The NLSW45-3Ex is suitable for monitoring flows of gaseous media in zone1 + temperature class T3 (NLSW45-

3Ex) in conjunction with the airflow sensor F3Ex and 2 Z-barriers.

The F3Ex sensor can be used in zone 1 as defined in EN60079-14= VDE0165 part l1, section 3.21 as a "simple

electrical equipment". In this case, it does not require certification.

The NLSW45-3Ex control unit has to be installed and operated outside the explosion hazard area! The Z-barriers

are ATEX approved: TÜV 99 Atex 1449 X II (1/2) GD C [EEx ia/ib] IIC

The switching hysteresis is at a fixed setting. A break contact which can be adjusted from 2s to 60s is included

as standard. If the start for the bridging period is not activated, the break contact is activated when appliance is

switched on.

The onus is on the installing company and the equipment operator to ensure compliance with the relevant

national explosion hazard regulations. Avoid static charging of plastic and cable parts. Ensure that the

appliances are effectively protected from damage. The fixed installation and effective protection of sensor

cables against damage are essential.

One area of application is, for instance, to monitor the cooling of the motor in the direction of flow

behind the unit to be cooled. The exhausted air temperature in this area can rise to 80°C and above.

The standard switching delay is 0,2 s. A delay of up to 10 s is possible on request. The switching

hysteresis is at a fixed setting. A break contact which can be adjusted from 2 s to 60 s is included as

standard. If the start for the bridging period is not activated, the break contact is activated when

appliance is switched on. This appliance can monitor thin liquid media (up to 10 bar) in conjunction

with the F3Ex sensor at a temperature range of 0…+60 °C.

Examples of possible applications include:

- Monitoring of filling levels

- Detection of air bubbles in a closed system

- Detection of stoppages and movements greater than 1 cm/s

Technical data

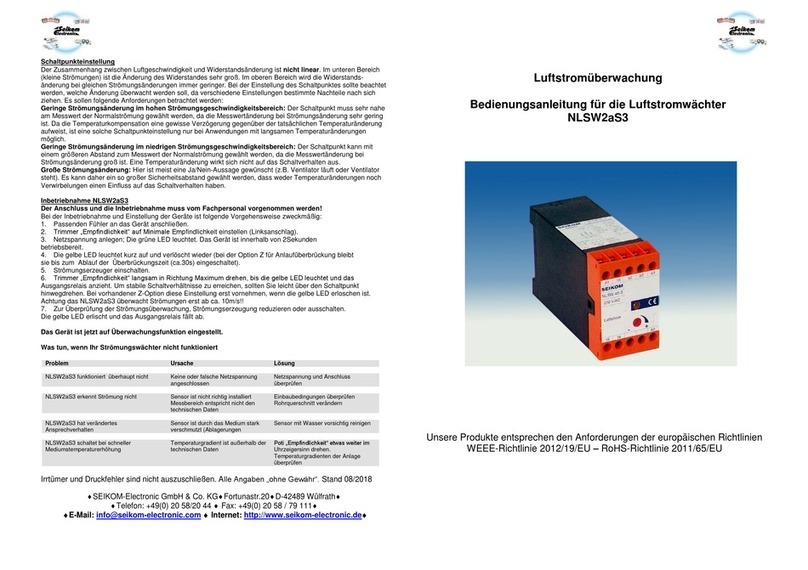

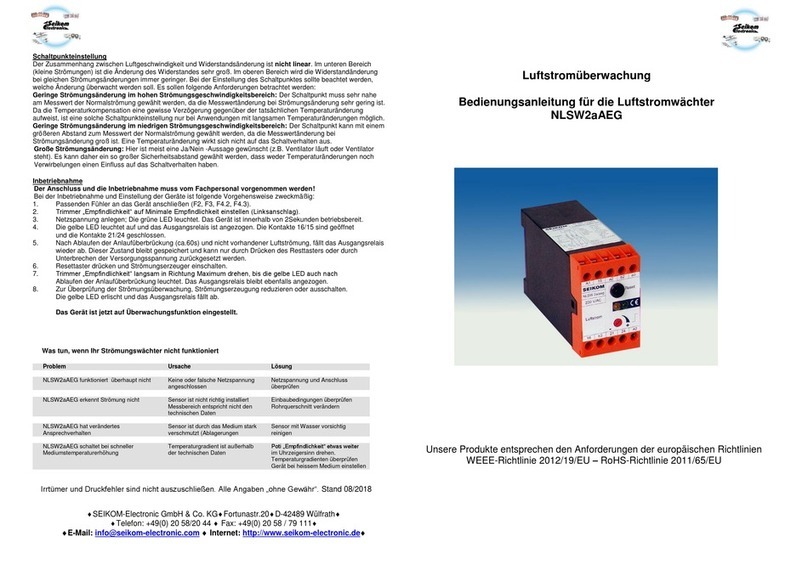

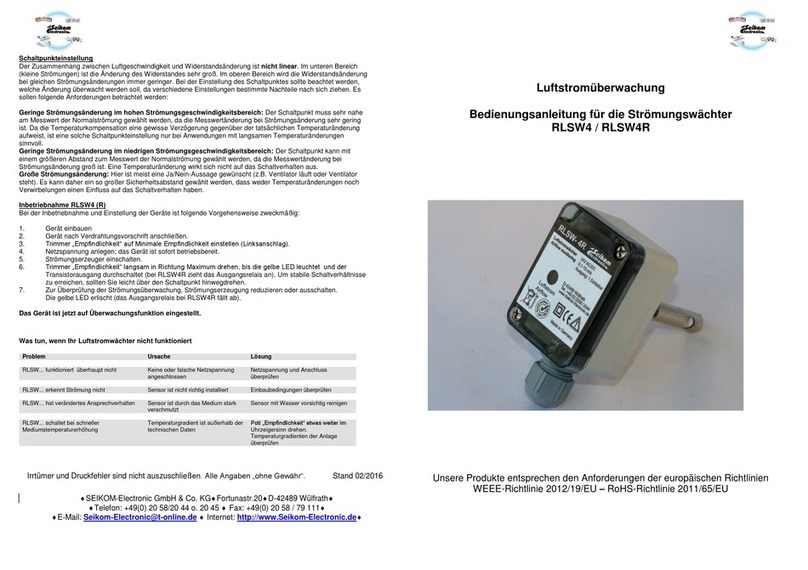

Type NLSW45-3Ex NLSW45-3Ex

Article-number 77029/Ex 63377/Ex

Operating voltage 24V AC/DC 230V/AC

Voltage tolerance ± 5% ± 6%

Over voltage category II II

Signal lamp, voltage Green LED Green LED

Power consumption 4VA 4VA

Ambient temperature -20..+60°C -20..+60°C

Switching output Relay, 1 change-over contact Relay, 1 change-over contact

Relay output 250VAC, 10A, 2.5kVA 250VAC, 10A, 2.5kVA

Airflow monitoring Relay energised when airflow

is present Relay energised when airflow

is present

Signal lamp, airflow Yellow LED Yellow LED

Start up delay Adjustable approx 5 - 60 s Adjustable approx 5 - 60 s.

Signal lamp, start up delay - -

Media temperature range -20..+120°C -20..+120°C

Adjustment of the switching point With potentiometer With potentiometer

Airflow range 0,1-20 m/s 0,1-20 m/s

Measuring probes F3Ex, F3.2Ex F3Ex,F3.2Ex

Electrical connection 10 Terminals, 2.5 mm² 10 Terminals, 2,5 mm²

Type of protection, housing IP40 IP40

Type of protection, terminals IP20 IP20

Contamination class 2 2

Dimensions L=120mm; B=45mm; H=73mm L=120mm; B=45mm; H=73mm

Certification symbols CE , TüV CE, TüV

Measuring principal

A temperature-sensitive resistor is heated according to the calorimetric measuring principle. The

temperature-sensitive resistor is heated by a second resistor. A flow in the medium dissipates heat from the

measuring resistor, causing the resistor temperature an impedance to change. This temperature change is

evaluated. Since both the velocity and the temperature of the flowing medium affect the dissipated heat, a

relationship must be created between flow an temperature. For his purpose, a second temperature-

dependent measuring resistor is located next to the first one. The second measuring resistor (temperature

compensation) is not heated and is only used for the temperature measurement.

Airflow > / = switch point Switching output is energised Yellow LED "Airflow" switch on

Airflow < switch point Switching output is not energised Yellow LED "Airflow" switch off

Installation Instruction F3-Ex

To avoid measurement errors, please bear the following points in mind when selecting the measurement location:

•The length of cable between the sensor and monitoring appliance should not be more than 100m. If the

sensor cable is laid in a conduit with other live cables (e. g. for monitors or solenoid valves), we

recommend the shielding of the sensor cable. The sensor must be connected with the evaluation unit

corresponding to the connection diagram. Incorrect connection leads to faulty operation.

•The sensor should be mounted in such a way that the air flow passes through the lateral opening. The

marking is intended as an assembly aid.

•Install the F3-Ex where is low turbulence, if possible.

•Do not install directly behind bends (distance approx 10 x bend radius).

•Install the probe in the middle of the duct (distance at least 1/3 of the duct diameter from the wall).

•Do not install directly behind the heating register (rapid changes in temperature may lead to the measured

values being falsified).

Cleaning

The airflow sensor contains a sensor element which is sensitivity to mechanical loading and which must not be touched

with hard and pointed objects. Any cleaning that may be necessary is possible in water (also with addition of detergents).

Let the unit drip off and dry renewed start-up.

Attention!!

Connection and commissioning must be performed by properly authorized and qualified personnel!

Connection to mains supply (L, N) must be made by means of a protected isolating switch with the usual

fuses. As a matter of principle, the General VDE Regulations must be complied with (VDE 0100, VDE 0113,

VDE 0160). If the potential-free contact is connected to an extra-low safety voltage, sufficient insulation

must be provided for the connecting cables up to the terminal, since otherwise the double insulation to

the mains voltage side may be impaired. The current load capacity of the potential-free contact is limited

to 10 A. Therefore, the electrical circuit of the potential-free contact must be protected by a 10.3 A fuse.