FoamPRO 3012 User manual

Unit

Serial

Number

System 3012

Model 3012

INSTALLATION AND

OPERATION MANUAL

Form 836

6/19

All quality FoamPro products are ruggedly designed, accurately machined, carefully assembled, thoroughly inspected

and tested. In order to maintain the high quality of your unit, and to keep it in a ready condition, it is important to follow

the instructions on care and operation. Proper use and good preventive maintenance will lengthen the life of your unit.

ALWAYS INCLUDE THE UNIT SERIAL NUMBER IN CORRESPONDENCE.

FoamPro • 26 Southern Blvd. • Nesconset, NY 11767 USA • 800-533-9511 • FAX 816-892-3178

2

Installation and Operation Manual

TABLE OF CONTENTS

SECTION PAGE

1 SAFETY ............................................................................................................................ 3

2 A QUICK LOOK AT HOW THE SYSTEM WORKS .......................................................... 5

3 SYSTEM COMPONENT DESCRIPTION ......................................................................... 7

4 INSTALLER SUPPLIED PARTS....................................................................................... 9

5 INSTALLATION PLANNING ............................................................................................ 12

6 FOAM PUMP AND HYDRAULIC CONTROL VALVE INSTALLATION ........................... 13

7 HYDRAULIC PLUMBING INSTALLATION...................................................................... 14

8 WATER AND FOAM PLUMBING COMPONENT INSTALLATION ................................. 16

9 ELECTRICAL EQUIPMENT INSTALLATION.................................................................. 21

10 MAKE SURE EVERYTHING IS WORKING RIGHT ........................................................ 27

11 CALIBRATION AND SETUP ........................................................................................... 30

12 OPERATING INSTRUCTIONS........................................................................................ 33

13 MAINTENANCE............................................................................................................... 40

14 TROUBLESHOOTING..................................................................................................... 41

15 SPECIFICATIONS ........................................................................................................... 46

16 WARRANTY ......................................................................................................Back Cover

NOTE TO SYSTEM INSTALLERS

IMPORTANT: Please provide a copy of the FoamPro manual to the end user of the equipment.

For additional FoamPro manuals, contact by FAX 816-892-3178, web site www.foampro.com,

or call 800-533-9511. Request Form No. 836.

3

Installation and Operation Manual

System 3012

The following special notices are used to notify and

advise the user of this product of procedures that may be

dangerous to the user or result in damage to the product.

NOTE: Notes are used to notify of installation,

operation, or maintenance information that is

important but not safety related.

CAUTION: Caution is used to indicate the presence

of a hazard, which will or can cause minor injury or

property damage if the notice is ignored.

WARNING: Warning denotes that a potential

hazard exists and indicates procedures that must

be followed exactly to either eliminate or reduce

the hazard, and to avoid serious personal injury, or

prevent future safety problems with the product.

DANGER: Danger is used to indicate the presence

of a hazard that will result in severe personal injury,

death, or property damage if the notice is ignored.

• Do not pump at pressures higher than the maximum

recommended pressure. [400 PSI (28 bar)]

• Do not permanently remove or alter any guarding

devices or attempt to operate the system when those

guards are temporarily removed.

• Always disconnect the power source before

attempting to service any part of the pump.

• Release all pressure within the system before

servicing any of its component parts.

• Drain all concentrate and water from the discharge

system before servicing any of its component parts.

• Check all hoses for weak or worn conditions after

each use. Ensure that all connections and fittings are

tight and secure.

• Use only pipe, hose, and fittings from the foam pump

outlet to the injection point, which are rated at or

above 400 psi (28 BAR) minimum rating, at which the

water pump system operates.

• Use only pipe, hose, and fittings from the hydraulic

oil pump to the foam pump hydraulic motor, which

are rated at 3000 psi (207 BAR) minimum working

pressure or better and are approved for mobile

hydraulic system use.

• Any electrical system has the potential to cause

sparks during service. Take care to eliminate

explosive or hazardous environments during service/

repair.

• Rotating drive line components can cause injury. Be

careful of rotating components when adjusting load

sense pump compensator.

• Slowly loosen the foam pressure line fittings and

allow the pressure to escape. Protect face and eyes

from any potential spray which may occur.

CAUTION: Do not attempt to operate the system at or

above a temperature of 160°F (71°C).

WARNING: Ensure that the electrical source of power

for the unit is a 12 or 24 Volt, negative ground DC

system. Power and ground lines must come directly

from the battery without any connections to other high

power devices, such as primer pumps, hose reels,

light bars, etc. Power required for the valve driver box

on the hydraulic motor-driven foam pump must have a

minimum current rating of at least 5 AMPS.

CAUTION: Periodically inspect the pump and the

system components. Perform routine preventive

maintenance as required. Failure to perform routine

maintenance may cause damage to the system.

See the maintenance section of this manual for

recommended maintenance procedures and intervals

between maintenance work.

NOTE: Read and understand these installation

instructions before proceeding with the equipment

installation.

CAUTION: Use only approved petroleum-base

hydraulic fluids meeting the specifications as noted

in Section 4. Never mix fluid types. Ensure all hoses

and seals are compatible with fluids used. Do not use

water or glycol-based fluids. Do not use phosphate

ester-type fluids.

1 Safety Before attempting to install a FoamPro System 3012, read all

of the following safety precautions and follow carefully.

4

Installation and Operation Manual

CAUTION: Dirt and contaminant’s are the primary

causes of premature wear and failure in any hydraulic

system. Use extreme care during assembly and

service to keep contaminant’s out of the system.

WARNING: Always disconnect the ground straps,

electrical wires and control cables from the Digital

Display Control Module and all other FoamPro

equipment before electric arc welding at any point on

the apparatus. Failure to do so will result in a power

surge through the unit that could cause irreparable

damage.

CAUTION: All DOT, SAE or other applicable

standards must be followed when installing

the hydraulic supply system. Pay close attention

to engine and transmission manufacturer drive

limitations.

CAUTION: Never attempt to cut or lengthen the

molded cables. Doing so will result in RFI/EMI

interference. Contact the factory if molded cables of

a different length are required.

CAUTION: To ensure the integrity of fitting

connections in the hydraulic system, use only SAE

JIC 37° flare or equal type hose connections.

CAUTION: To prevent damage to the hydraulic motor

seal, the motor case drain must have its own 1/4 inch

(6.3 mm) inside diameter hose installed to return

hydraulic oil to the reservoir.

WARNING: The load sense pump compensator is

preset at the factory for proper operation. DO NOT

adjust the load sense compensator.

CAUTION: The cables shipped with each FoamPro

3012 are tested at the factory with that unit. Improper

handling and forcing connections can damage these

cables which could result in other system damage.

CAUTION: The foam tank low-level sensor must be

utilized to protect the foam pump from dry running.

Failure to do so will void warranty.

CAUTION: The input power wire is not protected by

the system circuit breaker. Be careful not to damage

or short circuit this wire.

CAUTION: When pouring foam concentrate directly

into the foam pump, the inlet strainer is bypassed.

Make sure contaminant’s are not poured into pump

chamber. Premature pump wear or damage may

result if contaminant’s are allowed to enter pump

chamber.

CAUTION: Do not run the FoamPro 3012 for more

than one minute deadheaded against the pressure

gauge, as the foam pump could be damaged.

CAUTION: When operating the FoamPro in the

“Simulated Mode” function, an outlet for the foam

concentrate must be provided. Otherwise dangerous

excessive pressure may be built up in the apparatus

water piping and/or hoses. This outlet for the foam

concentrate can be provided by turning the “CAL/

INJECT” valve to the “CAL” position. A suitable

container must be provided to collect the foam

concentrate.

CAUTION: Do not mount electronics where they will

be exposed to direct water spray.

5

Installation and Operation Manual

System 3012

2 A Quick Look at How the System Works

The FoamPro 3012 system is an electronic and

hydraulic foam concentrate proportioning system

designed to provide the wide range of foam concentrate

injection rates necessary for both Class A and Class B

foam operations.

The FoamPro system will accurately deliver from 0.1%

to 10.0%, or from 0.1 to 12.0 gpm of foam concentrate

to the foam injection point. The maximum rated

concentrate flow rates obtainable are shown in the

system specifications in Section 15.

The FoamPro 3012 system is a flow-based

proportioning system that measures water flow and

then injects the correct proportional amount of foam

concentrate to maintain the desired percentage.

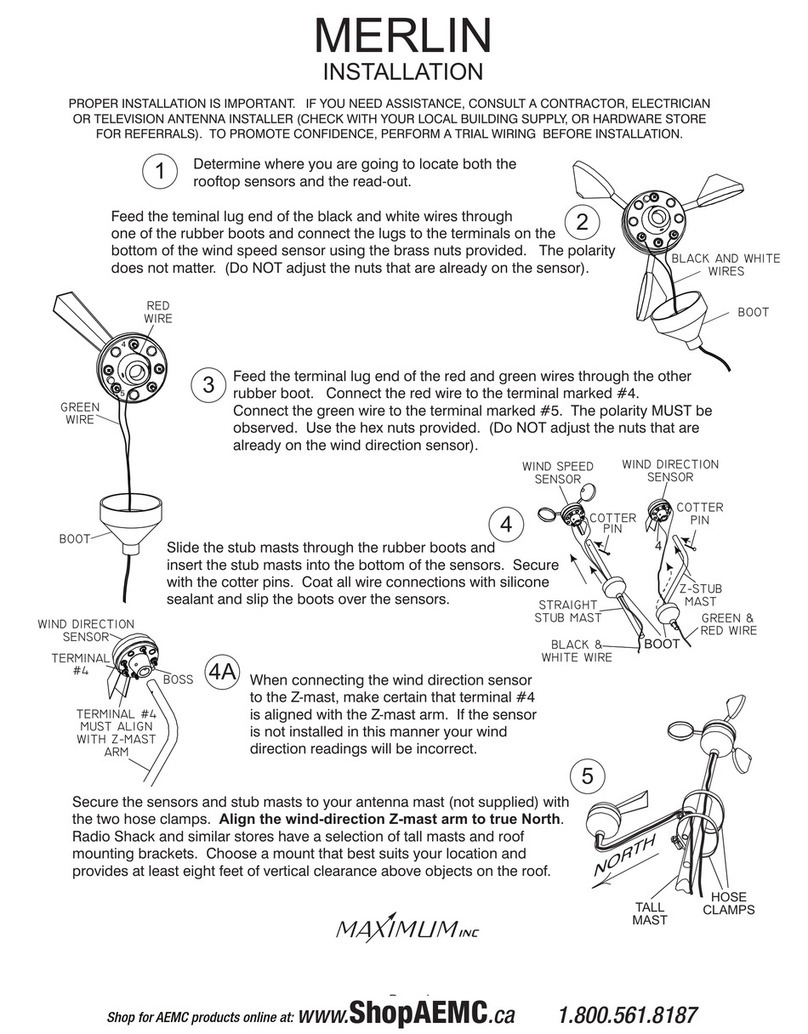

The basic FoamPro system is shown in Figure 2-1.

The flowmeter measures the water flow and sends

a signal to the Digital Display Control Module. A

speed-sensing device monitors the foam pump output.

Constant comparison of these two information signals

by the controller ensures maintenance of the desired

proportion of foam concentrate at all times based on

water flow rate, independent of any variations in fire

pump intake or discharge pressures. As water flow

increases or decreases, the foam concentrate rate

of injection is increased or decreased automatically

to correspond to water flow, maintaining the proper

concentrate percentage as selected on the Digital

Display Control Module.

CAUTION: If the power to the FoamPro unit fails or

is shut off during operation, the system will remain

in operation at the last setting. DO NOT close the

discharge to the system until the hydraulics are

disengaged. To turn the system off, it is required to

disengage the hydraulic drive PTO.

Foam concentrate is injected directly into the water

stream on the discharge side of the water pump. It is

then fed as foam solution into a standard fog nozzle,

an air-aspirated nozzle, a straight bore nozzle, or into

a CAFS system, by the main fire pump. Since the foam

is injected on the discharge side of the fire pump and

check valves are used at installation, contamination of

the booster tank, fire pump, and relief valve with foam

concentrate is eliminated.

Hydraulic power to operate the foam pump is to be

provided by a separate hydraulic pump driven by the

apparatus system.

Electrical power to operate the foam systems is

provided by the apparatus electrical system.

Order optional system components listed in Section 3

to accommodate system design and requirements. The

components listed have been tested with the FoamPro

systems and provide for optimum system performance.

FoamPro Model 3012 systems will pump Class A

and Class B (Aqueous Film Forming Foam, AFFF,

and Alcohol-Resistant Aqueous Film Forming Foam,

AR-AFFF) to capacity. Many brands of AR-AFFF

exhibit higher viscosity characteristics due to chemical

composition and polymers. As viscosity increases,

diminished flow may affect pump performance. Because

of numerous variables; including pump design, foam

cell configuration, inlet piping/components and system

layout; please contact FoamPro at 800-533-9511 for

application-specific recommendations when foam

viscosities of 2000 cps (Brookfield #3 spindle @ 30 rpm)

or higher are used.

6

Installation and Operation Manual

Figure 2-1 FoamPro 3012 System Layout

Foam Tank

Water Tank

Water Pump

Power & Ground

Connection Pin

A (Red) + 12 VDC

to + 27 VDC Pin B

(Black) Ground

Water Flowmeter

Line Strainer

Foam Pump Assy. Speed Sensor

Check Valve

Check Valve

(Optional)

Main Waterway

Check Valve

Flush Water

Shutoff Valve

Foam Tank

Shutoff Valve

Outboard

Pickup

Foam Injection Point

Single Discharge

Calibrate/Inject Valve

Foam Injection Check Valve

Hydraulic Motor

and Control Valve

Hydraulic Valve

Control Driver

Foam Tank

Low-Level

Sensor

Digital Display Controller

Multiple Discharge

with Manifold

7

Installation and Operation Manual

System 3012

3 System Component Description

The following components are packaged with the

standard FoamPro 3012 system:

1. Digital Display Control Module

2. Molded Cables

3. Foam Pump and Hydraulic Control Valve Assembly

4. Instruction Placard

5. Low-Level Sensor (One required. Not packaged

with the unit. Order separately.)

6. Calibrate/Inject Valve

7. Inlet Line Strainer

8. Check Valve 1/2"’ NPT Foam Injection. This NFPA

1906 (draft) required check valve prevents water

back flowing into foam system.

9. RFI/EMI Suppression Beads

10. FoamPro Paddlewheel Flowmeter or Manifold

(The flowmeter is a required component. The

size is specified and ordered under a separate

part number when the FoamPro is ordered. The

flowmeters are available with 1-1/2", 2", 2-1/2", 3",

and 4" NPT threads; or manifolds with Victaulic-

grooved ends in 1-1/2", 2", 2-1/2", 3” and 4" pipe

sizes. All flowmeters have grooved victaulic ends.

Insert-style flowmeters are available for larger pipe

diameters. Part numbers for the various flowmeters

can be found in Section 15. Up to 4 flowmeter

sensors can be used with the FoamPro System

when a MultiFlo interface is used.)

11. Hydraulic Load-Sensing Pump

1

4

3

2

8

7

6

5

11

10

9

8

Installation and Operation Manual

SYSTEM ACCESSORIES AVAILABLE

FoamPro MultiFlo Interface

Combines 2 to 4 flowmeters

for single point systems

System Placard Solid State Contactor

P/N 2510-0043

Nesconset, NY 11767US

A

Main Waterway Check Valve with Drain Port

Available in stainless steel.

NPT threaded ends with injection and drain ports

System

Specification Placards

Remote Start/Stop

Polypropylene Foam Tank(s)

8, 12 or 20 gallon capacity

Foam Manifold

All stainless steel with main waterway

check valve, water flowmeter, injection

port, and drain port. Victaulic grooved ends

For more information on these accessories, please see publications 856 and PL-21.

Electronic Concentrate

Management System

Electronic control for Dual Tank Systems

with interface to controller

Electronic Concentrate Management System

Electronic control of single or dual tank onboard

systems and an off-board pickup.

2002 Series and larger only

Main Waterway Check Valve

All stainless steel with Victaulic

ends and injection and drain ports

NFPA Calibration and Test Kit

For use with 1600 thru 3012 systems

Dual Injection Management System

Provides capability for switching between

two injection points

Single Tank Flush Kits

Both Internal and External flushing kits

9

Installation and Operation Manual

System 3012

4 Installer Supplied Parts

FoamPro 3012 systems are provided with major

components and accessories required for installation. Due

to differences in chassis and apparatus configurations,

the installer must provide hydraulic coolers, fluids,

reservoir, pipe, hoses, tubing, wire and fittings to satisfy

installation requirements. The following paragraphs list the

specifications for selection of these components. Before

beginning system installation, read this section thoroughly

to make sure the proper components are selected. For

detailed system installation instructions, refer to Sections 5,

6, 7, 8 and 9.

CAUTION: All DOT, SAE or other applicable standards

must be followed when installing the hydraulic system.

Pay close attention to engine and transmission

manufacturer drive limitations.

Hydraulic Pump Drive Selection

The foam pump for the FoamPro 3012 system is powered

by hydraulics. Power for the system comes from hydraulic

oil supplied by a hydraulic pump attached to the apparatus

engine. To obtain optimum performance from the hydraulic

motor-driven foam pump, FoamPro has designed the 3012

system to use a load-sensing, pressure-compensated

hydraulic pump. The FoamPro load-sensing hydraulic

pump provides proper hydraulic fluid flow with reduced heat

load, torque and horsepower requirements.

The FoamPro load-sensing hydraulic supply pump will

provide the correct fluid flow over the widest range of engine

speeds. See system specifications for the maximum required

pump speed to attain maximum performance levels. By

using a PTO ratio greater than 1.0, the minimum engine

speed for full system performance could be idle speed.

A transmission PTO should be used to drive the hydraulic

supply pump. Transmission PTOs have greater torque

capabilities and provide adequate power for the hydraulic

pump. Selection of a PTO transmission with a standard

SAE mounting pad will allow bolting the hydraulic pump

directly to the transmission. The FoamPro load-sensing

hydraulic supply pump has a standard 2-bolt SAE “B”

mounting flange and a 13 tooth, 16/32-pitch splined shaft.

Other shaft configurations are available. The shaft rotation

of the pump is clockwise when looking at the pump shaft, or

counterclockwise when facing the rear of the pump. Check

with the FoamPro factory for other configurations that may

be available. See Section 15 for pump dimensions.

Control of the PTO may be provided by a manual shift

lever, shift cable or solenoid. The manual shift-type PTO

may be left in gear all the time to circulate oil as soon as the

engine is started, since the load-sensing hydraulic pump

will draw less than 2 hp when operating in standby mode.

The PTO shift can be labeled “Service Disconnect.”

When selecting a transmission PTO, it is imperative that

consideration be given to frame clearances and the space

in which the hydraulic supply pump is to be mounted. For

new installations, initial design and planning will eliminate

clearance problems. When the FoamPro 3012 system is

being installed as a retrofit, all clearances must be taken

into account. Consult PTO and chassis manufacturers to

determine dimensions and clearances required.

CAUTION: The use of an accessory drive pad is

not recommended since adequate torque usually

is not available to drive the hydraulic supply pump

and accessories.

Choosing the Proper PTO

It is important to turn the hydraulic pump at the proper

speed to ensure that the correct hydraulic pressure is

produced over the full operating range of the foam system.

When selecting a PTO to drive the hydraulic pump,

compare the maximum RPM for the water pump with the

maximum RPM (2,500 RPM) for the hydraulic pump. Then

select a PTO that will provide the best performance at a

lower RPM.

For Example: the maximum speed you can turn the water

pump is 1,800 RPM. For the 3012 system hydraulic pump,

the minimum speed is 1,350 RPM, and the maximum

speed is 2,500 RPM. It is recommended to choose a PTO

with a range of 1 - 1.35 conversion rate (or higher).

10

Installation and Operation Manual

According to the above example, the following table

shows the Engine Speed with the corresponding Hydraulic

Pump Speed:

Engine Speed Hydraulic Speed

800 RPM 1080 RPM

900 RPM 1215 RPM

1000 RPM 1350 RPM

1100 RPM 1385 RPM

1200 RPM 1620 RPM

1300 RPM 1755 RPM

1400 RPM 1890 RPM

1500 RPM 2025 RPM

1600 RPM 2160 RPM

1700 RPM 2295 RPM

1800 RPM 2430 RPM

Oil Reservoir

A hydraulic reservoir will be required to be installed in the

apparatus. See Section 15 for minimum recommended

reservoir capacity. A larger reservoir may be installed and

is recommended if the apparatus is to run at maximum

capacity for an extended period of time and to allow air to

settle out of the oil.

The reservoir must have a diffuser on the inlet to prevent

entrapment of air into the system. A particle screen on the

oil outlet to the hydraulic pump of 150 mesh (125um) is

recommended to help keep dirt out of the system. A baffle

to separate the inlet and outlet sections should be installed

in the reservoir. A vented, filtered breather of sufficient

size to allow filling of oil is required and an oil drain plug

is recommended.

A sight gauge with thermometer is also recommended for

easy checking of the oil level and to monitor oil temperature.

The oil reservoir should be mounted away from heat

sources, such as exhaust systems, and be in a location that

allows easy access for checking and filling the oil.

The return line from the cooler to the reservoir should have a

replaceable type oil filter with at least a 10 microm absolute

rating and sized to at least a 15 gpm flow rate. Note the larger

the flow rate capacity of the filter, the longer the maintenance

interval can be (minimum replacement is annually).

Oil Cooler

An oil cooler capable of maintaining the temperature of

the hydraulic oil at 140° to 180°F (60° to 82°C) is required.

Use of an air-to-oil radiator-type heat exchanger mounted

in front of the apparatus radiator should provide adequate

cooling for the hydraulic system oil. An electric fan attached

to the oil cooler permits mounting of the oil cooler anywhere

fresh air circulation is available. A thermostat is required to

be included for quick warm up of the oil in cold climates.

Check the system specifications page in Section 15 for

minimum heat load information to properly size the cooler.

Oil to water heat exchangers can be installed, but they

present special problems such as sediment accumulation,

drainage and overheating when running in standby

mode for extended periods without discharging water.

If a hydraulic oil to water heat exchanger is to be used,

proper maintenance, monitoring and pumping procedures

must be followed. The oil to water exchangers must be

installed per the manufacturer’s recommendations and

NFPA requirements.

Hydraulic Oil

Ratings and data for the FoamPro 3012 system are based

on operating with premium hydraulic fluids containing

oxidation, rust and foam inhibitors. These premium fluids

include premium turbine oils, API CD engine oils per

SAE J183, M2C33F or G automatic transmission fluids

(ATF), Dexron (ATF) meeting Allison C-3 or Caterpillar

TO-2 requirements.

The recommended hydraulic fluid operating viscosities

are typically 70 to 278 SUS (12 to 60 cSt) within the

recommended temperature operating range for optimum

performance. The hydraulic oil should have an ISO rating of

between 32 to 68 depending on climatic conditions.

Hydraulic Hoses and Fittings

High pressure hydraulic hoses and fittings are to be rated at

3000 PSI (207 BAR) minimum working pressure. To reduce

the potential for leaks at the hydraulic fittings, use SAE 37°

flare JIC type fittings or SAE straight thread O-ring fittings.

See the table for required fitting sizes, minimum hose

size, and minimum hose pressure ratings for the hydraulic

components in Section 15.

Foam Concentrate Suction Lines

Fittings and hoses from the foam tank to the inlet of

the foam pump must be supplied. Use 1-1/2" (38 mm)

minimum inside diameter or larger clear suction hose

depending on the viscosity of the foam concentrate. Many

Class B foams are more viscous and may require

1-1/2" (38 mm) minimum or larger inside diameter hoses.

Use fittings and components that are rated for 23" Hg

(584.2mm) vacuum and 50 PSI (3 Bar) pressure or better.

The components used must be compatible with the foam

11

Installation and Operation Manual

System 3012

concentrates used. Fittings used must be made of brass

or 300 series stainless steel. If a flushing system is to be

used, the pressure rating of those components subjected

to main water pump pressure are to be rated to 400 PSI

(28 Bar) or better.

A drain/air bleed valve should be provided to allow draining

of the tank and easier priming of the foam pump.

Foam Concentrate Discharge Lines

Fittings and hoses from the discharge of the foam pump to

the foam injection point must be supplied by the installer.

Hoses and fittings are to be 1/2" (12.7 mm) minimum inside

diameter, rated at or above 400 PSI (28 Bar) working

pressure. Fittings and hoses must be compatible with all

foam agents to be used with the system. Use fittings of

brass or 300 series stainless steel.

WARNING: Do not use air brake tubing for foam

systems as the tubing is not compatible with most

foam concentrates.

Foam Concentrate Tank(s)

Foam concentrate tanks must be supplied to suit the

capacity required for the apparatus application. The tank(s)

should meet NFPA minimum standards for the design

capacity, including filler size, vapor pressure venting and

drain facilities.

Check Valves

It is required by NFPA to install a check valve in the foam

concentrate injection line to prevent foam concentrate

flow from the foam tank to the injection point (at the main

waterway) due to static head pressure. The concentrate

check valve is included with each system.

It is recommended that check valves be installed in all water

line locations such as flush lines, where foam concentrate

could drain back into the water pumps or tanks of the fire

apparatus. As a minimum, one check valve should be

installed where the water piping that will supply foam

solution connects to the apparatus water pump discharge.

Drain lines must be provided from all water and foam

solution piping components to prevent freezing in cold

weather. Multiple drain systems that allow individual drain

lines to connect with one another may allow foam or water

to circumvent the check valves. Care must be taken to

avoid this possibility as contamination of the water tank,

foam tank or water pump may result.

Electrical Requirements

Electrical power and wiring must be supplied from

the main apparatus electrical system to the FoamPro

3012 system. The power must be supplied directly

from the battery without any connections to other high

power devices, such as primer pumps, hose reels, light

bars, etc., with its own disconnect switch or a switch

or contactor actuated by the battery disconnect switch,

PTO switch or other device.

The system can be operated with either a 12 VDC or

24 VDC, negative ground, power source. The system

should be protected with a 5 AMP fuse for 12 VDC or

24 VDC systems.

All system components should all be powered from the

same terminal and ground connections should all be

common. Use a standard 14 AWG automotive hookup wire.

NOTE: See "POWER SUPPLY" on pages 24-25 in the

Electrical Installation Section for important installation

information.

CAUTION: Always disconnect the ground straps,

electrical wires and control cables from the Digital

Display Control Module, the control valve driver

box, and any other FoamPro equipment before

electric arc welding at any point on the apparatus.

Failure to do so will result in a power surge through

the unit, causing irreparable damage and is not

covered under warranty.

12

Installation and Operation Manual

Because of the potential differences in apparatus

plumbing and foam system configuration, it is not

practical to depict exactly how each FoamPro unit can

best be installed onto a particular apparatus. Most of the

information contained in the following sections, however,

will apply to any situation.

NOTE: It is recommended that you read the following

sections thoroughly before beginning installation of

the FoamPro 3012. It is also recommended that you

spend time planning and designing where and how

you intend to install this unit in the apparatus before

beginning the actual installation.

Determine the locations of the components to be

installed such as foam tank(s), foam pump, oil reservoir,

oil cooler, foam strainers, tank valves, flowmeter(s) and

hydraulic pump. Try to place components in locations

that require the least amount of hoses and fittings.

Locate the FoamPro system components in an area

that is protected from road debris and excessive heat

buildup. Since the master power switch and CAL/

INJECT valve are components you may need to access,

it is recommended that they be installed in an accessible

location in the vicinity of the operator’s panel.

The foam pump unit should be mounted below the

discharge of the foam tank(s) to provide for gravity feed

to the foam pump. Locate the foam tank(s) where the

refilling can be easily done with 5 gallon (19 liter) pails

and other methods suitable to the end user. Most water

tank manufacturers will build foam tanks into the booster

tank. When specifying integral foam tank(s), make sure

provisions are made for installation of the low-tank

level sensor as well as foam suction connections and

tank drainage.

5 Installation Planning

Determine a location on the operator panel of the

apparatus for the Digital Display Control Module.

Consideration must be given for routing the control

cable from the Digital Display Control Module to the

hydraulic control valve and the main waterway

flowmeters. If necessary, order longer or shorter cable

assemblies to suit the location demands.

CAUTION: Never attempt to cut or lengthen the

molded cables. Doing so will result in RFI/EMI

interference. Contact the factory if molded cables of

a different length are required.

High viscosity foam concentrates (2000 centipoise and

higher), or inlet lines longer than 10 feet, will require

the foam intake to be one size larger. When larger inlet

piping is used, a larger foam strainer is required to

reduce the pressure drop. A 1-1/2” strainer is supplied

with the unit. If smaller line sizes are used, use reducer

bushings to reduce the fitting size down. Do not use

a smaller strainer, especially when using class B and

AR-AFFF foams.

Like any hydraulic system, the FoamPro 3012 will

require cooling. An oil cooler must be provided for the

system and consideration must be given to the location.

The cooler must be mounted in an area where adequate

cool air can flow over the cooler fins. The ideal location

for an oil cooler is in front of the apparatus engine

radiator. Consult the chassis manufacturer to ensure

adequate fan capacity is available to provide the proper

air flow.

When planning the installation, consideration must also

be given to the hydraulic supply pump location, drive

configuration and hose routing.

13

Installation and Operation Manual

System 3012

6 Hydraulic Control Valve Installation

Hydraulic-Driven Foam Pump Assembly

The foam pump assembly must be mounted in a

horizontal position. The base of the foam pump must

be anchored to a surface or structure that is rigid and

of adequate strength to withstand the vibration and

stresses of apparatus operation. Figure 6-1 provides the

mounting dimensions for the FoamPro 3012 foam pump

and motor assemblies.

CAUTION: Flexible hose connections are required

between the major FoamPro components and the

main water system. Do not hard plumb the system.

Position the hydraulic control valve and foam pump

assembly so the circuit breaker/on-off switch is easily

accessible. Be sure the hydraulic hoses and the foam

concentrate hoses can be properly routed to the inlets

and outlets on the foam pump. Foam concentrate

should gravity feed to the foam pump inlet from the

foam tank(s). The foam pump must be mounted in an

area to avoid excessive exhaust system heat buildup.

Protection must be provided for the hoses and wiring

to prevent chafing and abrasion during operation of the

foam system.

Protect the foam pump base from excessive road spray

and debris. Although the system is sealed and designed

to be resistant to the harsh environment of firefighting

apparatus, a protected location with easy operator

access is the recommended installation location.

TO LERANCES

UNLESS OTHERWISE SPECIFIED (+ OR -) INCHES

ANGLES (MACH): 5

?

FRACT. (MACH): 1/64

DECIMAL .XX : .01

DECIMAL .XXX : .004

SURFACE

FINISH

125

MAX

DWG BY: DATE:

CHECKED BY: DATE:

THIS DRAWING IS THE PROPERT Y OF HYPRO

AND WITHOUT WRITTEN AUTHORIZATION,MUST

NOT BE COPIED OR COMMUNICATED.

REV.

PART NUMBER

SURFACETREATMENTSCALE

HEAT TREATMENT

MATERIAL

PART DESCRIPTION

375 Fifth Avenue NW

New Brighton, MN 55112

(651) 766-6300

REV. ECN REVISION DESCRIPTION DATE

REV.

EXPERIMENTAL PART NO.

ENGRG REL: DATE:

DRAWING BASED ON

ASME Y14.5M-1994

DO NOT SCALE PRINT

THIRD ANGLE

PROJECTION

CHKD

PART NUMBER

FORM FM-EN-023 REV___

RCB

10/28/06

S107-3012

ASSY - OUTLINE, 3012

S107-3012

NONE

14 3/8"

16"

13/16"

4 9/16" 4 5/16"

8 9/16"

1.52

10 3/8"

12"

13/16"

2 5/8"

15 3/8"

24 7/8"

TO LERANCES

UNLESS OTHERWISE SPECIFIED (+ OR -) INCHES

ANGLES (MACH): 5

?

FRACT. (MACH): 1/64

DECIMAL .XX : .01

DECIMAL .XXX : .004

SURFACE

FINISH

125

MAX

DWG BY: DATE:

CHECKED BY: DATE:

THIS DRAWING IS THE PROPERT Y OF HYPRO

AND WITHOUT WRITTEN AUTHORIZATION,MUST

NOT BE COPIED OR COMMUNICATED.

REV.

PART NUMBER

SURFACETREATMENTSCALE

HEAT TREATMENT

MATERIAL

PART DESCRIPTION

375 Fifth Avenue NW

New Brighton, MN 55112

(651) 766-6300

REV. ECN REVISION DESCRIPTION DATE

REV.

EXPERIMENTAL PART NO.

ENGRG REL: DATE:

DRAWING BASED ON

ASME Y14.5M-1994

DO NOT SCALE PRINT

THIRD ANGLE

PROJECTION

CHKD

PART NUMBER

FORM FM-EN-023 REV___

RCB

10/28/06

S107-3012

ASSY - OUTLINE, 3012

S107-3012

NONE

14 3/8"

16"

13/16"

4 9/16" 4 5/16"

8 9/16"

1.52

10 3/8"

12"

13/16"

2 5/8"

15 3/8"

24 7/8"

Figure 6-1 Pump/Motor Assembly Dimensions

Foam Pump and

Foam Pump

Relief Valve

Foam Discharge

and Calibration

Ports 1/2" NPT

Foam

Pump

Inlet

1" NPT

13/32" Dia

Mounting Holes (4)

Pump Oil

Sight Level

Gauge

Pump Dipstick and

Oil Refill Port

Gearbox Dipstick and

Oil Refill Port

Outlet Port

#10 SAE O-ring

Port

Inlet Port

#8 SAE O-ring Port

Gearbox Oil

Sight Level Gauge

TO LERANCES

UNLESS OTHERWISE SPECIFIED (+ OR -) INCHES

ANGLES (MACH): 5

?

FRACT. (MACH): 1/64

DECIMAL .XX : .01

DECIMAL .XXX : .004

SURFACE

FINISH

125

MAX

DWG BY: DATE:

CHECKED BY: DATE:

THIS DRAWING IS THE PROPERT Y OF HYPRO

AND WITHOUT WRITTEN AUTHORIZATION,MUST

NOT BE COPIED OR COMMUNICATED.

REV.

PART NUMBER

SURFACETREATMENTSCALE

HEAT TREATMENT

MATERIAL

PART DESCRIPTION

375 Fifth Avenue NW

New Brighton, MN 55112

(651) 766-6300

REV. ECN REVISION DESCRIPTION DATE

REV.

EXPERIMENTAL PART NO.

ENGRG REL: DATE:

DRAWING BASED ON

ASME Y14.5M-1994

DO NOT SCALE PRINT

THIRD ANGLE

PROJECTION

CHKD

PART NUMBER

FORM FM-EN-023 REV___

RCB

10/28/06

S107-3012

ASSY - OUTLINE, 3012

S107-3012

NONE

14 3/8"

16"

13/16"

4 9/16" 4 5/16"

8 9/16"

1.52

10 3/8"

12"

13/16"

2 5/8"

15 3/8"

24 7/8"

Motor Case Drain

#6 SAE

O-ring Port

Load Sense Port

#6 SAE O-ring Port

14

Installation and Operation Manual

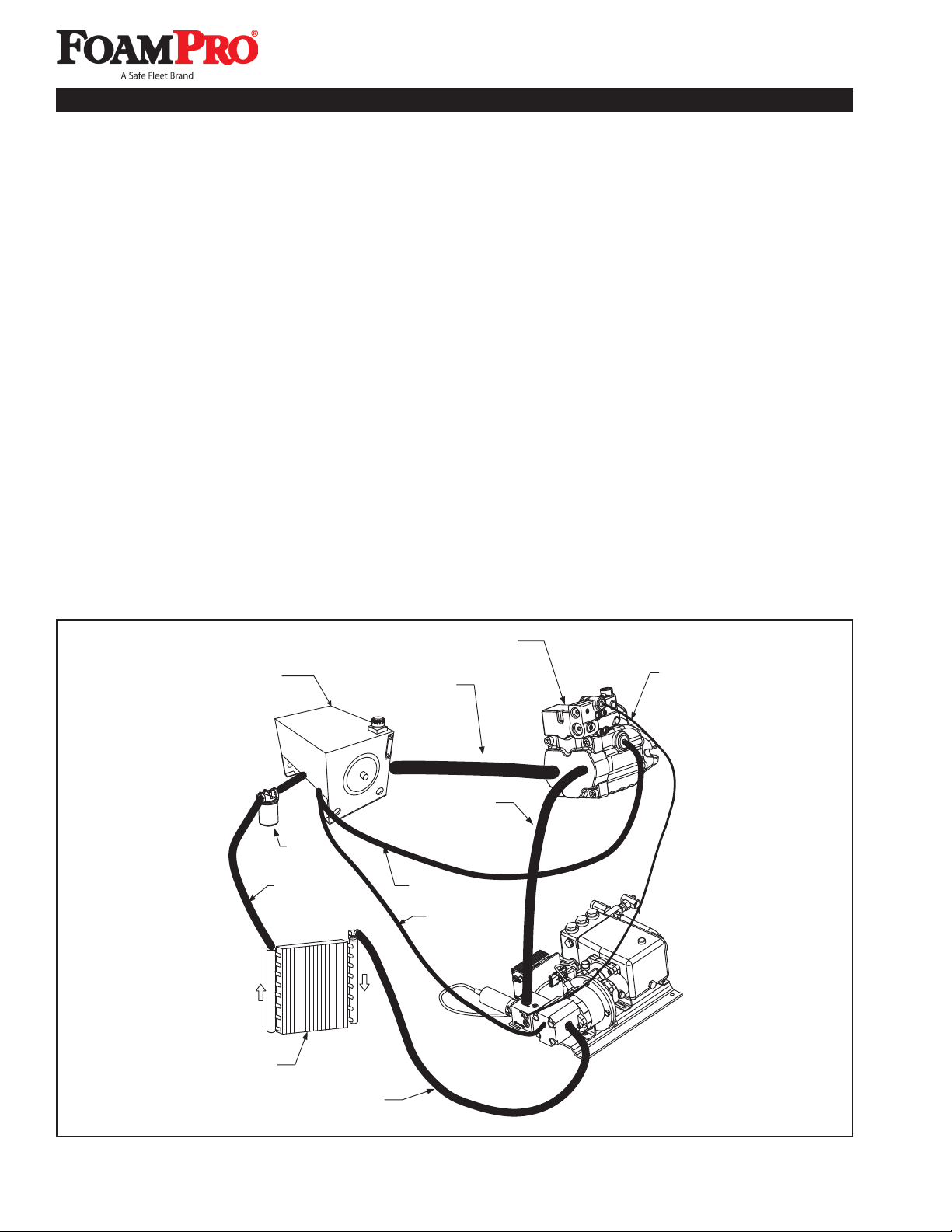

7 Hydraulic Plumbing Installation

Figure 7-1 provides some recommended guidelines for

the location of the hydraulic system components. When

making hydraulic component connections, ensure all

applicable DOT and SAE standards are followed. Use

hoses and fittings rated at 3000 PSI (207 BAR) working

pressure for the hydraulic oil high pressure lines. See

Section 15 for required fitting sizes, minimum hose size,

and minimum pressure ratings.

The fittings required to connect the hydraulic hoses

to the FoamPro 3012 and hydraulic supply pump are

SAE ORB (O-Ring Boss) fittings with SAE JIC 37° flare

swivel connections.

CAUTION: To ensure the integrity of fitting connections

in the hydraulic system, use only SAE JIC 37° flare,

SAE O-Ring Boss, or equal type hose connections.

CAUTION: Use only approved petroleum-based

hydraulic fluids as described in Section 4.

Never mix fluid types. Ensure all hoses and seals

are compatible with fluids used. Do not use water or

glycol-based fluids. Do not use phosphate ester-type

fluids. Other hydraulic fluids such as SAE 10W-40HD

motor oil are too viscous for proper load-sense

pump performance.

Hydraulic Power Source

The hydraulic power for the FoamPro 3012 system is

supplied by a hydraulic load-sensing pump mounted

on the fire apparatus engine, transmission, or auxiliary

PTO. The hydraulic pump supplied with the system has

been chosen to provide the required flow and pressure

to drive the FoamPro 3012 system.

Refer to Section 4 of this manual for further pump and

PTO information and Section 15 for detail dimensions

of the pump. See the table in Section 15 for all proper

hose sizes, pressure ratings, and fittings for the various

hydraulic components supplied by FoamPro.

Figure 7-1 FoamPro 3012 Hydraulic System Diagram

Hydraulic Reservoir

System Filter

System Return

Hydraulic Oil Cooler

Hydraulic Motor Return

Hydraulic Pump

Suction Line

Hydraulic Pump

Discharge

Hydraulic Pump

Case Drain

Hydraulic

Motor

Case Drain

Hydraulic Pump

Load Sense Line

Load Sensing

Hydraulic Pump

15

Installation and Operation Manual

System 3012

Oil To

Reservoir

Oil From

Hydraulic

Motor

Thermostat

Control

Valve

Electric

Fan

Oil

Cooler

Hydraulic Reservoir

The hydraulic reservoir for the system is to conform

to the description in Section 4 and to all SAE and

DOT standards. See table in Section 15 for minimum

reservoir capacity for the unit being installed.

Hydraulic Oil Cooler

An oil cooler is required in the hydraulic system to

ensure proper oil temperature for optimum performance

and to avoid damage to the hydraulic components.

The actual cooler size required will depend on the

system requirements, the location of the cooler, and

the manufacturer of the cooler. Typical oil to air cooler

connections are shown in Figure 7-2. The cooling

requirements for the system being installed are listed in

the table in Section 15.

If an oil to water exchanger is used, proper

maintenance, mounting, and operating procedures must

be maintained. A method to circulate cool, fresh water

must be provided when the hydraulic pump is engaged.

A drain port must also be provided to prevent freezing

and to allow flushing.

Hydraulic Supply Pump Connections

After completion of the mounting of all hydraulic system

components, hose connections must be made. A table

in Section 15 shows the connector and minimum hose

sizes, and Figure 7-3 shows the connection ports to

use for the hydraulic supply pump. Always use the

uppermost case drain port available.

Load-Sense Pump Adjustment

The supplied load-sensing hydraulic pump does not

require any adjustment. The load-sensing compensator

is adjusted to give you maximum performance

throughout the entire operating range. The adjustment is

set with the hydraulic pump engaged and the FoamPro

3012 turned off. The hydraulic pressure will be 700 PSI

(48 BAR) and output flow rate will be 2 to 4 GPM (7.5 to

15.2 lpm). When the FoamPro 3012 system is engaged,

the load-sensing pump will supply the required hydraulic

flow and pressure to operate the system.

Hydraulic Motor Control Valve

The hydraulic motor control valve is adjusted at the

factory for optimum performance. The valve is not to be

removed or adjusted.

Figure 7-2 Oil Cooler Hose Connections

Figure 7-3

Hydraulic Supply Pump Connection Ports

Pressure

Compensator

Adjustment

Load Sense

Adjustment

Load Sense Port

#4 SAE O-ring Port

Inlet Port

#24 SAE

O-ring Port

Outlet Port

#16 SAE

O-ring Port

Case Drain

Port #10

SAE O-ring

Port

16

Installation and Operation Manual

Foam Tank

Water Tank

Water Pump

Water Flowmeter

Line Strainer

Foam Pump Assy.

Check Valve

Check Valve

(Optional)

Main Waterway

Check Valve

Flush Water

Shutoff Valve

Foam Tank

Shutoff Valve

Outboard

Pickup

Foam Injection Point

Single Discharge

Calibrate/Inject Valve

Foam Injection Check Valve

Hydraulic Motor

and Control Valve

Hydraulic Valve

Control Driver

Foam Tank

Low-Level

Sensor

Digital Display Controller

Multiple Discharge

with Manifold

Installation and Operation Manual

8 Plumbing Component Installation

Figure 8-1 provides recommended guidelines for the

installation of the system components that handle water,

foam concentrate and foam solution. Note that additional

options such as dual-tank system, multiple flowmeters,

etc., are covered by the individual manuals included

with those systems and consideration must be given to

potential interferences.

Figure 8-1 FoamPro 3012 System Piping

Water and Foam

Speed Sensor

CAUTION: Flexible hose connections are required

between the major FoamPro components and the

main water system. Do not hard plumb the system.

Foam Pump Discharge Relief Valve

The discharge relief valve on the outlet port of the

hydraulically-driven foam pump is preset at the factory

to ensure optimum performance of the FoamPro 3012

system.

Power & Ground

Connection Pin

A (Red) + 12 VDC

to + 27 VDC Pin B

(Black) Ground

17

Installation and Operation Manual

System 3012

Installation and Operation Manual

Calibrate/Inject Valve

The calibrate/inject valve is supplied in the fitting kit

and is to be positioned as shown in Figure 8-1 in the

system. This valve must be accessible by the pump

operator during normal operations. The valve is a 3-way

directional control valve that selects where the output of

the foam system will go. Check to make sure the valve

is installed properly. Look at the ports as you move the

selector handle. The flow should go from the center port

to each of the end ports.

The hoses to and from the valve should be 1/2"

(12.7 mm) inside diameter and be pressure rated to

400 PSI (28 BAR) minimum working pressure or the

maximum discharge pressure of the fire pump. Fittings

are to be 1/2" NPT and made of brass or stainless steel

with the same minimum pressure rating as the hoses.

The hose(s) from the calibrate side of the valve(s) may

have a lower pressure rating since it is used for system

calibration only and is always vented to the atmosphere.

If the system is to be tested to NFPA standards, the

calibrate side hoses must be rated to 400 PSI (28 BAR).

The hose(s) from this port must be long enough to reach

a container outside the apparatus and may be coiled for

storage when not in use.

Line Strainer

The line strainer provided with the FoamPro 3012

system is sized properly for most applications. See

Section 4 for further information. The appropriate

strainer is to be installed on the inlet side of the foam

pump. The hose from the foam tank should have

adequate wall stiffness to withstand the vacuum of the

foam pump while it is running without collapsing [23" Hg

(584 mm HG)].

CAUTION: If a pressurized water flush system

is incorporated, the plumbing exposed to this

pressure must be rated at or above the operating

pressure or a minimum of 400 PSI (28 BAR).

Main Waterway Flowmeters

The FoamPro 3012 system is designed to accept flow

reading signals from the FoamPro paddlewheel-style

flowmeter. Proper flowmeter sizing is critical to system

accuracy. Select a flowmeter size based on actual

flows required, not standard pipe sizes. Refer to the

installation drawing in Section 15 for proper flowmeter

sizing.

The flowmeters require that the amount of turbulence

in the pipe being monitored is as low as possible.

Excessive turbulence produces unstable and inaccurate

flow readings. The following installation guidelines will

help attain the best readings and maintain accuracy of

the FoamPro system.

1. A minimum 5 times the pipe diameter of straight

run pipe without any fittings is necessary upstream

of the flowmeter. 10 times is better. The longer the

straight run, the lower the turbulence. The following

are the recommended straight run lengths for given

pipe sizes:

Pipe Recommended

Size Straight Run Pipe

1-1/2"’ (38 mm) 7-1/2 to 15" (191 to 381 mm)

2" (50 mm) 10 to 20" (254 to 508 mm)

2-1/2" (64 mm) 12-1/2 to 25" (317 to 635 mm)

3" (76 mm) 15 to 30" (381 to 762 mm)

4" (100 mm) 20 to 40" (511 to 1016 mm)

2. The downstream plumbing of the flowmeter is not

as critical, but straight runs without fittings help

maintain accurate flow readings. A minimum 5 times

the pipe diameter is recommended.

3. Do not mount a flowmeter directly after an elbow

or valve. Valves create severe turbulence when

they are “gated down” as shown in Figure 8-2.

4. Try to mount the flowmeters in a position that is

accessible for routine inspection and maintenance.

The FoamPro paddlewheel-style flowmeter fittings

are specially designed tees that make inspection and

maintenance of the flow sensor easy. The threads of the

tees are available in NPT with grooved victaulic ends, or

BSP with grooved victaulic ends. In horizontal runs, the

tees should be mounted as close to upright as possible

within the range shown in Figure 8-3.

With the use of a MultiFlo interface, two to four

flowmeters may be monitored simultaneously. A single

injection point that will supply foam agent to all foam

discharge outlets is required. See Form 880 provided

with the MultiFlo System for further information

Injection Point

The position of the injection point MUST be in a place

that is common to all discharges which require foam

capability. This position may be before or after the main

water flowmeter, but not within the straight run distance

required for the flowmeter as previously described.

A separate injection point is not possible for each

discharge. If multiple flowmeters are used, the injection

point must be installed before the flowmeters at the inlet

to their common manifold (See Figure 8-4).

18

Installation and Operation ManualInstallation and Operation Manual

Figure 8-2 Flowmeter Placement

Figure 8-3 Flowmeter Position Range

NOTE: Most foam concentrates by nature mix with

water very quickly, so each discharge from a manifold

will receive equal amounts of foam concentrate if the

manifold is properly designed and installed. A static

mixer or special mixing considerations may need to

be designed into the system, especially when using

thicker foam concentrates and those that may not

readily mix with water.

Foam Concentrate Check Valves

Check valves are provided to prevent foam concentrate

flow from the concentrate tank through the injection

point and into the main waterway when the system is

not in use. This is a NFPA requirement. See Figure

8-1 for component placement. The concentrate check

valves have a minimum cracking pressure of 12 PSI

(0.8 BAR) and are pressure rated to 400 PSI (28 BAR)

minimum working pressure. It is a good idea to inject

foam concentrate at a horizontal or higher angle to allow

water and debris in the water line to drain away from the

check valve(s) as shown in Figure 8-5. This will avoid

sediment deposits or formation of an ice plug in cold

weather applications.

Main Waterway Check Valves

A check valve positioned in the main waterway prior to

the injection point must be installed. This will prevent

foam solution in the waterway from entering the pump,

the main water tank, and other clean water suction

connections as shown in Figure 8-6.

CAUTION: The check valve is not to be used as a

substitute for proper flushing of apparatus lines

after usage.

Flushing System

Depending on the corrosiveness of the foam

concentrates used, or when changing foam concentrate

types or manufacturers, a flushing system must be

installed. Generally all Class B foam concentrates must

be flushed from the system after usage. Most Class A

foam concentrates are less corrosive and do not require

flushing after each usage. See Figure 8-7 for a typical

flushing system plumbing schematic.

Figure 8-4 Injector Fitting Placement

for Multiple Discharge

Figure 8-5 Foam Injector Position

DO

DON’T

Injector Above

Horizontal Plane

Injector Below

Horizontal Plane

Injection

Point

19

Installation and Operation Manual

System 3012

Flushing Foam Pumps

When returning the apparatus to ready condition after

foam operations, the FoamPro foam pumps should be

flushed. The following procedures can be used to flush

the foam pumps. Refer to Figure 8-7 and do the following:

1. Energize apparatus and establish water flow

through foam solution discharge.

2. Close foam concentrate tank shut-off valve and

open flush water supply valve.

3. Energize FoamPro 3012 and allow electric motor

driven foam pump to run until discharge is clear.

4. Shut off FoamPro 3012 system by depressing the

FOAM button on the Digital Display Control Module.

Close flushing water supply valve.

5. Close foam solution discharge and shut

down apparatus.

6. Open foam concentrate tank shut-off valve.

7. Perform required maintenance checks on the

FoamPro 3012.

Figure 8-6

Recommended Pump Installation

Main Waterway

Check Valve

Injection Port

(Optional location

on other side of

Flowmeter)

Flowmeter

Drain Port

Minimum length of nipple for

2-1/2’’ pipe is 12-1/2’’ (318 mm).

Refer to Table on Page 17 for

recommended nipple lengths for

different pipe sizes.

Drain Lines

On apparatus with multiple drain lines, the drains from

the foam solution discharge line should not be piped

into a multi-drain system before the check valves. The

standard multi-drain system from most manufacturers

will allow cross talk between the drain lines and the

apparatus water tank, resulting in contamination of

the water tank with foam. A separate drain system

should be provided for the foam solution piping to

prevent contamination of the water tank and fire pump.

Figure 8-7

Foam Concentrate Flushing System Diagram

From

Fire

Pump

From Foam

Tank

Check

Valve

Flush Water

Shutoff Valve

Swing Check

Valve

Appropriate ID

Hose

Foam Strainer

Mounted On Foam

Pump Inlet

20

Installation and Operation Manual

Outboard Pickup

An outboard pickup may be adapted to the foam pump

inlet. The pickup should be positioned between the foam

tank shutoff valve and the foam inlet line strainer. A tee

the same size as the tank to pump line, may be placed

in the suction line with the side leg of the tee going to

the outboard pickup shutoff valve at the panel. A sealed

quick connect-type fitting may be mounted to the panel

for easy access. The outboard pickup line should not

exceed 10 feet and the same line size and specifications

as the tank to pump line should be utilized. The shutoff

valves must be full-ported valves and be air tight.

A switch must be provided to disengage the low-level

sensor when using the outboard pickup. This switch

may be a separate panel-mount or one that is tied into

the pickup valve actuator.

NOTE: The tank shutoff valve must be closed before

opening the outboard valve when switching to

the off-board pickup. The off-board pickup valve

must be closed before opening the tank valve when

switching to the foam tank operation.

Figure 8-8

Outboard Pickup Diagram

Strainer

Outboard

Pickup Line

Full-Ported

Shutoff

Valve

Full-Ported

Shutoff Valve

Switch to disconnect

Low-Level Sensor

when in Off-board

Operation

Foam

Tank

Driver

Box

Foam

Pump

Assy.

Other manuals for 3012

1

Table of contents

Other FoamPRO Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

PCB Piezotronics

PCB Piezotronics IMI SENSORS 628F61 Installation and operating manual

Grundfos

Grundfos DIT-M Installation and operating instructions

Circutor

Circutor QNA 412 user manual

Seiwa

Seiwa SW RP05 operating instructions

BAFANG

BAFANG DP C171.CAN user manual

Honeywell

Honeywell Chadwick-Helmuth 8500C Maintenance manual