FoamFly The "Frog" User manual

TM

The coldÒ

Instruction Manual

Electric Foam Slowflyer

Designed By: Daniel J. Schwartz

Available Exclusively from:

www.FoamFly.com

4077 WoodCreek Dr.

Ypsilanti MI. 48197

USA

© 2004 FoamFly.com

©2004 FoamFly.com 2

Thank You for purchasing the FoamFly Frog Kit! Welcome to the

world of simple, durable foam flying machines. The Frog is sure to thrill, with it’s

unique style and simplicity. This plane is suitable for beginners, but it is

recommended that new pilots get the help of an instructor to trim their plane, and

help with the first flights.

Almost anybody can fly the Frog. It’s as easy to build, and more

durable than pre-fab planes that you might find at the hobby shop. But you build

this yourself. In addition to the well earned pride, you’ll have a complete

understanding of the structure, and if it should ever need repair, you’ll be able to

do it yourself without costly replacement parts.

The simple construction makes the plane quick and easy to assemble.

All the pieces are computer cut so that they fit perfectly every time.

Frog Specs & Recommended Equipment:

•WingSpan: 34”

•Length: 29”

•Wing Area: 238 Square Inches (1.65 Sq. Ft.)

•Ready To Fly Weight 7-9 Oz.

•Motor: GWS IPS-A (5.86:1 Gear Ratio)

•Propeller: 9x7, or 10x4.7 (9x7 Recommended)

•Batteries: 1200mAh 2-cell E-tec Lithium Polymer, or 7

cell 300mAh NiMHs. Basically any 2 Oz

battery.

•Receiver: GWS R4P (4 Channel)

•Servos: GWS Pico BB (or Hitec HS-50)

•ESC: GWS ICS-50 (2-Amp Speed Control)

3

Introduction:

FoamFly.com is more than just a hobby company. It’s a community too!

Please take pictures of your Frog, and upload them to the photo gallery. Feel

free to drop by and see what all the other foam junkies have been building.

There are free plans, and lot’s of tips and ideas as well as unique new planes

that you won’t find anywhere else.

Okay, you’ve got your Frog kit in front of you, and you’re ready to cruise the

skies. Only problem: the plane is lying in pieces in front of you. Well we can

take care of that too. There’s some techniques you’ll need to be familiar with to

make the most of your kit. I’ll refer to them as they’re needed, but the details of

those techniques will be in the Appendix at the end of this manual.

Let’s begin. Don’t let all the text in this manual scare you. Take each

step taken one at time, and you’ll find that everything is within your capabilities.

Here we go.

1) Identify all the parts:

You’ll need to know which part is which, unless you want to end up with the

flying equivalent of Frankenstein’s Monster. So, let’s start by taking a look at

what you’ve got here.

a) Foam Airplane Parts:

(1) Fuselage halves (Left and Right)

(2) Elevator

(3) Wing Center

(4) Wing Tips (Left and Right)

(5) Thin Strip for fuselage

(a) Fuselage Top

(b) Fuselage Bottom

(c) Battery Support

(d) Battery Door

Small Parts Sheet:

(6) Motor Pylon halves (Left and Right)

(7) Motor Pylon centers (Top and Bottom)

(8) Canopy Covers (2)

(9) Canopy Centers (2)

(10) Rudder

(11) Wing Ribs (2)

Foam Tools: Dihedral Jig

Even a foam plane needs a few odds and ends to tie everything together. As

the items are called for you’ll get more info on their intended uses.

b) Non-Foam Parts:

i) Laser Cut Control Horns (2)

ii) Motor Mount

You’ll need a few miscellaneous things too. See the appendix for a list.

©2004 FoamFly.com 4

2) Cut out the small parts

You’ll notice that some of the parts are attached together on the “small parts

sheet.” Before you can use any of these you’ll need to cut them free. Using

your razor knife, slice through the tabs and free the parts.

3) Tails:

It’s time to prepare the working surfaces of the Frog. The tails give the plane

it’s directional stability, and let you do the steering.

a) Rudder:

i) Flip Rudder “Right” side up

ii) Locate the hinge line

5

You’ll notice two small dimples in the top and bottom edges of the

rudder. If you line up your ruler with the two dimples You’ll have found

the line you need to cut. (Drawn in for clarity here.)

I prefer to use an, “integral skin hinge” for the rudder, but if you feel the

need, you can always cut the rudder off, and tape hinge it back in place.

i) Integral Skin Hinge:

(1) Cut hinge line 80% through.

(2) Fold Rudder back 180˚

(3) Bevel the moving part with Knife or Sanding Block

Be careful not to peel or cut the skin during this step. (See the

Appendix section, “Tapers and Angled cuts”)

b) Repeat this process for the elevator

c) Fit the rudder and elevator

together aligning their

respective slots. Make sure

the pieces are straight and

perpendicular. After you’ve

checked the fit you can glue

them together (See the

Appendix section, “Glue”)

©2004 FoamFly.com 6

4) Fuselage

After you’ve figured out which sides of the fuselage parts will be on the

inside of the plane, you need to peel the skin off the inside faces of the

fuselage halves. (See the Appendix section, “Cut & Peel”)

a) Attach the control surfaces

to the right half of the

fuselage. Glue the pieces

together using the slot in

the fuse, and the tab on the

rudder to get the pieces to

go on straight.

b) The Motor Pylon

i) Peel the skin off the insides of the left and right halves of the motor

pylon, and from both sides of the pylon center pieces.

ii) Align the top piece with the top edge of the Pylon, insert the motor

mount into the slot, and press the three pieces together until they fit

flush. (You may have to scrape the foam a bit with the motor

mount to make a suitable groove. Set the Motor mount aside.

iii) Here’s your chance to actually spray the glue. Lightly spray the

insides of both halves, and both sides of the center pieces. When

the glue is ready, carefully align the foam pieces and press them

firmly together.

iv) Carefully narrow one end of the motor mount until it fits tightly all

the way into the hole in the back of the gearbox. Use a little Epoxy,

7

or Polyurethane Glue, or Foam safe CA, to attach the motor mount

into its slot in the pylon.

c) The Fuselage top and bottom:

i) Find the shorter tapered strip of foam. Give it a bend to align it with

the curve in the top part of the fuselage tail. It can help to draw it

over the edge of a table to get a smoother bend.

ii) Paint on the glue, and glue that striop of the top half of the back of

the fuselage. Start at the tail, and work forward slowly aligning the

strip with the edge of the fuselage, bending it around the corner,

and going straight up the back. Trim off any excess with your

razor.

iii) Using the longer tapered strip of foam, glue from the tail forward

working your way around the bottom edge until a 1/2 inch past the

point of the nose. Cut off any excess.

iv) Find the 5” strip of foam. Cut off a piece large enough to support

your battery pack, and glue it in place leaving a little room at the top

for the battery wires to reach around.

©2004 FoamFly.com 8

v) Using the 7” strip of foam glue it in place just below the wing slot to

reinforce the fuselage.

vi) Glue the Pylon to the half of the fuselage that you’ve already

started. It has a slot that should fit right onto the strip a t the back

of the fuselage. Align the bottom edge of the Pylon with the top of

the wing slot. Make sure that the motor mount is parallel with the

flat bottom of the fuselage. Depending the the thickness of your

foam, you may need to compress the pylon slightly to match the

width of the fuselage strips.

vii) Peel the inside surface of the long strip used on the top of the

fuselage. Give it a gentle curve by pulling it across the table edge,

and then glue it to the top of the fuselage, working forward from the

Pylon, glue along the edge of the fuselage, and make sure to leave

an opening slightly larger than the length of the battery, so you can

get it in and out easily. Trim off the excess.

9

viii) Test fit the servos into place in the opening in the fuselage. They

should go on the inside with the top of the servo case flush with the

bottom of the opening. Before sticking anything, it’s a good idea to

power up, center the servo arms, and put the little connectors into

the servo arms. Attach the sticky tape to the servos so that the

arms point into the plane, and then attach one servo to the inside of

each half of the fuselage, making sure that they don’t hit each other

when you lay the halves together.

ix) Cut two 1” pieces of the excess foam strip that you have. Glue

them to the inside of the fuselage halves at the base of the tailboom

on either side to support the pushrods. You can also use tubing or

a small straw taped or glued into place.

x) Pushrods:

(1) find two suitable pieces of .032” wire. You need to push the

wires carefully through the foam with a slight twisting motion.

You might want to practice on scrap foam first. You can also

get the hole started with a long pin, or sewing needle.

(2) The Rudder pushrod goes on the right hand side of the plane,

parallel to the top of the tail boom, and 1 foam thickness away

from the top. The wire should pierce the foam about 2 inches

from the front of the vertical stabilizer, and come out on the

inside 2.5 inches further along.

(3) The Elevator pushrod goes on the left hand side of the plane,

entering the foam 1 thickness away from the bottom, and

heading towards a point 1 thickness away from the top of the

tail boom where it meets the fuselage.

(4) Route the pushrods inside the fuselage poking them through

the small support pieces as you work your way forward to the

servos.

(5) Work the pushrods back and forth until they slide smoothly.

©2004 FoamFly.com 10

xi) Now fit the rest of your gear. Thread the motor wire through the

pylon, and slide the motor onto the stick. Double stick, or scotch

tape the receiver in place. Try to position it so you will have access

later. Connect motor BACKWARDS (Red to Black, and Black to

Red.) , and plug in the servos and ESC. Turn everything on now,

and make sure that you have the correct servo plugged in the

correct place. TEST fit the halves of the fuse together. Allow one

pushrod to ride on top of the other so that it can move freely.

xii) When you are confident, glue the two halves together. Don’t forget

to put glue on the other half where the wing reinforcement, pylon,

and battery box will touch it. Work from the back to the front, and

be careful to make sure everything lines up between the two

halves, especially the wing slots.

5) Wings:

a) Decide which side will be the top of the wings. The foam usually has a

lumpier side, and a smoother side. I prefer to have the smoother side

on the top of my wings, but it doesn’t matter much as long as all

sections of the wing end up the same

b) When you roll the wingtips make sure you end up with a LEFT and a

RIGHT!!! This is EXTREMELY important. The wingtip pieces are

essentially identical until you form the airfoil into them. So watch out, a

plane with two left wings doesn’t fly too well.

c) Peel the bottom surfaces of each wing section (note: you only really

need to do this with the green foam) and then roll the wings into shape:

Now that you know which side is up for your wings, roll the airfoil shape

into them. (See the Appendix Section, “Rolling the Foam”)

11

Now the wing pieces probably have more curve than they need. Grab

one of wing ribs with the airfoil shape, and use it to check your airfoil. If

it’s not an exact fit, massage the wing a little until it’s pretty close. The

glue will do the rest.

(Note: If you have the FoamFly.com Wing Jig, you can bake wings for

this plane using the same standard airfoil.)

d) Use the foam Dihedral Jig to sand the required angle into each wing

section. Slide the tool onto the tip of the wing that you’re working on,

and then sand or cut the root of the wing exactly vertical. You can do

this easily by holding your sanding block against the edge of your

kitchen counter, and then pressing the wing end against it. (I would

recommend that you slide the wing back and forth, and not the sanding

block. It’ll help protect your counters, and maybe your marriage.) Be

sure to keep the wing in it’s finished airfoil shape while you’re sanding.

If you like, you can slip one of the ribs under the wing about 1” from the

root, and press down on it to hold the airfoil shape while sanding

e) Repeat the process for the center wing section, sliding the jig exactly 8”

onto the wing, and then do the same for the other end of the center

section. By sanding an equal angle into both the wing center, and tips,

you can ensure an even fit.

f) Slide the center section of the wing through the slot in the fuselage, until

it is exactly centered and straight.

g) Glue the wing ribs to the bottom of the wing at the far ends of the center

section.

h) Now glue the wing tips into place

©2004 FoamFly.com 12

6) Finishing Touches:

a) Find a short strip, and bend it to match the curve over the battery box.

Cut the strip to be just slightly longer than the opening. (So it will be a

tight fit.) Cut two pieces of tape the same width as the strips, (about

5/8” ) and tape the outside of the door in place at the bottom. Open the

battery door all the way, and press it tightly against the fuse. Tape the

inside of the door hinge. If the door starts to become loose, a piece of

scotch tape folded over at one end makes a handy latch.

b) Now to make the Canopy Covers:

i) Glue the Canopy Centers to the Canopy Covers. If you feel the

need to stop at this point and pretend that you are Mr. Spock, go

ahead. Next. You may need to trim away a little of the canopy

centers to allow full freedom of movement for the servo arms.

ii) Using a paperclip, bend a small hook with a wide base and glue it

to the inside of the top of each canopy cover. Connect the two

halves with a small rubber band, and twist the two halves until the

rubber band pulls taught. You can easily install and remove the

covers by slipping one half through the fuse, and then snapping the

two pieces into place.

c) Glue the Control Horns into the Surfaces. The Rudder Control Horn

goes on the right hand side of the Rudder. The Elevator Control Horn

goes on the underside of the Elevator, on the left hand side of the

Fuselage. Make small cuts with your X-Acto knife where the control

horns will line up with the pushrods, and test fit the control horns in

place. Now glue them in, with a little Epoxy, or foam safe CA. Make

sure the holes are lined up directly over the hinge line.

13

I really like these control horns. They’re designed specifically for foam,

as they put a much larger surface area into the foam for glue to hang

onto. I’ve had them laser cut in two sizes for use on a variety of

airplanes. If you’d like to get more of them to use in your own projects,

they’re available at the FoamFly.com Store in the Accessories section.

d) After you hook up the control horns, center the servos, and then center

the control surfaces. I recommend using the Dubro Mini-EZ connectors.

They’re definitely the easiest way to attach the pushrods to the servos,

but if you can’t want to get some of them, the traditional way works fine.

Make a small Z-Bend in the end of each pushrod. These will lock into

the control horns. Near the Servo end, make a V bend about 3/8” tall.

Once you’ve figured out how long the pushrods need to be, you can

make a similar Z-Bend at the other end, and cut off the excess. You’ll

need to remove the servo arms from the servo to get them over the Z-

Bend. You can use the V to make slight adjustments to the length of

the pushrods.

7) Control Throws and Balance:

a) Throws.

i) Elevator: .75” maximum in either direction (about 30˚)

ii) Rudder: 1.25” maximum in either direction (about 40˚)

If you’re a beginner, you might want to start with smaller movements

than these, but eventually you’ll want to work your way to these settings.

b) CG: If you use all the recommended equipent, you shouldn’t have any

problems with the balance, Here’s how to double-check. The Frog

should balance at a point about 2” back from the leading edge of the

wing. If you put your fingers under the wing at the highest point, that’s

where it should balance. The Frog is fairly forgiving, so if it’s within 1

finger’s width of that point you’re probably okay.

You’re Done!

©2004 FoamFly.com 14

But wait there’s more! Now how much would you pay?…

8) How paranoid are you? There are several levels of reinforcement that can

be added to the Frog.

a) First off, if you’ll be landing on anything other than the soft green grass

of your local field, you’ll want to run a piece of packing tape FLAT along

the bottom of the fuselage from the base of the battery door to halfway

up the tail boom. Use your razor to cut from the edge of the tape to the

fuse about 1 cut every 1/2 inch only where the curves are. Then fold up

the edges of the tape working from the back to the front, overlapping the

cuts to work around the curves. ( hope that makes sense.)

b) Second, if you think you might be crashing into anything, you’ll probably

want to run a similar piece of tape from the Pylon to the other end of the

battery box. But wair there’s more.

c) If that’s not enough, you can wrap a 2.5 inch piece of tape over the

leading edge of the wing right where it goes through the fuselage. (A

good reinforcement if you’re planning to fly the plane overweight.) I

never bothered to do this.

9) Which brings me to repairs. With luck you shouldn’t need any serious

repairs. That being said, I’ll get to the Number 1 repair secret. In most

cases the glue will let go before the foam tears in a crash. The great thing

about 3M-78 is that it can be re-activated with HEAT. This means that if the

tail, or half the fuse pops loose, you can simply warm it all up with an

ordinary hairdryer, and press the pieces back together QUICKLY while it’s

still hot. I just heat evenly until I can feel my fingers burning, and then I

press the pieces together, remove the heat, and hold for 5-10 seconds. This

works great, because the new joint is the same strength as the old one, and

you haven’t added ANY WEIGHT.

a) For what we shall call “more serious” repairs, I recommend Formula

560 “canopy” glue for tears in the foam, it dries clear, and remains

flexible when dry. You can use Foam safe CA, or Epoxy if that’s too

much of a pain, and various kinds of tape for the rest. Be creative, and

think light.

10) Flight Instruction:

a) Your first flight: After checking the control throws, make sure that the

control surfaces actually move in the right direction. Right for right, left

for left, up when you pull the stick back, and down when you push the

stick forward. First launch should be a hand-toss. With all the control

surfaces centered, give full throttle, and give a toss directly into the

wind. Make sure you’ve got enough room to maneuver. Adjust the

trims so that the plane is climbing slowly at full throttle. If you’ve been

flying Firebirds, or other 2-channel planes, remember that you’ll have to

add up elevator in a turn to maintain altitude.

15

b) Note: The plane may seem underpowered, depending on the weight, at

lower throttle settings. Keep this in mind: The motor is mounted high

above the wing, and this gives it a lot of leverage to force the nose

down. If it seems like the plane doesn’t have enough power, give a little

up elevator, you should find that it will still climb easily. This is actually

a joy for me, and anyone who’s used to how badly most slowflyers will

pitch-up.

c) Other Note: Always keep a little throttle on. That big heavy propeller

will drag the plane out of the sky. If you keep it spinning a little, it will

remove most of that drag, and the plane should glide gracefully. If you

get into trouble, full throttle can help you maneuver, the prop wash

passes directly over the control surfaces, so the more air, the more

control you have.

You’re still reading? Go fly already. ;)

Enjoy your Frog. Share photos if you can, and don’t hesitate to get in touch if

you have questions, or need help setting up your plane.

Sincerely,

-Dan

©2004 FoamFly.com 16

APPENDIX:

The Tools: (and things you’ll need)

1) .032” wire for pushrods

2) Knives: a Razor knife, and an X-Acto would both be useful.

3) Glue: 3M “Insulation 78” contact cement, or Foam-Safe CA, or Elmer’s

White glue, or RC-56 type white glue, or Epoxy. You’ll probably want a

couple of these for good measure.

4) Tape: You’ll want 2” wide clear packing tape, and also some “crystal clear”

Scotch Tape if you can find it. If not, you can cut down the packing tape.

5) Sandpaper. Any Medium grit should do fine.

6) Pliers: Something suitable for wire bending.

7) A couple of paperclips, and a rubber band.

The Techniques: You’ll probably want to practice these on a piece of the scrap

foam.

1) “Cut & Peel”

In certain areas you’ll need to peel some of the skin from the foam to

ensure that you get a good solid glue joint. If you don’t do this, everything

will be fine, but in case of an “impact” the skin could peel away, and you’d

have to glue it back in place (A real pain.)

Here’s how you do it. Stick your knife/razor point (or your fingernail) just

under the edge of the skin, and lift up one corner. Now carefully peel back

the skin. Do it slowly, the skin can tear when the peel reaches the little

holes. It won’t tear if you pull with small tugs held close to the foam. If you

practice this will make a lot more sense.

2) “Tapers & Angled Cuts”

a) It's almost impossible to cut a straight line freehand. So, what's your

number one tool for angled cuts? Your kitchen counter. Why not?

Formica is everybody's first choice for making hotwire templates, and

it’s tough, so use it where you find it. Lay your foam on the counter with

the end of the foam flush exactly at the edge of the counter. To

accurately control the angle of the cut, position a metal ruler on top of

the foam. If you place the straightedge directly above the counter’s

edge, you get a perfectly straight cut. If you slide the ruler back from

the edge, you get a perfect angled cut. Just make sure to get your

fingers out of the way as the hot wire or knife comes by.

b) Your other option gives you a little more time while you’re working.

Simply Cut & Peel the area where the bevel is going to be, and then

using a medium sandpaper like 200, or 250, carefully sand away the

bare foam until you have a smooth angle.

3) “Glue” (Working with the contact cement)

a) “Basic Gluing”

The contact cement will test your patience. I know you’ll be

tempted to stick the pieces together immediately, but don’t be give in.

The 3M-78 will form the strongest bond, if you allow it to dry for AT

LEAST 8 minutes before putting the pieces together, and probably

much longer. Put the glue on BOTH surfaces to be joined. If you’re not

17

used to contact cement, remember you really only get ONE CHANCE at

putting the pieces together. It really is instant gluing! (except for the

waiting, but that’s already over at that point)

b) “Advanced Gluing”

The 3M-78 is ideally a spray glue, and there are some instances

where you can actually spray it during this project. You’ll want to make

sure that you carefully mask off any areas where you don’t want the

glue. You can do this by cutting custom shaped glue shields out of

paper, or masking tape. Be sure to test your masking tape on the scrap

foam to make sure that it doesn’t peel the skin off when you remove it.

For the rest of the areas (Like attaching the wings) you’ll want to

brush the glue on. Just spray some on some waxed paper, and use a

scrap of foam, or a disposable brush to paint it right on both surfaces to

be glued.

The 3M-78 has a long working time. After application, the glue can

sit for over half an hour and still make a full-strength bond. If you plan

ahead a little, you can apply the glue to all the fuselage surfaces in the

order that you’ll be assembling them, and the first ones will be ready to

press together by the time that you’re done applying glue to the least.

Then proceed in order, for an exceptionally quick build.

4) “Rolling the Foam”

You’ll be bending the foam to form the airfoil for the wings. You’ll also

need to bend the windshield and Hood parts to conform to their curves.

You need to get a feel for how much pressure the foam will take before

it gives.

a) Wings: Find yourself a section of 2” PVC pipe, (Or a BaseBall Bat,

Rolling Pin, Kitchen Counter, Bathtub edge, etc…) and press the wings

firmly and evenly down onto it to form the airfoil shape. It doesn’t take

too much pressure. The airfoil curves more sharply right near the

leading edge, so you can use smaller diameter pipe (or a Broomhandle

etc.) to add a little more curvature there if you feel it’s necessary. It’s

also acceptable to just use your thumb, and the side of your index finger

to work the leading edge bend a little.

b) Other Parts: Small parts that need rolling can be rolled over a pen, or an

X-Acto knife handle etc. These items generally take very little effort to

bend, but should still be formed over a solid object to avoid wrinkles.

©2004 FoamFly.com 18

19

Kit packing Checklist:

Foam Airplane Parts:

Fuselage halves (Left and Right)

Main Wing

Wingtips (Left, and Right)

Horizontal Stabilizer

Long Tapered Strip

Short Tapered Strip

Top Strip

Small Parts Sheet

Foam Tools:

Dihedral Jig

Non-Foam Parts:

Wood Motor Mount

Laser Cut Control Horns (2)

This Instruction Manual

Other FoamFly Toy manuals

Popular Toy manuals by other brands

Eduard

Eduard BRASSIN 632 029 manual

BlueArrow

BlueArrow Venus DLG Construction and flight manual

GAME OF BRICKS

GAME OF BRICKS 42100 instruction manual

Fisher-Price

Fisher-Price GEOTRAX P1370 user manual

Dancing Wings Hobby

Dancing Wings Hobby T09 AeroMax instruction manual

VTech Baby

VTech Baby Crawl and Learn Bright Lights Ball user manual

Tiger Electronics

Tiger Electronics Vlad the Impaler instructions

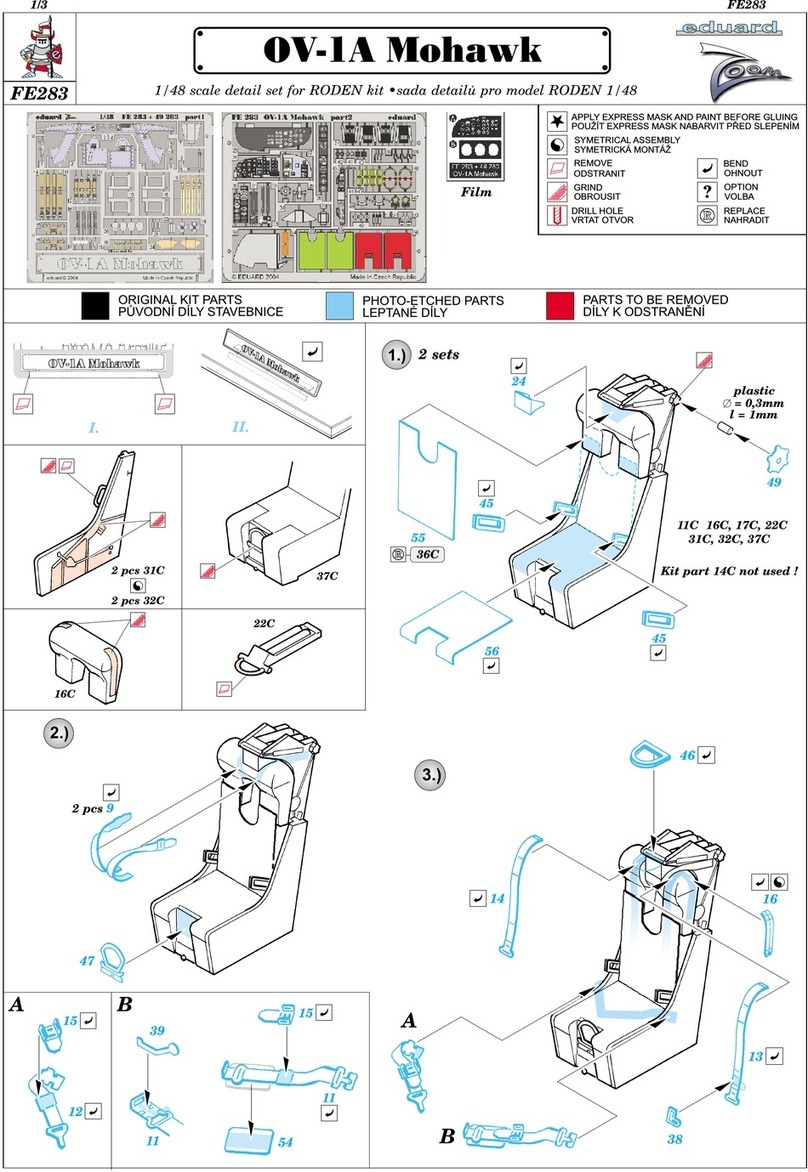

Eduard

Eduard Zoom OV-1A Mohawk quick start guide

V-tech

V-tech Spin & Giggle Gears user manual

MD SPORTS

MD SPORTS Barrington SOC054 078B Assembly instructions

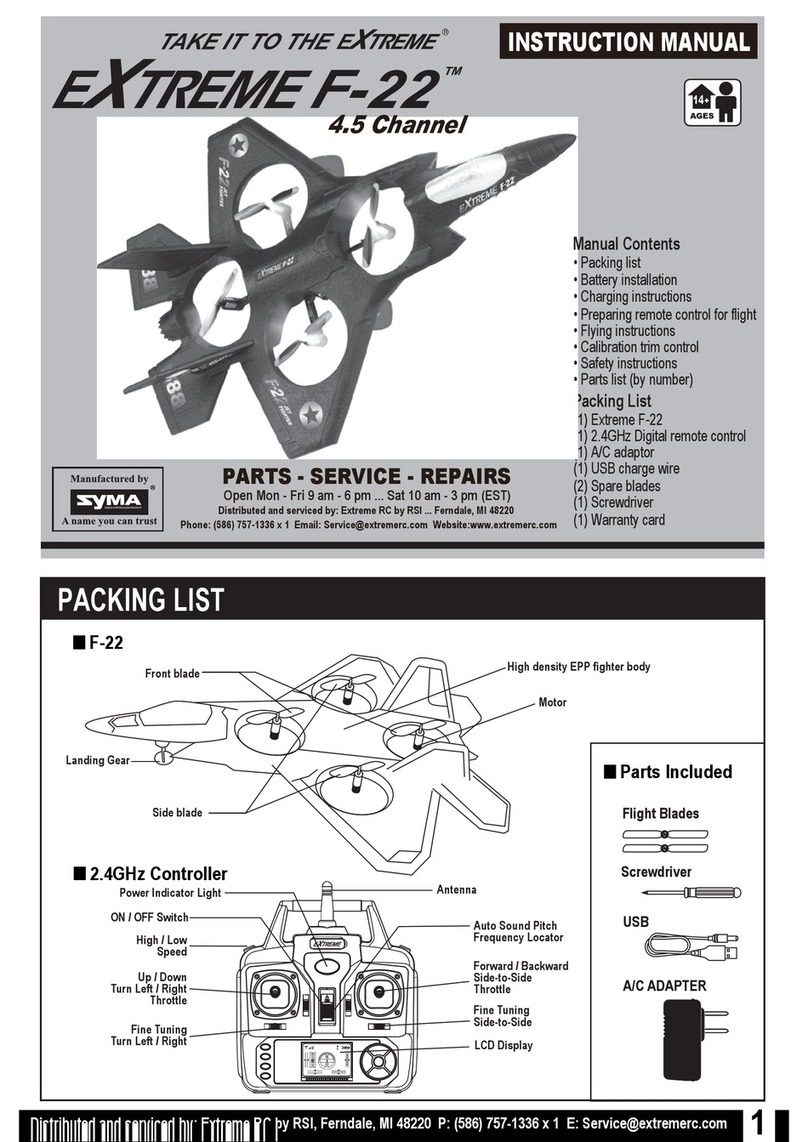

Extremerc

Extremerc Extreme F-22 instruction manual

esky

esky HUNTER operating instructions