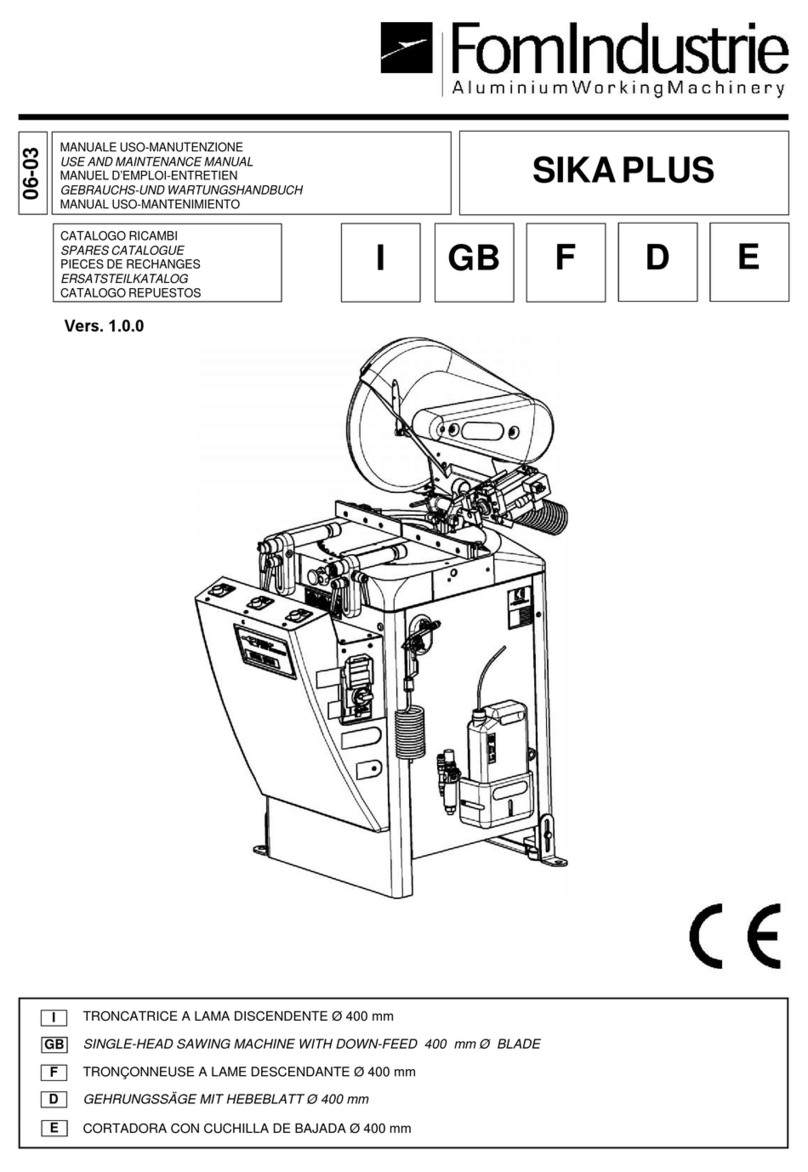

FOM INDUSTRIE SIKA PLUS User manual

31

SIKAPLUS

GB

SIKA PLUS

USE AND MAINTENANCE MANUAL

SPARESCATALOGUE

32

GB

SIKAPLUS

INDEX

1 GENERALINFORMATION...............................................................................................................33

1.1 WARRANTY .....................................................................................................................................33

2 PRELIMINARYINFORMATION........................................................................................................33

2.1 FOREWORD ....................................................................................................................................33

3 IDENTIFICATIONPLATEANDCERTIFICATION.............................................................................34

3.1 OTHER PLATES ON THE MACHINE............................................................................................... 34

3.2 TECHNICALSPECIFICATIONS .......................................................................................................35

3.3 NOISE EMISSIONOF THE SIKA 400 SAWING MACHINE .............................................................36

4 HEALTHANDSAFETYDIRECTIONS.............................................................................................. 37

4.1 FOREWORD ....................................................................................................................................37

4.2 INTENDED MACHINE USE..............................................................................................................37

4.3 GENERAL SAFETY WARNINGS ..................................................................................................... 37

4.4 SAFETYDEVICES ...........................................................................................................................38

4.5 AREAS OF RISK AND RESIDUAL RISKS........................................................................................38

5 TRANSPORTANDINSTALLATION .................................................................................................39

5.1 HANDLING .......................................................................................................................................39

5.2 INSPECTIONS..................................................................................................................................39

5.3 POSITIONING AND INSTALLING THEMACHINE...........................................................................39

5.4 CHIPS AND FUMES COLLECTION ................................................................................................. 40

6 CONTROLS ...................................................................................................................................... 41

7 ELECTRICALANDPNEUMATICCONNECTIONS ..........................................................................42

7.1 ELECTRICAL AND AIR CONNECTION COMPONENTS................................................................. 42

7.2 MOTOR STARTING SWITCH - SAFETY DEVICES......................................................................... 43

8 ADJUSTMENTS ...............................................................................................................................44

8.1 HORIZONTALVICESPOSITIONING ............................................................................................... 44

8.2 VERTICALVICEPOSITIONING(OPTIONAL)..................................................................................45

8.3 CUTTINGANGLES...........................................................................................................................46

8.3.1 HEAD ROTATION ............................................................................................................................ 46

8.3.2 HEADINCLINATION ........................................................................................................................47

8.4 ADJUSTING THE BLADE LUBRICATION FLOW............................................................................. 48

8.5 ADJUSTING THE BLADE DOWN FEED ..........................................................................................49

8.6 ADJUSTING THE BLADE DOWN FEED SPEED (RAPID - OPERATING DOWN FEED) ..............49

8.7 ADJUSTING THE AIR INTAKE PRESSURE .................................................................................... 50

8.8 ADJUSTMENTS ON THE AIR INTAKE FILTER ............................................................................... 50

9 OPERATING..................................................................................................................................... 51

10 MAINTENANCE................................................................................................................................ 53

10.1 GENERALPRECAUTIONS ..............................................................................................................53

10.2 DAILYMAINTENANCE..................................................................................................................... 53

10.3 BLADEREPLACEMENT .................................................................................................................. 54

10.4 BELTREPLACEMENT ..................................................................................................................... 55

10.5 CHANGING THE “PVC” PADS ON THE VICES ............................................................................... 56

10.6 VICECYLINDERREPLACEMENT...................................................................................................56

10.7 CLEANING THE VICE CYLINDER STOP VALVE ............................................................................ 56

11 ELECTRICAL AND PNEUMATIC DIAGRAMS ................................................................................. 57

33

SIKAPLUS

GB

1 GENERAL INFORMATION

Complycarefullywiththetechnicalinstructionsbeforesettingthemachinetoworkandfollowalldirectionscontained

inthismanual.

Thismanual,andallliteratureattached,shouldbestoredinaplacewithineasyreachandknownbyallemployees in

chargeofoperationandmaintenance.

1.1 WARRANTY

Thecompanyguaranteesthatthismachinehasbeentestedunderpeakrunningconditionswithexcellentresults.This

guaranteeisvalidforaperiodof12monthsandcoversconstructionmaterialsanddefectsonly.Theclienthasthe

rightsolelytothereplacementoffaultyparts,excludingtransportandpackingcosts.

Thisguaranteedoesnotcoverdamagecausedbydroppedcomponents,tamperingorbadoperation,disgregardof

maintenance instructions or faulty handling by the operator. No compensation will be made in case of machine

inactivity.Thisguaranteeisnotbindingifpaymentconditionshavenotbeenmet.

Alllabourandreplacedpartscostsnotcoveredbythisguaranteemustbepaiddirectlytotheservicetechnicianwho

willpresenttheclientwithamaintenanceslip.Aregularinvoicewillsubsequentlybesupplied.

Maintenancecharges and spares costs are takenfrom PriceLists inforceat thetime.

2 PRELIMINARY INFORMATION

2.1 FOREWORD

Thismanualcontainsinstructionsforuseandmaintenanceaswellasdrawingsanddirectionsfororderingsparesfor

SIKA PLUS, a machine manufactured by FOMINDUSTRIE. Allinfo concerning installation and operation of this

machinearecontainedinthismanual,togetherwithnotesonadjustmentsandmaintenance.

WARNING:

- Alltransport,installation,maintenanceandrunningoperationofthismachinemustbecarriedoutby

skilledoperators.

- By“OPERATOR”wemeanpeopleabletocarryoutsuchoperationsascleaning,servicing,connecting,

adjusting,handlingandputtingthemachineintoservice.

34

GB

SIKAPLUS

03-01

03-02

1

3

2

3 IDENTIFICATION PLATE AND CERTIFICATION (Fig. 03-01)

Figureshowsplateindetailanditslocationonthemachine.

NOTE:

Type, code and production number marked on the plate, must be referred to anytime you contact the

manufacturereitherforinformationorfororderingspares.

3.1 OTHER PLATES ON THE MACHINE (Fig. 03-02)

1-Safetywearon:earplugs,goggles,gloves

2-Bladerotationdirection

3-Cuttinglubricationflowadjustment

35

SIKAPLUS

GB

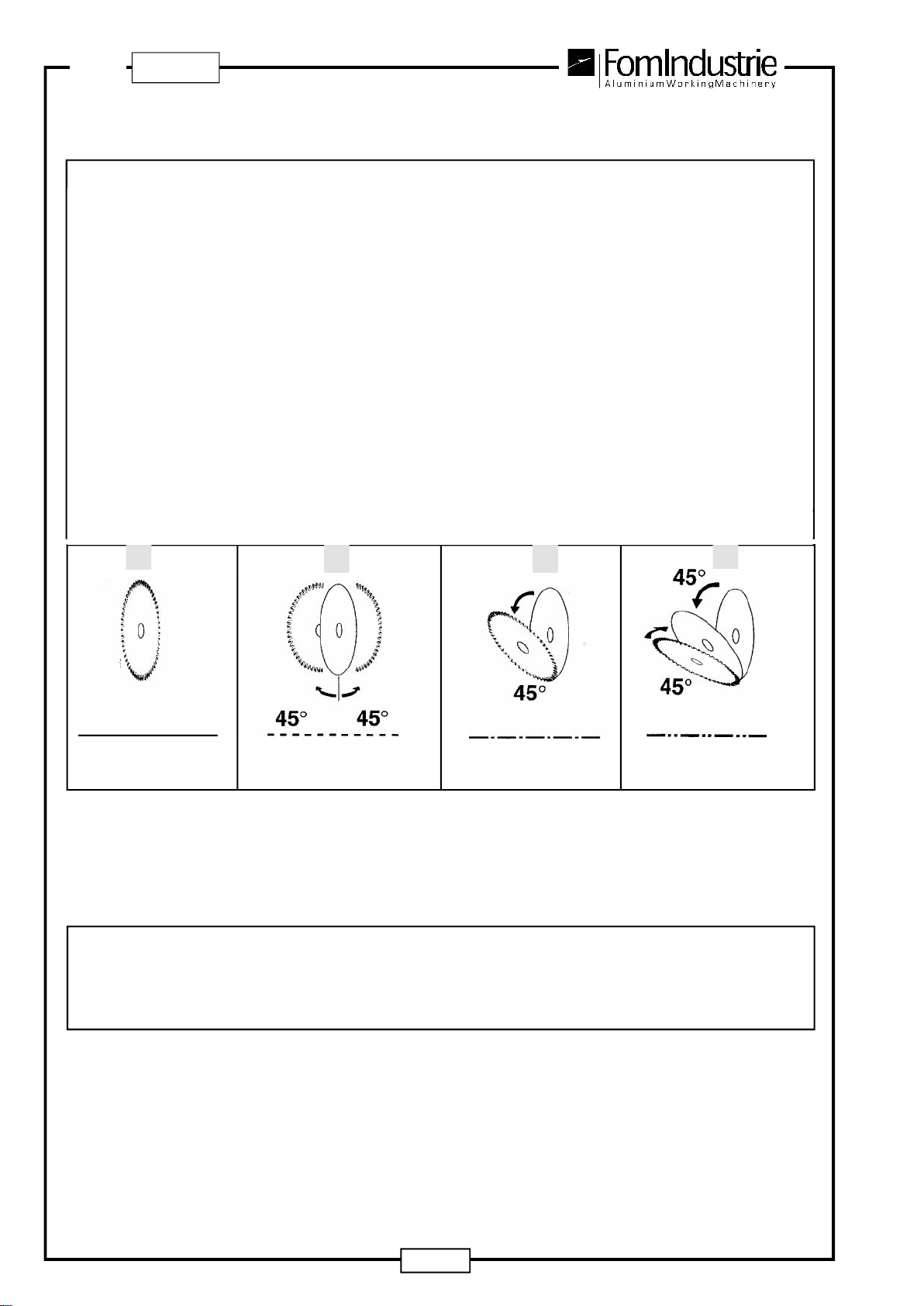

3.2 TECHNICALSPECIFICATIONS

• Tungstencarbidesawblade:Ø400mm

• Threephasemotor: 2.2 Kw (3 HP) - 2800 rpm - 230/400V - 50 Hz

• Bladerotationspeed:2800rpm

• Bladespindle:Ø 32 mm

• Motor-bladetransmissionbybelt

• Bladeprotectiveguard

• Cutswith:headat90°

headangledto45°LH,to45°RHandtopositionsinbetween

headangledto45°LHandturnedto90°,to45°Lh(andtopositionsinbetween)

• Headpositioningto90°and45°LH/RHwithconicalpinandself-retainingrelease

• 2pneumaticviceswithsafetyservovalves

• Doubleworkingpressureservocontrolledinlowpressure

• Workingpressure:7bar

• Headdownfeed:hydraulic(adjustabledownfeedspeed,rapidupfeed)-SIKAPLUScodeXZ-10567

manual-SIKAPLUScodeXZ-10568

• Airconsumptionperworkcycle:1.3Nl(XZ-10568)-3Nl(XZ-10567)

• Atomisedcuttinglubrication

• Setupfor theinstallationof chipsandfumesextractionsystem

• Setupforconnectiontorollertable

Suppliedasstandard:

Compressedairgun

Optional:

VerticalLH/RHvice

Kitformicrodroppureoilcuttinglubrication

03-03B

Kg. 170

Overalldimensionsandweight(XZ-10568)

925

1745

03-03A

Kg. 170

Overalldimensionsandweight(XZ-10567)

1131

1565

732

732

36

GB

SIKAPLUS

03-04

90° head: continuous line Head tilted 45° LH: line-point-

line

Headturned45°LHand/or45°RH:

dash line Headtilted45°LHandturned45°

LH: line - 2 points-line

CUTTINGDIAGRAM

NOISE LEVELS ACCORDING TO ISO 3746

LWA Acousticpowerlevel ........................................................................................... dB(A)110.9

LpA Acousticpowerlevelatoperatorstation .............................................................. dB(A)111.2

3.3 NOISE EMISSION OF THE SIKA PLUS SAWING MACHINE

37

SIKAPLUS

GB

4 HEALTH AND SAFETY DIRECTIONS

4.1 FOREWORD

Everyoperatorofthemachineshouldbefullyawareofthelocationandfunctionofallcontrolsandalsoofmachine

characteristics, therefore they should read this manual thoroughly. Unauthorized tampering or replacement of

machineparts,useoftools,accessories,materialsother thanthoserecommendedbythemanufacturer,canlead

toaccidentsforwhichthemanufacturercannotbeheldresponsible.

4.2 INTENDED MACHINE USE

TheSIKAPLUSsawingmachinehasbeendesignedforcuttingprofilesectionsmadeofaluminium,plasticor

lightalloyprofilesections.

Othermaterialsarenotcompatiblewithitscharacteristics.

WARNING:

Thismachineisnot suitableforworkingin areassubjecttofireor blast risks.

4.3 GENERAL SAFETY WARNINGS

- Theterm“OPERATOR”specificallyreferstothepersonorpersonsentrustedwithinstalling,operating,adjusting,

carryingoutmaintenance,cleaning,repairingandhandlingthemachine;“DANGEROUSAREAS”referstoany

areainsideand/ornearthemachineinwhichthepresenceofanexposedindividualconstitutesarisktothehealth

andsafetyofthatperson;“EXPOSEDINDIVIDUAL”referstoanypersonstandingfullyorpartiallyinadangerous

area.

- Accordingtotheprovisionsof“lightinginworkareas”,theplacewherethemachineisusedmusthavenoareas

inshadow,glaringlights,ordangerousstrobeeffectscausedbythelightingintheworkshop.

- Furthermore,efficientventilationmustbeguaranteedintheworkplacewiththeuseofasuitableextractionsystem

wherenecessary.

- The machine must be operated by skilled staff only and is designed for machining “NON-TOXIC” and “NON

AGGRESSIVE” materials; the use of any products other than these absolves FOM INDUSTRIE from any

responsibilityfordamagecausedtothemachine,personsorproperty.

- Themachinecanworkatambienttemperatures of0 °Cto+ 40°C

- Theremovalofguardsandsafetydevicesisabsolutelyforbidden.

- Theareaswheretheoperatorworksshouldalwaysbekeptclearandcleanfromanyoilresidue.

- Beforesettingtowork,theoperatormusthaveaperfectknowledgeofthelocationandworkingoperationsofall

controlsaswellasthemachinecharacteristics.

- Theworkcommandsmustbecarriedoutbyoneoperatoronly;actionbymorethanoneoperatorisonlyallowed

intheloadingphase.

- Routineandspecialmaintenanceoperationsmusttakeplacewhenthemachineisidleanddisconnected.

- Any work on the pneumatic systems must only be performed after having discharged the pressure inside the

circuit.

- Electricalconnectionsshouldbemadeaccordingtothegeneralinstallationrulesforthepreparationandoperation

ofelectricalsystems.

- Electricalinstallationandconnectionsmustonlybemadebyskilledpersonnel.

NOTE:

Theterm“skilledpersonnel”referstopeopletrainedatspecialcoursesandwithaprevious experience

inthefield.

- Skilledpersonnelmustalsobefamiliarwithfirst-aidtechniquesintheeventofaccident.

- Staffinvolvedinoperating,maintenance,cleaning,inspectionetc.willinanycasehavetocarefullyobservethe

safetyrulesinforceinthe countrywherethe machineis tobeused.

Alloperatorsshoulddressinasuitablemannerfortheworkplaceandforthejobtobecarriedout.

Machineandmaintenanceoperatorsshouldnotwearneckchains,braceletsorrings.

38

GB

SIKAPLUS

4.4 SAFETY DEVICES

1 - Bimanualcontrolvalveforbladedownstroke(onlyonautomaticversion).

2 - 2vicenon-returnsafetyvalves(oneforeachhorizontalvice)

3 - Mobilebladesafetyguard

04-01

2

1

3

4.5 AREAS OF RISK AND RESIDUAL RISKS

Despitethesafetyguardsanddevicesprovidedonthemachine,therearesomeareastobeconsidered“risk” areas

ifmisusedbypersonnel.

Thepictureshowstheareawherecontrolandoperationofthemachinearehandledinstandardoperatingconditions

(guarddown).

That areaposes no risk andis described asthe “OPERATOR CONTROLAREA”.

Risk area, forced evacuation of fumes; it is forbidden for anyone to stand in this area unless the machine has been

connected to an extraction system.

ZONA OPERATORE

OPERATORAREA

39

SIKAPLUS

GB

05-01

A

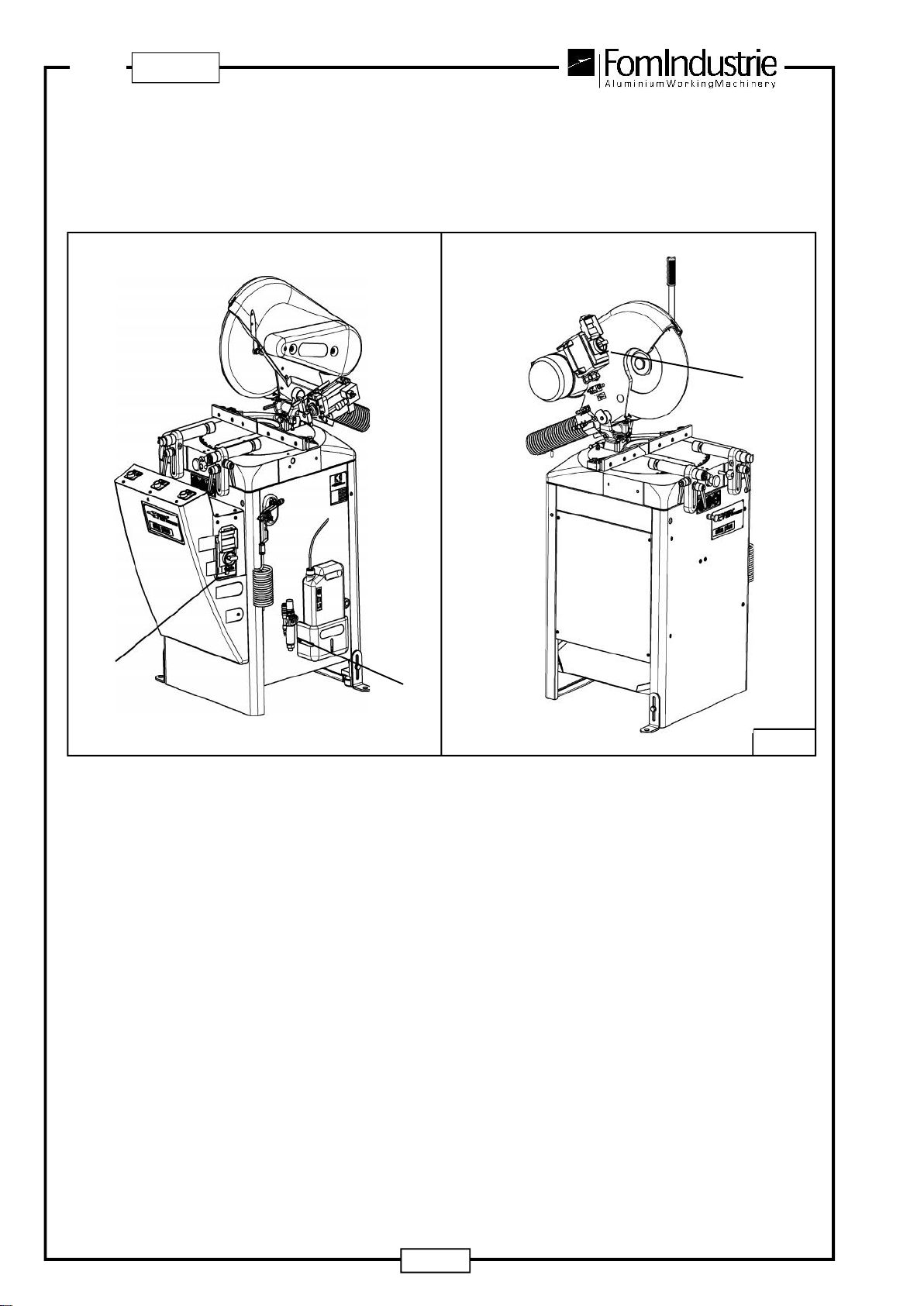

5 TRANSPORT AND INSTALLATION

Themachineisdeliveredinoneofthefollowingways:

packedonawoodenpallet,packedonawoodenpallet

andincartons,packedonawoodenpalletandina

woodencrate.

Insidethemachine(clearlyinsight),thecustomerwillfind

notonlytheinstructionmanual,butalsoapackcontaining

thetoolkitandtheelementsforanchoringtotheground.

5.1 HANDLING (Fig. 05-01)

Themachine,packedornot,hastobehandledcarefully

andwithsuitableforklift.Whenliftingorpickingupbefore

positioning, make sure not to damage the most fragile

parts,namelycablesorhoses,usingsuitableequipment.

5.2 INSPECTIONS

- Makesurethatenvironmenthasnoareasinshadow,

dazzlingraysordangerousstroboscopiceffectsdue

tolighting.

- Makesurethatnodamageoccurredduringtransport.

- Makesurethatmachine rests evenlyonfloor.

- Make sure that there is enough room around the

machine to carry out all maintenance operations

safelyandeasily.

5.3 POSITIONING AND INSTALLING THE

MACHINE

Afterchoosingtheplace,installationbegins.

Secure the machine to the floor using the two corner

brackets“A”-Fig.05-02suppliedwithit.

Securethebracketstothemachineandfloorasshownin

Fig.05-02below,makesurethatthemachineislevel(if

necessary, place little pieces of plate under the stand)

beforefixingthecornerbrackets).

05-02

40

GB

SIKAPLUS

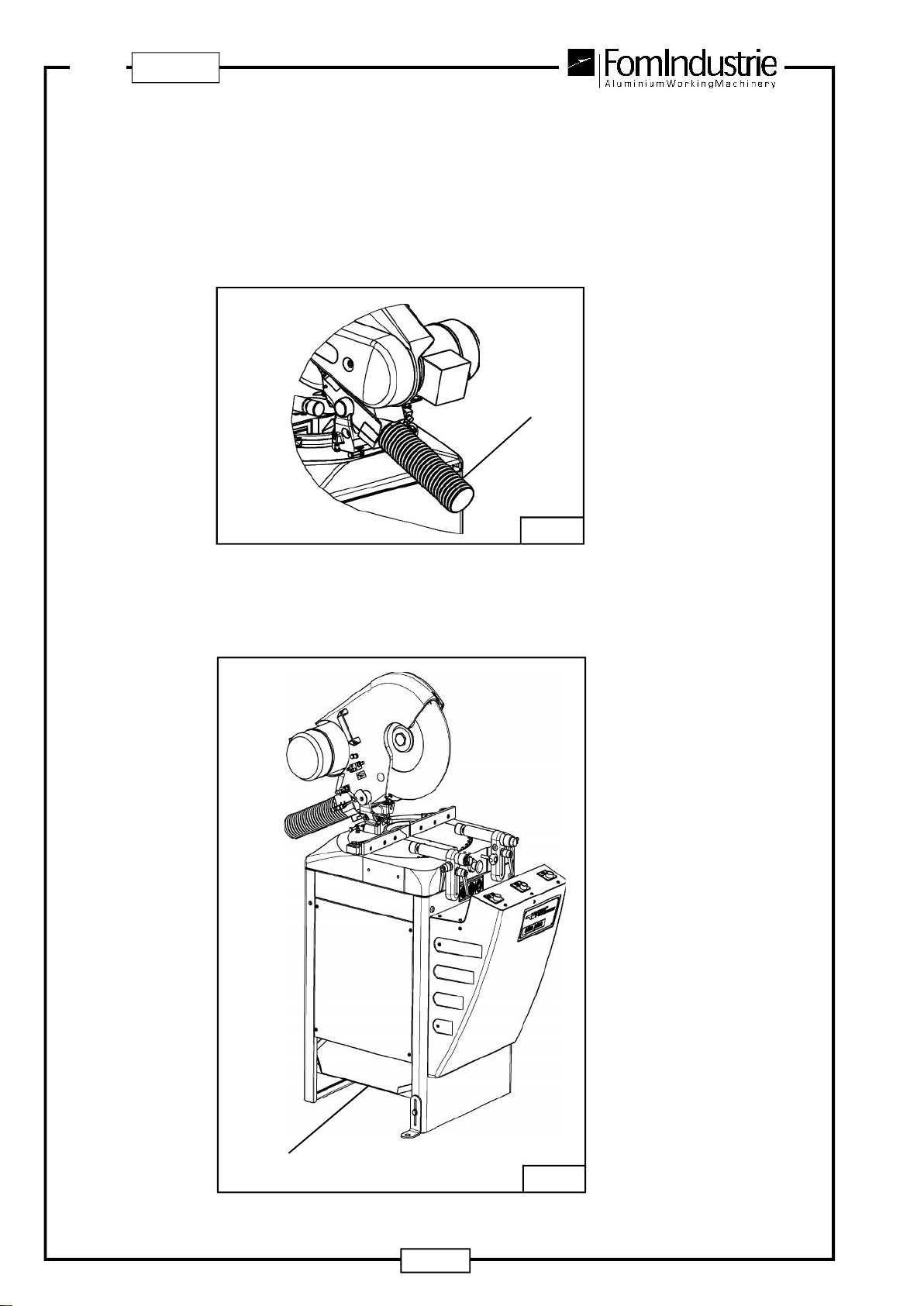

5.4 CHIPSANDFUMESCOLLECTION

Attheback ofthe machinethereisaflexiblehose,forconnectionto anextractionsystemtotake awaytheflying

chipsand fumesproducedbycutting (seeRef.“1”- Fig.05-03).

Primadiallacciarel'aspiratoreallamacchina(direttamenteconuntuboflessibiledidiametro80mm.oppureattraverso

unariduzione),éconsigliabilerimuovereiltubo“1”-Fig.05-03allentandolarelativafascetta.

N.B.Theexhaustermustbeinstalledbytheuserunderhisownresponsibility.

Itisadvisabletofitacontainertocollectchipsandoilresiduefromcuttingwhichshouldbepositionedlaterally

nextto slide“A” (seeFig. 05-04).

1

05-03

A05-04

41

SIKAPLUS

GB

06-01

123

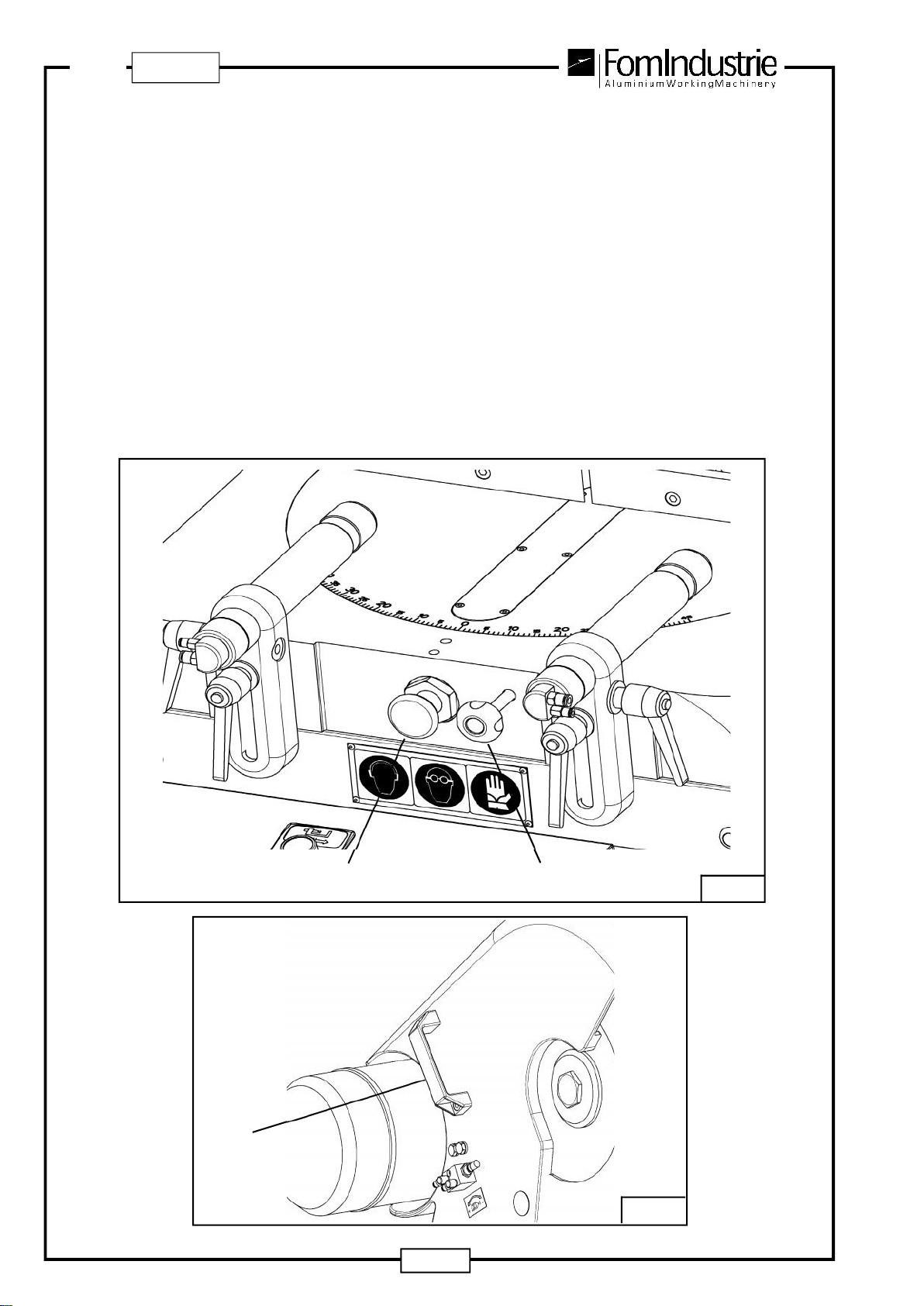

6 CONTROLS

6.1 CONTROL PANEL - SIKA PLUS cod. XZ 10567 (Fig. 06-01)

1 - CLOSE VICES / HEAD DOWNSTROKE - CUT button

2 - OPENVICES button

3 - HEAD DOWNSTROKE - CUT button

6.2 CONTROLS - SIKA PLUS cod. XZ 10568 (Fig. 06-02)

1 - CLOSE VICES/ OPEN VICES button

2 - HEAD DOWNSTROKE- CUT Lever

06-02

1

2

42

GB

SIKAPLUS

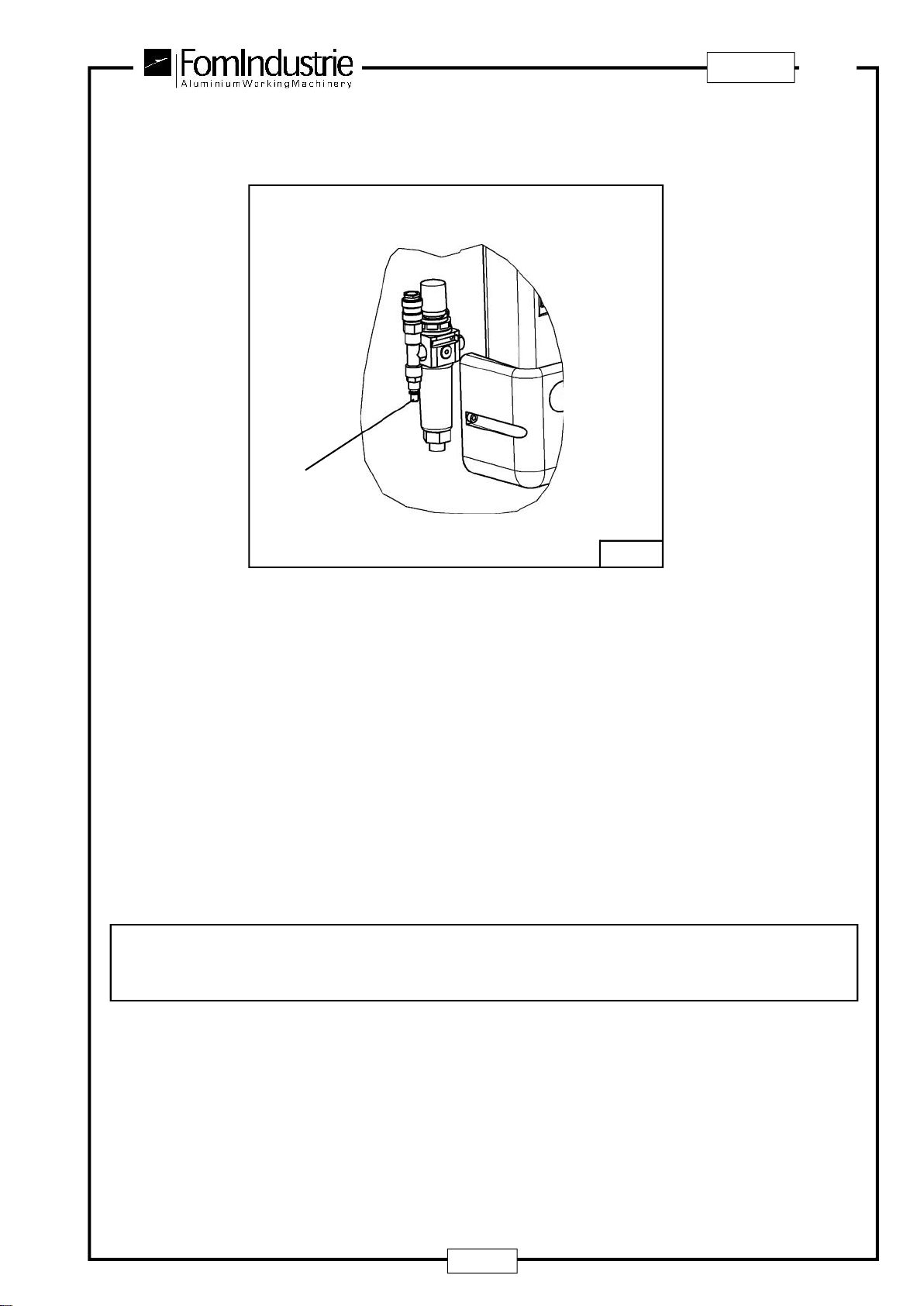

7 ELECTRICAL AND PNEUMATIC CONNECTIONS

7.1 ELECTRICAL AND AIR CONNECTION COMPONENTS (Fig. 07-01)

1-On/Offswitch

2 - Air intake filter

Beforestarting

Before starting the machine, it must first be checked that the mains power supply is efficient, safe and reliable,

protectedbyanautomaticsupplylineswitchandproperlyearthed.Thisappliesalsotothecompressedairsupply

whichmustbeofsufficientsectionfor therequiredcapacityandavalvefittedsothatthesupplycanbecutofftothe

machine.If the airdistributionlineisof considerable length,then appropriatereleasebarrels must beprovidedat

suitablepointstodrainoffthecondensation.

Beforecarryingoutanyoperationsofthissort,makesurethatthepowersupplyavailableisthesameasthatrequired

bythe machine. Checkthat themain switch(400V -three-phase)isset to0(zero).

Connectiontotheelectricalpowersupply

A-400VTHREE-PHASEpowerlead

Ifthemachinedoesnotalreadycomesuppliedwithplugsforconnectiontothepowersupply(400V),connectthepower

leadstotherelativeplugs.

Protectthepowercableswithadifferentialoverloadcutoutswitch.

Shouldthepowersupplywirebecut,resetconnectionreferringtothewiringdiagram(Cap.11).

Ifthedirectionofbladerotationisnotthesameastheoneshownbythearrowonthemachine,inverttwoofthethree

phasesofthepowersupply.

07-01

12

1

SIKAPLUSAUTOMATIC SIKA PLUS MANUAL

43

SIKAPLUS

GB

07-02

1

7.2 MOTOR STARTING SWITCH - SAFETY DEVICES

Themotorstartingswitch:

Can be locked: when the machine is switched off for maintenance; lock the switch with a padlock to

preventaccidentalstarting.

Ismagneto-thermic: so that it switches off automatically in case of short circuit or overheating; everytime this

occurs,theoperatorshouldcheckthattheelectriccircuitandmotorareinorder.

Hasareleasecoil: thatautomaticallyswitchesoffintheeventofapowercut.Thispreventsthemotorfromstarting

againallofasuddenwhenthevoltagereturns.

NOTE:

Inordertocomplywithspecifictechnicalandsafetydirections,manufacturerssupplythemotorstartingswitchwith

onevoltageonly(forinstanceone-phase230V,three-phase230V,three-phase400V,andsoon).

Inserthoseinfitting“1”- Fig. 07-02

44

GB

SIKAPLUS

8 ADJUSTMENTS

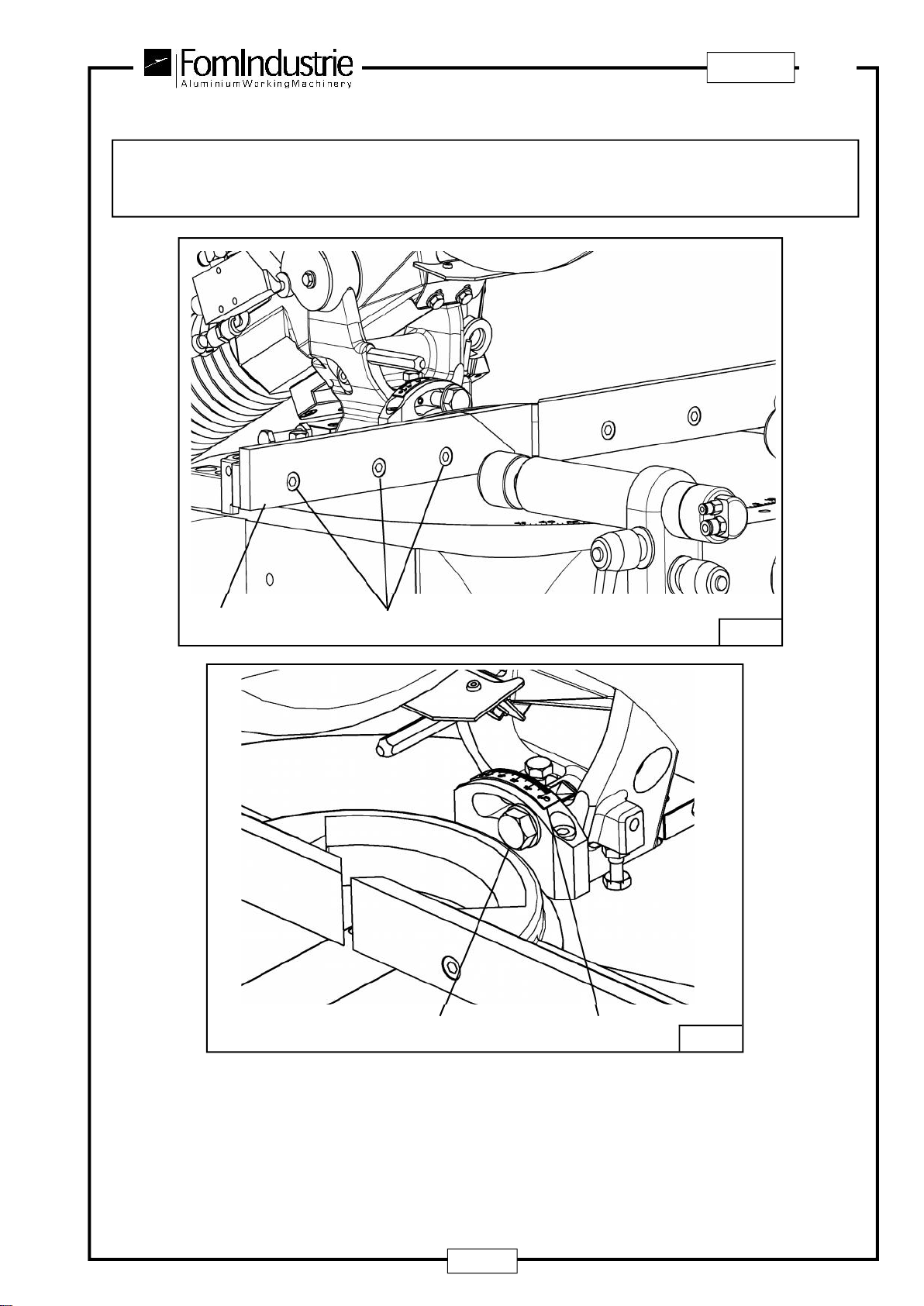

8.1 HORIZONTAL VICESPOSITIONING (Fig. 08-01)

Forbestpositioningofthehorizontalvicesonthesurfaceoftheprofile,themethodsbelowshouldbefollowed:

1) Undoreleasehandle“A” tosetthedistancefromtheprofile.

2) Undoreleasehandle“B” toadjustthevicesassemblybothverticallyandlaterally.

Thehorizontalvicesareequippedwithasafetyvalvetopreventopening:iftheairsupplytothevicefails(whenthey

areclosed)theywillnotopen;whentheairsupplyreturnsthemachinefucntionsarerestored.

A

08-01

B

45

SIKAPLUS

GB

8.2 VERTICAL VICE POSITIONING (OPTIONAL) (Fig. 08-02)

1) Undoreleasehandle“A” tosetthedistancefromtheprofile..

2) Undoscrew“B” toadjustthevicevertically.

Toexcludetheverticalvice,turntap"C".

08-02

A

B

C

46

GB

SIKAPLUS

8.3 CUTTING ANGLES

8.3.1 HEAD ROTATION

TheheadoftheSIKAPLUScanberotatedasfollows:

- From 90° to 45° RH

- From90° to 45°LH

Byfirstundoingknob "1"-Fig.08-03 andthenpullingbutton“2”-Fig. 08-03theheadisfreetorotate.

Usethehandle“3”- Fig.08-04torotatetheheadtotherequiredposition.

Mechanicalendoftravelstopsdeterminesthepositions:

-90°

- 45° RH

- 45° LH

Theintermediatecuttingpositionsareobtained,afterpullingoutbutton“2”-Fig.08-03, byrotatingthebladeusing

thehandle“3”- Fig.08-04.

Thevernierscaleisetchedintotheworktable

Readingofftheanglerequired,securetheheadbytighteningknob“1”-Fig.08-03andreleasingbutton“2”-

Fig.08-03.

08-03

3

2 1

08-04

47

SIKAPLUS

GB

8.3.2 HEAD INCLINATION

IMPORTANT:

beforeincliningtheheadtheLHvicejaw"1"-Fig.08-05,mustberemovedbyundoingthescrews"2"-Fig.

08-05,andsubstitutingitwiththevicejawprovided.

Toinclinetheheadfrom90°to45°totheleftincludingtheintermediateangles,undoscrew"A"-Fig.08-06,thenincline

theheadwhilereadingtheangleoffthevernier"B"-Fig.08-06.

Lastly,tightenscrew"A"-Fig.08-06.

Theheadcanalsoberotatedandinclinedsimultaneouslytotheleft.

08-06

08-05

12

AB

48

GB

SIKAPLUS

08-07

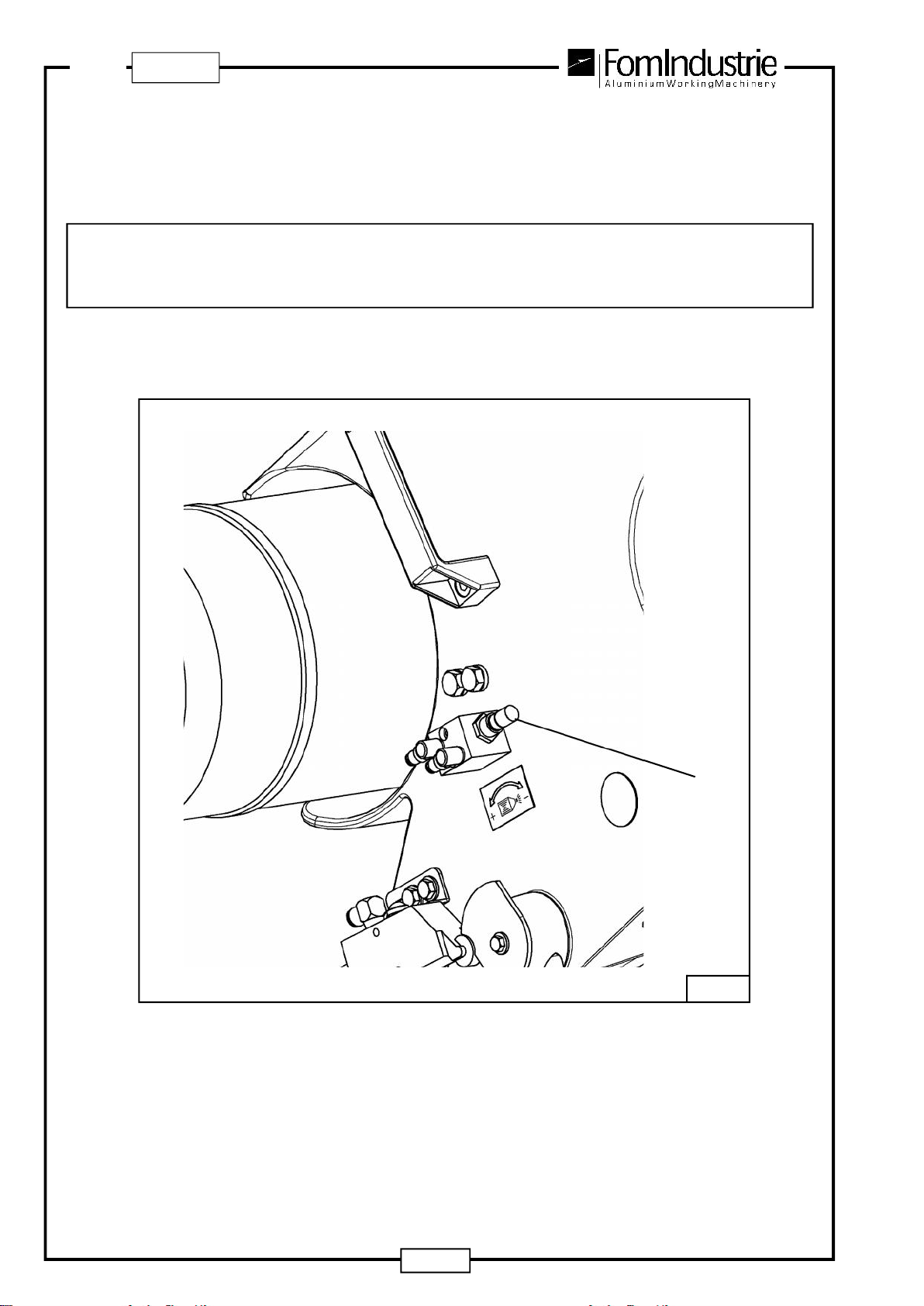

8.4 ADJUSTING THE BLADE LUBRICATION FLOW (Fig. 08-07)

Theflowoflubricantforthebladeisadjustedbythefollowingprocedure

Turningtheknurledknob"A"clockwisedecreasestheflow,turningitcounterclockwiseincreasestheflow.

IMPORTANT:

Intheoiltankforcutting(orblade)lubrication,putonly:

OILFORCUTTINGALUMINIUM.

A

49

SIKAPLUS

GB

8.5 ADJUSTING THE BLADE DOWN-FEED - SIKA PLUS AUTOMATIC (Fig. 08-08)

Turningknob“A”clockwisedecreasesthebladedown-feedspeed;turningknob“A”counterclockwise increases

thespeed.

8.6 ADJUSTINGTHEBLADEDOWN-FEEDSPEED(RAPID -OPERATINGDOWN-FEED)-SIKA

PLUS AUTOMATIC (Fig. 08-08)

Themachineheadhastwodown-feedspeeds:

- rapid

- operating

Theformerallowsafastapproachtotheworkpiece.

Thelatter(slower)issuitableforcutting.

Loosenscrew“A” andreleasebar“B”asshown.

Whenthebarmeetsthepneumaticmicroswitch“C”,rapidspeedturnstooperatingspeed(slow).

D

CA08-08

NOTE:

“BLADE DOWN FEED SPEED” and “BLADE LUBRICATION FLOW” adjustments are usually set to

standardwhenmachineistestedatthemanufacturer’sworkshop.

B

50

GB

SIKAPLUS

8.7 ADJUSTING THE AIR INTAKE PRESSURE (Fig. 08-09)

Toincreaseordecreasetheairintakepressure,turnknob“A”(liftup,adjustandpushdownagaintosecure).

8.8 ADJUSTMENTS ON THE AIR INTAKE FILTER (Fig. 08-09)

DISCHARGINGCONDENSATION

withoutdisconnectingtheairsupplyhose,pressknob“B” makingsurethattherelativeringisopen.

Thecondensationisinanycasedischargedautomatically(alwayswiththeringopen)eachtimetheairsupplyhose

isdisconnected.

08-09

A

B

Table of contents

Other FOM INDUSTRIE Saw manuals