Contents

1 About this document........................................................................ 5

1.1 Information on the operating instructions.............................................. 5

1.2 Related applicable documents................................................................ 5

1.3 Scope......................................................................................................... 5

1.4 Explanation of symbols............................................................................ 6

1.5 Further information................................................................................... 7

2 Safety information............................................................................ 8

2.1 Intended use............................................................................................. 8

2.2 Improper use............................................................................................. 10

2.3 Cybersecurity............................................................................................ 10

2.4 Limitation of liability................................................................................. 11

2.5 Modifications and conversions................................................................ 11

2.6 Requirements for skilled persons and operating personnel.................. 11

2.7 Operational safety and specific hazards................................................. 12

3 Product description........................................................................... 14

3.1 Product ID.................................................................................................. 14

3.2 Product characteristics............................................................................ 16

4 Transport and storage....................................................................... 24

4.1 Transport................................................................................................... 24

4.2 Unpacking.................................................................................................. 24

4.3 Transport inspection................................................................................. 24

4.4 Storage...................................................................................................... 24

5 Mounting............................................................................................. 25

5.1 Overview of mounting procedure............................................................. 25

5.2 Preparing for assembly............................................................................. 25

5.3 Mounting location..................................................................................... 28

5.4 Mounting the device................................................................................. 28

5.5 Mounting external components............................................................... 30

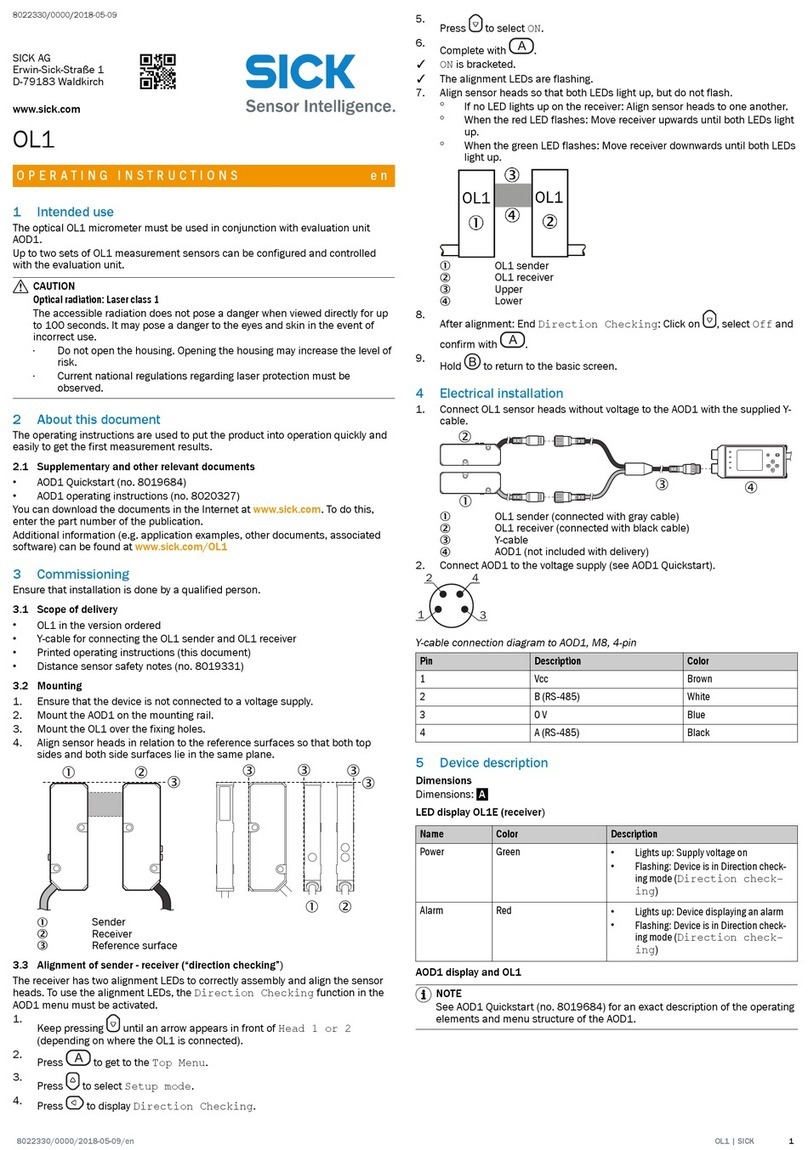

6 Electrical installation........................................................................ 31

6.1 Safety......................................................................................................... 31

6.2 Wiring instructions.................................................................................... 35

6.3 Overview of all interfaces and connection options................................ 35

6.4 Pin assignments of electrical connections............................................. 39

6.5 Instructions for electrical installation when the ambient temperature

can fall below 0°C................................................................................... 41

6.6 Connecting the supply voltage................................................................. 42

6.7 Wiring the digital input............................................................................. 43

6.8 Wiring the data interface.......................................................................... 45

7 Commissioning.................................................................................. 46

CONTENTS

8024536/18Y1/2022-12-12 | SICK O P E R A T I N G I N S T R U C T I O N S | RFU61x PoE 3

Subject to change without notice