Table of Contents

Table of Contents........................................................................................................................1

Preface........................................................................................................................................ 3

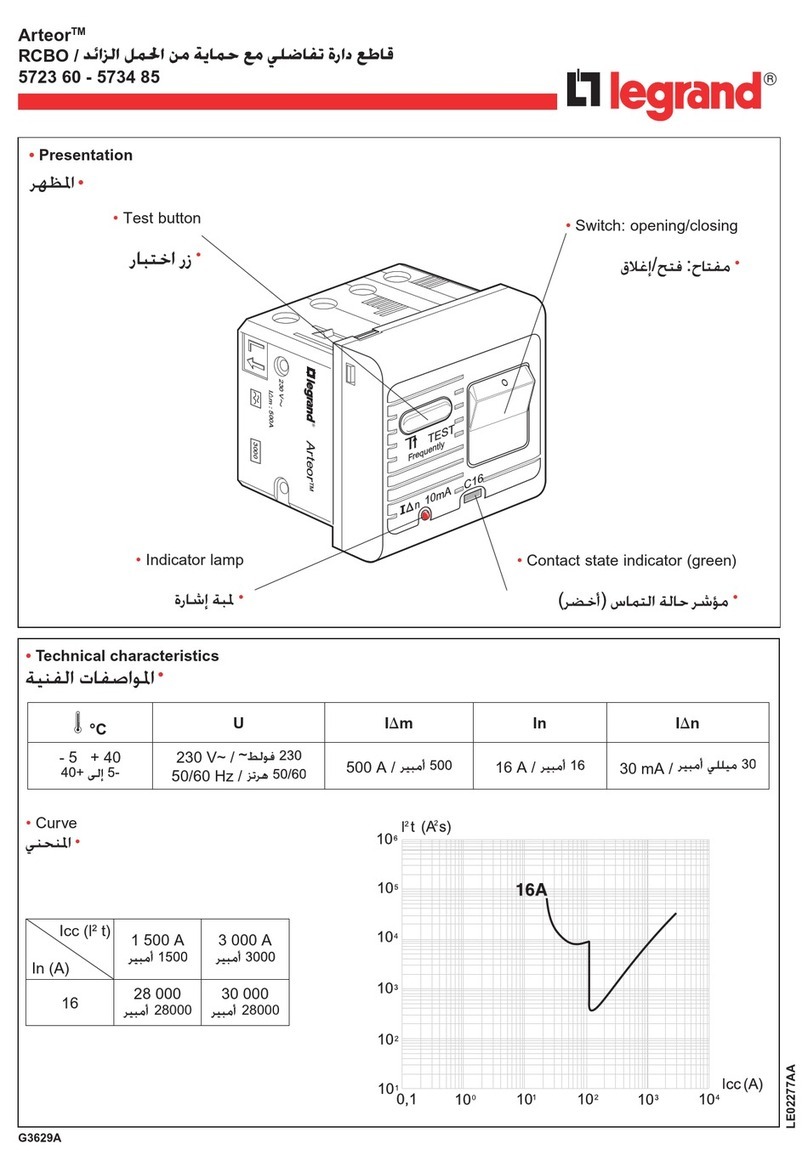

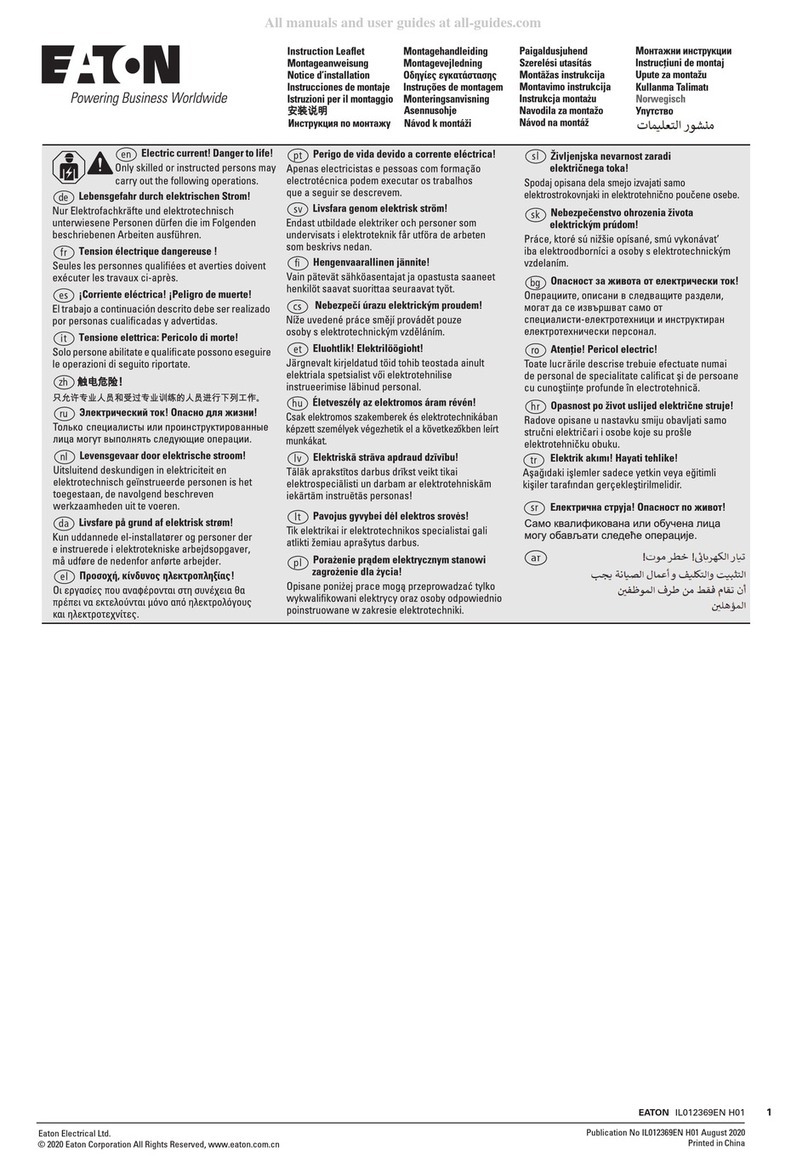

1 Safety Precautions....................................................................................................................4

2 Product Overview.................................................................................................................... 6

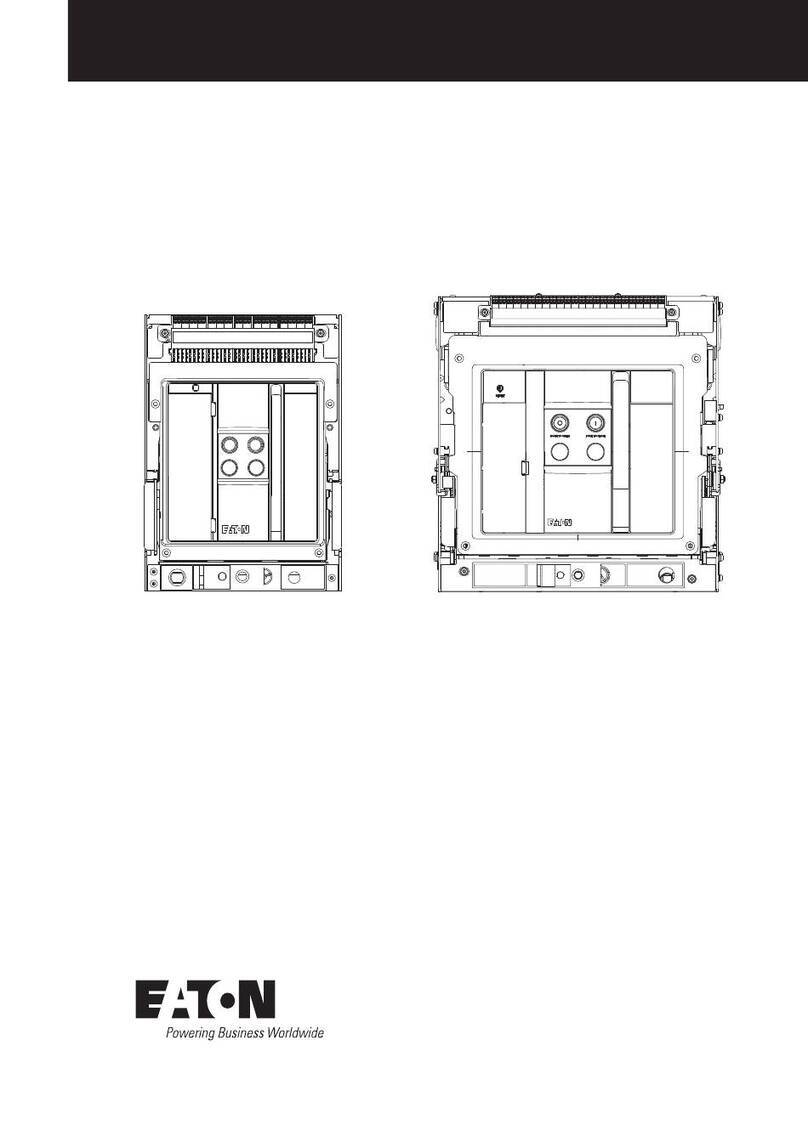

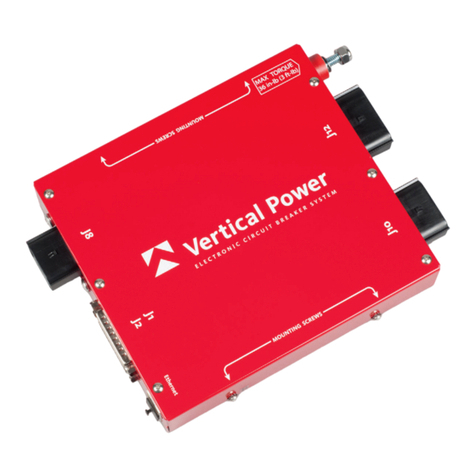

2.1 Description........................................................................................................................6

2.2 Appearance....................................................................................................................... 7

2.3 Principles of Design..........................................................................................................7

2.4 Arc alarm strategy.............................................................................................................8

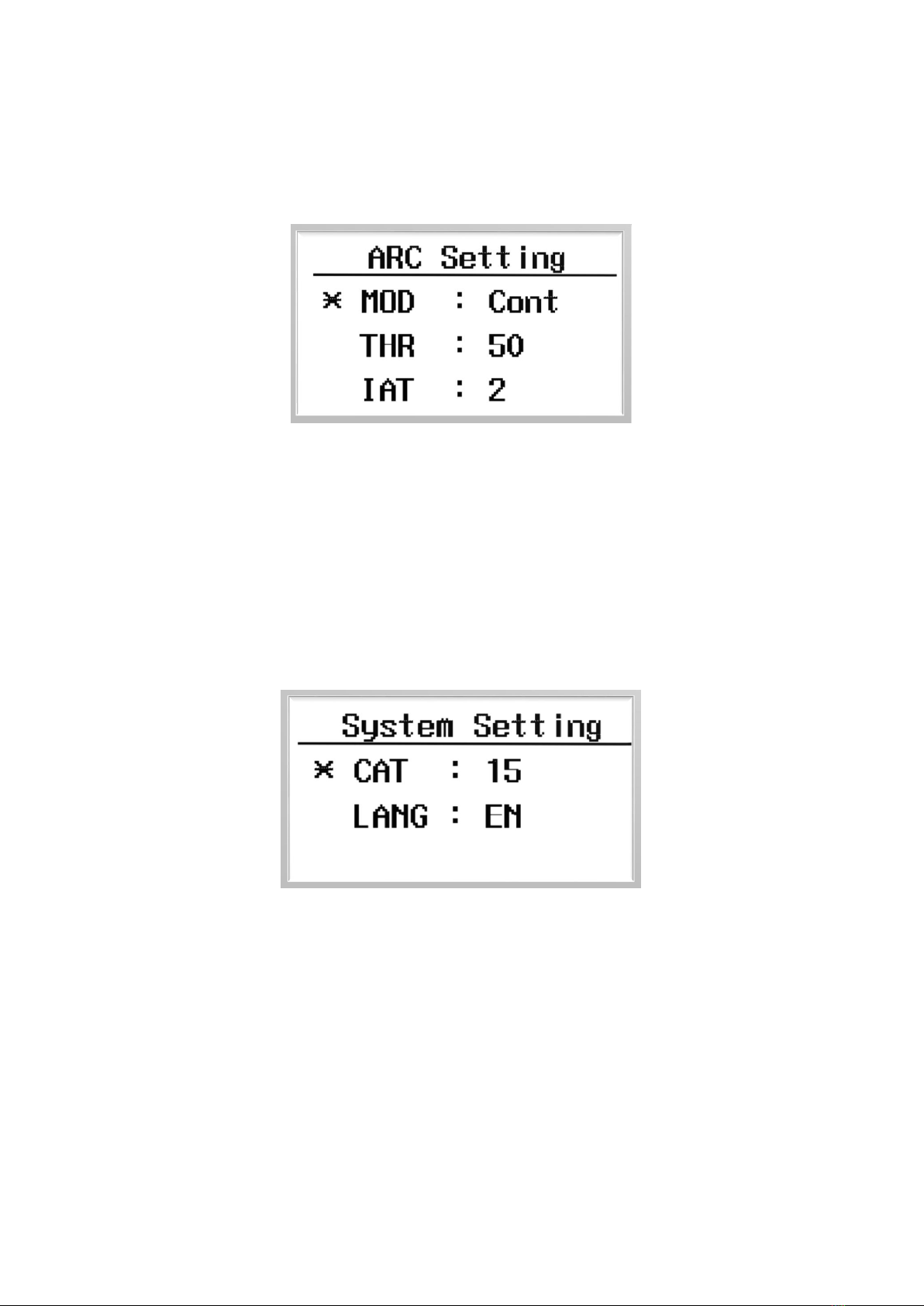

2.4.1 Arc mode....................................................................................................................8

2.4.2 Arc alarm strategy......................................................................................................8

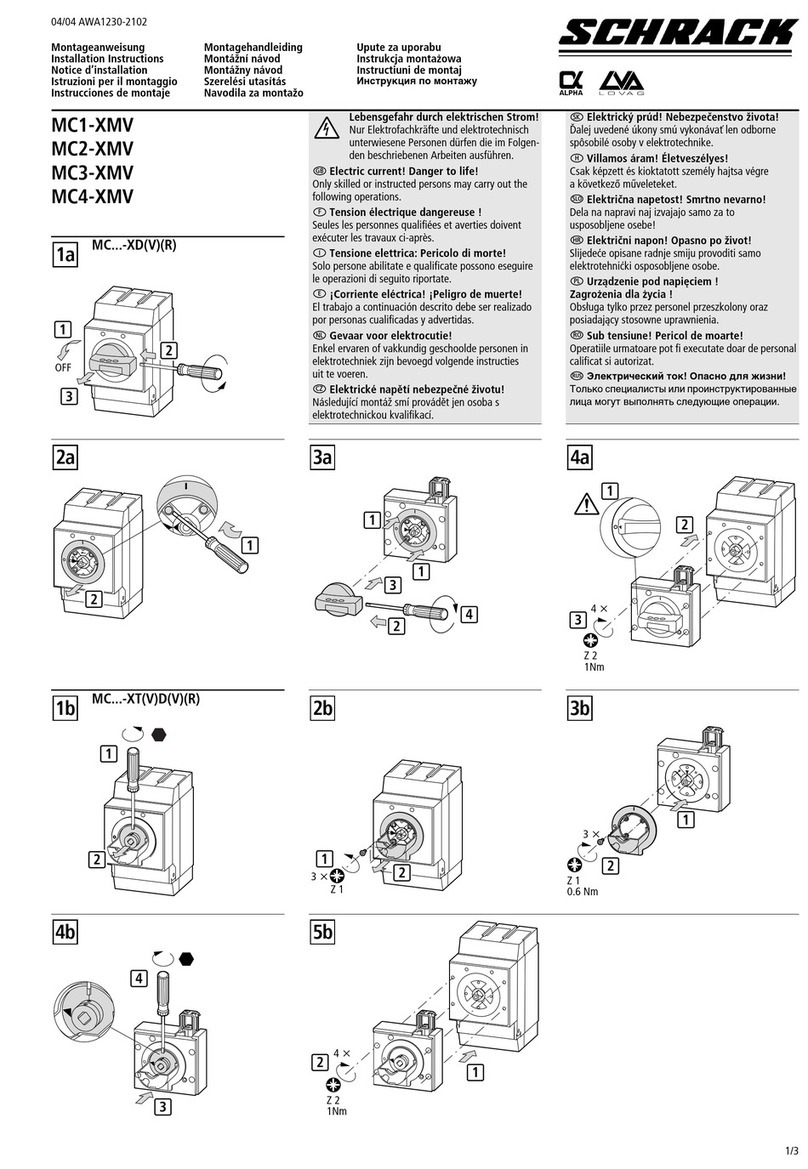

3 Installation............................................................................................................................... 9

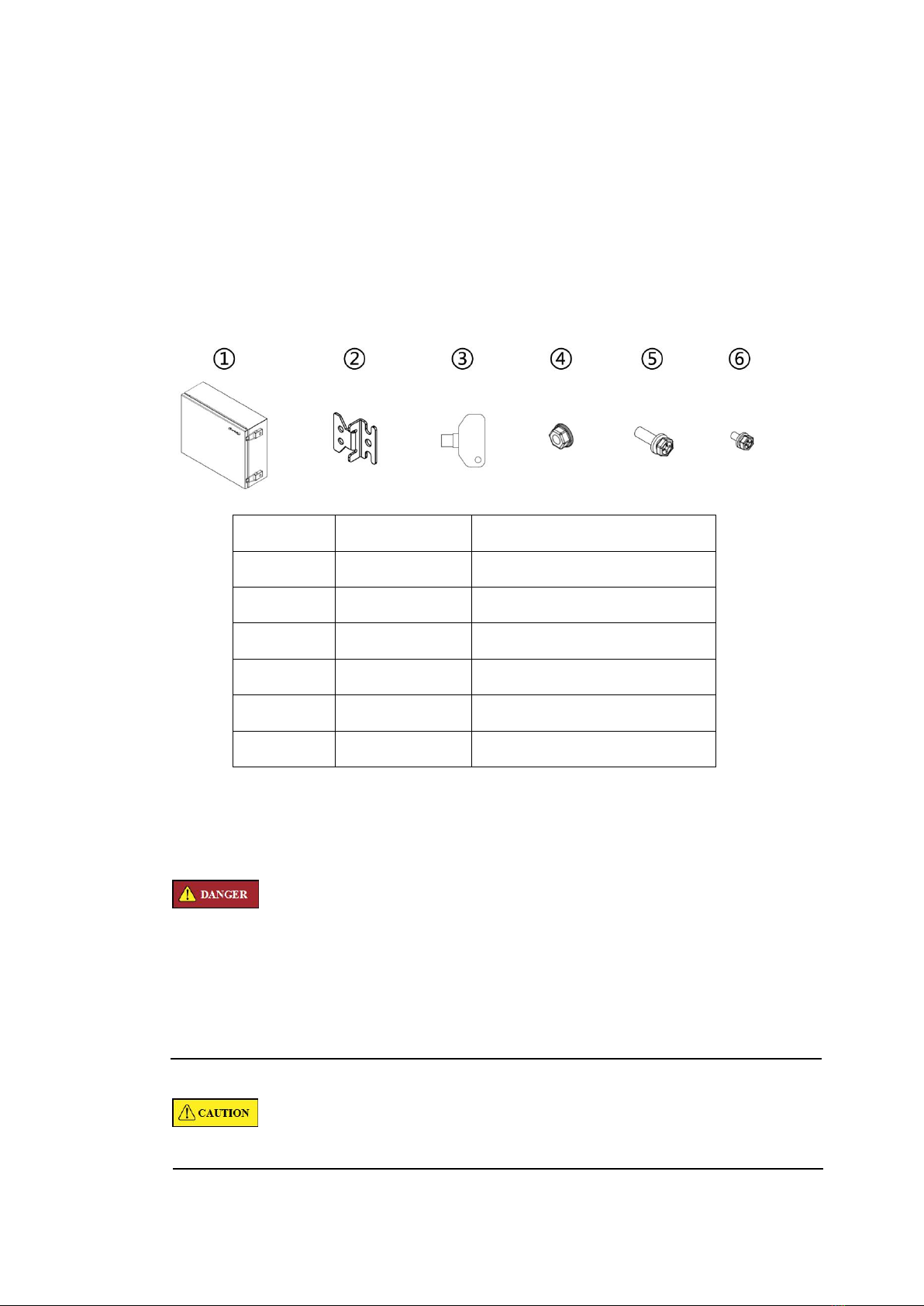

3.1 Scope of Delivery............................................................................................................. 9

3.2 Requirements for Installation............................................................................................9

3.3 Procedure........................................................................................................................ 10

4 Electrical Connection.............................................................................................................11

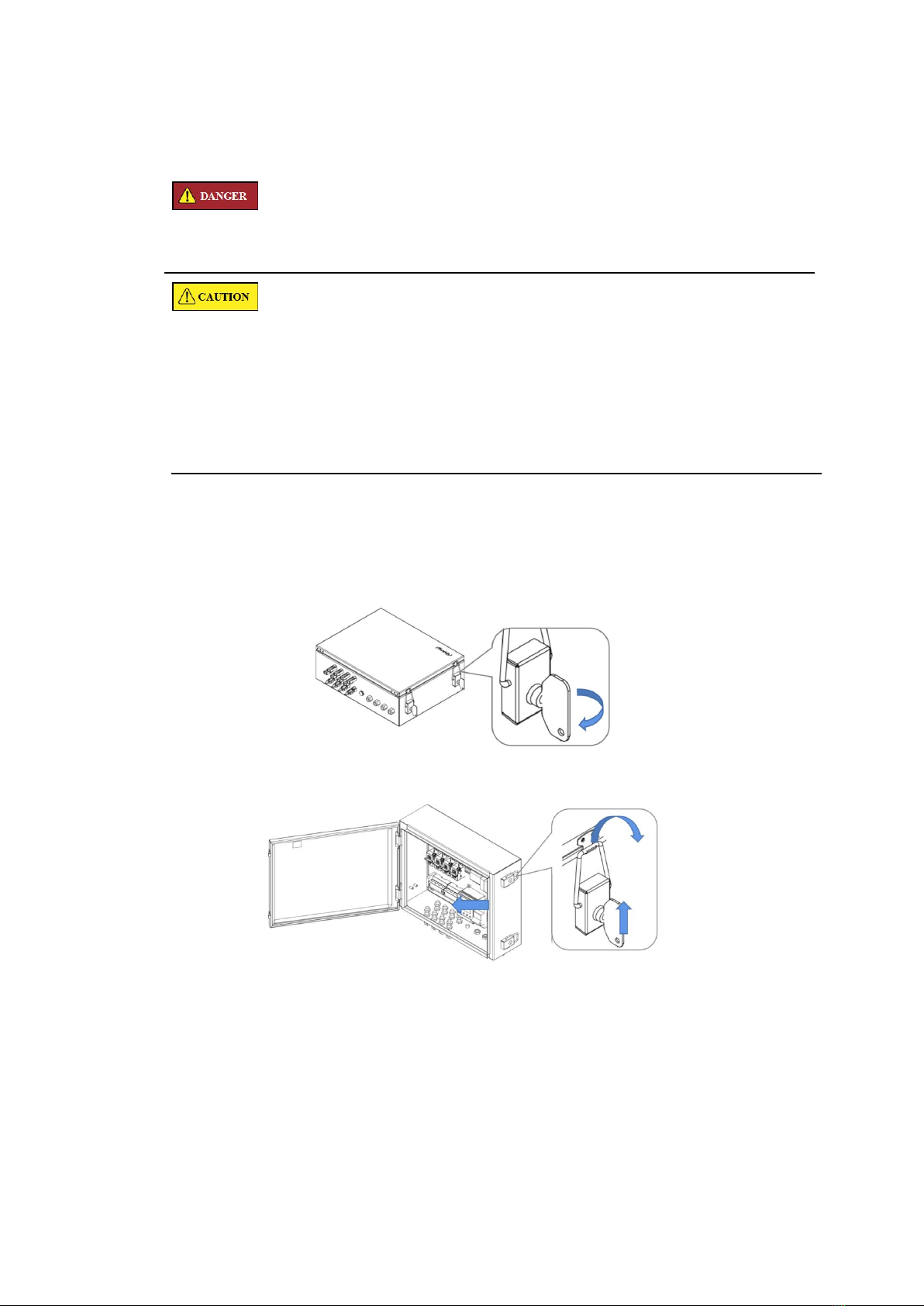

4.1 Opening the product....................................................................................................... 11

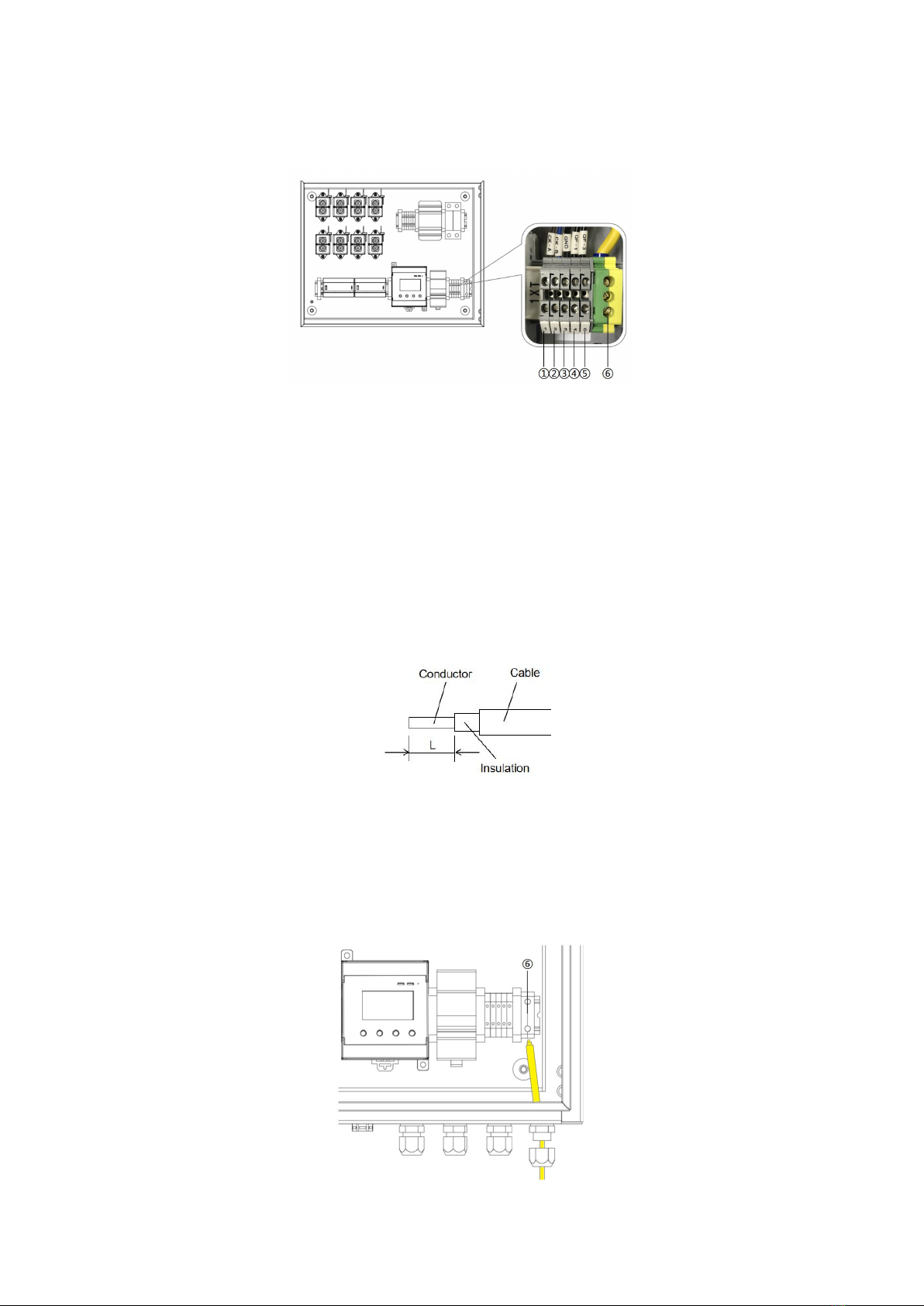

4.2 Overview of the Connection Area.................................................................................. 12

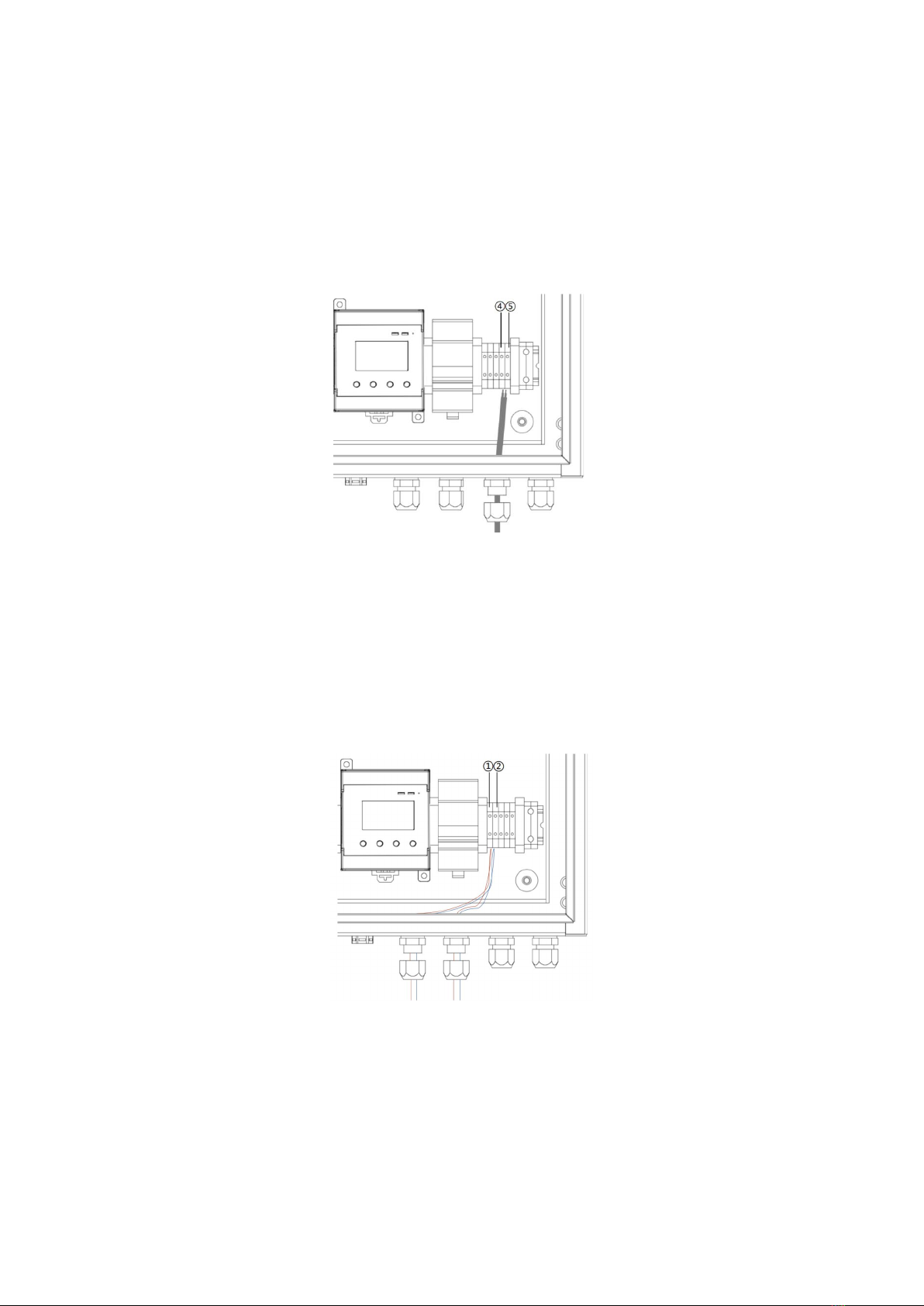

4.3 PE cable connection........................................................................................................12

4.4 AC power cable connection............................................................................................13

4.5 RS485 cables connection................................................................................................13

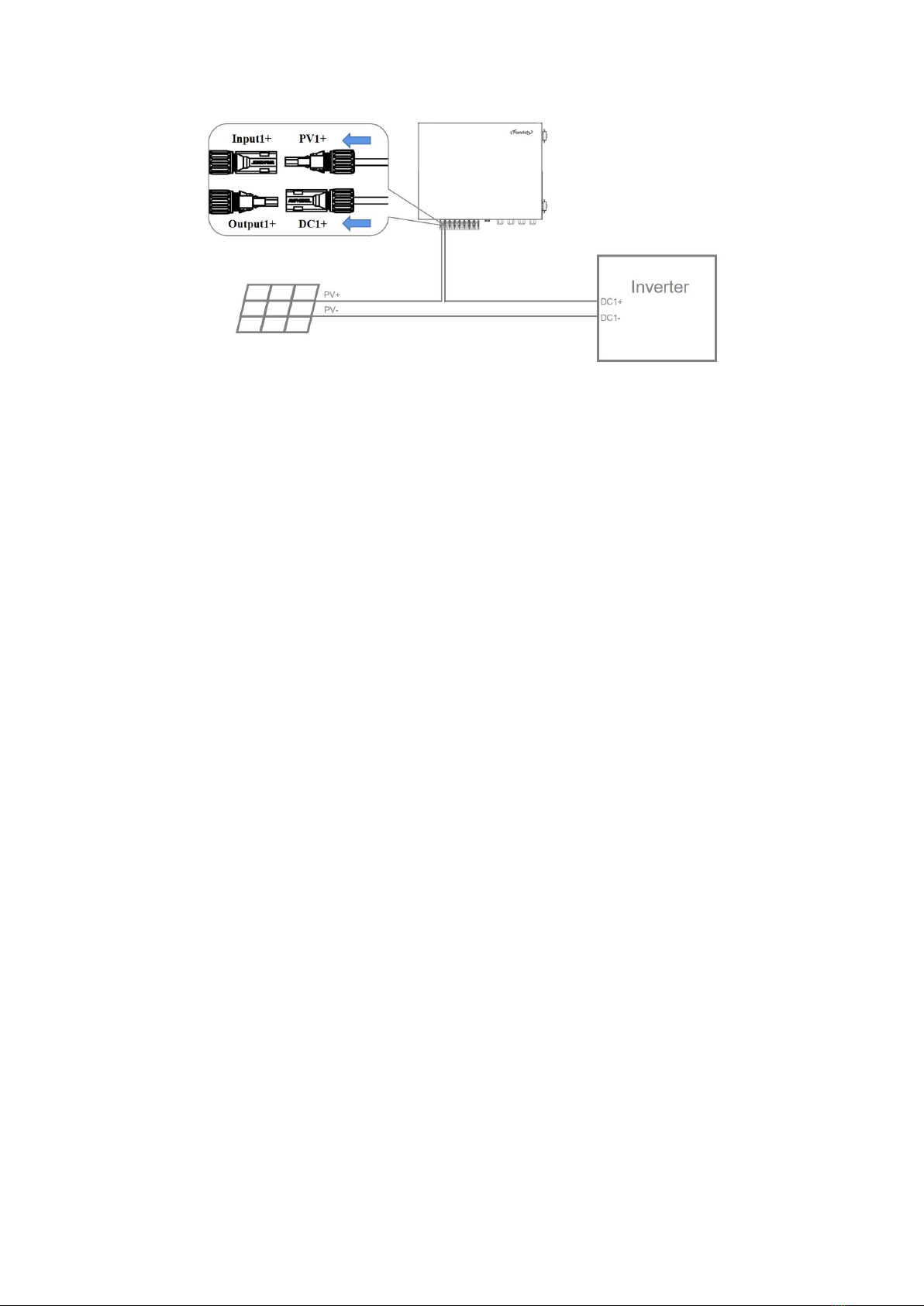

4.6 PV String Cables Connection......................................................................................... 13

5 Operation............................................................................................................................... 15

5.1 Checking before Operation.............................................................................................15

5.2 Operation........................................................................................................................ 15

6 Setting.................................................................................................................................... 16

6.1 Host Module................................................................................................................... 16

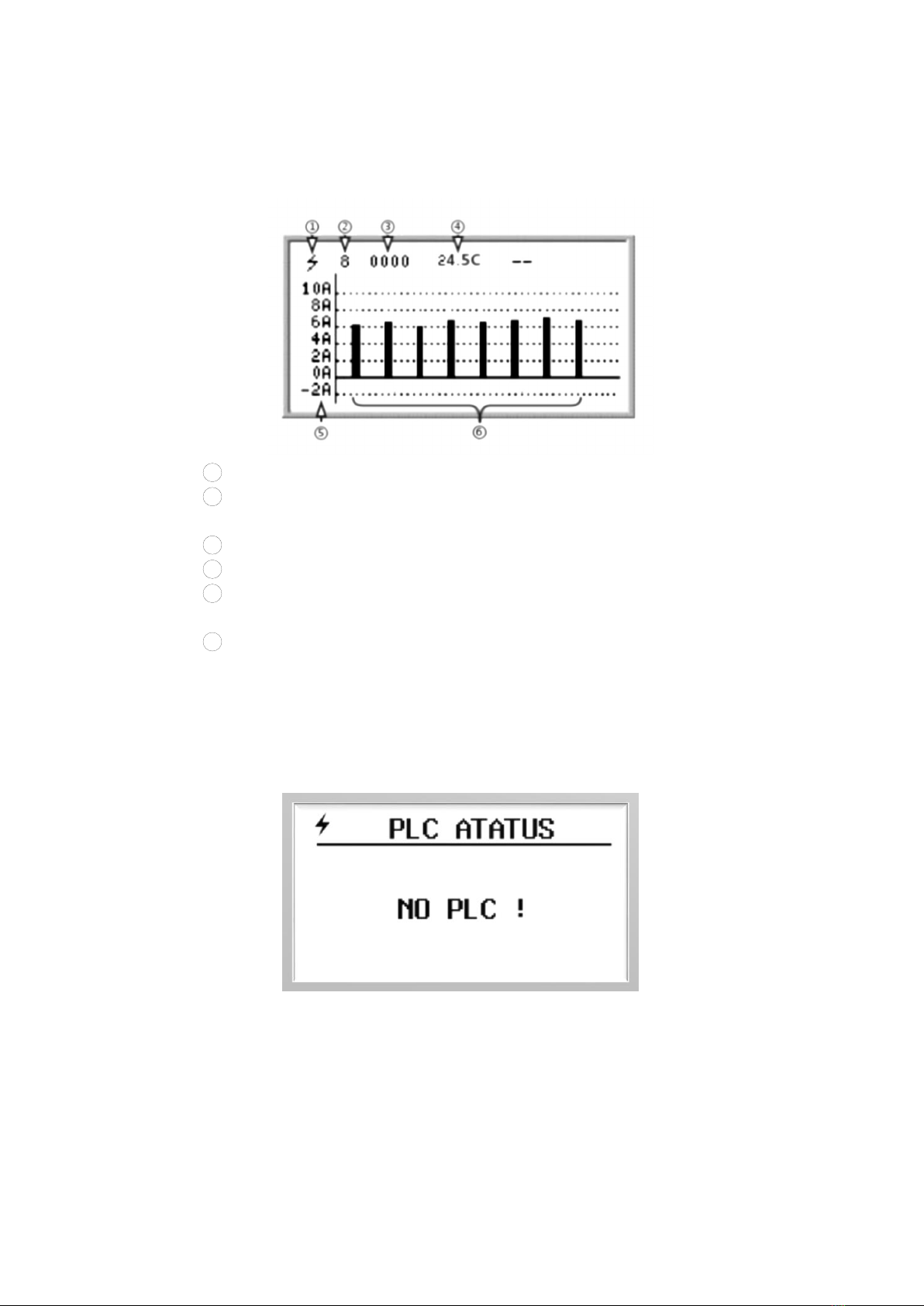

6.2 Power On Interface......................................................................................................... 16

6.3 Current Interface.............................................................................................................17

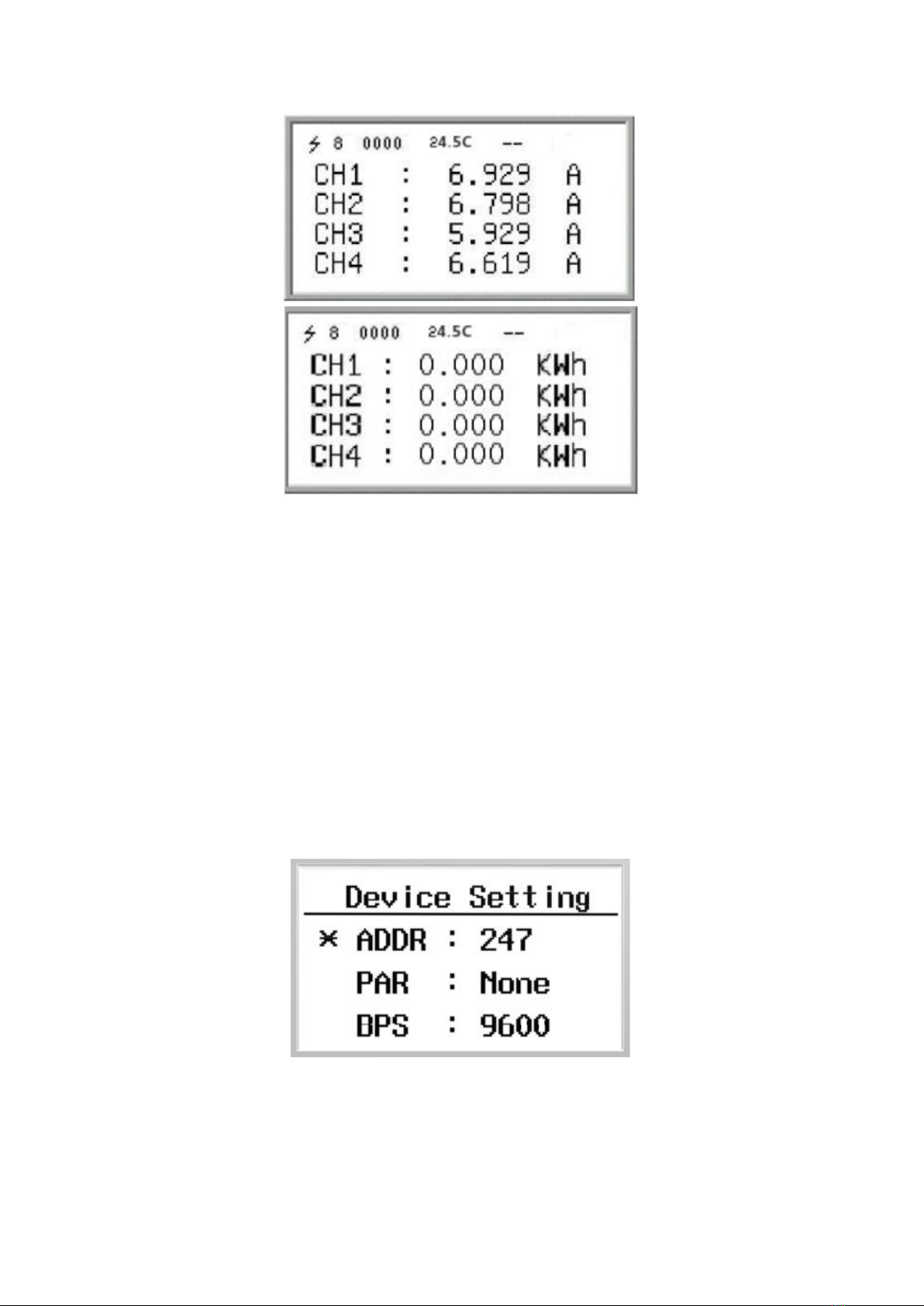

6.4 Current and Power Generation Data Interface................................................................17

6.5 Setting Interface..............................................................................................................18