FoamFly FAT P-47 User manual

TM

c^q mJQT

Instruction Manual

Electric Foam Slowflyer with “Fat and Flat©” construction.

Designed By: Dan Schwartz

Available Exclusively from:

www.FoamFly.com

4077 WoodCreek Dr.

Ypsilanti MI. 48197

USA

© 2006 FoamFly.com

!

©2006 FoamFly.com 2

Thank You for purchasing the Fat P-47! Welcome to the world of

simple, durable foam flying machines. The Fat P-47 is sure to thrill, with its sleek

styling, and old-timer flair. This plane is suitable for beginners, but it is

recommended that new pilots get the help of an instructor to trim their plane, and

help with the first flights.

Almost anybody can fly the Fat P-47. It’s as easy to build, and more

durable than pre-fab planes that you might find at the hobby shop. But you build

this yourself. In addition to the well-earned pride, you’ll have a complete

understanding of the structure, and if it should ever need repair, you’ll be able to

do it yourself without costly replacement parts.

The “Fat and Flat©” Construction makes the plane quick and easy to

assemble. All the pieces are specially designed to interlock, and are computer

cut so that they fit perfectly every time.

Fat P-47 Specs:

•Wingspan: 30”

•Ready To Fly Weight 7-9 Oz.

•Motor: GWS EPS-300c (or CD-Rom, or Brushless)

•Propeller: 7”-9” (9x7 Recommended)

•Batteries: 2-cell 1200mAh Lithium Polymer, or 7 cell

450mAh NiMHs. Basically any 1.5 – 2.5 Oz

battery.

•Receiver: GWS R4P (4 Channel)

•Servos: GWS Pico BB (or Hitec HS-50)

•ESC: GWS ICS-300 (15-Amp Speed Control for

brushed setups)

Introduction:

FoamFly.com is more than just a hobby company. It’s a community too!

With pilots and designers from all over. Please take pictures of your P-47, and I’ll

put them in the photo gallery. Feel free to drop by and see what all the other

foam junkies have been building. There are free plans, and lots of tips and ideas

as well as unique new planes that you won’t find anywhere else.

NEW!! FoamFly kits are now easier to assemble. New techniques make all the

most tedious steps unnecessary.

Okay, you’ve got your P-47 kit in front of you, and you’re ready to cruise the

skies. Only problem: the plane is lying in pieces in front of you. Well we can

take care of that too. There are some techniques you’ll need to be familiar with

to make the most of your kit. I’ll refer to them as they’re needed, but the details

of those techniques will be in the Appendix at the end of this manual.

Let’s begin. Don’t let all the text in this manual scare you. Take each

step one at time, and you’ll find that everything is within your capabilities. Here

we go.

3

Identify all the parts:

You’ll need to know which part is which, unless you want to end up with the

flying equivalent of Frankenstein’s Monster. So, let’s start by taking a look at

what you’ve got here.

a) Foam Airplane Parts:

(1) Fuselage halves (Left and Right)

(2) Fuselage Center

(3) Horizontal Stabilizer

(4) Elevator

(5) Rudder

(6) Wings (2)

(7) Wing Support Ribs (6)

And of course even a foam plane needs a few odds and ends to tie

everything together. Take a few moments to inspect what you’ve got here.

As the items are called for you’ll get more info on their intended uses.

b) Non-Foam Parts:

i) Plastic Control Horns (Included)

ii) .032 Wire for Pushrods

iii) Wood for Motor Mounting (Depends on which motor type)

Let’s Begin:

1) Note: It is much easier to decorate the pieces BEFORE assembling them,

so think about your color scheme now. Also, if you’re thinking of adding

landing gear, it will be much simpler to do it during the assembly process

than afterwards. (See Appendix Section, “Landing Gear”)

©2006 FoamFly.com 4

2) Fuselage:

a) Lets start with the main

piece. It’s made up of 3

pieces. Now’s the time

to color in the windows.

Again, if you’re installing

landing gear, or want to

tuck the radio gear inside

the fuse, do it now. Don’t

attempt to line up the wing slots, they are deliberately offset. Line up

the outer edges instead. Glue the 3 layers together, contact cement is

preferred.

b) Motor Cutout:

i) This will vary greatly depending on what type of motor you’re

planning to use. But the two most basic types are geared motors

(brushless or not) and outrunners (always brushless).

ii) You may need to modify the mounting setup depending on your

setup, but templates for the most common mounts are included in

the appendix. Look everything over before cutting to ensure that

your motor will fit.

iii) Line up the motor mount template with the fuselage (A little

gluestick helps hold it in place while you’re working.) Cut the foam

along the marked line.

iv) For outrunner motors, you might also need to make a support for

the motor mount. If so, cut 4 small triangles from the scrap foam

and glue them in place alongside the motor cutout. Usually a circle

of plywood, or a couple of popsicle sticks makes a good mount.

Then mount your motor with a few tiny woodscrews.

v) The geared motors most often mount on a stick. 10mm square is

the usual size, but 3/8” will work just as well. The geared motor

template includes the outline for positioning just such a stick.

3) Wings:

a) Form the airfoil:

i) Make sure you end up with BOTH LEFT and RIGHT WINGS!!!

This is EXTREMELY important. The wing pieces are essentially

identical until you form the airfoil into them. So watch out, a plane

with two left wings doesn’t fly too well.

5

ii) Roll the wings into shape: (See the Appendix Section, “Rolling the

Foam”)

b) After the wing panels are formed, test fit the pieces. The airfoil should

be a good fit in the slot on the fuselage pod without forcing it. You can

bend the leading edge with finger and thumb if necessary.

c) Run strapping tape (the kind with the strings in it) along the leading and

trailing edge of the wing on the bottom.

4) Assembly:

a) Tape hinge the elevator in the center of the horizontal stabilizer, then

tape the rudder in place on the fuselage.

©2006 FoamFly.com 6

b) Put the horizontal stabilizer into the slot in the tail. Hot Glue Weld the

horizontal stabilizer into place. (See Appendix Section, “Hot Glue

Welding”)

c) Fit the wings into the fuselage. Put one wing into the slot until it is

halfway through. Get it positioned right, and hot glue weld it in place.

d) Get ready. Squeeze some hot glue into the wing slot from the other

side, and then put the opposite wing in place quickly. Align the two

wings to be even, and with the correct dihedral as shown, then Weld

them in place along the seam where they meet the fuse.

e) Install the servos.

i) Position the servos where they will have the easiest path to the

receiver and control surfaces. Cut a hole through the plane, insert

the servo and wire, and use the hot glue gun to “rivet” them in

place.

7

f) Glue the Control Horns into the Surfaces.

i) The Rudder Control Horn goes on the side of the rudders angled so

that it will point at the servo location.

ii) The Elevator Control Horn goes on the underside of the Elevator,

on the same side as the rudder horn. Make small cuts with your X-

Acto knife where the control horns will line up with the pushrods,

and press fit the control horns in place. Make sure the holes are

lined up directly over the hinge line, and hot glue weld them in

place.

iii) Run the pushrods as straight as you can. A small piece of tubing

(Like a cocktail straw) works great as a support.

g) Mount the motor on the stick.

h)

©2006 FoamFly.com 8

i) Mount the receiver and speed control under one wing.

ii) Mount the battery to one side of the fuselage with Velcro. Position

battery as necessary for best balance. The CG of the Fat P-47 is

about 1.75” back from the leading edge of the wing.

i) You can decorate the plane with either foam safe paint, or my favorite,

Sharpie markers. Get creative. I’m sure you can find pictures online of

the markings on your favorite warbird.

You’re Done!

You’re still reading? Go fly already. ;)

P.S. This manual was completed at 1:18am, so if it doesn’t make sense, email

9

APPENDIX:

The Tools: (and things you’ll need)

1) Knives: a Razor knife, and an X-Acto would both be useful.

2) Glue: UHU Creativ` contact cement, or White glue, or Epoxy. AND, you’ll

definitely want a hot glue gun and glue sticks.

3) Tape: You’ll want 2” wide clear packing tape, or some “crystal clear” Scotch

Tape if you can find it.

4) Pliers: Something suitable for wire bending.

5) .032 wire for pushrods

6) .047 wire to connect the rudders.

7) .055” wire & 1/32” plywood for landing gear (optional)

The Techniques: You’ll probably want to practice these on a piece of the scrap

foam.

1) Gluing:

a) Contact Cement:

The contact cement will test your patience. I know you’ll be

tempted to stick the pieces together immediately, but don’t give in. The

UHU Creativ’ will form the strongest bond, if you allow it to dry for AT

LEAST 5 minutes before putting the pieces together, and probably

much longer. Put the glue on BOTH surfaces to be joined. If you’re not

used to contact cement, remember you really only get ONE CHANCE at

putting the pieces together. It really is instant gluing! (except for the

waiting, but that’s already over at that point.)

The UHU Creativ’ has a long working time. After application, the

glue can sit for half an hour and still make a full-strength bond. If you

plan ahead a little, you can apply the glue to all the fuselage surfaces in

the order that you’ll be assembling them, and the first ones will be ready

to press together by the time that you’re done applying glue to the last.

Then proceed in order, for an exceptionally quick build.

b) Hot Glue Welding:

Although the hot glue gun can be used to attach flat sections, it

dries too quickly to give you much time. The glue gun works best when

the parts are already assembled, and you simply need to make the fit

permanent.

Rather than continually pulling back the gun, leaving a glob of glue

behind, move the gun forward, keeping just enough glue flowing that the

tip slides easily, and leaves a seam of glue pressed deep into the corner

of the joint. This takes a little practice, but leaves an unobtrusive glue

joint that is incredibly strong. Quick and easy too!

2) “Rolling the Foam”

a) You’ll be bending the foam to form the airfoil for the wings. Find

yourself a section of 2” PVC pipe, (Or a Baseball Bat, Rolling Pin,

Kitchen Counter, Bathtub edge, etc…) and press the wings firmly and

evenly down onto it to form the airfoil shape. It doesn’t take too much

pressure. The airfoil curves more sharply right near the leading edge,

so you can use smaller diameter pipe (or a Broom handle etc.) to add a

little more curvature there if you feel it’s necessary. It’s also acceptable

to just use your thumb, and the side of your index finger to work the

leading edge bend a little.

©2006 FoamFly.com 10

3) “Landing Gear” or So that’s what the ribs are for!

a) Bend landing gear supports with an extra loop on top. Tie the loop to a

piece of 1/32” plywood with thread or dental floss, then glue everything

in place.

b) Glue the plywood/gear combo in between the layers of foam ribs. The

plywood helps distribute the force of the wire, and keep the gear in

place. Then, contact cement the ribs in place, and hot glue weld around

them.

c) The P-47 should have two large wheels, one under each wing just

under the leading edge, and a small one in the tail.

4) Motor Mount Templates:

StickMotor Mount

Cut out

Glue 3/8” wood

as shown.

11

Outrunner Motor Mount

Cut out

use cutout foam

to make “gussets”

for outrunner style

motor mount.

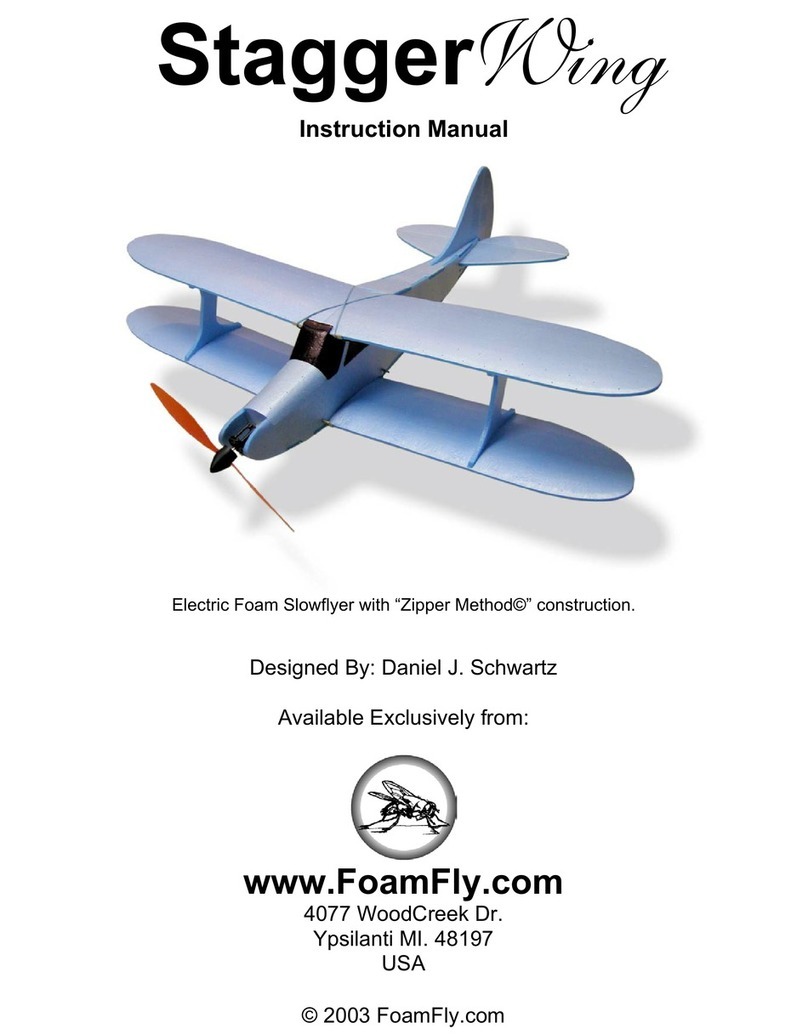

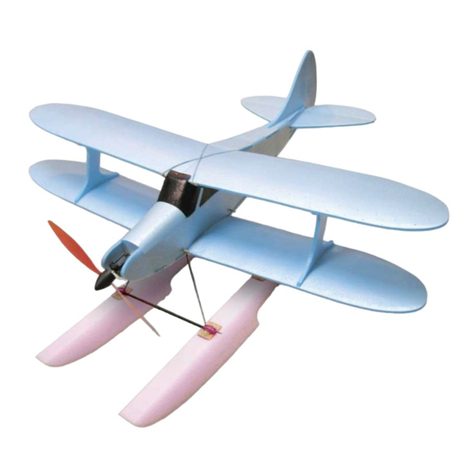

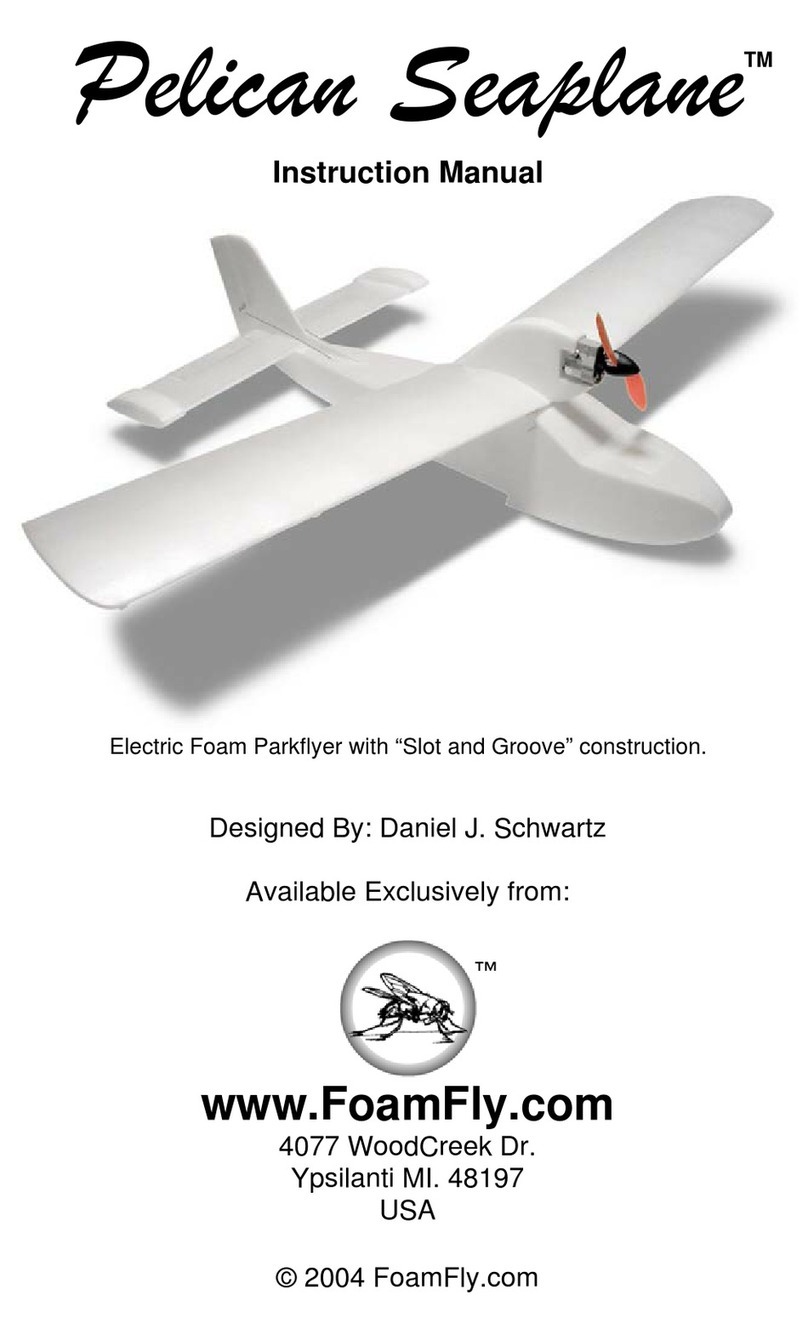

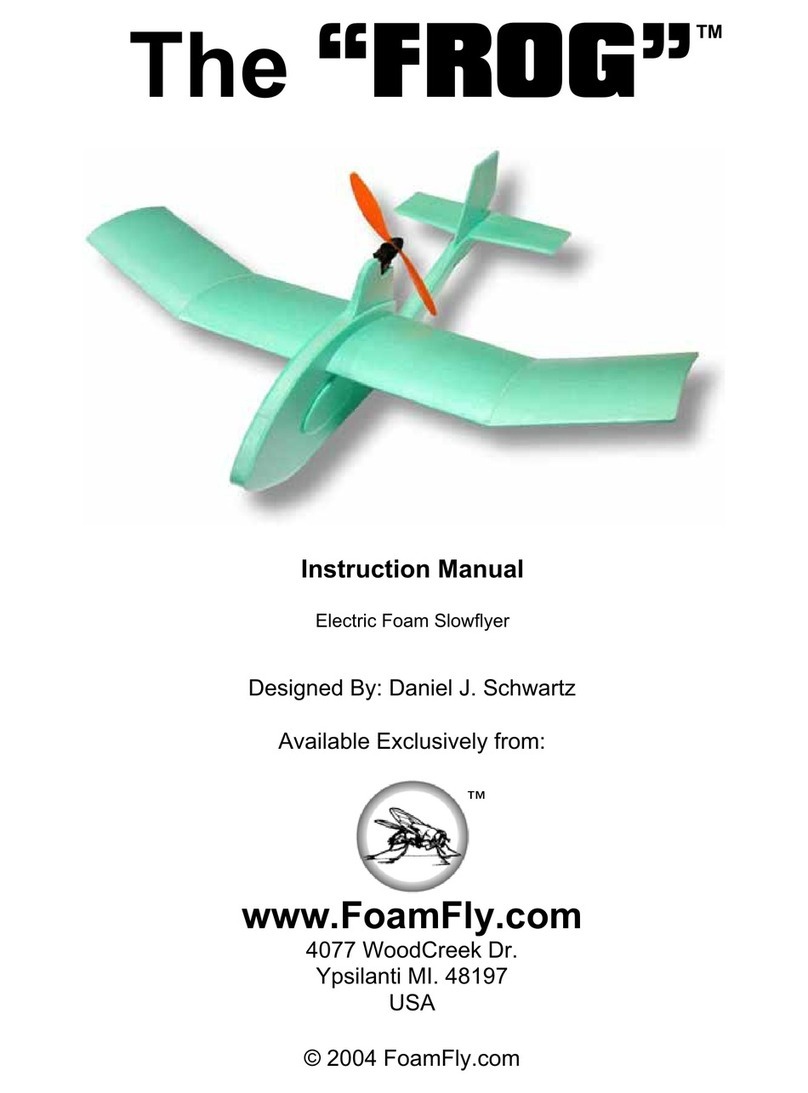

Other FoamFly Toy manuals