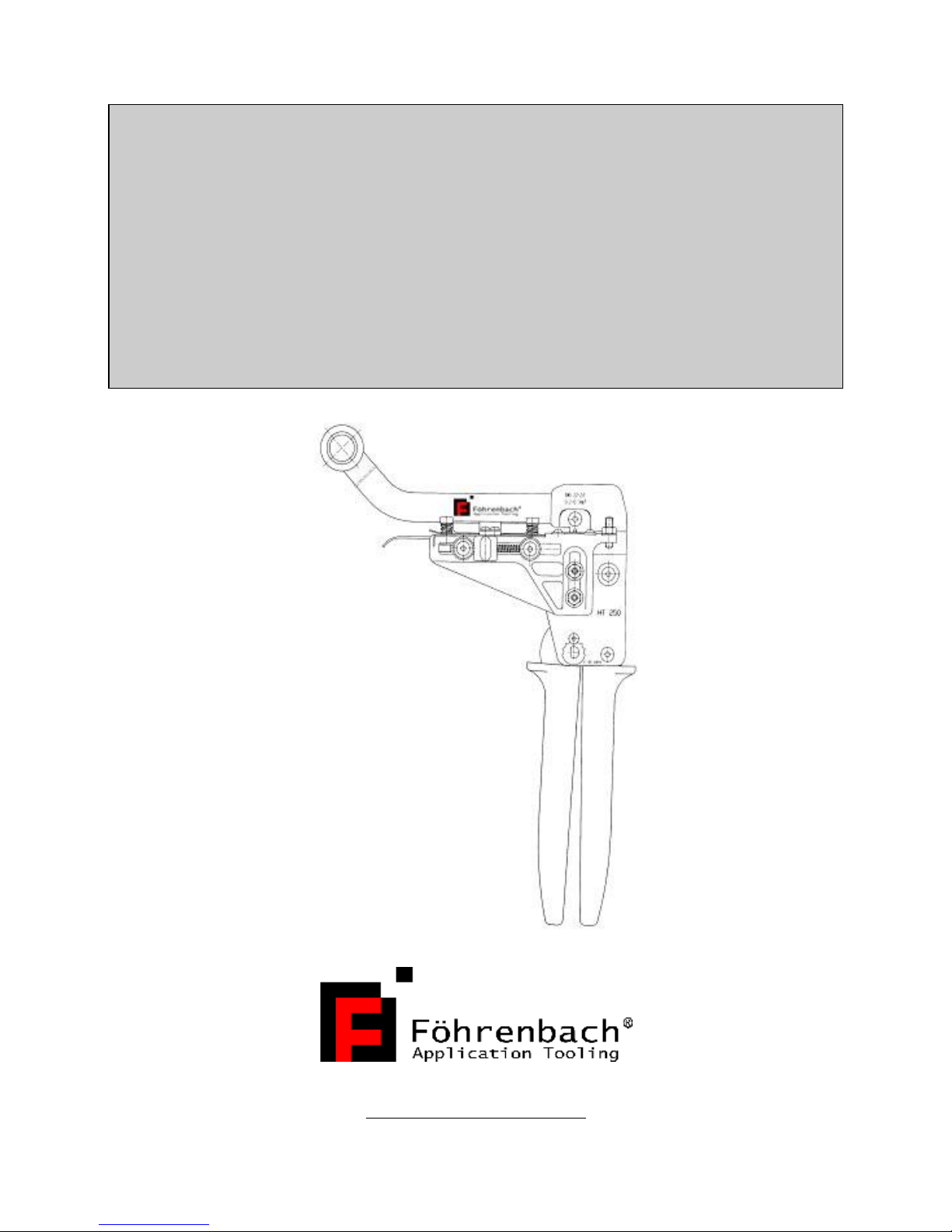

Foehrenbach HT250 User manual

HT250

HandpistolforDubox

AWG 22-24

User’sguide

www.foehrenbach.be

Instruction manualHT250 www.foehrenbach.be

Date: August 2007 Documentrev. : 6Page : 2/ 11

CONTENTS

1.DESCRIPTION..................................................................................................3

2.OPERATING INSTRUCTIONS..........................................................................3

3.ADJUSTMENTS................................................................................................4

4.MAINTENANCE.................................................................................................5

5.PARTS...............................................................................................................7

6.COMPANYADDRESS......................................................................................10

CERTIFICATEOFCONFORMITY..........................................................................11

Instruction manualHT250 www.foehrenbach.be

Date: August 2007 Documentrev. : 6Page : 3/ 11

1. DESCRIPTION

ThehandtoolHT250isdesigned tocrimpDuboxterminalswithsmall reelinthewirerange

AWG 22-24.

Theterminalsareguidedinafeed track,fedwithhand (yellowlever),positionedincrimp

toolingandcrimped.DuringthecrimpactiontheDuboxterminaliscutofffromthecarrierstrip.

2. OPERATING INSTRUCTIONS

1.Placethehandtoolinyourlefthand,sothatthemovablehandle(item11 ,figure1)may

beactuatedbyyourthumb.

2.Actuatewiththerighthandthe yellowlever(item6,figure2)whichfeedstheDubox

terminalintothecrimpingarea.

3.Usewirewhichisstrippedoveralengthof2.75 ±0.25mm.

4.Placethewireintothebarreloftheterminalsothattheendofthewiretouchesthewire

stop.

5.Closethehandtoolbymoving themobil handlewhilethe wireisheldinposition.

6.Whenthehandtooliscompletelyclosed,the movablehandle

(item11,figure1)maybereturnedtoitsstartingposition.

7.Finallytakethecrimped terminalfromthehandtool.

Note:

Thehandtoolhasstops,whichpreventsopening thetoolbeforethe crimpaction is

completed. Shoulditbenecessary,the stopcanbereleasedbyturningtheratchet wheelat

thebackofthetoolinthedirectionindicatedbythetwoyellowarrows.Keepthemovable

handleunderlightpressureduringthisoperation.

Instruction manualHT250 www.foehrenbach.be

Date: August 2007 Documentrev. : 6Page : 4/ 11

3. ADJUSTMENTS

Adjustmentsofcrimpheight:

Eventually, thetoolhingescanwear,sothat the crimpheightmustbereadjusted(see

belowspecifiedheight).

Thisisdonebylooseningthescrew(item21,figure1)androtatingthestoprings

(item20 , figure1)onestoptochange thecrimpheight approximately0.05mm (0.002

inches).

Adjustmentoffeedtrack unit (seefigure2)

CAUTION:Noadjustmentsshouldbemadewithscrew(item21,fig1),nut(item22,

fig1)andwithscrew(item23,fig1).

Adjustmentoffeeding:

Loosenscrews(item13,fig2)and turnscrew(item27,fig2)tothe left forfurther

feedingofterminaland tothe rightforlessfeeding.The fed terminalmustlayabove

theanvil.Tightenscrew(item13,fig2)afteradjustment.

Adjustmentofcutterplate:

Loosenscrews(item18,fig2)andplacecutterplate(item19,fig2)againstthe anvil.

Tightenscrews(item18, fig2)afteradjustment.

Note:1)Duringadjustmenthandtoolmustbeinclosedposition.

2)When closinghandtool(withoutterminal),thecutterplatemaynotmoveup.

Adjustmentofterminalposition:

Loosenscrews(item18, fig2)andadjustterminalpositioner(item17,fig2)sothatthe

feed fingerlocatestheterminalsthroughthepilotholes.Tighten screws(item18, fig2)

afteradjustment.

Note: 1)The terminalpositionermaynotdamage theinsulation barrelorwirebarrel

ofterminal.

2)Thisadjustmentmayaffectthebellmouthoftheterminal.

Instruction manualHT250 www.foehrenbach.be

Date: August 2007 Documentrev. : 6Page : 5/ 11

4. MAINTENANCE

•Regularchecksmustbemade forpossiblegoldbuild-uponcrimperandanvil.

•Ifnecessary,thesepartsmaybecleaned.

•Damagedpartsmust bereplacedimmediately.Forpartnumbersseepartslist.

Attention!

-Applythetoolonlyforthepurposeasmentionedinchapter1.

-Applythetoolonlyinadryandwell illuminated environment(1000lux).

-Applyalwaysacorrecteyeprotection.

Instruction manualHT250 www.foehrenbach.be

Date: August 2007 Documentrev. : 6Page : 6/ 11

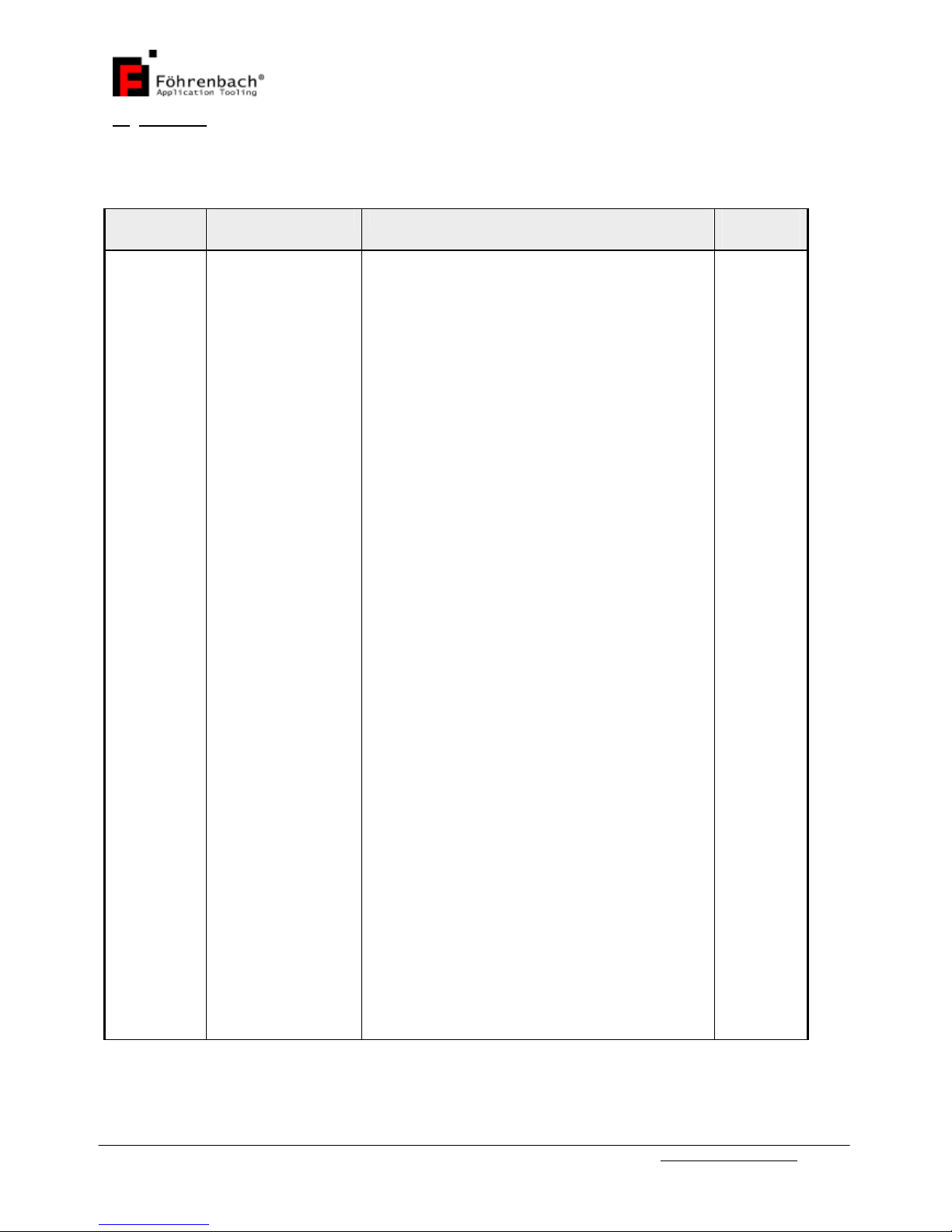

Figure1

Instruction manualHT250 www.foehrenbach.be

Date: August 2007 Documentrev. : 6Page : 7/ 11

5. PARTS

Partsforfigure1

itemno part No description

qtyper

assy

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

26

27

28

29

35

37

38

39

40

41

42

43

44

45

180998

5315-001-002

172391

172392

180999

172397

181000

181001

181002

181003

181004

181005

172388

190583

181006

172394A

181007

5315-001-009

5305-003-006

190582

5305-003-050

191623

5305-003-009

180699

5315-001-008

5305-004-008

181008

5305-001-017

5305-003-009

181009

181010

191607

191608

5310-001-006

191609

5305-035-003

191610

5305-003-008

Housing

Dowelpinø2x9,7

Pawl

Extensionspring No19

Handle,permanent

Connectingpin

Spacerplate

Retainer

Retainercoverplate

Connectingplate

Handle, mobile

Shaft

Hingepin

Stoproll

Eccentricpin

Extensionspring No35

Coverplate

Dowelpinø3m6x12

But.hd.capscrewM4x7

Stopring

But.hd.capscrewM3x4

Feedingstop

But.hd.capscrewM4x16

Crimpunit

Dowelpinø3m6x10

Hex.soc.c’sinkhdscrewM4x10

Guidingblock

Soc.hd.cap screwM3x12

But.hd.capscrewM4x14

Bushingø6

Bushingø8

Reelbracket

RodendM6

Hexnut M6Din934

Compression springNo59

Waher6,0Din1440

SpecialnutM6

But.hd.capscrewM4x12

1

1

1

1

1

2

1

1

1

2

1

1

1

1

1

1

1

1

4

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

2

Instruction manualHT250 www.foehrenbach.be

Date: August 2007 Documentrev. : 6Page : 8/ 11

46

48

49

50

51

52

53

181011

191593

181012

172393

181013

5310-007-003

5305-003-003

Plasticgrip

Washerø4,2x12 x1,5

NutM4Din985

Pinø2x7,2

Stop

Washerø3,2x7

But.hd.capscrewM3x10

2

4

2

1

1

1

1

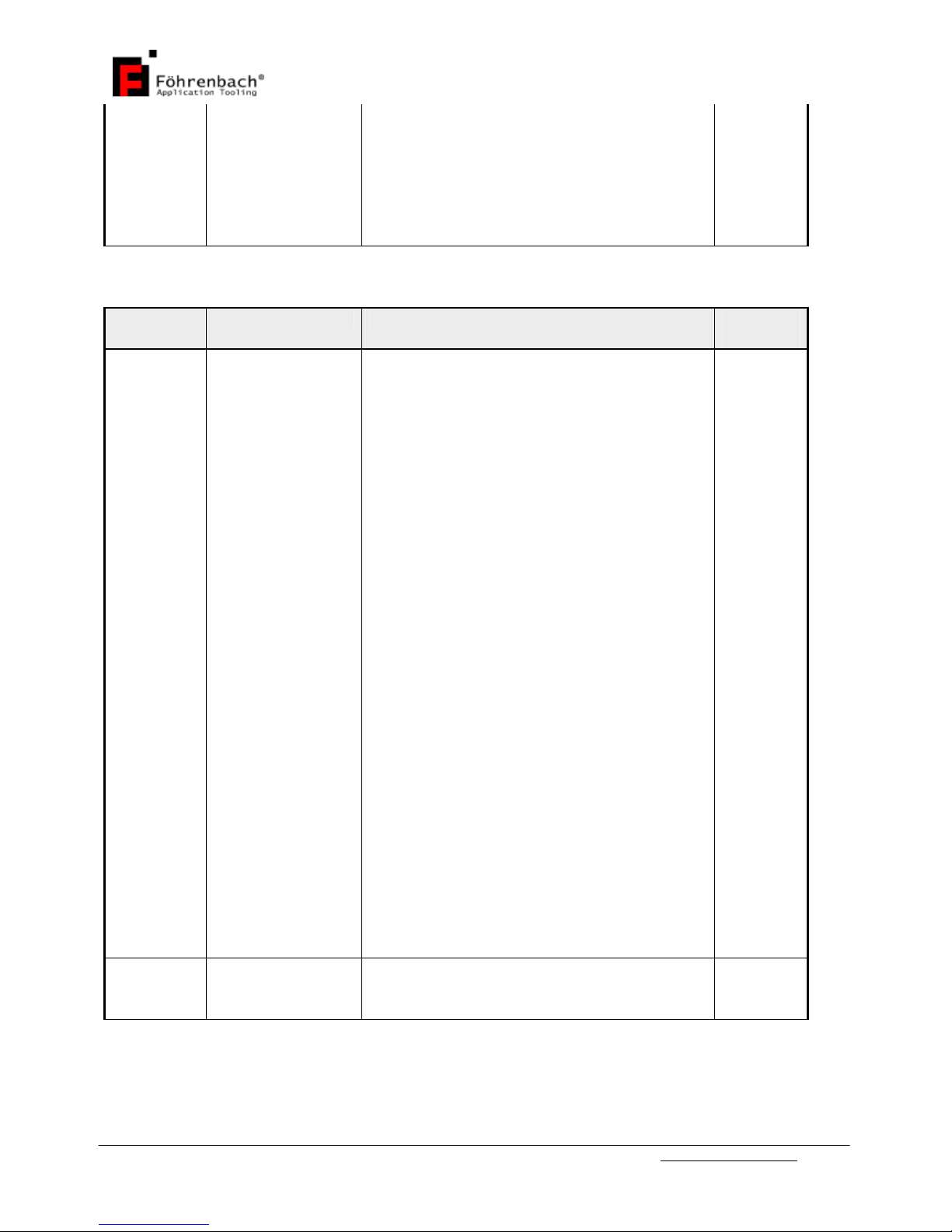

Partsforfigure2

itemno part No description qtyper

assy

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

181014

191591

191592

191593

191594

181015

181016

191597

181017

191599

191600

181018

5305-003-051

181019

181020

191604

181021

5305-003-050

181022

191614

5305-007-013

5310-002-002

5305-007-010

5305-003-051

181023

5305-007-010

5305-007-062

180983

180984

Feedtrack

Distanceplate

Stoppin

Washer 4.2x12x1.5

Feedfingerpivot

Feedlever

RondendM3

Compression spring

Feedfinger

JawfingerspringNo60

Stopscrew

Terminalguide

ButtonheadcapscrewM4x5

Feedtrackcover

Compression springNo129

Spring holderscrew

Terminalpositioner

ButtonheadcapscrewM3x4

Cutterplate

Carrierstripguidingplate

SocketsetscrewM4x15

HexagonalnutM4DIN934

SocketsetscrewM4x8Din916

ButtonheadcapscrewM4x6

KnurledscrewM4x16Din653

SocketsetscrewM4x8

SocketsetscrewM4x20

Stopbushing

Distanceplate

1

2

1

5

1

1

1

1

1

1

1

1

3

1

2

2

1

4

1

1

1

1

1

2

1

1

1

1

190115

190116

190117

Keyforcrimpheightadjustment

Upperpinwrench2mm

Pinwrench2.5mm

1

1

1

Instruction manualHT250 www.foehrenbach.be

Date: August 2007 Documentrev. : 6Page : 9/ 11

Figure2

Instruction manualHT250 www.foehrenbach.be

Date: August 2007 Documentrev. : 6Page : 10 /11

6. CONTACT

FöhrenbachApplication Tooling

Krijgsbaan 128

2640 Mortsel

Belgium

E-mail: application.tooling@foehrenbach.be

URL: www.foehrenbach.be

Thetechnicaldatainthispublicationhasbeencarefullycheckedandassembled.Noliabilityfrominaccuraciesorerrorsisassumed.Therighttochangeor

improvethisdocument without notice isreserved.

Instruction manualHT250 www.foehrenbach.be

Date: August 2007 Documentrev. : 6Page : 11 /11

CERTIFICATEOFCONFORMITY

Weherebycertifythatthe hand toolHT250describedbelowhasbeen manufacturedand

inspected,and isconformtoapplicabledrawings,requirementsand specifications,according

toFCI specTA-317.

Serialnumberof hand tool:………………………..

Specification:

•WirerangeAWG 22-24:0.22-0.33mm²

•Crimpheight0.83–0.89mm

.0325 -.0350inches

Adjustedcrimpheightbymanufacturer:…………mm

Table of contents