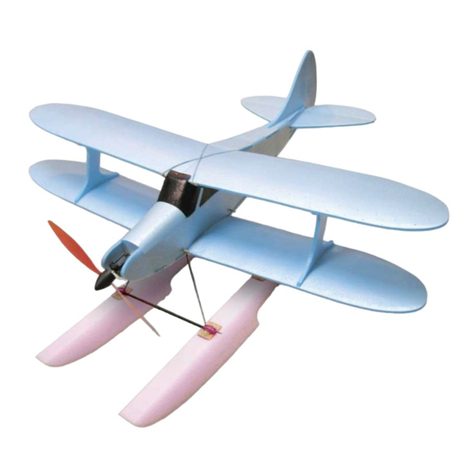

FoamFly Insta-Plane B-25 User manual

TM

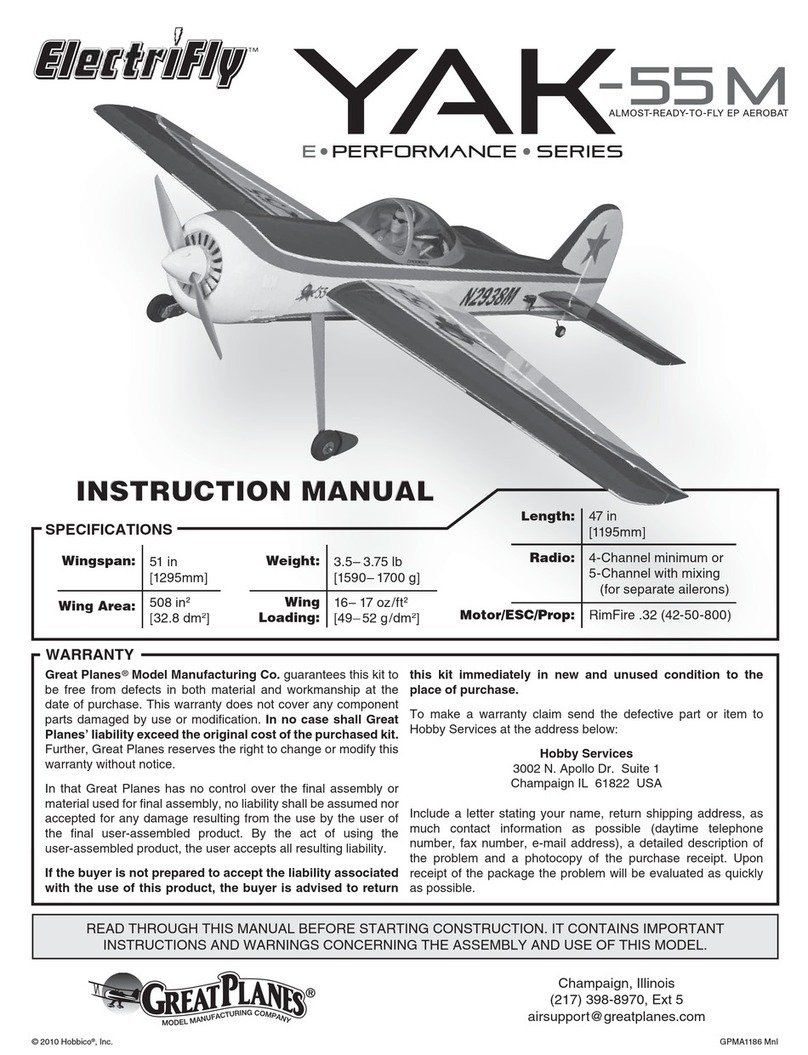

“Insta-Plane”

B-25

Heavy Twins Series

Instruction Manual

Electric Foam Parkflyer

Designed By: Daniel J. Schwartz

Available Exclusively from:

www.FoamFly.com

4077 WoodCreek Dr.

Ypsilanti MI. 48197

USA

© 2005 FoamFly.com

1

Thank You for purchasing a FoamFly Insta-Plane! Welcome to the world of

simple, durable foam flying machines. The Insta-Plane is sure to thrill, with its profile

styling, and amazing performance. This plane is not recommended for complete

beginners, but it isn’t something to be afraid of either. It’s as easy to build, and more

durable than pre-fab planes that you might find at the hobby shop.

The Insta-Plane Construction makes the plane quick and easy to assemble. All

the pieces are specially pre-cut with only a few jobs left for you to do. You can literally

have this plane up and flying in under an hour. Experience helps, and I recommend

reading these instructions thoroughly before beginning.

Insta-Plane “Heavy Twin” Specs:

•Ready To Fly Weight 5 Oz.

•Motors: EDP-50 x 2

•Propeller: 3x3 or 3x2

•Batteries: 450mAh 2-cell Lithium

•Receiver: GWS R4P (4 Channel)

•Servos: GWS Pico

•ESC: GWS ICS-100 (5-Amp Speed Control)

Introduction:

FoamFly.com is more than just a hobby company. It’s a community too! Please

take pictures of your plane, and upload them to the photo gallery. Feel free to drop by and

see what all the other foam junkies have been building. There are free plans, and lot’s of

tips and ideas as well as unique new planes that you won’t find anywhere else.

Okay, you’ve got your kit in front of you, and you’re ready to cruise the skies. Only

problem: the plane is lying in pieces in front of you. Well we can take care of that too.

There are some techniques you’ll need to be familiar with to make the most of your kit. I’ll

refer to them as they’re needed, but the details of those techniques will be in the Appendix

at the end of this manual.

The Insta-Planes are so easy to assemble that one instruction manual suits them

all. There are a few variations, but I’ll try to cover all of them. Any items unique to your

plane will be mentioned on the exploded view on the following pages.

1) Identify all the parts:

You’ll need to know which part is which, unless you want to end up with the flying

equivalent of Frankenstein’s Monster. So, let’s start by taking a look at what you’ve

got here.

a) Foam Airplane Parts:

(1) Fuselage Sections (Center, 2-sides & Servo cover)

(2) Wings

(3) Ailerons

(4) Elevator

(5) Vertical Stabilizers (Some models)

(6) Motor Nacelles or Fuselage booms

b) Laser Cut Control Horn

c) DuBro E/Z Connectors

d) .032” wire & plastic tubing

2) Fuselage:

a) All the Insta-Plane fuselages go together the same way. The three layers

sandwich together to form a strong hollow structure. I like to glue these parts

with contact cement (See the Appendix section, “Gluing”) but a variety of other

glues fit the bill here as well.

b) Things to consider:

©2005 FoamFly.com 2

i) If you plan ahead it’s possible to build the ESC and the Y-connectors into

the hollow space in the fuselage. But, if that seems like too much work,

you’ll be able to bundle the wires and tuck them under the plane later.

ii) Before you glue the sections together, now is the perfect time to color in

the windows on the center section.

3) Wing:

a) Figure out which side will be the top of the wings. The wings have grooves cut

into them where the aileron torque rods will go. Those grooves go on the

BOTTOM of the wings.

b) Roll the wings into shape: Now that you know which side is up for your wings, roll

the airfoil shape into them. (See the Appendix Section, “Rolling the Foam”)

c) The Insta-Planes are either High-Wing, Low-Wing, or Shoulder Wing. So,

depending on which model you have, either fit the wing onto the matching

notches in the fuselage, or slide it through the slot in the main fuselage.

d) Attach the nacelles or tail booms. There are two types:

i) Slide in parts are easy. Just push the nacelle over the wing until it meets up

with the notches cut into the wing. This will help you to line it up straight.

ii) Snap on nacelles are only slightly more complicated. Using a knife, split the

closed section at the back of the nacelle if necessary for your model. Then

gently slide the nacelle straight back from the leading edge of the wing until

the tabs snap into the slot in the wing.

e) Tape hinge the ailerons into place in the slots in the wing.

4) Tails:

a) In general it’s easier to tape hinge the moving half of the elevator to the

nonmoving half before installing the whole elevator into the plane. However, in

some cases, this must be done after. Check the exploded view for specifics.

b) Vertical Tails, if separate fit over the tabs at the end of the elevator, and will be

glued into place.

5) Glue it up:

a) Parts that fit flat against each other are best glued with contact cement, but other

glues will work also. Parts that slot together and other seams are most easily

glued with a hot glue gun. (See Appendix section, “Hot Glue Welding”)

6) Motors:

a) Put the propellers on the motor shafts before installing the motors into the plane.

b) The motors should be a snug fit into the slots in the nacelles. Line the motors up

with the wires pointing inwards.

c) Two tips:

i) Align the motors so that the propellers can stop evenly while horizontal.

This will help keep them off the ground.

3

©2005 FoamFly.com 4

5

ii) Consider pointing the motors ever so slightly to the right to help counteract

propeller torque.

d) Weld the motors in place with hot glue where they meet the foam.

7) Radio Gear:

a) The Servo bays are pre-cut to be a perfect fit for GWS Pico Servos, but you

should be able to make modifications to fit servos in the same size range.

b) Plug the servos into the receiver, and power it up. Make sure that the sticks, and

the trims are centered. Put the two-arm servo arms onto the servos pointing

straight out the sides.

c) Slide the servo wires through the slots in the fuselage sides, and set the servos

into the bays.

d) Glue the cover into place, being careful not to get any glue on the servos

themselves.

e) The GWS Pico 4ch receiver is a perfect fit in the fuselage.

f) Plug everything in, making sure the servo plugs face the right way

8) Controls:

a) Put the DuBro E/Z connectors into the servo arms. Two on the forward servo

facing the wing, and one on the rearward servo facing the other way. This way

the pushrods for the ailerons and elevator won’t interfere with each other.

b) Elevator:

i) Make a slit in the bottom of the elevator, and fit the plastic control horn into

place, so that the hole is lined up over the hinge line. Hot Glue Weld the

control horn in place.

ii) Fit the Z-Bend end of a piece of wire into the control horn, and slide the

other end through the E/Z Connector. If necessary, glue a small piece of

tubing in the middle of the fuse to support the wire.

c) Aileron Torque Rods:

i) This is probably the single most important control setup on the plane. When

your ailerons are finished, you want to have more up throw than down. To

accomplish this you’ll need to lean the arm of the torque rods in the direction

that you want more travel.

ii) Bend a small loop in the end of a piece of wire, then make a 90 degree

bend about 5/8” down from the loop.

iii) Slide two 3/4” lengths of plastic tube onto the wire, near the bend. Make a

second bend at right angles to the first one far enough down the wire so that

it reaches the aileron.

iv) Make a second torque rod that is the mirror image of the first.

©2005 FoamFly.com 6

v) Test fit the torque rods into the grooves in the bottom of the wing, and cut a

slot into the bottom of the aileron where it lines up with the rod. Use another

short piece of tubing in that slot, and hot glue weld all the tubes into place

when the ailerons work smoothly.

vi) Fit the Z-Bend end of a short piece of wire into each of the loops on the

torque rods, and the other end through the E/Z Connectors on the servo

arms. If they’re a loose fit in the loops, you can use some plastic tube (or

wire insulation) to tighten it up.

d) Finishing Touches:

i) Make sure everything is

plugged in, and check to see

that the controls move

smoothly, with even throws.

ii) You can attach the battery with

Velcro or tape as required to

balance properly.

iii) Tie up and tape down any

loose wires. The ESC, the

antenna, etc…

9) Fly it:

a) Double check the CG, and that the controls actually move in the right directions.

b) Center all the controls, and give the plane a gentle push at about 3/4 throttle.

c) Get the plane trimmed for level flight, and…Have Fun!

d) Collect them all. ;)

7

APPENDIX:

The Tools: (and things you’ll need)

1) Pliers: Something suitable for wire bending.

2) Knives: a Razor knife, and an X-Acto would both be useful.

3) .032” wire for pushrods and possibly landing gear

4) Glue: UHU Creativ’ contact cement, Hot Glue Gun, or Foam-Safe CA, or Elmer’s

White glue, or RC-56 type white glue, or Epoxy. You’ll probably want a couple of

these for good measure.

5) Tape: You’ll want some “crystal clear” Scotch Tape if you can find it. If not, you can

cut down packing tape.

The Techniques: You’ll probably want to practice these on a piece of the scrap foam.

1) Gluing:

a) Contact Cement:

The contact cement will test your patience. I know you’ll be tempted to stick

the pieces together immediately, but don’t be give in. The UHU Creativ’ will form

the strongest bond, if you allow it to dry for about 5 MINUTES before putting the

pieces together, and probably much longer. Put the glue on BOTH surfaces to

be joined. If you’re not used to contact cement, remember you really only get

ONE CHANCE at putting the pieces together. It really is instant gluing! (except

for the waiting, but that’s already over at that point)

The UHU Creativ’ has a long working time. After application, the glue can

sit for nearly half an hour and still make a full-strength bond. If you plan ahead a

little, you can apply the glue to all the fuselage surfaces in the order that you’ll be

assembling them, and the first ones will be ready to press together by the time

that you’re done applying glue to the last. Then proceed in order, for an

exceptionally quick build.

b) Hot Glue Welding:

Although the hot glue gun can be used to attach flat sections, it dries too

quickly to give you much time. The glue gun works best when the parts are

already assembled, and you simply need to make the fit permanent.

Rather than continually pulling back the gun, leaving a globe of glue behind,

move the gun forward, keeping just enough glue flowing that the tip slides easily,

and leaves a seam of glue pressed deep into the corner of the joint. This takes a

little practice, but leaves an unobtrusive glue joint that is incredibly strong. Quick

and easy too!

2) “Rolling the Foam”

a) You’ll be bending the foam to form the airfoil for the wings. Find yourself a

section of 2” PVC pipe, (Or a Baseball Bat, Rolling Pin, Kitchen Counter, Bathtub

edge, etc…) and press the wings firmly and evenly down onto it to form the airfoil

shape. It doesn’t take too much pressure. The airfoil curves more sharply right

near the leading edge, so you can use smaller diameter pipe (or a Broom handle

etc.) to add a little more curvature there if you feel it’s necessary. It’s also

acceptable to just use your thumb, and the side of your index finger to work the

leading edge bend a little.

Other FoamFly Toy manuals

Popular Toy manuals by other brands

Krick

Krick Lisa M. Building instructions

Phoenix Model

Phoenix Model MXS instruction manual

Eduard

Eduard Weekend Edition I-16 TYPE 10 Assembly instructions

LaserPegs

LaserPegs Strike Eagle G1670B Cargo Plane instruction manual

SAB Heli Division

SAB Heli Division GOBLIN 420 RAW manual

Fisher-Price

Fisher-Price M9974 instructions