Flashing

Installing Flashing on a Metal Roof

Wheninstallingtheashingonametalroof,

it is required that putty tape be used between

theashingandtheroof.Theashingmustbe

secured to the roof using #8 x 3/4" screws and

then sealed with roof coating to prevent leak-

age through the screw holes. A roof coating

must also be applied around the perimeter of

theashingtoprovideaproperseal.

www.fmiproducts.com

125655-01B 11

VENTING INSTALLATION

Continued

10 FOOT RULE

Alluegasoutletchimneyterminationsmust

extend a minimum of 3 feet in height above

the highest point where it passes through

the roof and must be at least 2 feet above

the highest point of the roof that is within a

horizontaldistanceof10feet(seeFigure19).

FINISHING FIREPLACE

Combustible materials, such as wallboard,

gypsum board, sheet rock, drywall, plywood,

etc. may make direct contact with sides and top

aroundthereplaceface.Itisimportantthat

combustible materials do not overlap the face

itself. Brick, glass, tile or other noncombustible

materials may overlap the front face provided

they do not obstruct essential openings like

louvered slots or any other opening. When

overlapping with a noncombustible facing

material, use only noncombustible mortar or

adhesive.

24"Min.

24"Min.

18"

Min.

Typ.

Figure 18 - Multiple Chase Installation

10'

2'Min.

10'

3'Min.

2'Min. 3'Min.

Levelof

FlueGas

Outlet

Figure 19 - 18 Foot Rule

Terminations/Spark Arrestor

Thereplacesystemmustbeterminatedwith

thelistedroundtoporchaseterminations.In

any case, refer to the installation instructions

supplied with the termination.

CAUTION: Do not seal open-

ings on the rooftop ashing. Fol-

low the installation instructions

provided with the termination

being used.

RTL-12D

Levelof

FlueGas

Outlet

Stainless

InnerFlue

Pipe

Waterproof

Caulking

Storm

Collar

Flashing

Underlap

Shingles

Figure 17 - Termination

Overlap

Shingles(Top

andSidesof

FlashingBase)

CHASE INSTALLATIONS

Instructions for chase installations are

included with the chase style termination

chosen. In a multiple chase installation, be

sure to provide adequate distance between

terminations to prevent smoke spillage from

one termination to another. We suggest that

terminations be separated at least 24", center

to center and stacked at a vertical height dif-

ferenceof18"(seeFigure18).

Note: If a decorative shroud is to be installed,

contact the manufacturer for specications.

Secure

Termination

toOuter

Pipewith3

Screws

www.fmiproducts.com 125655-01B12

REFRACTORY PANEL INSTALLATION

IMPORTANT: Installation of brick

should be done after the re-

place is placed in a permanent

location.

1. Removegrate,screenassembliesandall

hardwarecomponentsoutoftherebox.

Thebottom panel ispre-installed in the

rebox.Makesurethebottomrefractory

panelsiscenteredinthereboxandush

withthefrontofthereplace.

2. Placecardboardontopofbottomrefrac-

tory panel as a protection to prevent ship-

ping and scratching during installation of

the other panels.

3. Position"Z"shapedgrateretainingbrack-

ets on top of the notched area toward the

rearofthebottomrefractory.Theyshould

be positioned a distance apart as shown

inFigure20.

4. Install rear refractory panel. This panel

hasatopandbottom.Todeterminewhich

is which, match up the pattern on the rear

panel with the left and right sides before

Figure 21 - Installing Refractory Panels

LEFT BRICK

PANEL

PANEL

RIGHT BRICK

REAR BRICK

PANEL

BOTTOM

BRICK PANEL

GRATE GRATE RETAINER

ASH PANEL

BRACKET (2x)

UPPER CORNER

BRACKET (2x)

Figure 20 - Installing Grate Retainers

installingtherearpanel.Makesurepanel

is center before continuing.

5. Installtherightandleftrefractorypanels

with the gas line knockouts orientated

down toward the bottom refractory. Align

the left and right panels with the rear panel

so the grout lines line up.

6. Install the upper corner brackets and

tightensetscrews(Figure21).

7. Installgratebyplacingrearlegsintoslots

inthegrateretainers(Figure21).

www.fmiproducts.com

125655-01B 13

WARNING: Risk of re! Re-

place grate with FMI PRODUCTS,

LLC grate only (see Parts, page

20). This grate has been de-

signed to keep the operation of

your replace safe and efcient.

INSTALLING SCREEN

1. Slideroundendofscreenrodintoringsat

top of screen. Attach one push-on nut to end

of rod before attaching last ring of screen.

2. Inserttheroundendscreenrodintohole

on the left and right side of smoke shelf

(Figure22).

REFRACTORY PANEL INSTALLATION

Continued

Gas line hook up should be done by your

supplieroraqualiedserviceperson.

Note: Before you proceed, make sure your

gas supply is turned off.

Useonlya1/2"blackironpipeandappropri-

atettings.

1. Removeknockoutindentationonrefrac-

toryorrebrickwalllocatedaboverefrac-

tory hearth oor. Knockout indentation

mustbermlytappedwithanysolidobject

such as a 1/2" dowel until it is released.

Removefragmentedportionsofrefractory

(seeFigure23).

2. Remove gas line cover plate located on

eithersideofreplaceandpulloutinsula-

tion from gas line conduit sleeve. Save

insulationforreuse.Replacescrews.

3. Runa1/2"blackirongaslineintoreplace

through the rear at gas line conduit sleeve (if

usingaraisedplatform,addheight).Provide

sufcientgaslineintoreplacechamberfor

ttingconnection(seeFigure24).

Note: Secure incoming gas line to wood

framing to provide rigidity for threaded end.

4. Repackinsulationaroundgaslineandinto

sleeveopening.Seal any gapsbetween

gas line and refractory knockout hole with

refractory cement or commercial furnace

cement,Installthegasapplianceorcap-off

gas line if desired.

Figure 23 - Gas Line Access

Side

Firebrick

Finished

Side

Brick with

Access

Hole

Outsideof

Fireplace

GasLine

Conduit

Insulation

Gas

Conduit

Cover

1/2"Dowel

Seal

Opening

with

Refractory

Cement

Outsideof

Fireplace

GasLine

Conduit

Repack

Insulation

Incoming

1/2" Black

IronPipe

Side

Firebrick

Finished

Side

ProvideEnough

Threaded

EndforFitting

Connection

Figure 24 - Gas Line Installation

Remove

Knockout

Rating

Plate

HoleforScreen

Rod

Leading

Bricks

Figure 22 - Installing Fireplace Screen

3. Mountatendofscreenrodwith#10x5/8"

to center of smoke shelf.

4. Installotherscreenrodinsamemanner.

OPTIONAL GAS LINE INSTALLATION

www.fmiproducts.com 125655-01B14

CAUTION: All gas piping

and connections must be tested

for leaks after the installation

is completed. After ensuring

that the gas valve is on, apply

soap and water solution to all

connections and joints. Bubbles

forming show a leak. Correct

all leaks at once. DO NOT USE

AN OPEN FLAME FOR LEAK

TESTING AND DO NOT OPER-

ATE ANY APPLIANCE IF A LEAK

IS DETECTED. LEAK TESTING

SHOULD BE DONE BY A QUALI-

FIED SERVICE PERSON.

WARNING: Do not operate an

unvented gas log set in this re-

place with the chimney removed.

A gas line or gas log lighter may be installed

for the purpose of installing a vented or vent-

free decorative gas appliance incorporating an

automatic shutoff device and complying with

theStandard for Decorative Gas Appliances for

Installation in Vented Fireplaces, ANSI Z21.60

or American Gas Association draft requirements

for Gas Fired Log Lighters for Wood Burning

Fireplaces, Draft NO. 4 dated August, 1993.

OPTIONAL GAS LINE INSTALLATION

Continued

If you install a decorative gas appliance

(vented gas log), the decorative gas appliance

must comply with the Standard for Decorative

Gas Appliance for Installation in Solid Fuel

Burning Fireplaces, ANS Z21.60 or Z21.84

and shall also be installed in accordance with

the National Fuel Gas Code, ANSI 7223NFPA

54 latest edition.

Ifyouwishtoinstallanunvented(vent-free)

gas log set, only unvented gas log sets which

have been found to comply with the standard

forunventedroomheaters,ANSIZ21.11.2are

tobeinstalledinthisreplace.

WARNING: If the replace

has been used for wood burning,

the rebox and chimney must be

cleaned of soot, creosote and

ashes be a qualied chimney

cleaner. Creosote will ignite if

heavily heated.

WARNING: When using a

decorative vented gas log, the

damper must be removed or

permanently locked in the fully

openposition andthe glassdoors

must be in the fully open position.

PUREFIRE HOOD INSTALLATION

1. ThePureFirehoodsuppliedwiththisre-

place is packaged in a separate box and

placedinthereboxduringshipping.

2. Removehoodfrombox.Locatebrackets

(quantity 2) and screws (quantity 4) for

hood installation in the hardware bag.

3. Usingscrewsprovided,securethebracket

totheinnerdomeofthereplaceasshown

inFigure25.Theleftandrightbracketare

different.Theedgethatisstraightwillbe

closertothereplaceopening.

4. Lifthoodupintothereplaceandplaceit

ontheretainingbrackets(Figure25).The

rear of the hood will touching the rear of

thereplace. Figure 25 - Installing PureFire Hood

www.fmiproducts.com

125655-01B 15

Figure 27 - Installing Bottom Door Frame

and Air Deectors

Bottom

DoorRail

Ash Box

Center

Brick

Air

Deector

Ring

Handle Screws

DOOR ADJUSTMENT

Removedoorsandslightlyloosenlowerpivot

clipsandupperspringclips.Replacedoors

and fully close them. Use 1/8" shims (any

material)toleveldoors.Oncepropersetting

is achieved, carefully open doors enough so

thatyoucanaccessspringclipswithaPhillips

screwdriver.Tightenscrews.SeeFigure29.

Figure 28 - Installing Bi-Fold Doors

Spring

Clip

InsertPin

intoSpring

Clip

Pivot

Hole

Insert

Bottom

PivotPin

intoHole

FoldDoor

andSlide

TopPins

IntoTrack

Figure 29 - Adjusting Bi-Fold Doors

INSTALLING GLASS DOORS

Spring clips have been installed but some

adjustmentsmaybeneeded.Ifdoorsdonot

close properly or do not appear straight, see

Door Adjustment.

1. With bi-fold doors completely folded,

insert bottom pivot pin into pivot hole

located near bottom corner of front face

opening and swing door to vertical posi-

tion making sure top pins slide into door

track.Doorisinstalledwhentopdoorpin

snaps into spring clip.

2. Repeatstep1forremainingdoor.

Ifyounddoorsdonotcloseproperlyordo

not appear level or straight, proceed with

section on door adjustment,

Spring

Clip

AIR DEFLECTOR AND GLASS DOOR INSTALLATION

IMPORTANT: Install glass door

frame before installing glass door.

INSTALLING DOOR FRAMES

1. Remove screws from smoke shelf (see

Figure26).

2. Mount top door frame and secure with

screws removed in step 1.

3. Removecenterashrefractorybypulling

ringhandle(seeFigure27).

4. Removeashbox.

5. Removethreescrewslocatedatfrontof

rebox(seeFigure27).

6. Align bottom rail mounting holes with

holesatfrontofreboxandsecurewith

screws removed in step 5.

7. Placeash boxinplace.Replacecenter

ash refractory.

Figure 26 - Installing Top Door Frame

TopDoorFrame

SmokeShelf

INSTALLING AIR DEFLECTORS (42''

MODELS ONLY)

Slideairdeectorinbetween thefrontside

face and side brick panel (see Figure 27).

The notched end of the deflector sits on

bottomhearth.Airdeectordoesnotrequire

any fastening.

Thefrontsidefacesandsidebrickpanelswill

holdthedeectorinplace(seeFigure27).

www.fmiproducts.com 125655-01B16

Figure 30 - Bi-Fold Glass Doors

DoorsFullyClosed

FireplaceFront

Doors

FullyOpened

FireplaceFront

OPERATION AND MAINTENANCE GUIDELINES

Figure 31 - Operating Damper Handle

Damper

Weight

ToClose

Damper

ToOpen

Damper

Damper

Weight

OUTSIDE AIR AND DAMPER

HANDLE OPERATION

Thedamperhandle,whichopensandcloses

the damper blade, is located in the upper front

faceofthereplace.Pushingthehandlefor-

ward and up through the keyway slot will free

damperbladetoautomaticallyopen.Pushing

the handle forward and down will lock damper

bladeclosed(seeFigure31).

GLASS DOORS

Glass doors are optional with the replace.

Whenreplaceisinoperation,doorsmustbe

fullyopenedorfullyclosedpositiononlyorare

hazardmaybecreated(seeFigure30).

Areplaceequippedwithglassdoorsoperates

muchdifferentlythanareplacewithanopen

front.Areplacewithglassdoorshasalimited

amount of air for combustion.

Excessiveheatwithinthereplacecanresultif

toolargeareisbuiltorifcombustionairgate

isnotcompletelyopen.Thefollowingtipsshould

be followed to assure that both the replace

and glass door retain their beauty and function

properly.Boththeuedamperandglassdoors

mustbefullyopenedbeforestartingre.Thiswill

providesufcientcombustionairandmaintain

safetemperaturesinrebox.

IMPORTANT: The glass must be allowedto

warmslowlyandevenly.Thetemperedglasswill

withstandagradualtemperatureriseto550°F,

whichismorethananormalrewillgenerate.

Suchmaterialsaspitch/waxladenlogs,verydry

mill end lumber and large amounts of paper or

cardboard boxes can create an excessively hot

reandshouldnotbeburnedinthisreplace.

Alwayskeeptherewellbackfromthedoors

andneverallowamestocontacttheglass.

WARNING: Fireplaces

equipped with glass doors

should be operated only with

doors fully opened or doors fully

closed. Doors, if left partly open,

may draw gas and ame out of

the replace opening creating

risks of both re and smoke.

Cleaning Glass

Cleanglasswithanycommercialglasscleaner

or soap and water. Do not use any abrasive

materialtocleanglass.Donotcleanglasswith

anycoolwaterifglassisstillhotfromthere

and smoke.

www.fmiproducts.com

125655-01B 17

PUREFIRE EMISSION CONTROL SYSTEM

This replace is equipped with a PureFire

Emission Control System. The Catalytic

Hoodsystemreducesparticulatesemissions

inawoodburningreplacetomeettheEPA

Wood-Burning Fireplace Program Phase 2

emission level.

TheEPAqualifyinglabel,shownonpage18,

willbeafxedtothecatalyst.Beforelighting

therstre,removeandmaintainthislabelin

a safe place if needed for permits or building

inspection.Priortobeginninginstallation,con-

tactyourlocalbuildingofcialtodeterminethe

needtoobtainapermit.Forproperoperation,

catalyst must be replace every 3 to 5 years.

FUELING GUIDELINES

Thereplacegratemustalwaysbesecured

totheretainingbracketsprovided.Theposi-

tion of the grate must be centered against the

backwalloftherebox.

Burn only dry, seasoned (cured) wood with

less than 20% moisture. Avoid the use of

treated, painted and laminated wood. Never

burngarbageorotherforeignmaterials.Do

notusearticiallogs,colorednewspaperor

petroleumbasedrestarters.Avoidwoodwith

high salt content. All of these materials may

contain compounds which can shorten the

life of the catalyst. Wet or unseasoned wood

may lower catalytic temperatures and result

ininefcientoperation.

Thecatalystisdesignedtofunctionatopti-

mumefciencywhenthereplaceisburning

clean, dry, cord wood as replace fuel.A

simple visual inspection of the chimney dur-

ing the wood burning process will determine

catalyst performance.

The fuel load should always be placed on

thebackofthegrate. Usecleandry wood,

seasoned cord wood is the best choice.

Never burn trash, plastics, gasoline, rubber,

industrialsolvents,ammableliquids,naptha,

household garbage, material treated with

petroleum products, leaves, paper products,

cardboard or salt driftwood.

RefertoyourFMIPRODUCTS,LLCHome-

owner's Guide includedwithyourreplacefor

properrebuildingtechniqueandashremoval

procedures.Thesefuelingguidelinesmustbe

followed in order to achieve maximum emis-

sionsperformancefromthePureFireSystem.

OPERATION

Theproperuseofawoodburningreplace

equipped with the catalyst will signicantly

reducetheemissionsthatitproduces.Simple

fuel considerations with regard to moisture

content, size, and quality of fuel will help

control the production of wood smoke and

improve the performance of the catalyst and

replace efciency. With proper care, the

catalyst will provide years of fuel savings

and lowered emissions. By following some

simple guidelines, you will ensure maximum

performance and longevity.

Thesmokethatisusually seencomingout

of a chimney is essentially a combination of

unburned fuel (carbon and hydrogen) and

moistureintheformofwatervapor.Thecata-

lyst is a technology that provides secondary

combustion for the wood burning process.

MAINTENANCE

ThePureFireSystemisamaintenancefree

technology.Donotattempttoremoveorclean

thecombustor.Thedirectamefromthere

will clean the combustor. Only a certified

technicianshouldremovetheunit.Toensure

properreplaceoperation,thePureFireSys-

tem should be replaced every 3 to 5 years

(see Parts on page 20).

NOTE:Chimneysmokemaybevisibleduring

therst8to10minutesofreplaceoperation

whenthereisrstgettingstartedandthe

nal8to10minutesofoperationwhilethere

isdissipating.Undernormaloperatingcondi-

tions, you should see little or no smoke coming

out of the chimney. If continuous smoke is

visible, make sure only dry seasoned wood

isbeingburned.Ifvisiblesmokecontinues,

the combustor has ceased to function or there

isthermalcrumbling.CallFMIPRODUCTS,

LLCat1-866-328-4537forreplacementparts.

www.fmiproducts.com 125655-01B18

PUREFIRE EMISSION CONTROL SYSTEM

Continued

WARRANTY

FMIPRODUCTS,LLCwarrantyobligations

for the PureFire Emissions Control System

are limited to the terms set forth below.

FMI PRODUCTS, LLC warrants to the

consumer who purchases a new solid fuel

burningreplacecontainingaPureFireEmis-

sionsControlSystemasanewcomponent,

to replace the catalyst at no charge should

it cease to function within three years from

thedateofpurchase.ThePureFireCatalytic

Componentisdesignedtoperformefciently

forthreeyearsofreplaceoperation.ONLY

recommendedfuelsshouldbeburned.Fol-

low the fueling directions in manufacturers

operation manual. For warranty purposes,

proof of fireplace purchases is required.

Labor for removal and/or installation of the

catalytic component is not the responsibility

of the manufacturer.

NeitherFMIPRODUCTS,LLCnorthedealer

who sells the PureFire Emissions Control

Systemisresponsibleforindirect,incidental,

special, punitive or consequential damages

arising out of the improper use of this product

or the continued use of this product beyond

the required replacement period.

MANUFACTURER: FMI Products, LLC

MODEL NO: GCAT50 & VGCAT50

PARTICLE EMISSIONS: 4.4 GRAMS/KG OF WOOD BURNED

FIREPLACE

SMOKE EMISSIONS RANGE

Higher Emissions

Lower Emissions

012.0

THIS MODEL

EPA PHASE 2 EMISSIONS LEVEL

4.4 5.1

Better Worse

U.S. Environmental Protection Agency

Wood-burning Fireplace Program

Phase 2 Qualified models are cleaner and pollute less than those models that

have not met this emissions level. Exposure to smoke has been associated with

respiratory illness and other health problems. Models that have lower smoke

emissions may reduce your risk.

PHASE 2 QUALIFIED

For more information go to www.epa.gov/burnwise

Fireplaces with lower emissions produce less smoke when installed and operated properly.

* EPA has determined, based on testing by an accredited independent laboratory and a certification

of conformity by a nationally recognized certification body, that this model qualifies at the Phase 2

emissions level for U.S. EPA's Voluntary Fireplace Program.

For proper operation, catalyst must be replaced every 3 to 5 years.

125574-02

MANUFACTURER: FMI Products, LLC

MODEL NO: GCAT42 & VGCAT42

PARTICLE EMISSIONS: 4.4 GRAMS/KG OF WOOD BURNED

FIREPLACE

SMOKE EMISSIONS RANGE

Higher Emissions

Lower Emissions

012.0

THIS MODEL

EPA PHASE 2 EMISSIONS LEVEL

4.4 5.1

Better Worse

U.S. Environmental Protection Agency

Wood-burning Fireplace Program

Phase 2 Qualified models are cleaner and pollute less than those models that

have not met this emissions level. Exposure to smoke has been associated with

respiratory illness and other health problems. Models that have lower smoke

emissions may reduce your risk.

PHASE 2 QUALIFIED

For more information go to www.epa.gov/burnwise

Fireplaces with lower emissions produce less smoke when installed and operated properly.

* EPA has determined, based on testing by an accredited independent laboratory and a certification

of conformity by a nationally recognized certification body, that this model qualifies at the Phase 2

emissions level for U.S. EPA's Voluntary Fireplace Program.

For proper operation, catalyst must be replaced every 3 to 5 years.

125574-07

www.fmiproducts.com

125655-01B 19

TECHNICAL SERVICE

You may have further questions about in-

stallation, operation, or troubleshooting.

If so, contact FMI PRODUCTS, LLC at

1-866-328-4537.

When calling please have your model and se-

rialnumbersofyourreplaceready.

Youcanalsovisitourwebsiteat

www.fmiproducts.com.

REPLACEMENT PARTS

If this product is missing a part or has a

broken component, please do not return it

to the store. Call FMI PRODUCTS, LLC at

1-866-328-4537 to answer questions and

replace parts under warranty.

Note: Use only original replacement parts.

This will protect your warranty coverage for

parts replaced under warranty.

When calling or writing, please have your

model and serial numbers of your replace

ready.

Modelandserialnumberinformationareinthe

replace'sratingplatelocatedonthereplace

smoke shelf.

www.fmiproducts.com 125655-01B20

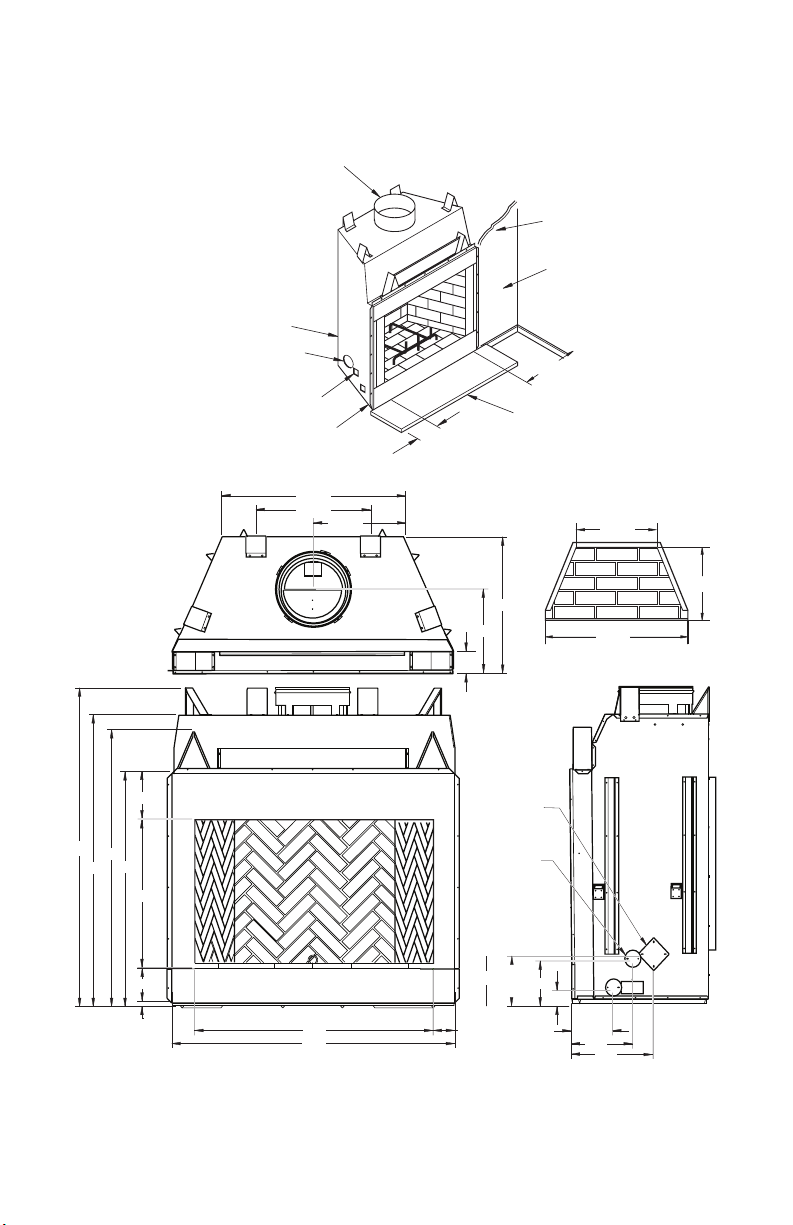

PARTS

MODELS (V)GCAT42/50(H)A SERIES AND (V)JCAT42/50(H,S) SERIES

1

21

20

5

6

7

10

9

11

12

13

16/17

15

14

8

24

23

3

25

18

2

22

19

4

26

27

28

29

30

This manual suits for next models

9

Table of contents

Popular Other manuals by other brands

NextBase

NextBase Click Lite Instructions for installation and use

Evenheat

Evenheat Studio Pro 24 operating instructions

Wilo

Wilo Control SC-Fire Electric Installation and operating instructions

Nokia

Nokia Xpress-on user guide

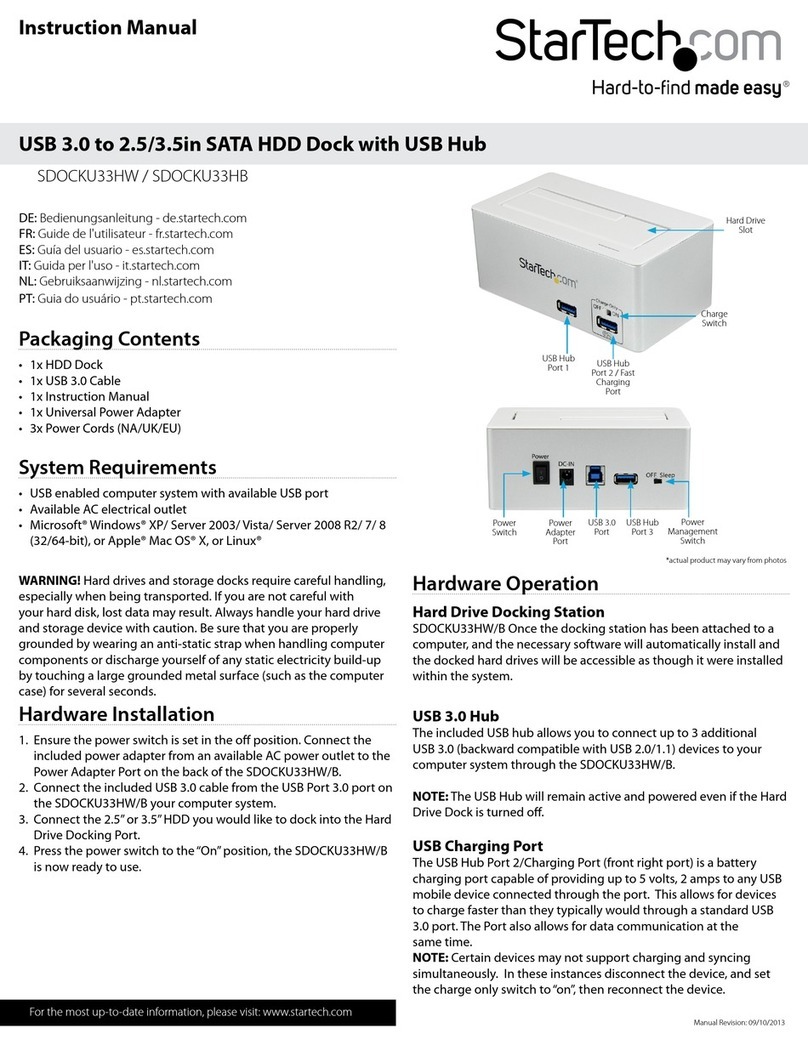

StarTech.com

StarTech.com SDOCKU33HB instruction manual

BT

BT BT-CSIM-T user guide