Foley 325 User manual

Foley

.

OWNERS

MANUAL

325

SCISSOR

SHARPENER

—

NOTICE

—

READ INSTRUCTIONS

AND SAFETY RULES

BEFORE USING.‘

\...-r"

ONE YEAR GUARANTEE

All Foley equipment

is

guaranteed to be sturdily constructed and free ol defects

in

workmanship

or

material

It within

one

year

lrom

date

01 shipment, any parts should prove defective replacement parts will be furnished tree ol charge

when detective part IS returned postpaid tor inspection

Guarantee

does

not

cover

damage sustained

in

transit

or

caused by

misuse

We

reserve

the right

to

make

changes In design, Construction

or

materials

on

all Foley machines

without

notice

FOLEY MANUFACTURING COMPANY 3300 FIFTH ST. N.E. MINNEAPOLIS, MINN.

ROOll11

TABLE OF CONTENTS

CHECKING SHIPMENT &REPLACEMENT

OF DAMAGED PARTS

INSTRUCTIONS FOR SHARPENING SCISSORS

AND SHEARS

GRINDING

TIPS

AND MAINTENANCE.

REPLACEMENT OF GRINDING WHEELS

EXPLODED DIAGRAM

PARTS

LIST

.

PAGE NO.

GENERAL INSTRUCTIONS FOR USE AND OPERATION

OF MODEL 325 FOLEY SCISSOR SHARPENER

IMPORTANT

If is Very simple

to

operate the Foley Scissor Sharpener. All you need do is learn the

adjustments before starting to grind your first scissors. This will

save

you time and trouble.

First read all the general instructions given in the manual. Have sharpener in front of you

as

you read the manual.

CHECKING SHIPMENT OF MACHINE FOR

DAMAGE AND COMPLETENESS

Examine Shipment: Carefully inspect the machine for in

transit damage. Look particularly for cracked castings, bent

or

broken parts. Any loss of,

or

damaged parts should be

reported to the freight agent immediately. Secure the freight

agent’s notation of loss

or

damage

on

the freight bill. Trafiic

regulations require the transportation company to stand

cost of repair

or

replacement.

REPAIR OR REPLACEMENT OF

DAMAGED MACHINE

You may elect

to

file your

own

claim against the transpor-

tation company. In

case

of damage

to

easily replaced" parts.

order and pay for the

new

parts needed; enter your claim

for their value against the delivering carrier. Return entire

machine to Minneapolis for complete rebuilding only in

case

of serious damage.

Alternatively, you may ask the factory

to

repair

or

replace

without cost

to

you. In this case, the following papers must

be sent

to

Minneapolis

so

parts replacement may be

assessed against the transportation company:

(a) Itemized report showing

nature

and extent of damage.

See exploded view drawing for parts identification.

(b) Paid freight bill, bearing agent’s notation of damage.

(c) Original bill of lading, and invoice (if available).

SAFETY FIRST

All

grinding wheels

are

breakable and the following safety

precautions should be observed:

1. Handle and

store

grinding wheels carefully.

2. Discard grinding wheels that

are

badly chipped.

3. Always

mount

agrinding wheel using blotters between

the grinding wheel and the flanges.

4. Do

not

over—tighten the flange

nut.

5. Do

not

run

agrinding wheel faster than that specified

on

the wheel blotters.

6. Do

not

stand in line with

a

grinding wheel the first

minute it is

run.

7. Never jam agrinding wheel into the work piece.

8. Always

wear

eye protection when operating any grind-

ing machine.

OPERATION

—

SCISSORS

AND

SHEARS

l.

Scissors and shears

are

sharpened

on

the right hand

wheel

as

shown in Photograph No. 1. For

most

scissors

only tl1e right clamp is required. For long shears both

clamps may be used.

2. Clamp the blade securely with the scissors usually

over-

hanging the clamp base about

‘/s”

to ‘V1./’. With the

grinder oil, check the blade against the wheel for proper

beveL

3.

If

the bevel does

not

match, loosen the allen

screw

in

the pivot guide and adjust for proper bevel. Check the

setting by turning

on

the

motor

and lightly touching the

blade

to

the wheel. Matching the scribe lines

on

the

Pivot Guide and Pivot Base Clamp

will

give proper

bevel for most scissors, however it is best

to

match

the bevel furnished by the scissors manufacturer. Do

not

tighten the Pivot Guide

screw

too

tight

or

the

support assembly will

not

slide freely

on

the rod.

4. Holding the clamp assembly lightly with both hands,

and starting at the base of the blade, grind the blade

from the base

to

the tip. Grinding pressure should be

light and the feed must be

a

smooth steady motion from

left to right with

no

stopping. The feed should be slight-

ly faster and the grinding pressure eased off toward the

tip

to

prevent burning the tips.

5. Check

to

see

that the bevel has cleaned up

over

the

entire length. One

or

two

passes

are

usually enough.

6. Sharpen the other blade in the

same

manner.

7. Hone each blade lightly with

a

fine stone to

remove

the

burrs. Open and close the blades carefully until the

operation is smooth.

For certain shears you may wish to adjust the Clamp Base

to

either the right

or

left

on

the Clamp Pivot. You

can

make this adjustment by loosening the alien

screw

in the

back of the Clamp Pivot.

Photograph #1

PINKING SHEARS ;

NOTE: The individual teeth of pinking shears

must

never

be filed

or

ground. Check each pair of shears carefully

because

if

the teeth do

not

mesh accurately

or

have been

deformed, you probably

cannot

salvage them and you

should

turn

them down.

1. Pinking shears

are

sharpened

on

the left hand wheel.

Loosen the

two

bolts which hold the slide bar,

move

the

bar to the left hand position and lock the

two

screws

provided.

2. Place the shears with the handle

to

the left and the teeth

pointing up. See Photo No. 2.

Adjust the Pivot Guide

to

match the bevel. Check the

adjustment by touching the‘ wheel lightly with blade

to

make certain you have the right setting.

Photograph #2

3. Sharpen the blade from the base

to

the tip as you did

with scissors. Maintain

a

light

even

feed with

no

stop-

ping. Sharpen until you have anice

even

bevel the full

length of the blade.

4. Sharpen the other blade and close the shears carefully

afew times until they

are

smooth.

5. Test the shears by cutting clotl1.

If

the grind looks good

but the shears do

not

cut

properly, do

not

try to adjust

the

center

screw.

The shears should be returned

to

the

manufacturer.

GRINDING TIPS

To get started and

to

get the feel for grinding. it is wise

to

purchase several pairs of low quality, low priced scissors

for practice.

Grinding wheels will give asmoother finish after they have

been used for

a

short time. Alight coat of oil

on

the wheel

will give

an

even

liner grind.

MAINTENANCE

Keep the slide bar and supports clean and free of grinding

dust. Do

not

oil the slides

or

pivots.

Your grinder is equipped with oil retaining porous bronze

bearings. Every three

or

four months, unplug the

motor

supply cord and

turn

the grinder forward. Place

one

or

two

drops of clean SAE 20 machine oil in each hole marked

“OIL”.

Do

not

over

oil.

REPLACEMENT OF GRINDING WHEELS

Use only wheels rated for 3500 RPM

or

better. Foley

wheels

are

recommended

as

they

are

made especially for

thejob.

After replacing, the wheel should be trued using adressing

brick

or

a

diamond dresser.

bcwmQBLJbmmam

DIA.

NO.

I-‘E-‘O-'

I0!-‘O\Dm\JO‘\U1-I-\u.JNJv-d

14

15

16

17

18

19

20

21

22

23

24

25

PARTS

LIST

FOR 325-01 SCISSOR SHARPENER

PART NO.

325001

325002

325003

325010

325011

325012

325013

325014

325015

325016

325017

325018

325023

370158

370880

398030

B250613

B251201

B251211

325024

R000524

R000857

R000555

325019

359028

OPTIONAL EQUIPMENT

370159

32801

370989

31701

327050

PART NAME

Clamp Base

Clamp Base

Pivot

Pivot

Guide

Slide

Bar

L.H.

Support

Bar

R.H.

Support

Bar

Slide

Rod

Clamp

L.H.

Support

Bracket

R.H.

Support

Bracket

Nameplate

Clamp Spring

Replacement

Lite

Bulb

Grinding Wheel 4-5/8

x

1/4

x

1/2

Arbor

Motor

115V 60 HZ

3.2

AMPS 3500

R.P.M.

Decal

—

Caution

Sock Hd. Cap

Sc.

1/4-20 UNC

x

3/8 Long Nylok

Hex Cap

Screw

1/4-20 UNC

x

3/4 Long

Sock Cap Screw 1/4-20 UNC

X

3/4 Long

Thd. Cutting

Screw

Plain

Washer 1/4 SAE

Hex Key 3/16

Across

Flats

Driv—Lok

Pin

3/4 Long 1/8

Dia.

Inside

Wheel Flange

Spacer

Assorted

Scissor

Screws

Package

of

50

Scissor

Vise

Shear &

Scissor

Pliers

Scissor

Screw

Extractor

Corrugating

File

for

Barber

Shears

stiqns?

\

.

'

is

c

o

I‘:

'

t

.\n :./

‘

800

'

328

0

7140

3300 N.E. 5th Street

0

Minneapolis, Minnesota 55418

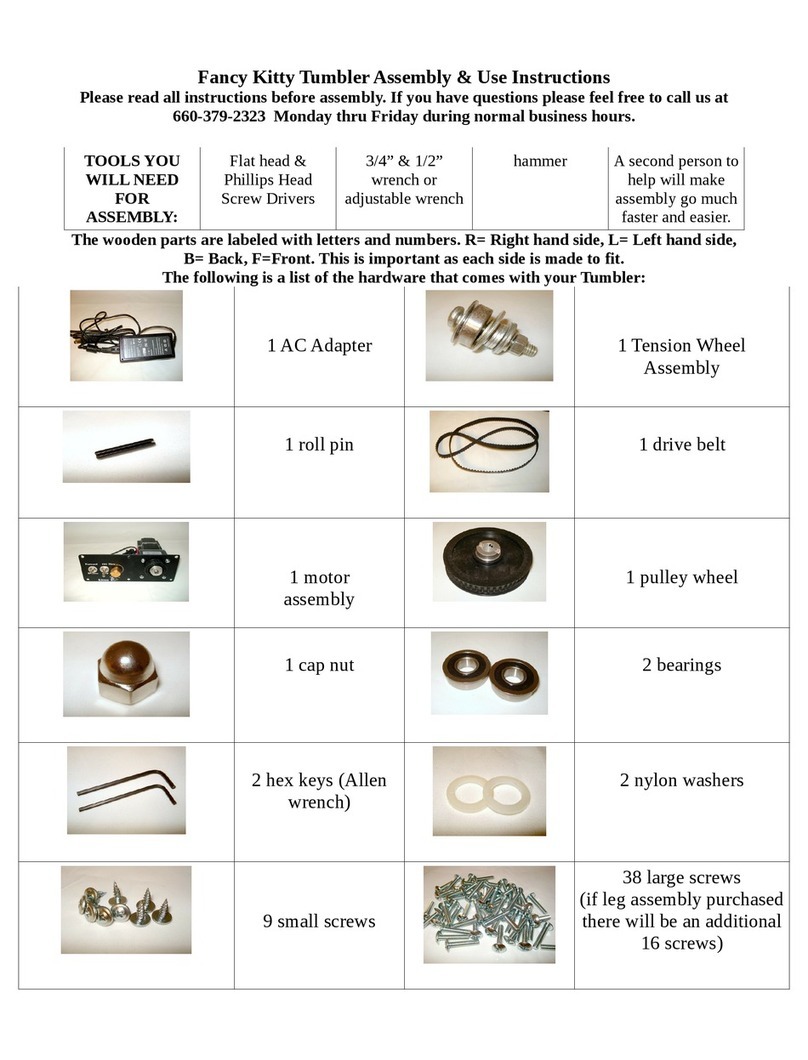

Table of contents

Popular Power Tools manuals by other brands

Würth

Würth 1952 006 630 Translation of the original operating instructions

Makita

Makita STRAIGHT SHEAR JS1660 instruction manual

Cembre

Cembre B-TC950A Operation and maintenance manual

Clarke

Clarke Metalworker CL251MH Operating & maintenance instructions

Ingersoll-Rand

Ingersoll-Rand 1100PS4-EU instructions

Ryobi

Ryobi HG500 Operator's manual

Ingersoll-Rand

Ingersoll-Rand QM7 Series Maintenance information

Metabo

Metabo BP 10 manual

Makita

Makita TW001G instruction manual

Atlas Copco

Atlas Copco ETV STB63-70-B13-B Safety and operating instructions

Anova

Anova TP4600 Instructions & user's manual

Timco Tools

Timco Tools PSJ100 Assembly and operation manual